Wire bonding packaging body

A technology of wire bonding and packaging, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems affecting the overall performance of multi-chip wire bonding package 10, and save production time and cost, improve overall performance, and avoid coupling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

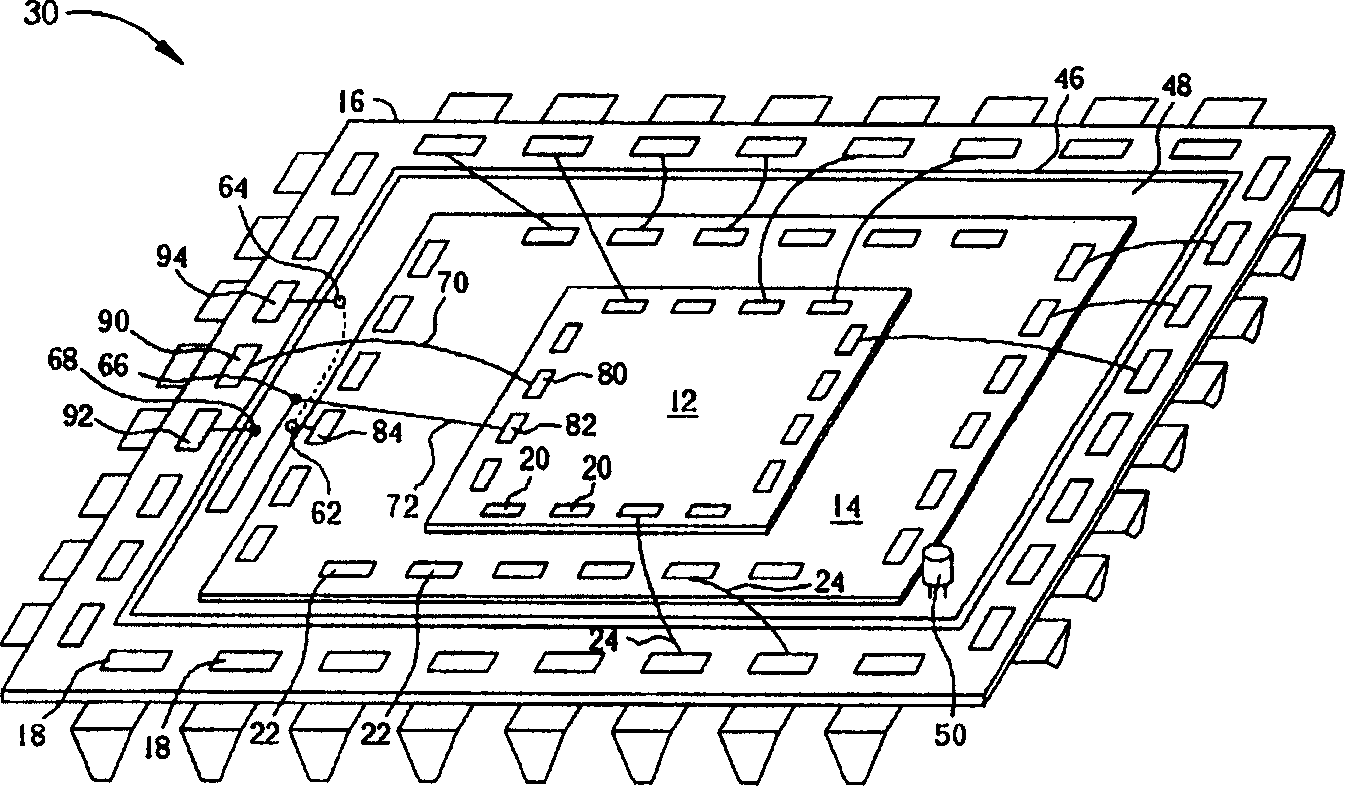

[0016] see image 3 and Figure 4 , image 3 It is a schematic diagram of a wire bonding package 30 in a preferred embodiment of the present invention, Figure 4 It is a side view of the wire bonding package 30 . In addition to the first die 12, the second die 14, the shell 16 and a plurality of pins for electrically connecting the die pads 20 and 22 on the first die 12 and the second die 14 to the shell 16 In addition to the bonding wires 24 on 18 , the wire bonding package 30 further includes a circuit board 48 disposed within the lead frame 46 of the housing 16 .

[0017] In a preferred embodiment of the present invention, the casing 16 is a quad flatpack (QFP), and the circuit board 48 is a double-layer circuit board. However, in the wire bonding package of the present invention, the housing 16 can also be a ball grid array (BGA) or a dual in-line package (DIP), The circuit board 48 can also be a multi-layer circuit board with a single layer or more than two layers. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com