Vernier caliper

A vernier caliper and measuring claw technology, which is applied in the field of vernier calipers, can solve the problem of no depth measuring rod and the like, achieve the effect of saving manufacturing time and cost, and ensuring quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

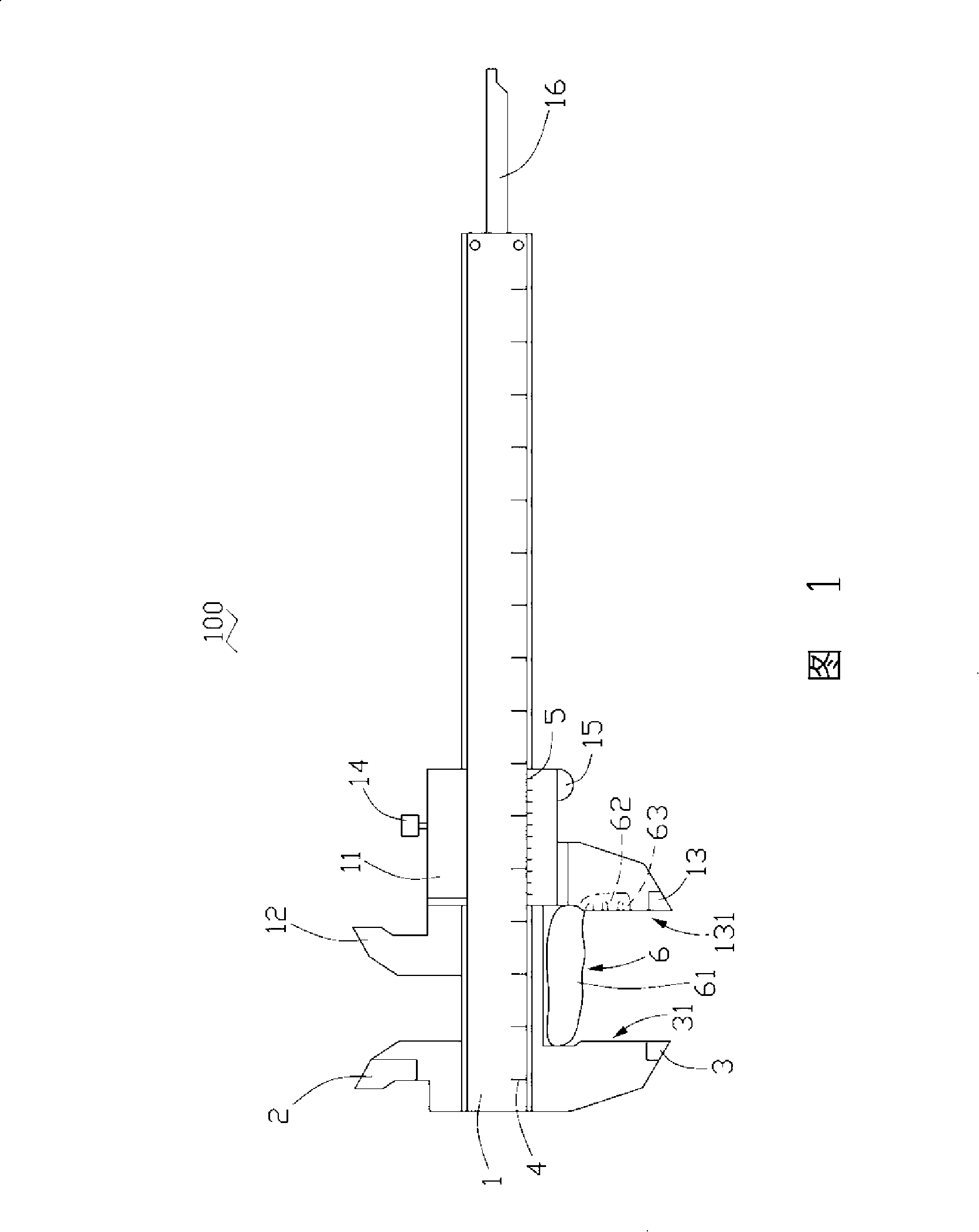

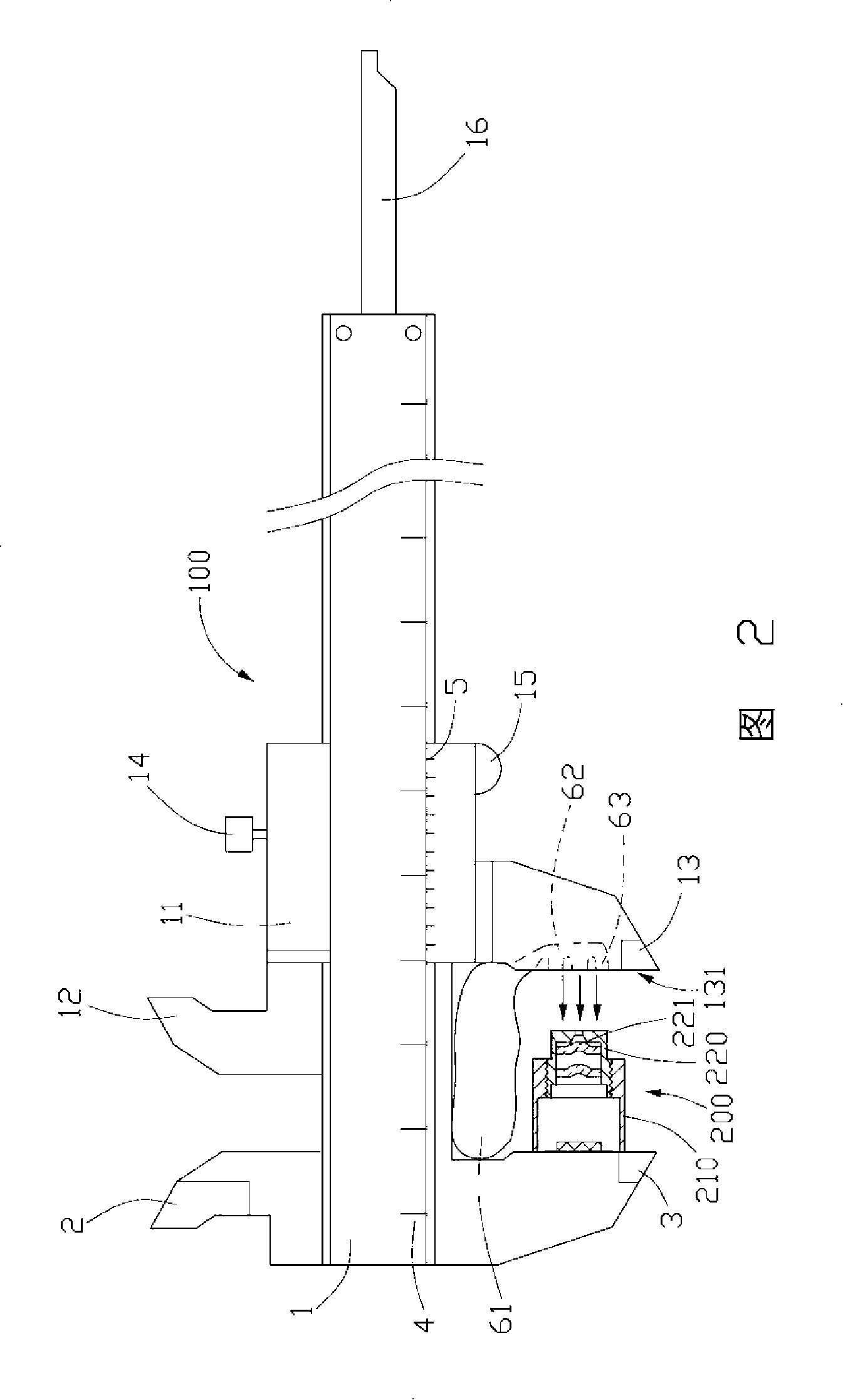

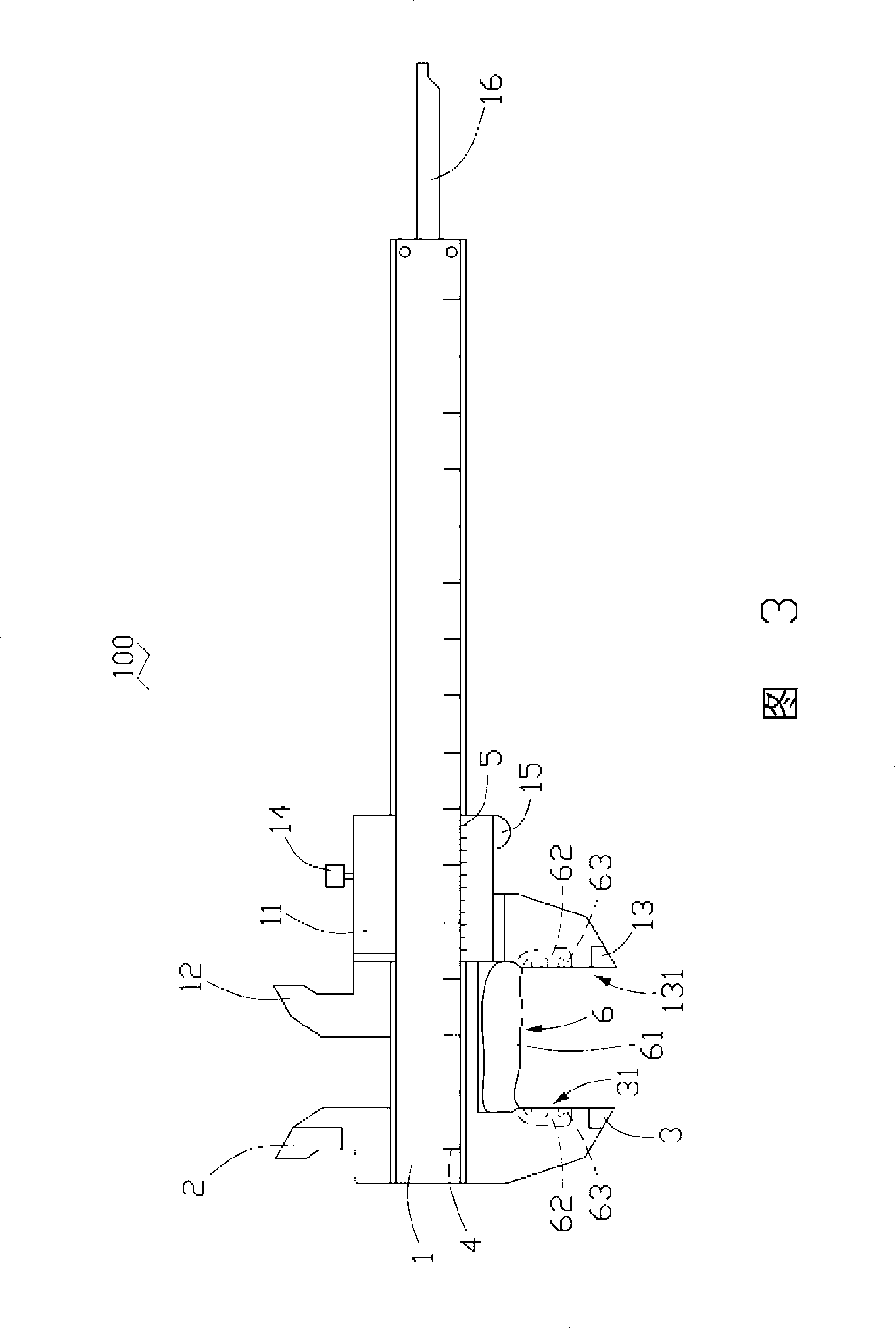

[0016] Referring to FIG. 1 , this embodiment takes a vernier caliper of 0-150mm as an example for illustration. The vernier caliper 100 has a main scale 1 , a slider 11 that can slide along the main scale 1 and an air blowing device 6 .

[0017] A first inner measuring claw 2 and a first outer measuring claw 3 are respectively formed above and below one end of the main ruler 1 . The first inner measuring claw 2 and the first outer measuring claw 3 can be integrally formed with the main ruler 1 . It can also be combined into one after molding separately. At the other end of the main scale 1, a depth rod 16 for measuring depth that moves in synchronization with the slider 11 is formed. In addition, a main scale scale 4 is provided on the main scale 1 along its length direction, and an auxiliary scale scale 5 is provided on the slider 11 .

[0018] The slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com