Cutting Tool Made By Additive Manufacturing

A technology of cutting tools and cutting edges, which is applied in the field of preparation and design of metal cutting tools, can solve expensive problems, achieve the effects of improving mechanical properties and wear resistance, increasing design flexibility, and saving manufacturing time and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments described herein may be more readily understood by reference to the following Detailed Description and Examples, as well as the foregoing and following. However, the elements, devices, and methods described herein are not limited to the specific embodiments described in the Detailed Description and Examples. It should be realized that these Examples are illustrative only of the principles of the invention. Various modifications and alterations will be apparent to those skilled in the art without departing from the spirit and scope of the invention. As used herein, the term cutting tool refers to a hard component used to remove material from a workpiece.

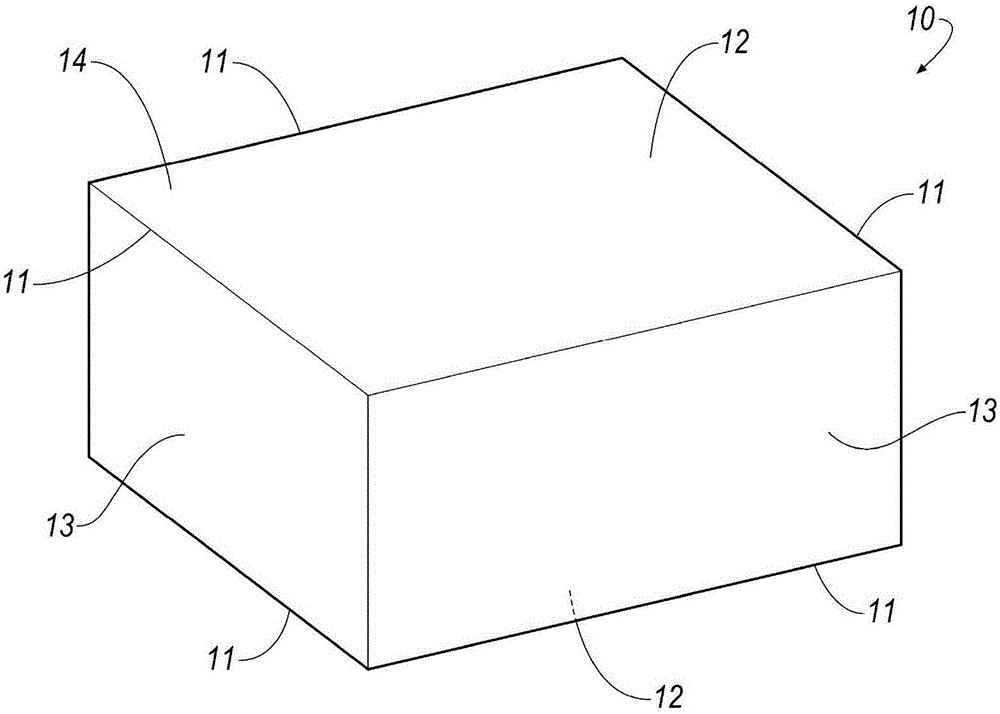

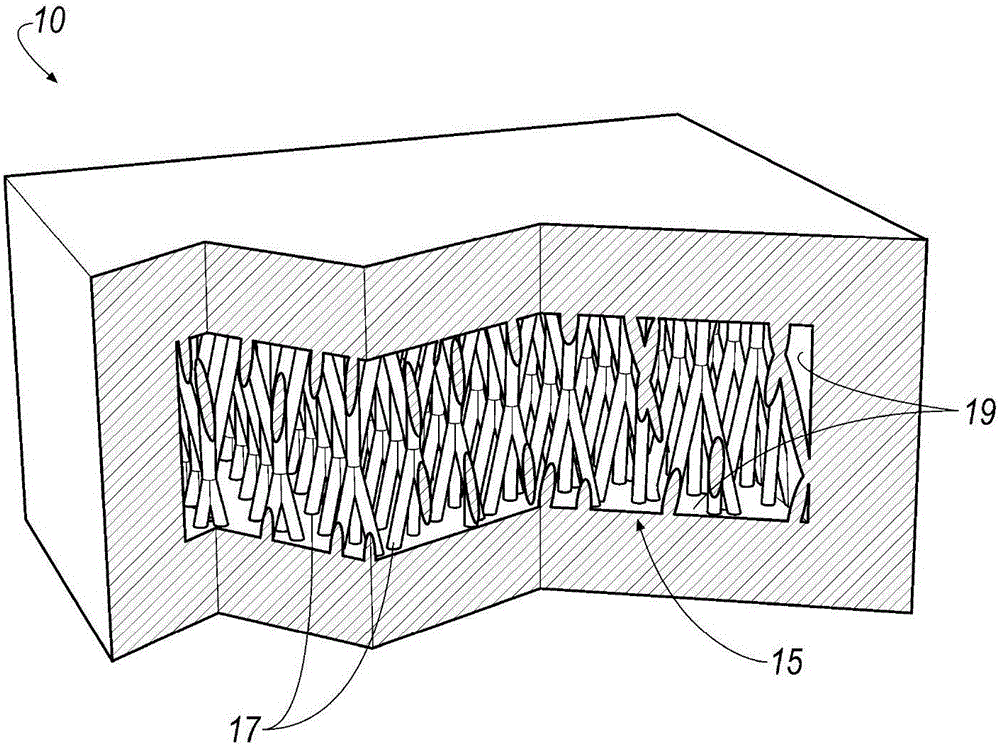

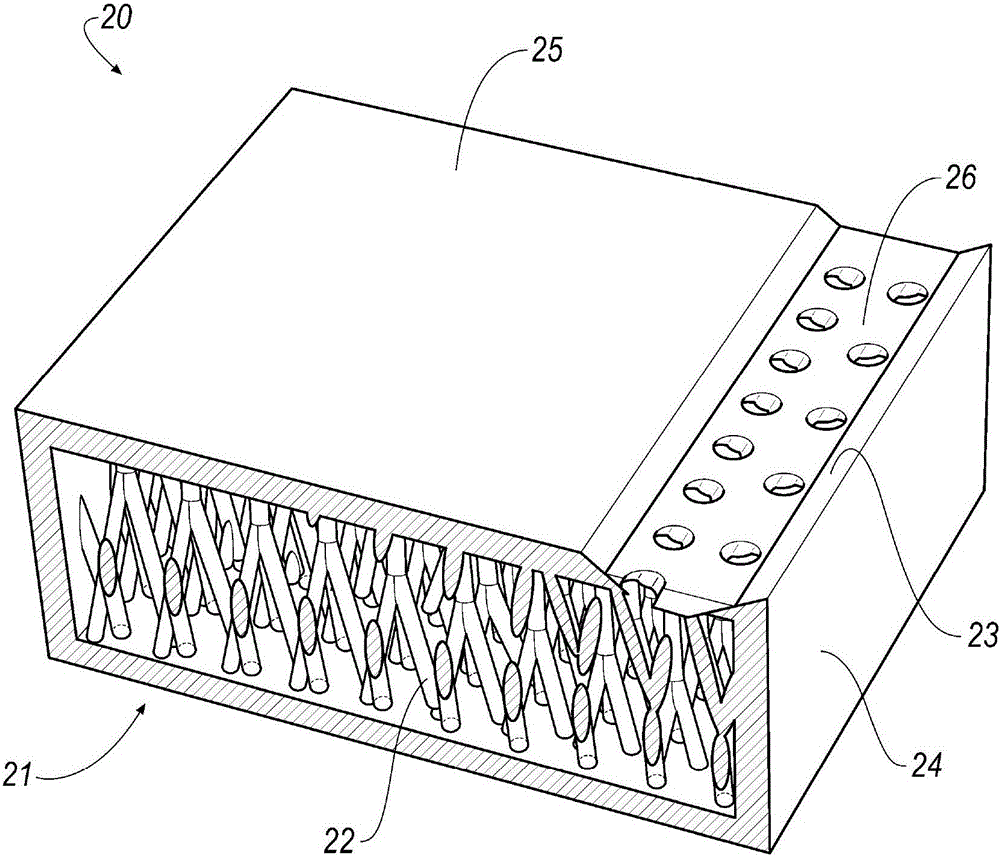

[0015] figure 1 A cutting insert 10 according to one embodiment of the invention is shown. In this embodiment, the cutting insert has a generally rectangular form, but the cutting insert may be of any desired shape suitable for metal cutting, such as another insert type, an end mill or a drill. Furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com