Package method and device for fiber bragg grating with adjustable central wavelength and adjustable temperature coefficient

A fiber grating, center wavelength technology, applied in the direction of cladding fiber, optical waveguide light guide, etc., can solve the problems of temperature compensation package effect change, large size, unable to adjust the center wavelength of fiber grating, etc. The effect of saving production time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

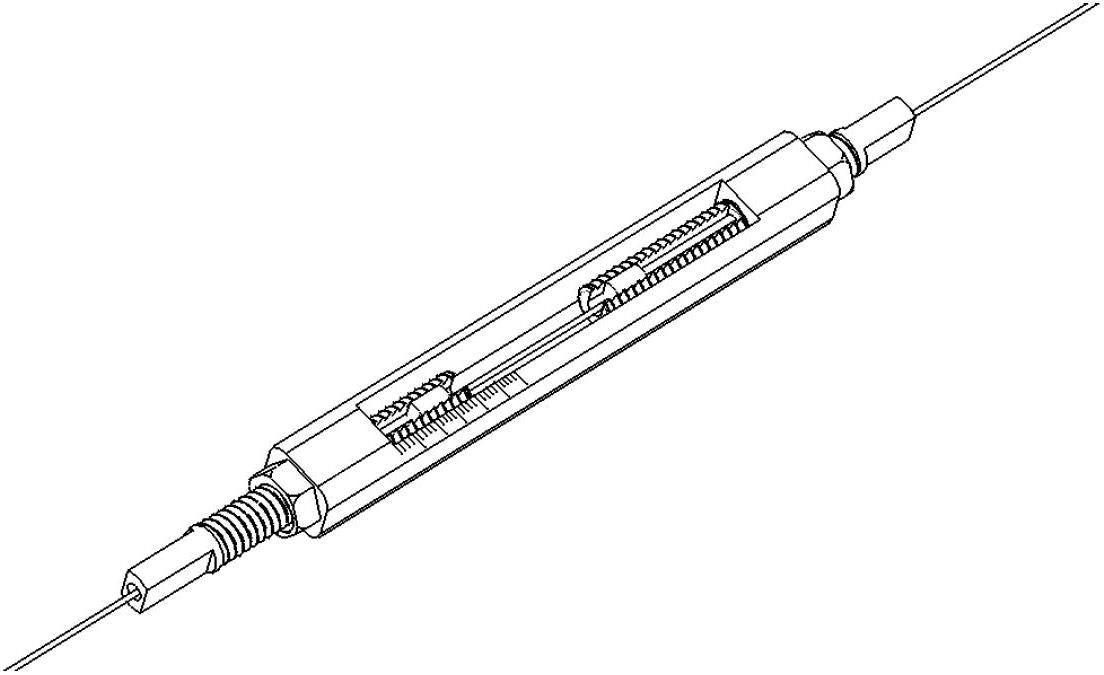

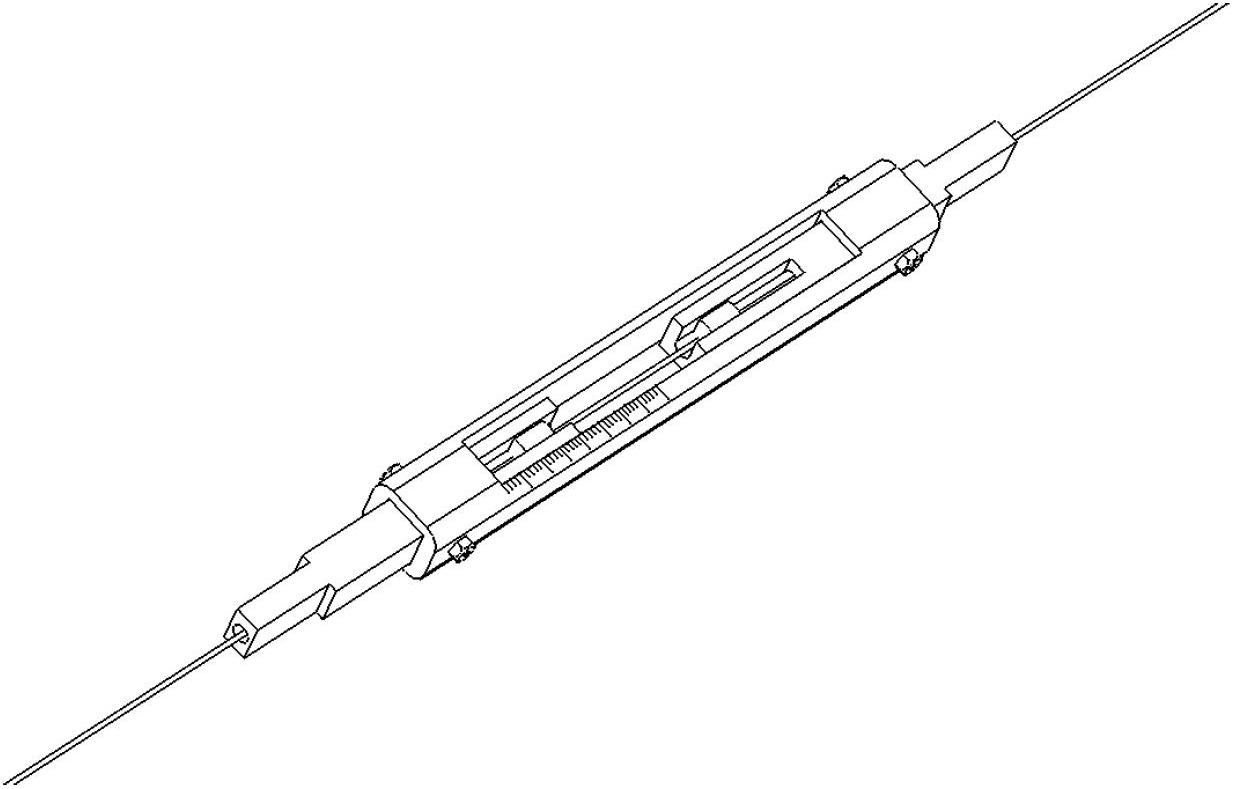

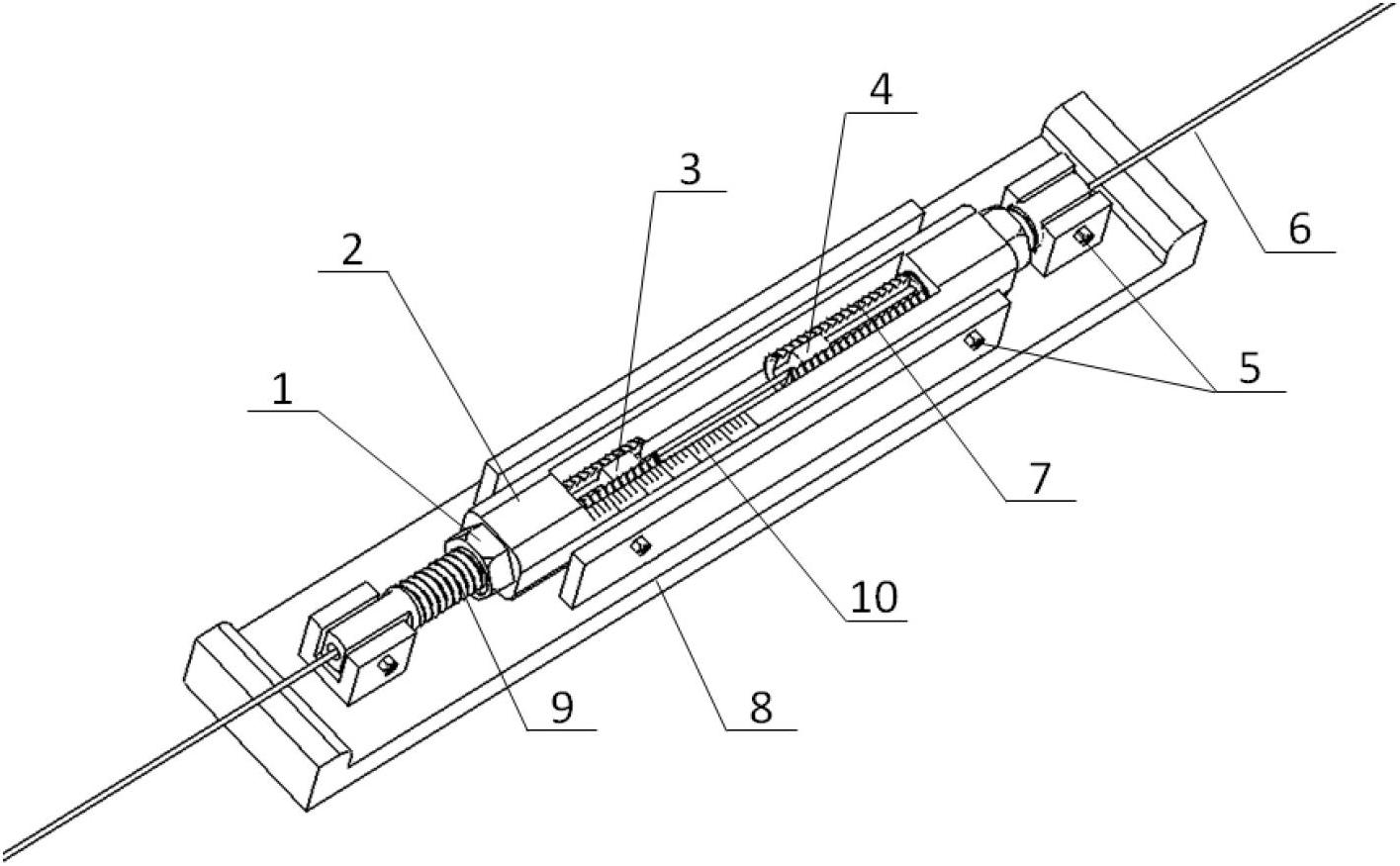

[0029] Example. A packaging method with adjustable central wavelength and temperature coefficient of a fiber grating. Two ends of a casing with a cavity in the middle are respectively connected with two adapter rods with low thermal expansion coefficient and high thermal expansion coefficient through a thread structure. Into the cavity of the casing, the two pigtails of the fiber grating are respectively fixed on the adapter rods at both ends, and the two adapter rods are used as compensation elements to change the positions of the two fixed points at the tail of the fiber grating as the temperature changes, thereby changing the The prestress applied on the fiber grating realizes temperature compensation, and the temperature coefficient of the fiber grating can be adjusted by adjusting the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com