Motor stator insulation framework

A technology for insulating skeleton and motor stator, which is applied to the shape/style/structure of winding insulation, electrical components, electromechanical devices, etc. The effect of reducing input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the description of the drawings.

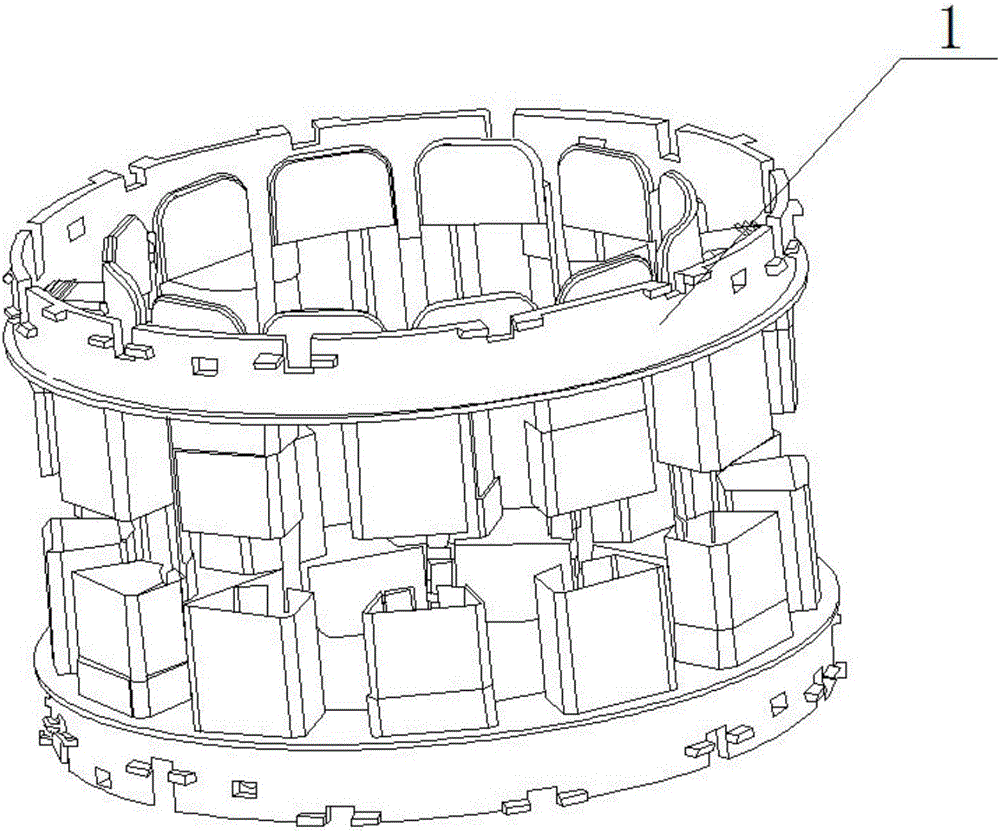

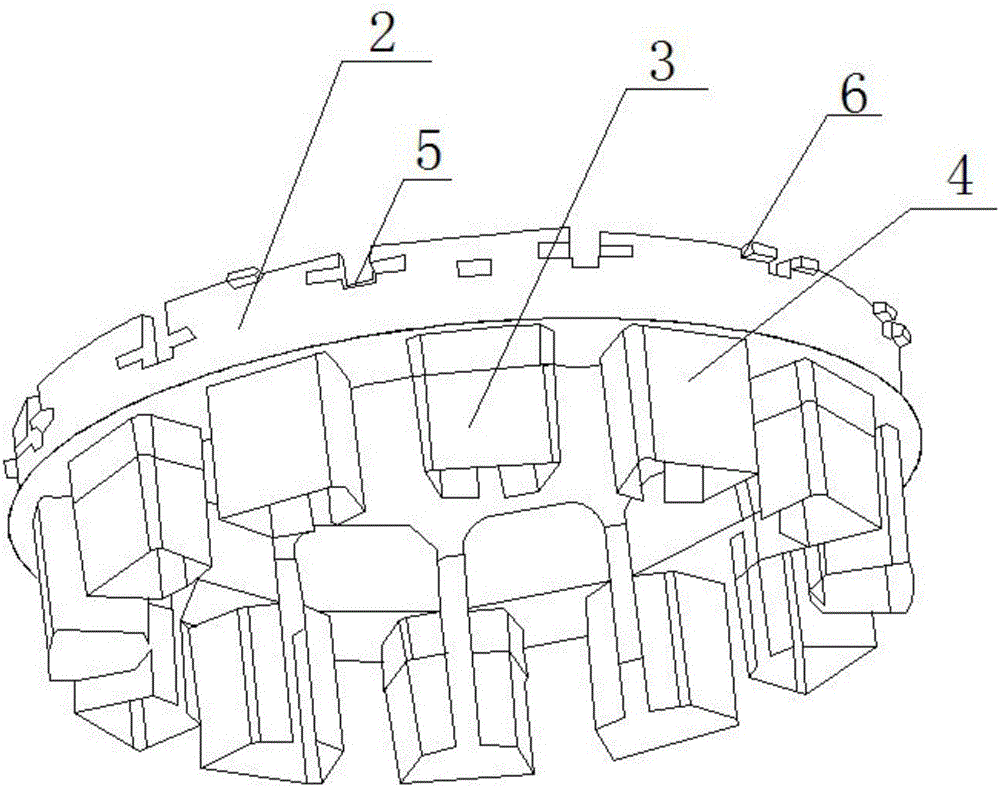

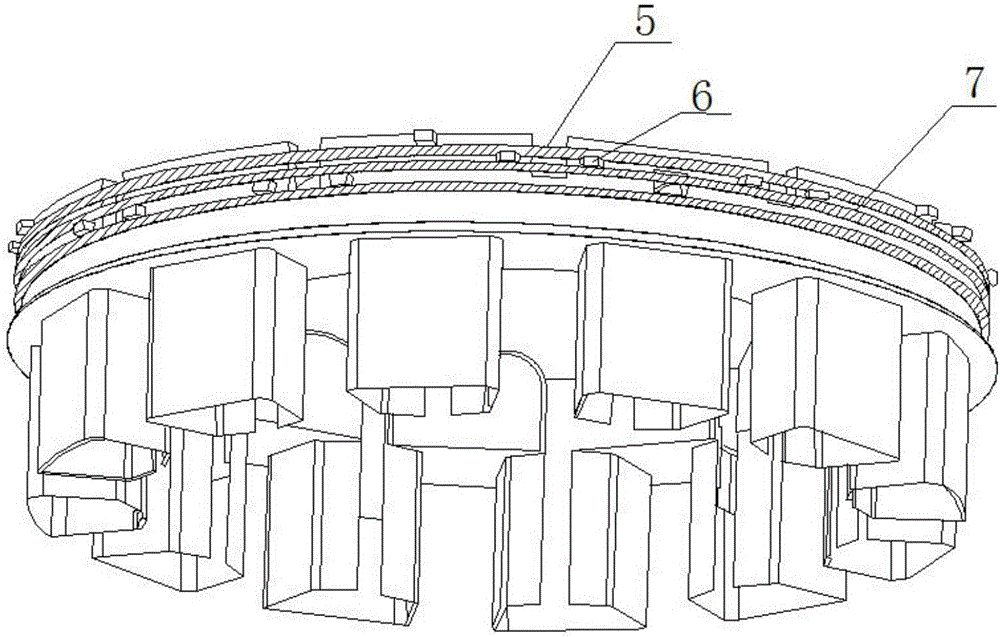

[0019] Such as Figure 1~3 As shown, a motor stator insulation frame includes two frame bodies 1. The frame body 1 includes an end ring 2, an inner ring groove 3, and an outer ring groove 4. The lower end of the end ring 2 is evenly distributed with a number of inner ring grooves 3 and outer ring The ring groove 4, the outer ring groove 4 and the inner ring groove 3 are alternately arranged. The end ring 2, the inner ring groove 4 and the outer ring groove 3 are an integrated structure, which is injection molded by an injection mold. The end ring 2 has several depths on the outside Different insulation gaps 5 are provided with wire-blocking protrusions 6 outside the insulation gaps 5. The two frame bodies 1 are flipped and buckled. The outer ring groove 3 and the inner ring groove 4 are connected by a snap-fit, overlapping and matching each other. The number of out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com