Thin-oxide devices for high voltage i/o drivers

A technology of output driver and output circuit, which is applied in the direction of logic circuit connection/interface layout, logic circuit coupling/interface using field effect transistors, etc., can solve problems such as excessive restrictions and complicated practical use of means, and achieve cost saving and manufacturing the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above-mentioned objects, features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail in conjunction with the attached figures.

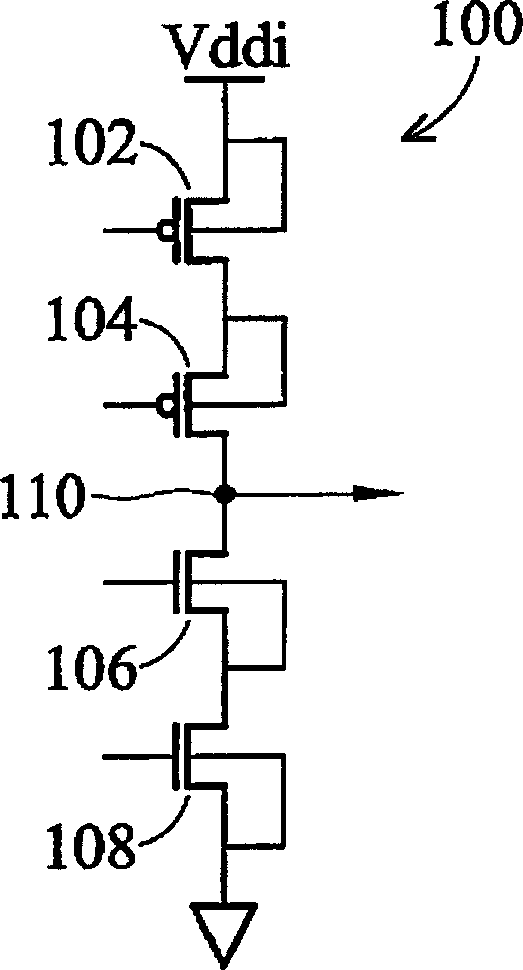

[0025] Figure 1A It is a schematic diagram showing an I / O driver 100 with thin oxide devices according to an embodiment of the present invention. I / O driver 100 is shown implemented using only thin oxide components. In this example, thin oxide PMOS transistors 102 and 104 along with thin oxide NMOS transistors 106 and 108 are arranged in series as a stack between an I / O power supply with I / O voltage (VDDI) and ground structure. The transistors 106 and 108 together act as a step-down module to pull the voltage on the output node 110 to a low potential. The transistors 102 and 104 are jointly used as a boost module to boost the voltage on the output node 110 to a high level. Its I / O voltage (VD DI ) is higher than a core voltage VDD C for core circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com