Method for preparing high-concentration nano-silver particle conductive ink through two-step method and conductive ink

A technology of nano-silver particles and conductive ink, which is applied in inks, household utensils, applications, etc., can solve the problems of complex nano-silver conductive ink technology, save preparation time and cost, improve preparation efficiency, and reduce process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

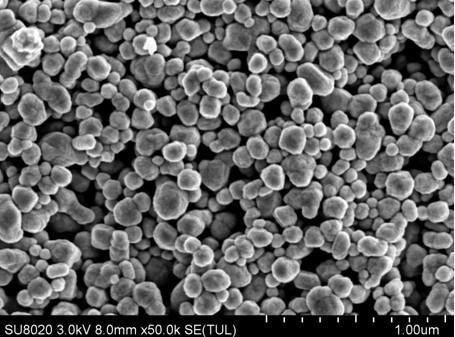

[0022] (1) Dissolve 1.37 g of silver nitrate and 1.07 g of polyvinylpyrrolidone (PVP) in 40 ml of ethylene glycol, stir until a transparent solution; put the solution into a household microwave oven and heat it for 90 s; cool the reaction solution to room temperature , you can get nano-silver particle conductive ink. The morphology of the conductive components in the ink is as follows figure 1 Shown, wherein the average particle size of nano-silver particles is 107nm.

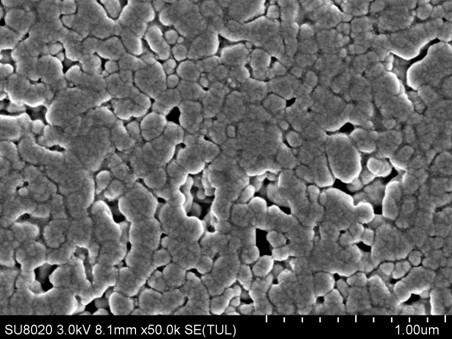

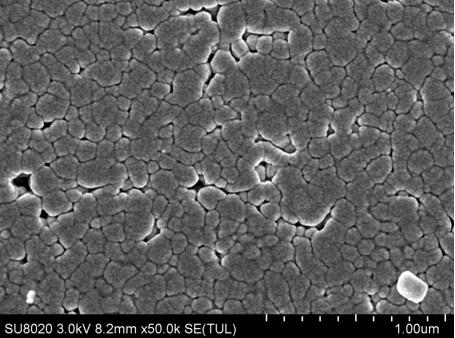

[0023] (2) Put the above ink into a syringe, control the ink flow rate through a syringe pump, use Epson photo paper as the base, and perform direct writing on a two-dimensional stepping platform, and put the photo paper into an oven to dry; dry The subsequent samples were hot-pressed and sintered at 100 °C and 10 MPa for 10 min. The morphology of the samples after sintering is shown in figure 2 , put it into the thin film thermoelectric test system (MRS-3M) to measure its resistivity, and the average resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com