Manufacturing method of one-sided double-contact flexible circuit board

A flexible circuit board, single-sided and double-contact technology, which is used in the manufacture of printed circuits, the formation of printed circuits, and the formation of electrical connection of printed components. Copper surface damage and other problems, to achieve the effect of saving production cost and production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

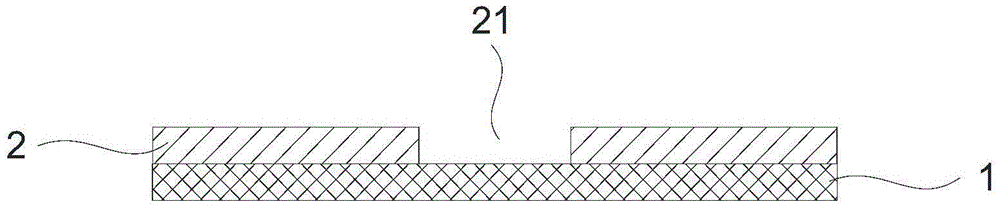

[0018] Such as figure 1 As shown, a front cover film window 21 is provided at the position corresponding to the pad to be exposed on the front cover film 2 , and the front cover film window 21 is 0.15mm smaller than a single side of the required pad. Then the front cover film 2 and the pure copper foil 1 are pressed together.

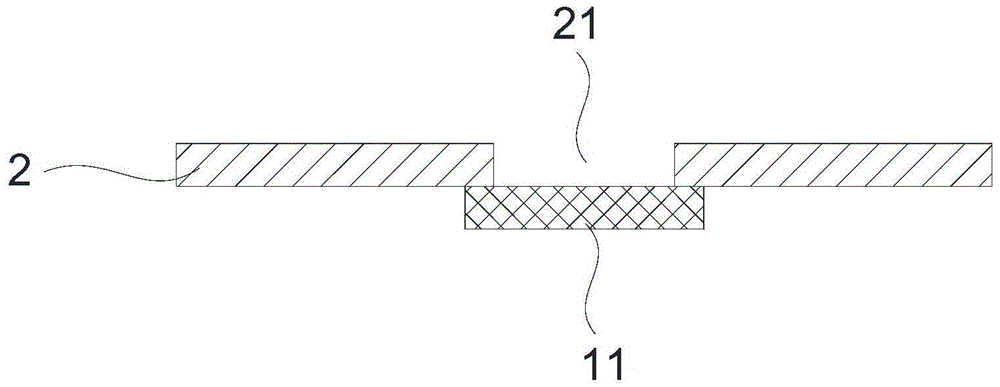

[0019] Such as figure 2 As shown, the pure copper foil 1 is etched to form a copper circuit by making a circuit pattern, and the pure copper foil corresponding to the position of the window 21 of the front cover film of the copper circuit is reserved to form a pad 11 .

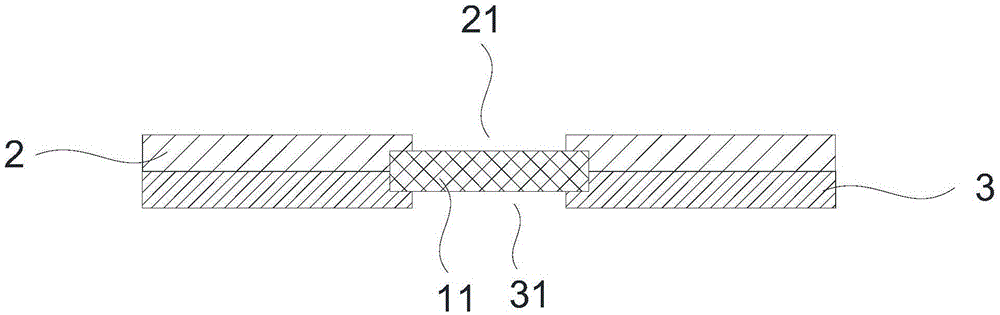

[0020] Such as image 3 As shown, a back cover film window 31 is provided at the position corresponding to the pad 11 to be exposed on the back cover film 3 , and the back cover film window 31 is 0.1 mm smaller than a single side of the required pad 11 . The back cover film 3 is pressed on the side of the copper circuit opposite to the front cover film 21, and the position of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com