Battery pack assembly and vehicle having same

A battery and battery bracket technology, applied to battery pack components, electrical components, secondary batteries, etc., can solve the problems of electrical danger and cost, and achieve the effect of saving manufacturing time and materials and simple functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] figure 1 Firstly, a vehicle 1 , here a motor vehicle, is shown with an electric motor 2 as drive motor and with a battery pack 3 which forms a traction battery. According to the exemplary embodiment, therefore, it is a purely electrically operated motor vehicle 1 . Naturally, the invention also includes a so-called hybrid vehicle which, in addition to one or more electric motors 2 , also has an internal combustion engine (not shown in the drawing).

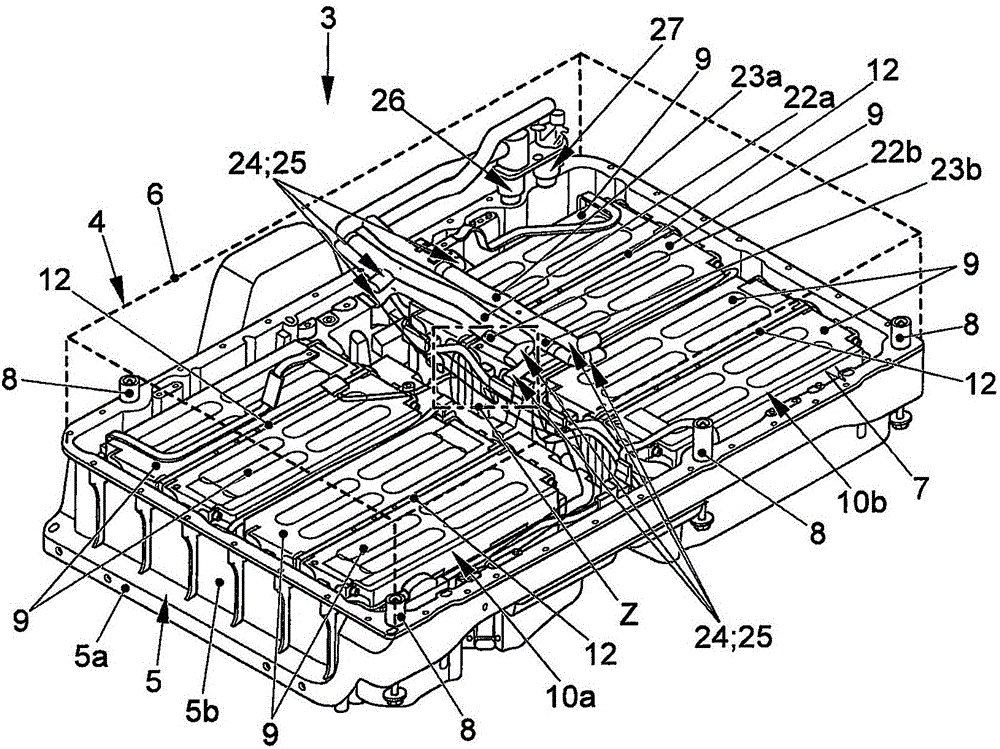

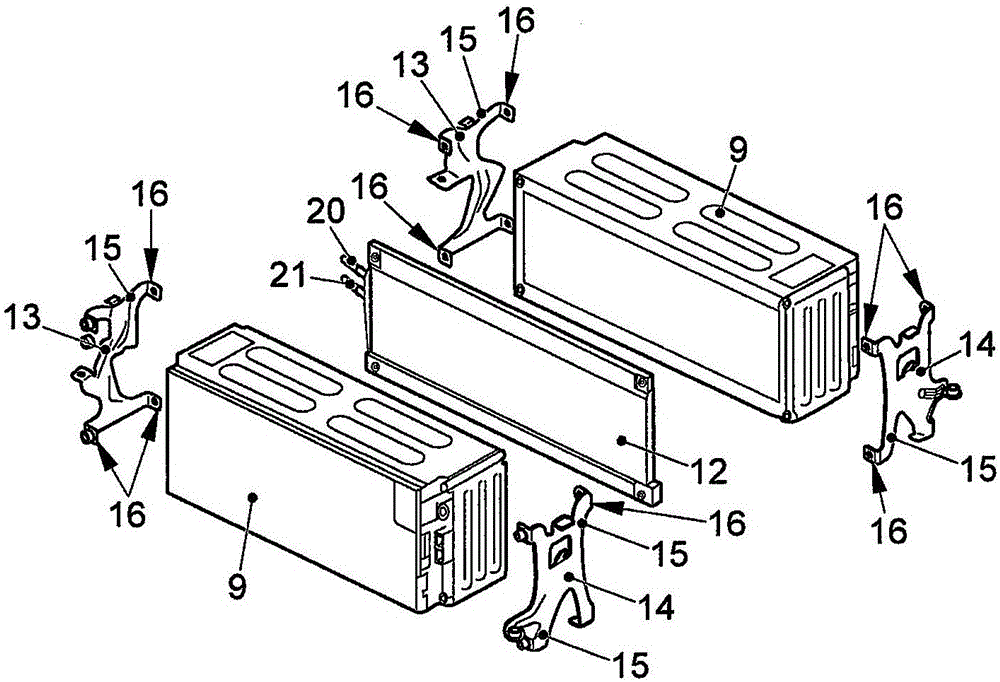

[0031] according to figure 2The battery pack 3 has a battery housing 4 with a bottom-formed battery holder 5 , which is here pot-shaped with a holder bottom 5 a and an upwardly directed holder wall 5 b. This form of the battery holder 5 corresponds to the preferred form of the battery housing 4 with regard to waterproofing. Assigned to the battery holder 5 is a cover element 6 , shown only schematically, which is placed on the free end 7 of the cup-shaped battery holder 5 and is figure 2 The hollow cylindrical centeri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com