Punching and bending integrated machine

An all-in-one machine and punching and bending technology, which is applied in the field of all-in-one punching and bending machines, can solve the problems of inability to realize data sharing of processing parameters, low production efficiency, and low processing accuracy, and achieve the effect of saving debugging time and manufacturing time, and reducing mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

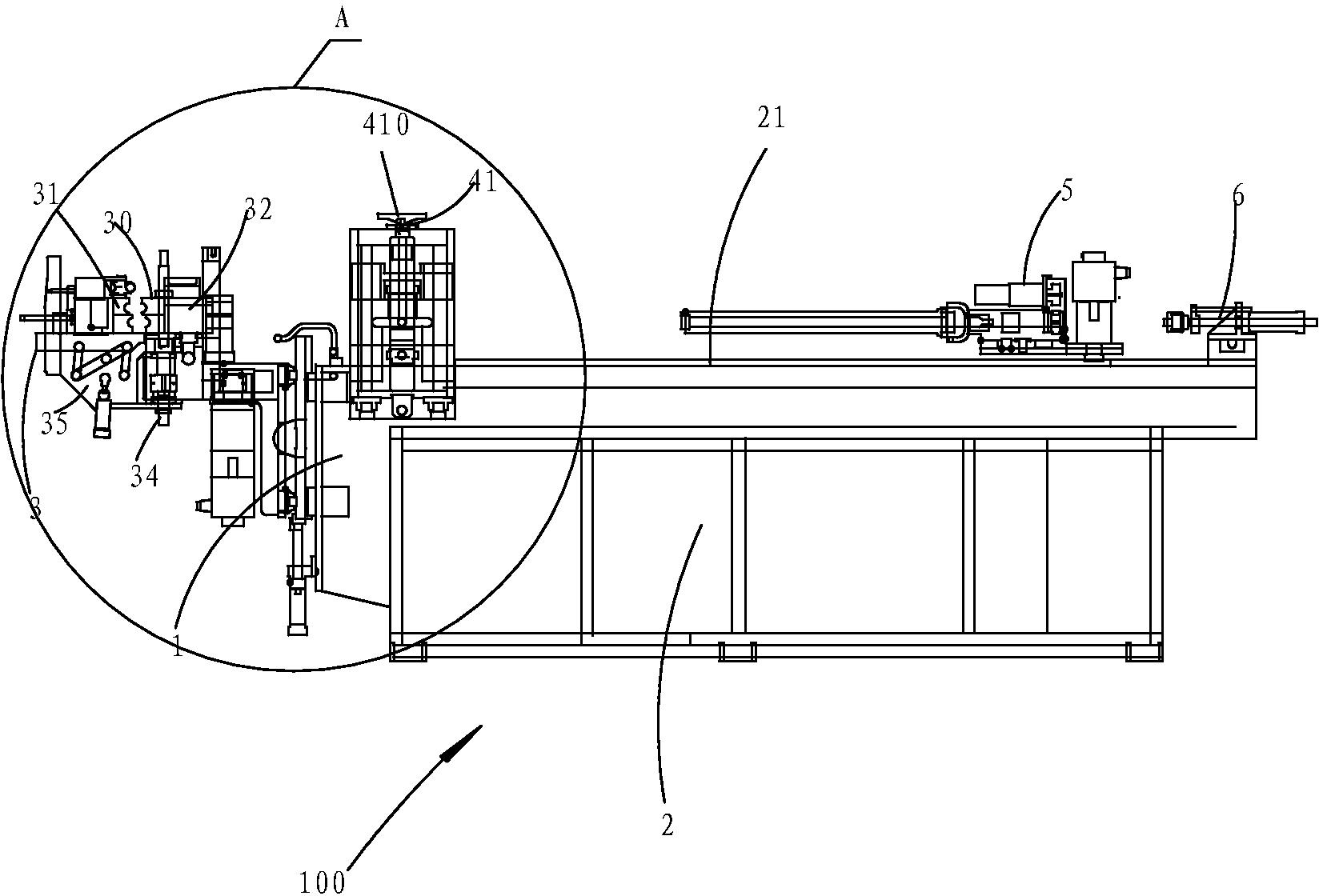

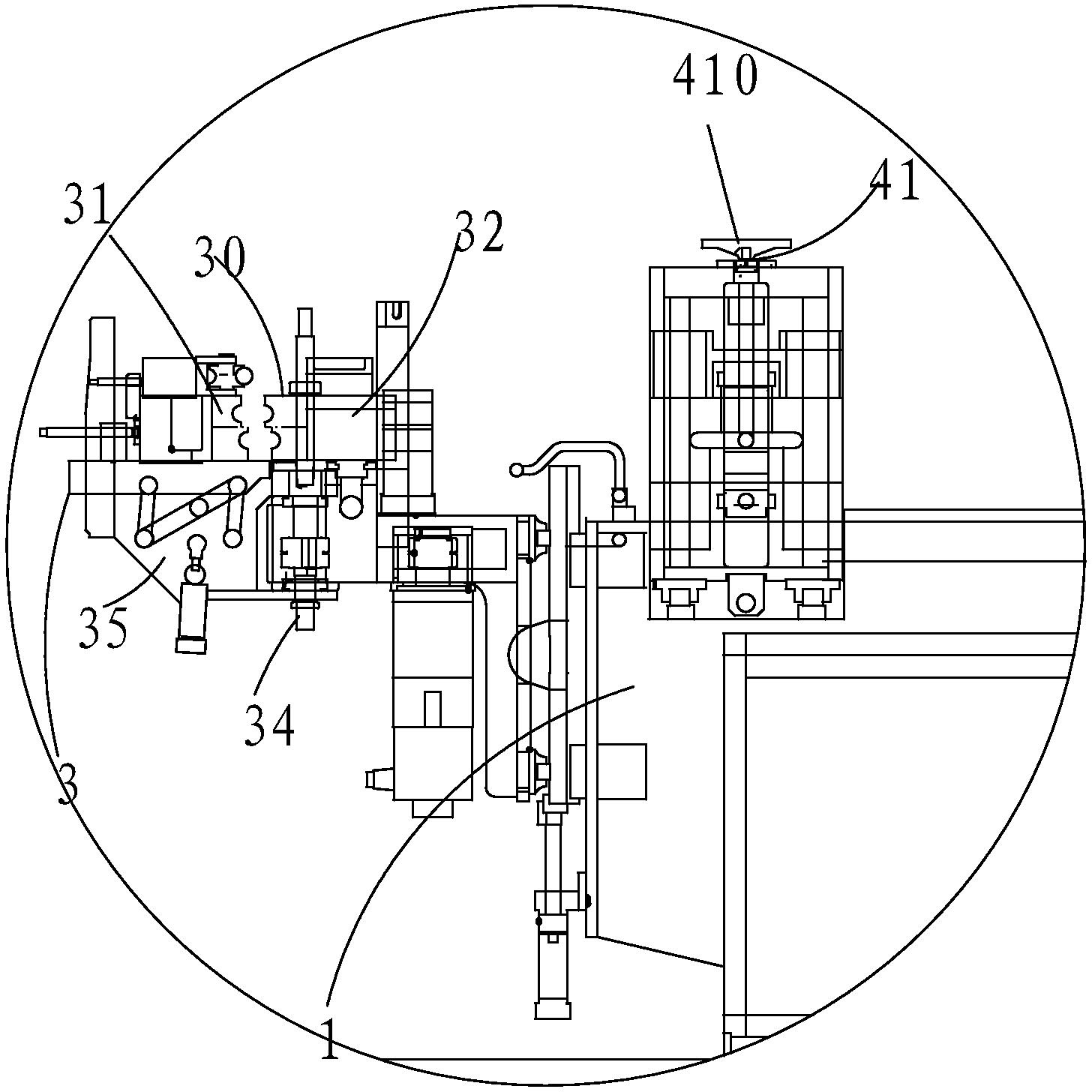

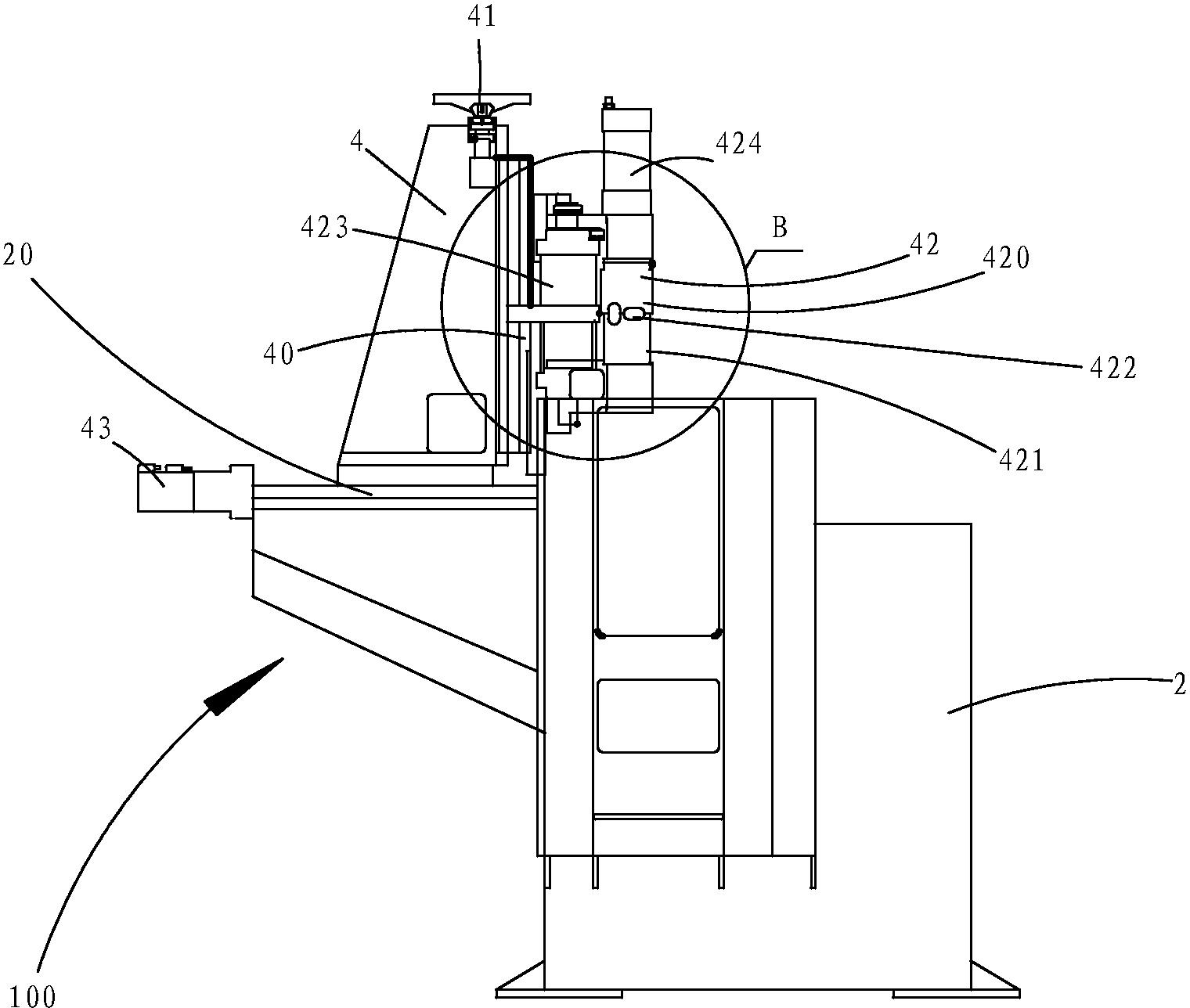

[0011] See Figure 1 to Figure 4 , A punch-bending integrated machine 100, comprising: a machine head 1, a body 2, a pipe bending mechanism 3 installed on the machine head 1, an avoiding machine base 4 installed on the body 2, a feeding device 5, and a core pulling device 6 The avoiding machine base 4 is provided with a mold mounting seat 40 and a mold adjusting device 41, the mold mounting seat 40 is equipped with a punching mechanism 42, which includes a punching upper die 420, a punching lower die 421. Punching mandrel 422, avoiding clamping cylinder 423, and punching cylinder 424; said punching mandrel 422 is set on the end surface of the piston rod of punching cylinder 424 and is fixedly connected to the piston rod. The pipe bending mechanism 3 is composed of pipe bending die 30, The clamping die 31, the clamping die 32, the pipe bending cylinder, the pipe bending spindle 34, and the pipe bending arm 35 fixed on the pipe bending spindle 34 are composed of a clamping die 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com