Production method for asymmetric prominence and picture element structure

A manufacturing method and pixel structure technology, applied in semiconductor/solid-state device manufacturing, nonlinear optics, optics, etc., can solve problems such as large height difference and affect the light reflection effect of asymmetric protrusions 128', and achieve high uniformity , Save manufacturing time and cost, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0069] Manufacturing method of asymmetric protrusions:

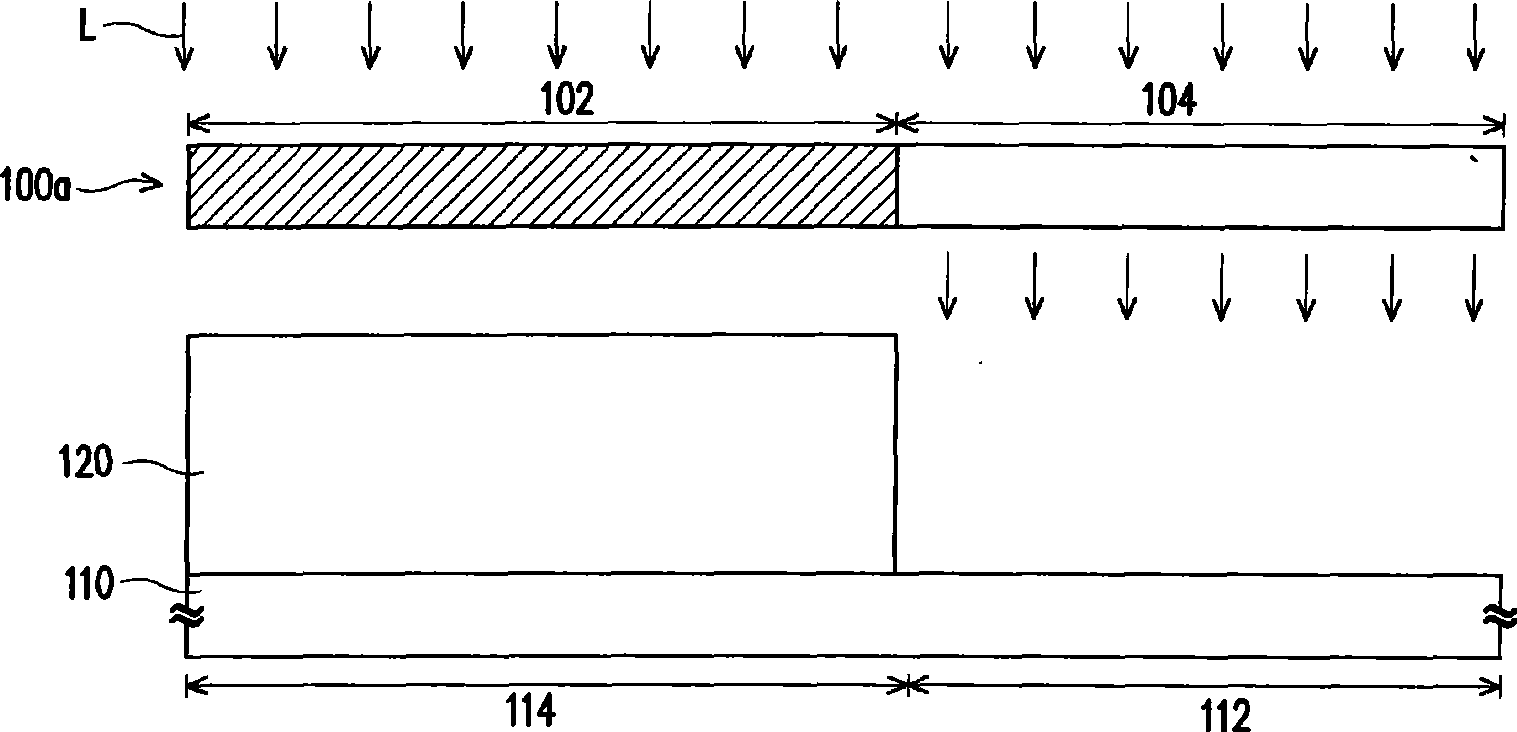

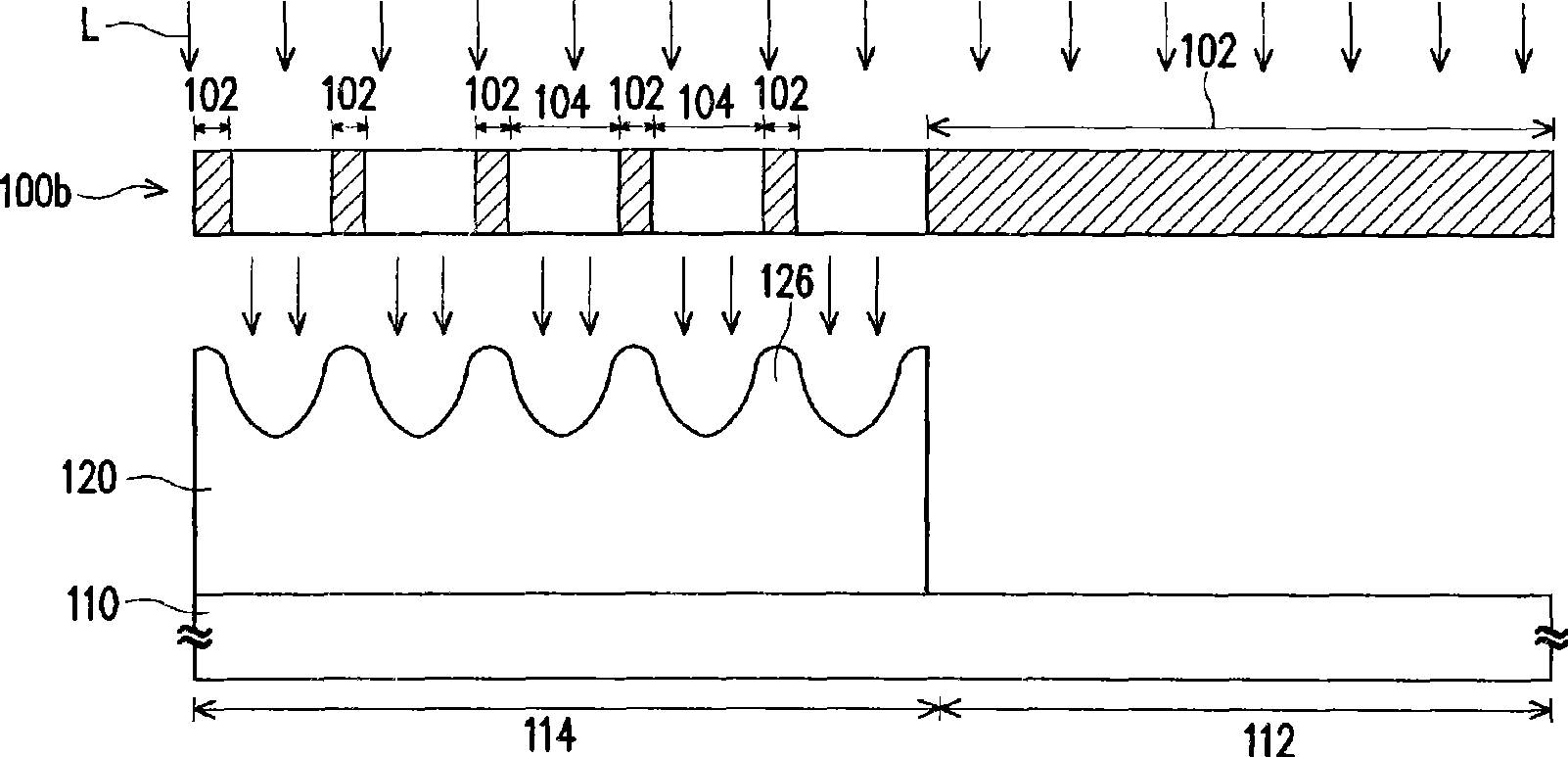

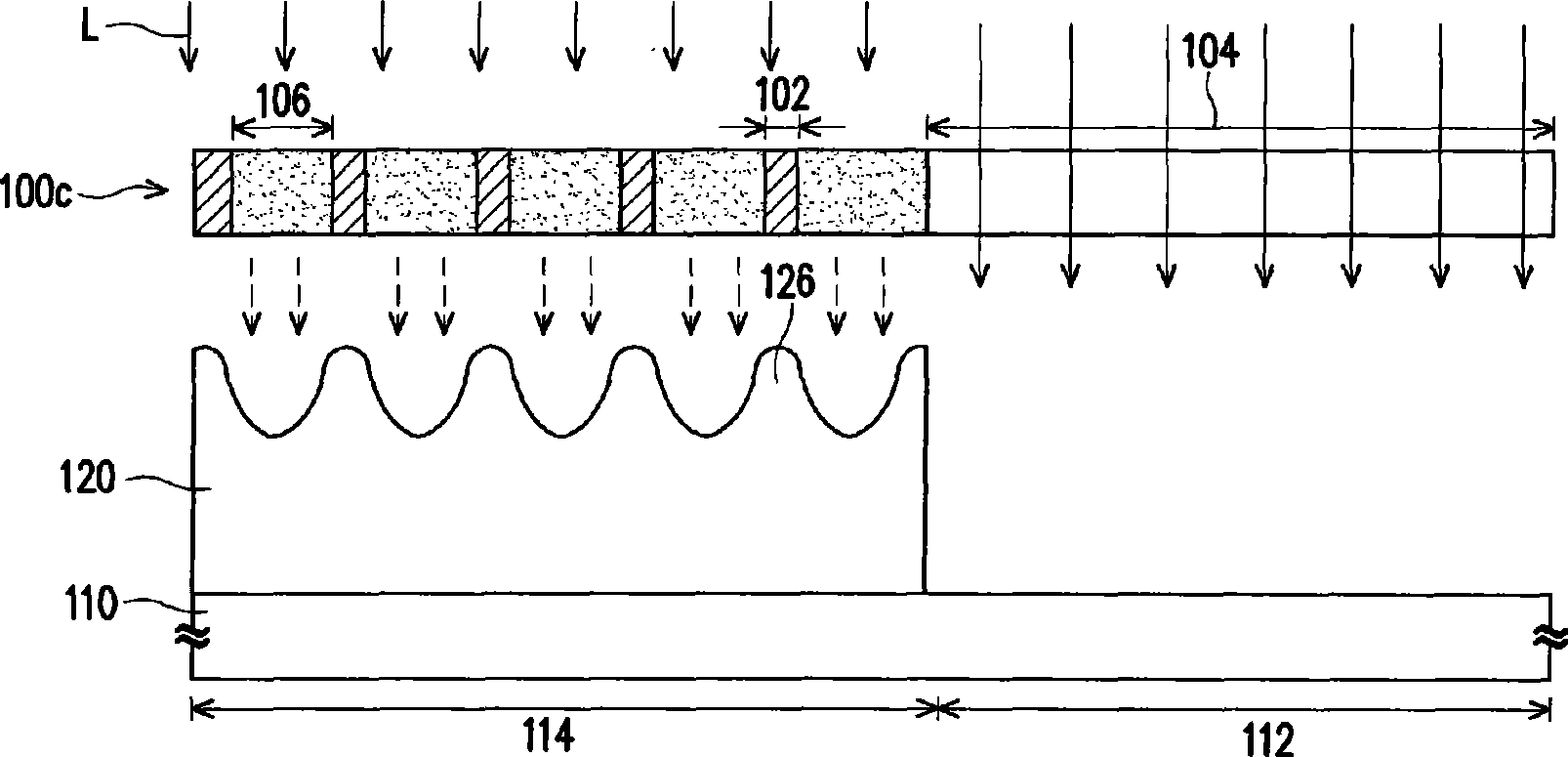

[0070] Figure 5A ~ Figure 5B It is a schematic flowchart of a method for manufacturing an asymmetric protrusion in a preferred embodiment of the present invention. Please refer to Figure 5A , firstly, a substrate 210 is provided. The substrate 210 can be a glass substrate, a quartz substrate, a plastic substrate, or other suitable substrates. After that, if Figure 5A A film layer 220 is shown formed on the substrate 210 . The method of forming the film layer 220 is, for example, spin coating method, printing method (Printing), chemical vapor deposition (Chemical Vapor Deposition, CVD) and so on. In addition, the material of the film layer 220 may be an organic photosensitive material, such as pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com