Inclined hole electrosparking processing device and method for adjusting position and angle of electrode

A processing device and electric spark technology are applied in the field of oblique small hole EDM devices, which can solve the problems of inconvenient use of precision numerical control EDM machine tools, difficulty in ensuring hole center position accuracy, and high processing costs, so as to solve the problem of electrode positioning. Difficulty, the effect of saving manufacturing cost and time, reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

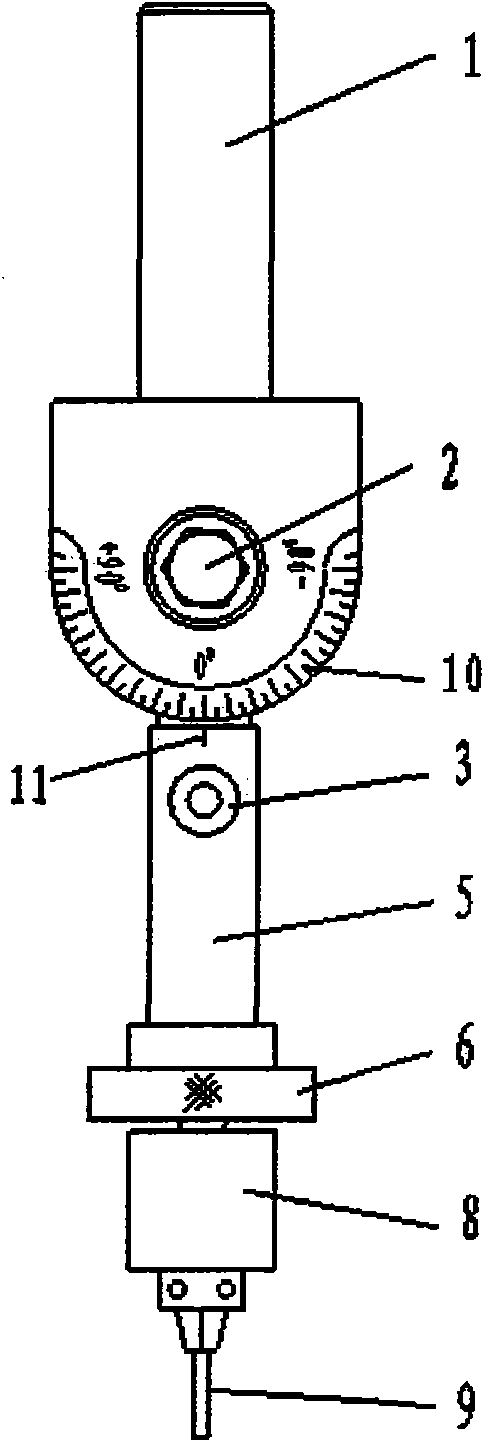

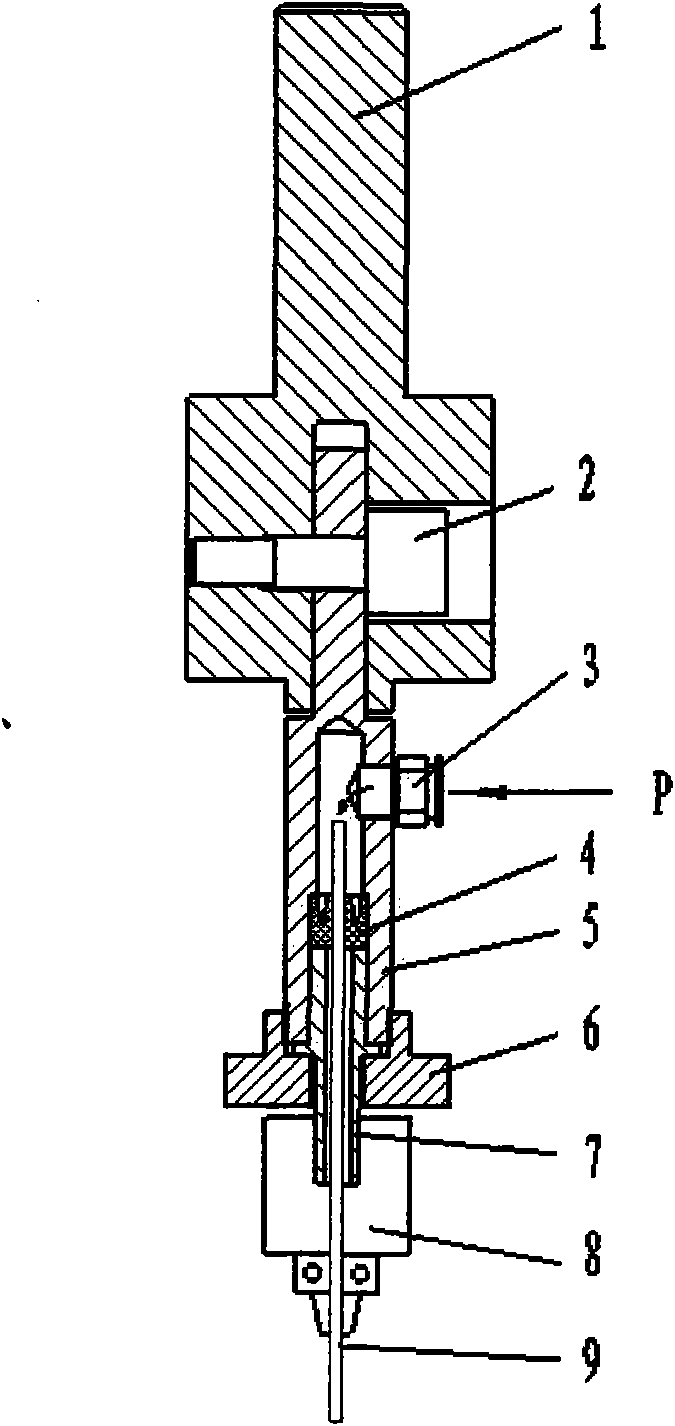

[0045] This embodiment is an EDM device for oblique small holes. Such as figure 1 with figure 2 As shown, the device includes a coupling body 1, an electrode deflection shaft 5, a positioning clamping screw 2, an oil inlet 3, a rubber seal 4, a fixing nut 6, a positioning shaft 7, a drill chuck 8 and a hollow hole electrode 9. .

[0046] The connecting rod of the electrode deflection shaft 5 is located in the rectangular slot of the coupling body 1 and is clamped and positioned by the positioning clamping screw 2. The equal-diameter end of the positioning shaft 7 is located in the shaft hole of the electrode deflection shaft 5, and there is a clearance fit between the two, and the fixing nut 6 is used to fix it. The rubber seal 4 is located in the shaft hole of the electrode deflection shaft 5. The hollow hole electrode 9 is inserted into the positioning shaft 7 through the inner hole of the drill chuck 8 and the rubber seal 4. The oil inlet 3 is located in the middle of the ...

Embodiment 2

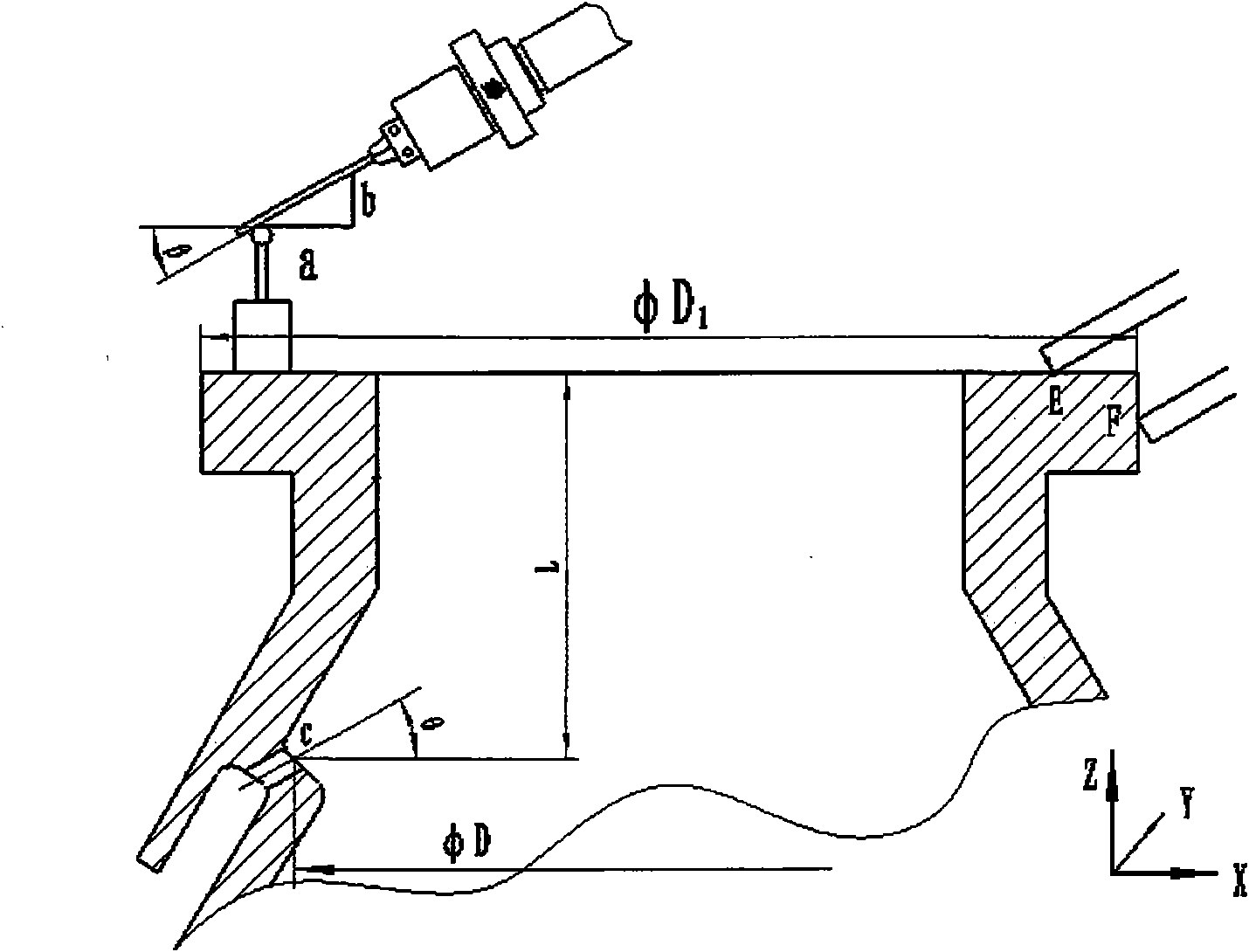

[0053] A method for adjusting the electrode angle and position when machining an oblique small hole with an angle of 0 degrees with the X axis on a CNC EDM machine using the oblique small hole EDM device described in the first embodiment, the method includes the following details step:

[0054] Step 1. Clamp and locate the parts;

[0055] Step 2. Mount the oblique small hole EDM on the elastic chuck of the machine tool spindle through the coupling body 1, loosen the positioning clamping screw 2, and rotate the electrode deflection axis 5, according to the angle between the oblique small hole and the X axis is 0 According to the requirements, adjust the angle β between the electrode and the X axis; align the engraved line 11 on the electrode deflection axis with the +90° position on the dial 10, and pre-tighten the positioning clamping screw 2;

[0056] Step 3. Install rubber seals and electrodes according to the processing aperture requirements;

[0057] Step 4. Rotate the main shaft...

Embodiment 3

[0063] A method for adjusting the electrode angle and position when machining the oblique small hole with an angle of 30 degrees with the X axis on the CNC EDM machine using the oblique small hole EDM device described in the first embodiment, the method includes the following details step:

[0064] Step 1. Clamp and locate the parts;

[0065] Step 2. Mount the oblique small hole EDM device on the elastic chuck of the machine tool spindle through the coupling body 1, loosen the positioning clamping screw 2, and rotate the electrode deflection axis 5, according to the angle between the oblique small hole and the X axis is 30 According to the requirements, adjust the angle β between the electrode and the X axis initially, align the engraved line 11 on the electrode deflection axis with the +60° position on the dial 10, and pre-tighten the positioning clamping screw 2;

[0066] Step 3. Install rubber seals and electrodes according to the processing aperture requirements;

[0067] Step 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com