Patents

Literature

111results about How to "Good Performance Guaranteed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

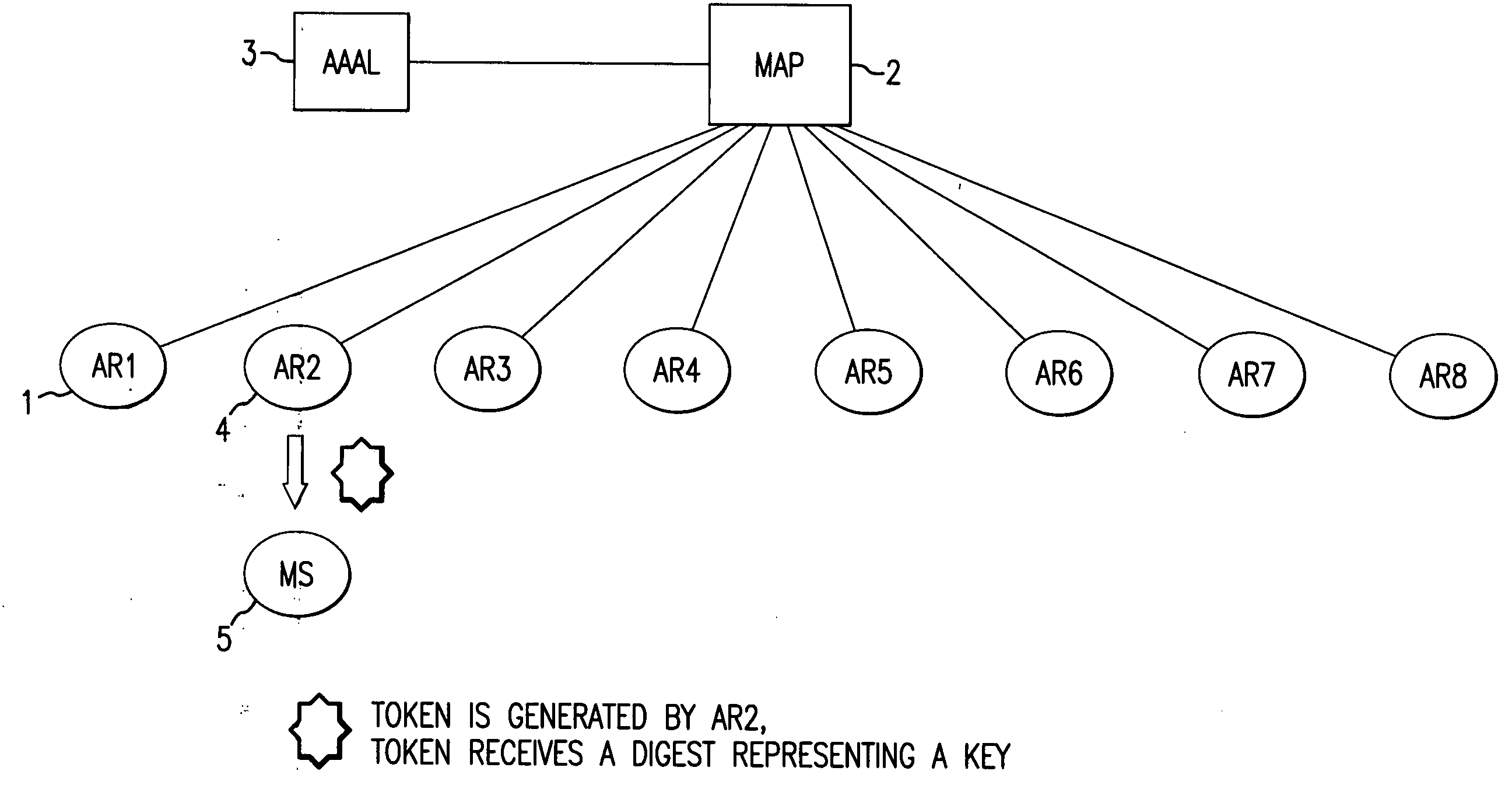

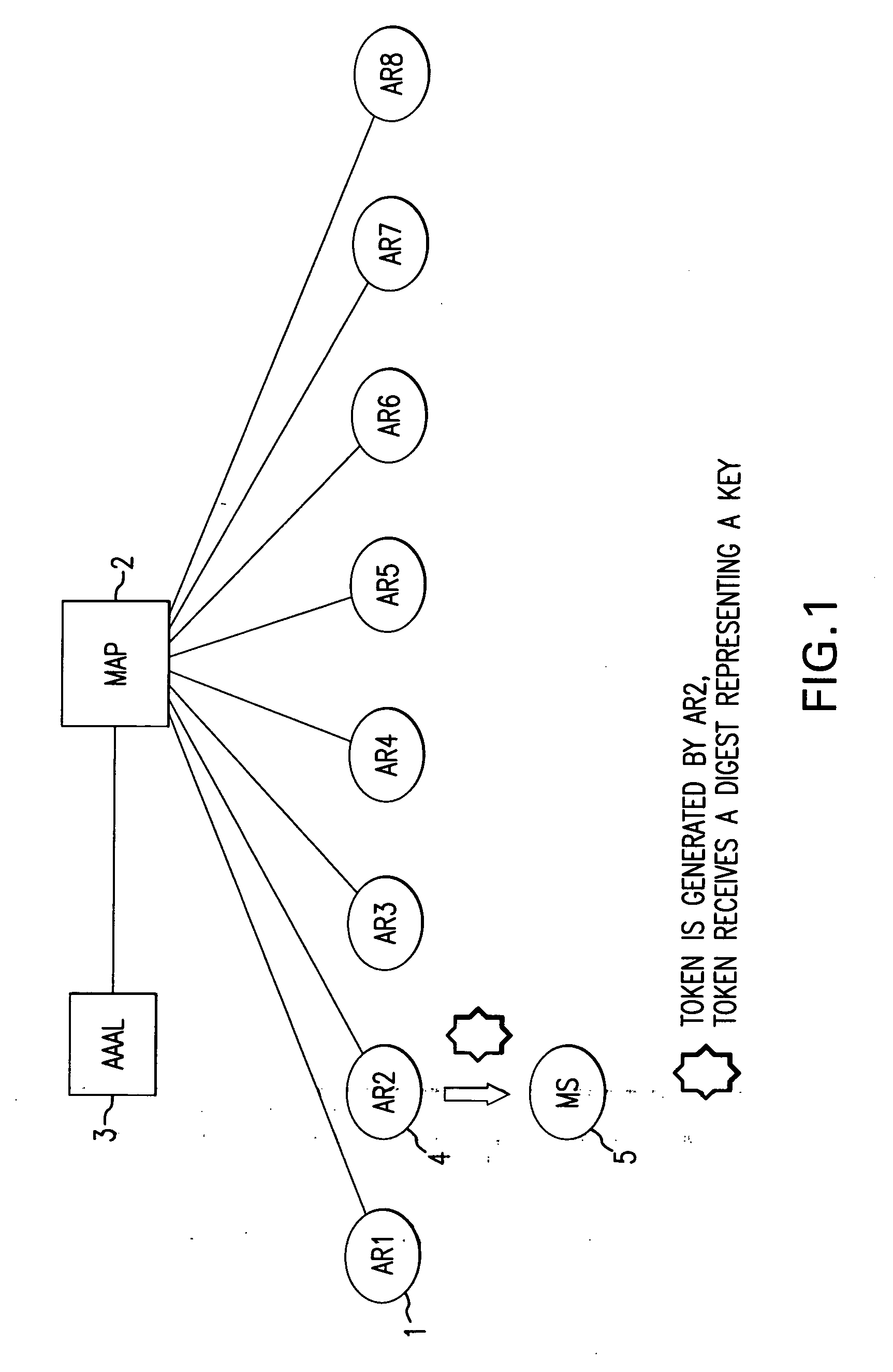

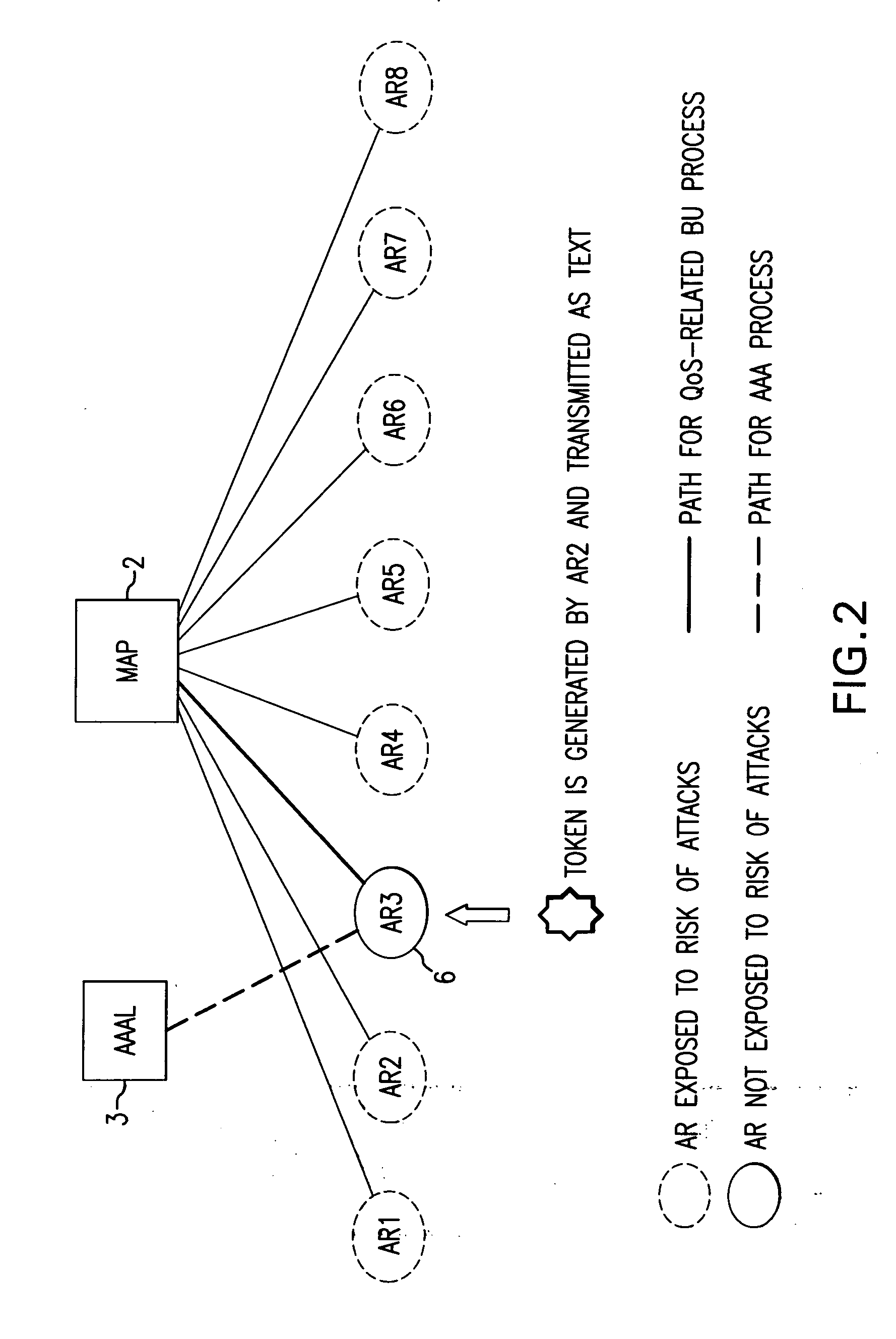

Verifying check-in authentication by using an access authentication token

InactiveUS20050079866A1Good Performance GuaranteedEffective protectionUnauthorised/fraudulent call preventionEavesdropping prevention circuitsMobile radioComputer science

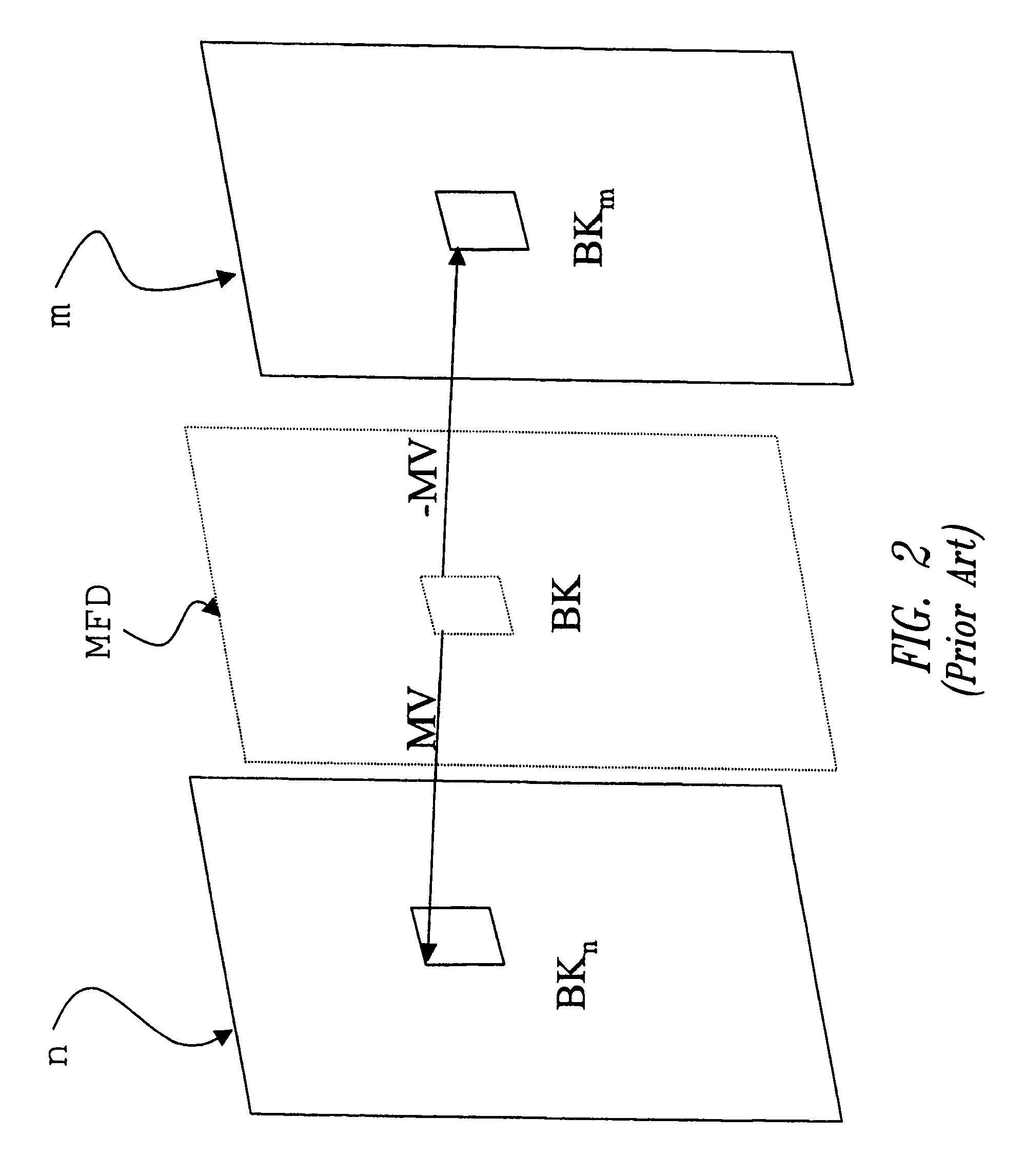

A simple and efficient means of checking the registration authorization is proposed by the method and the device for checking the registration authorization prior to the start of the re-registration process based on a registration query from a mobile radio terminal to at least one access device for an intra-domain handover in a mobile communication network. In the network, a token which has been sent by an access device to a mobile radio terminal and has been stored in at least one trust table of at least one access device, is received by at least one further access device during a registration query from a mobile radio terminal and compared with tokens stored in at least one trust table prior to the start of the registration for the purpose of verifying the registration authorization, and the registration is started if an authorization is present.

Owner:SIEMENS AG

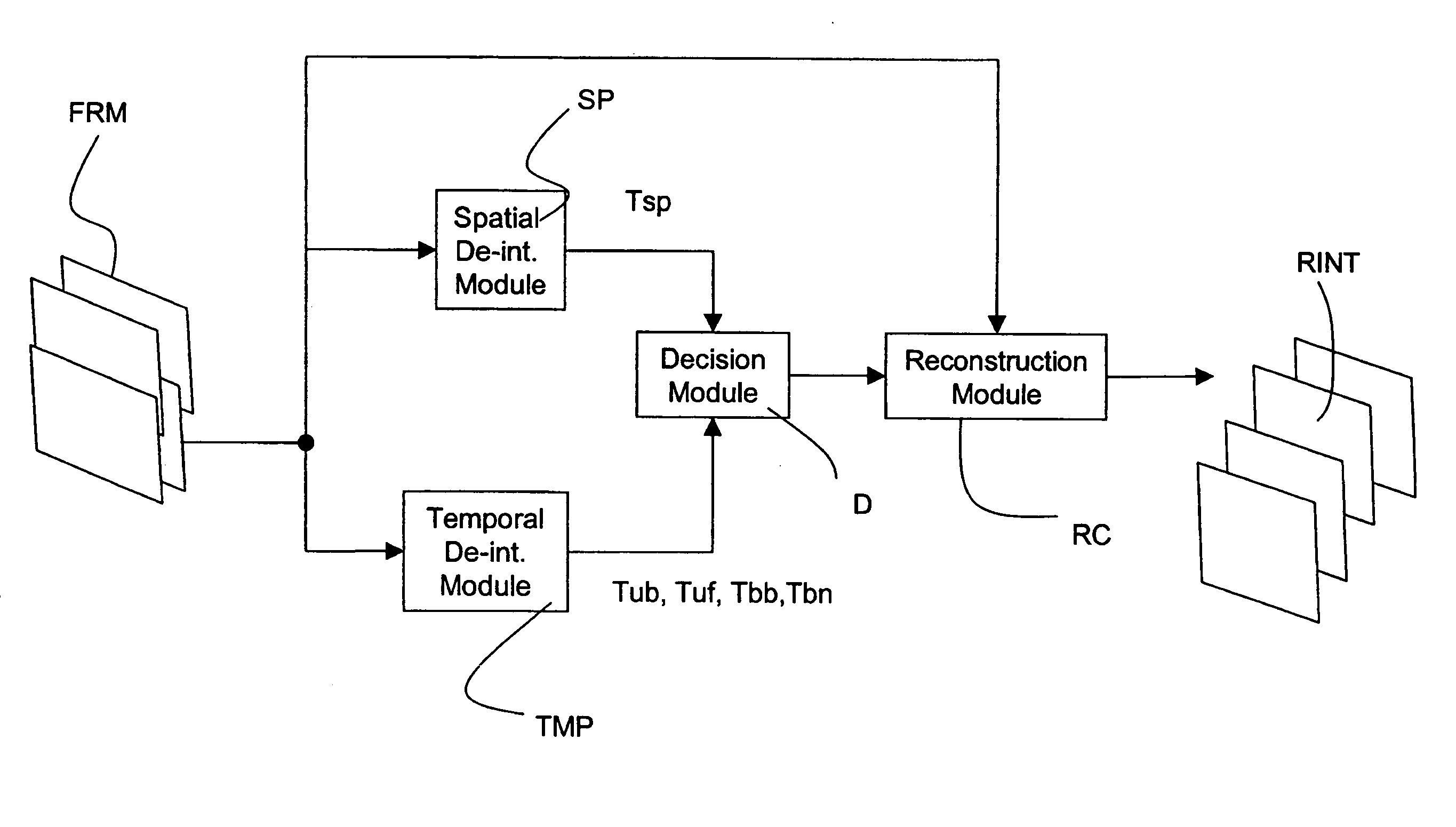

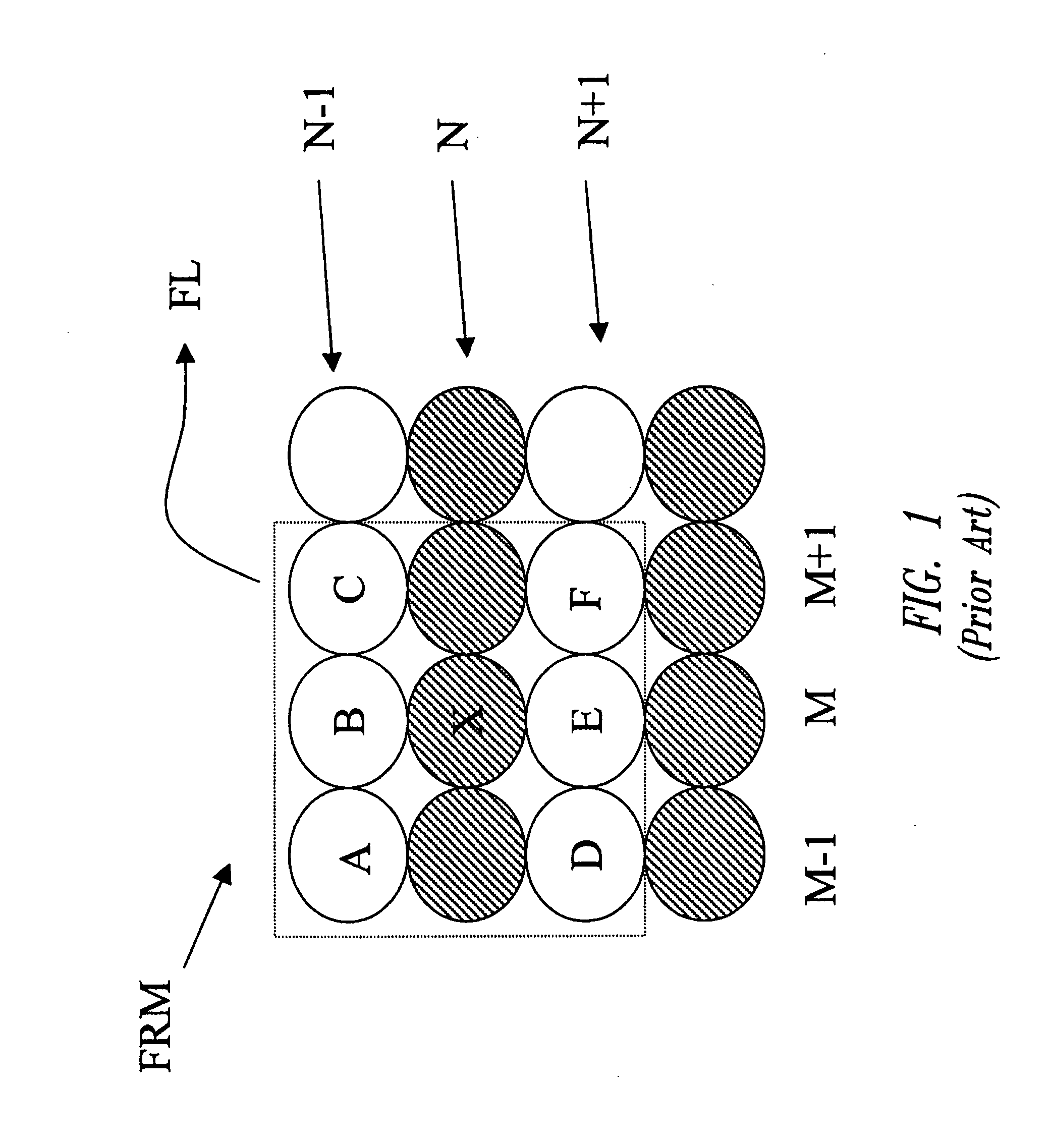

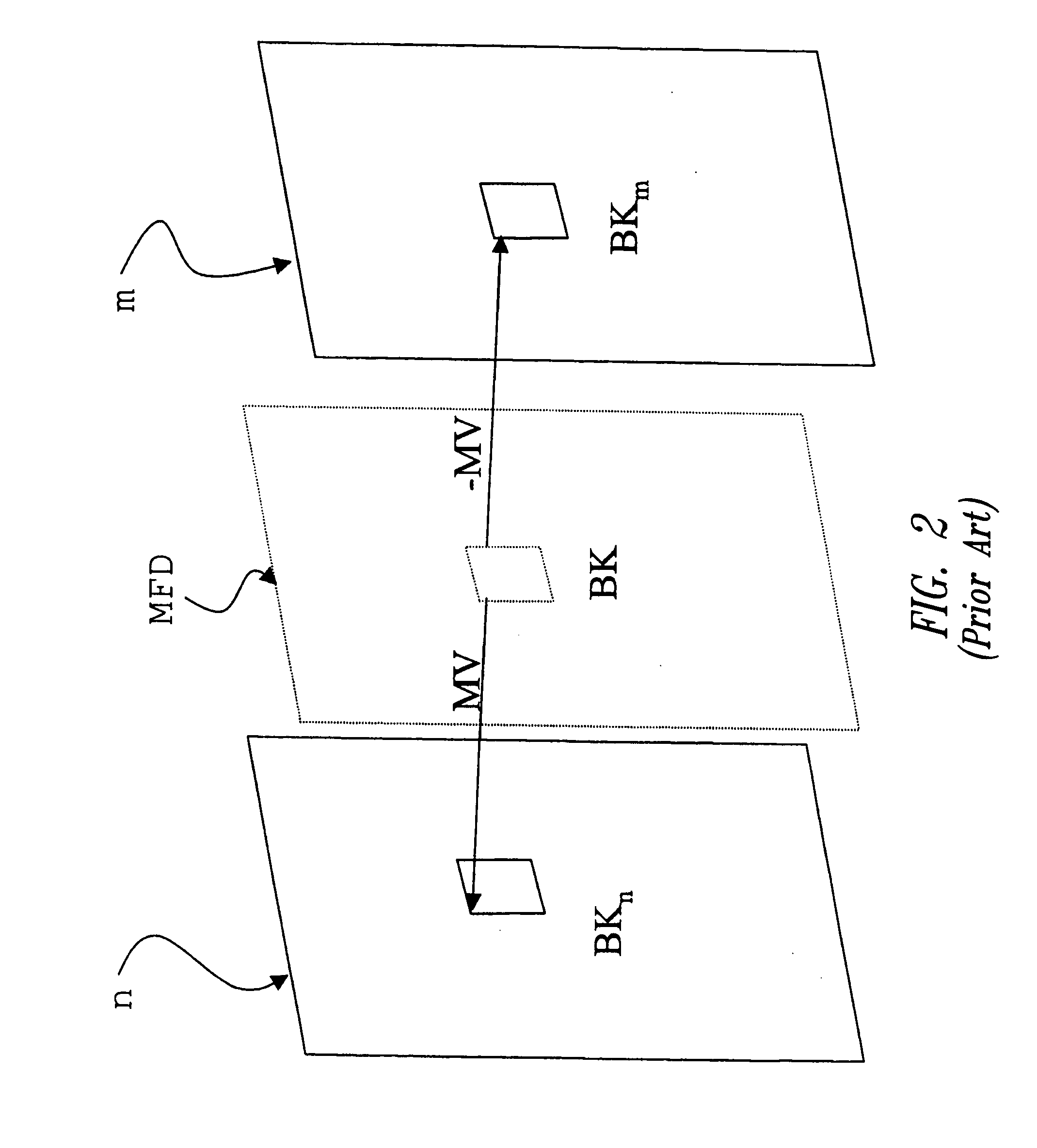

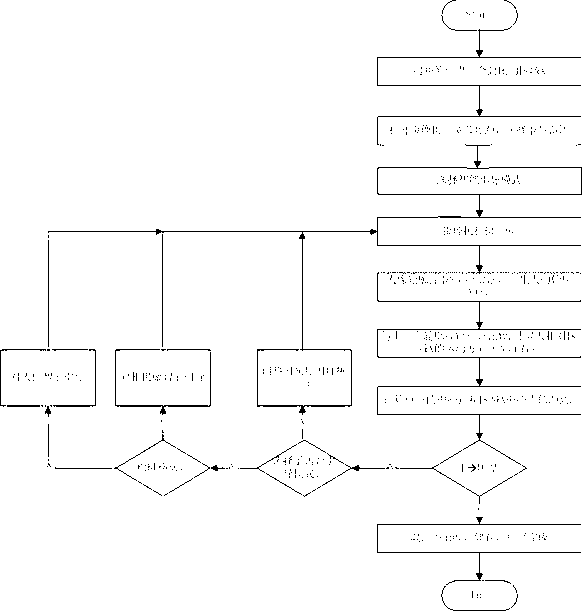

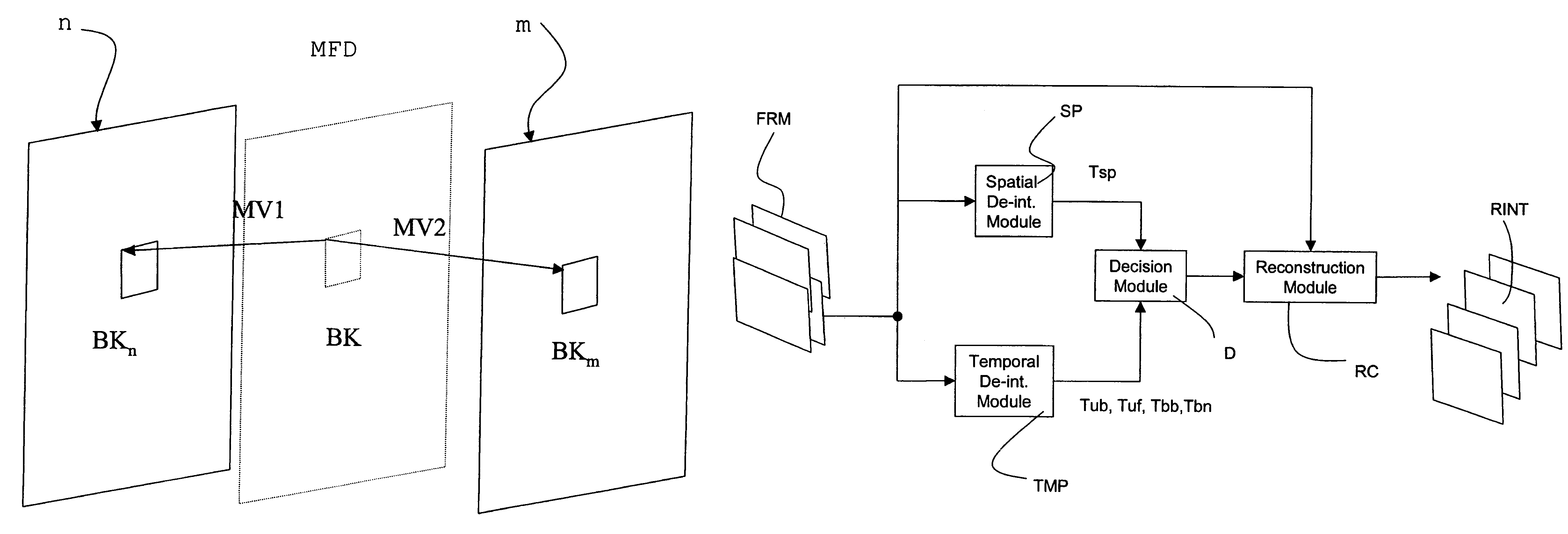

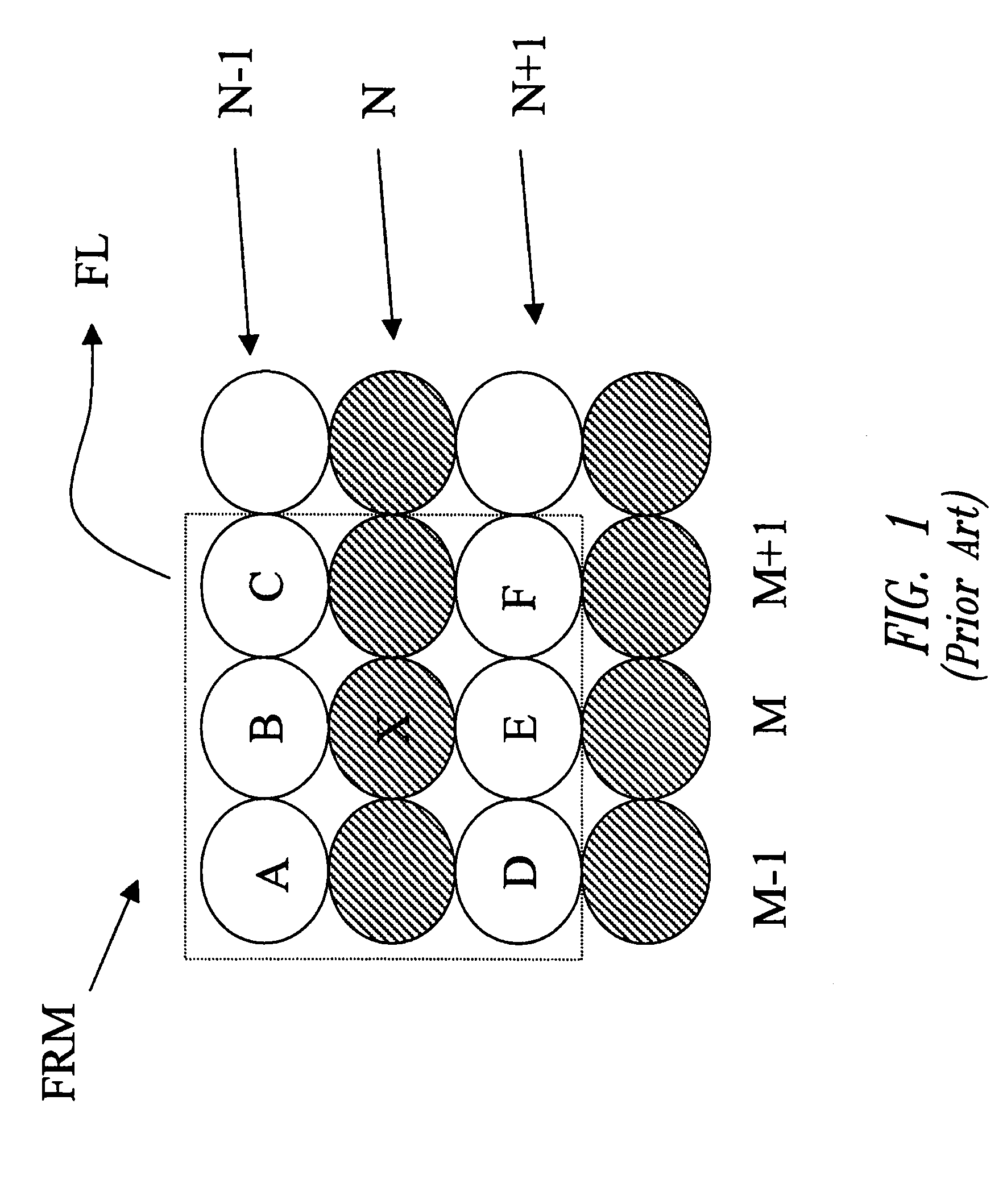

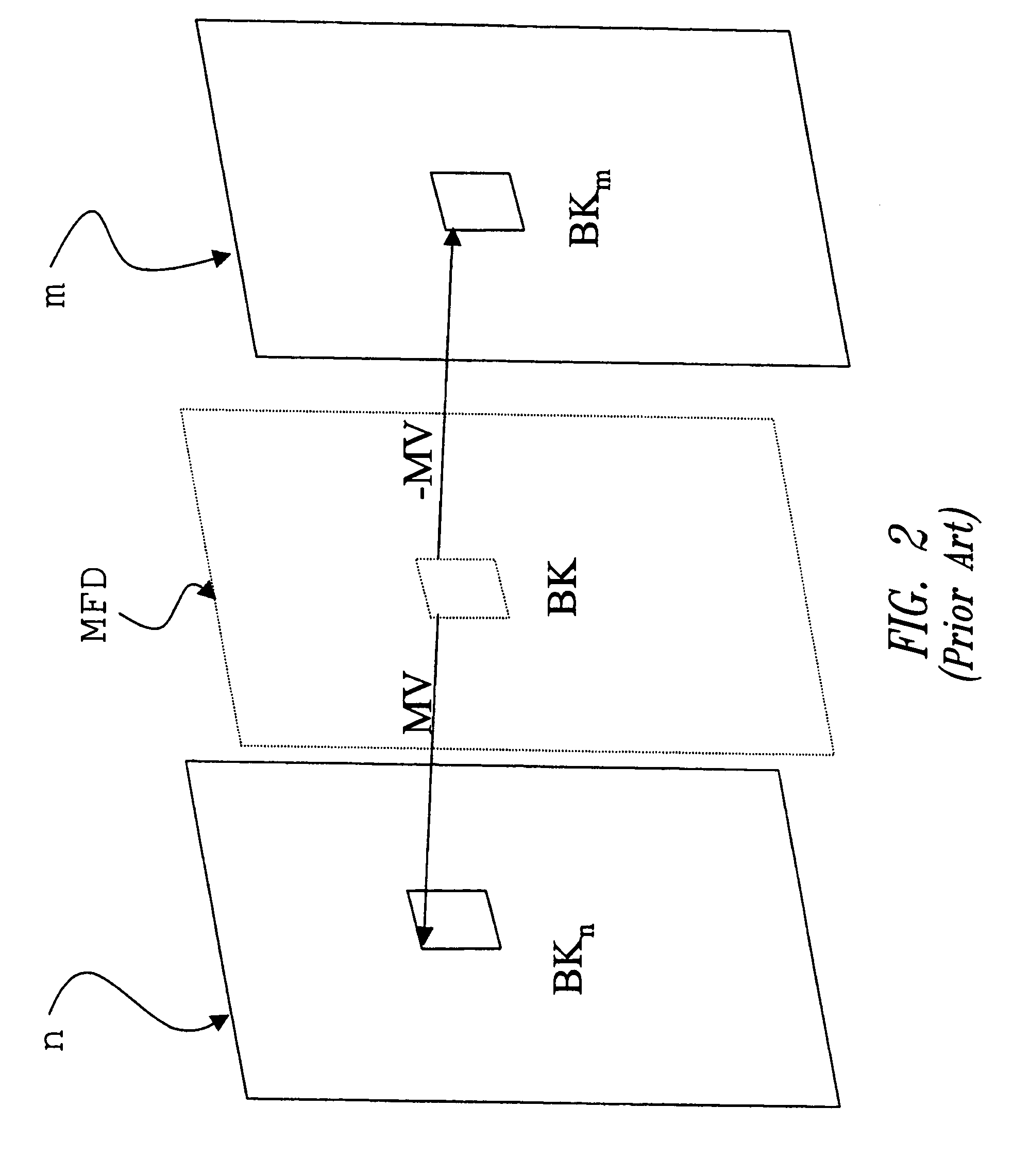

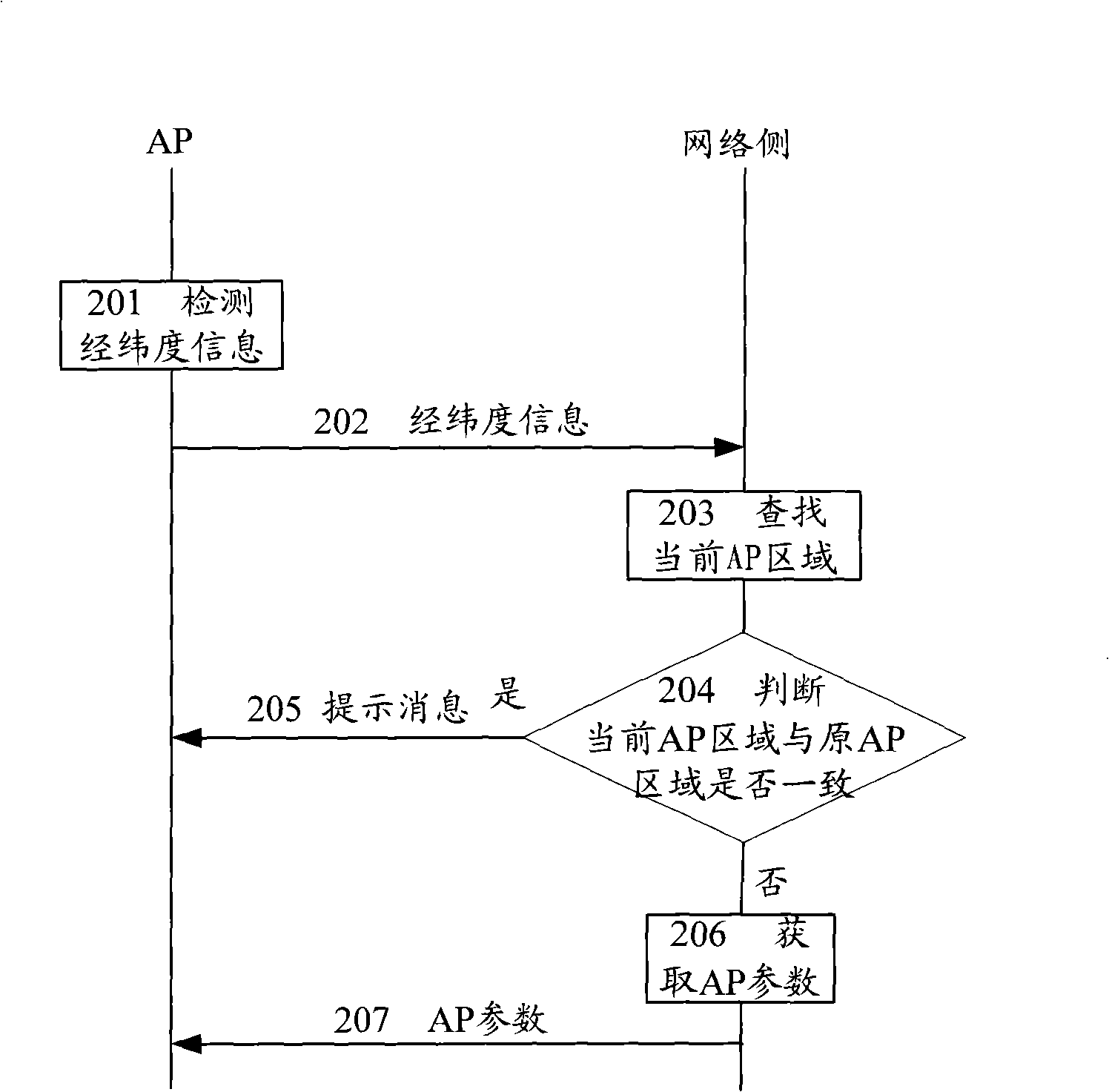

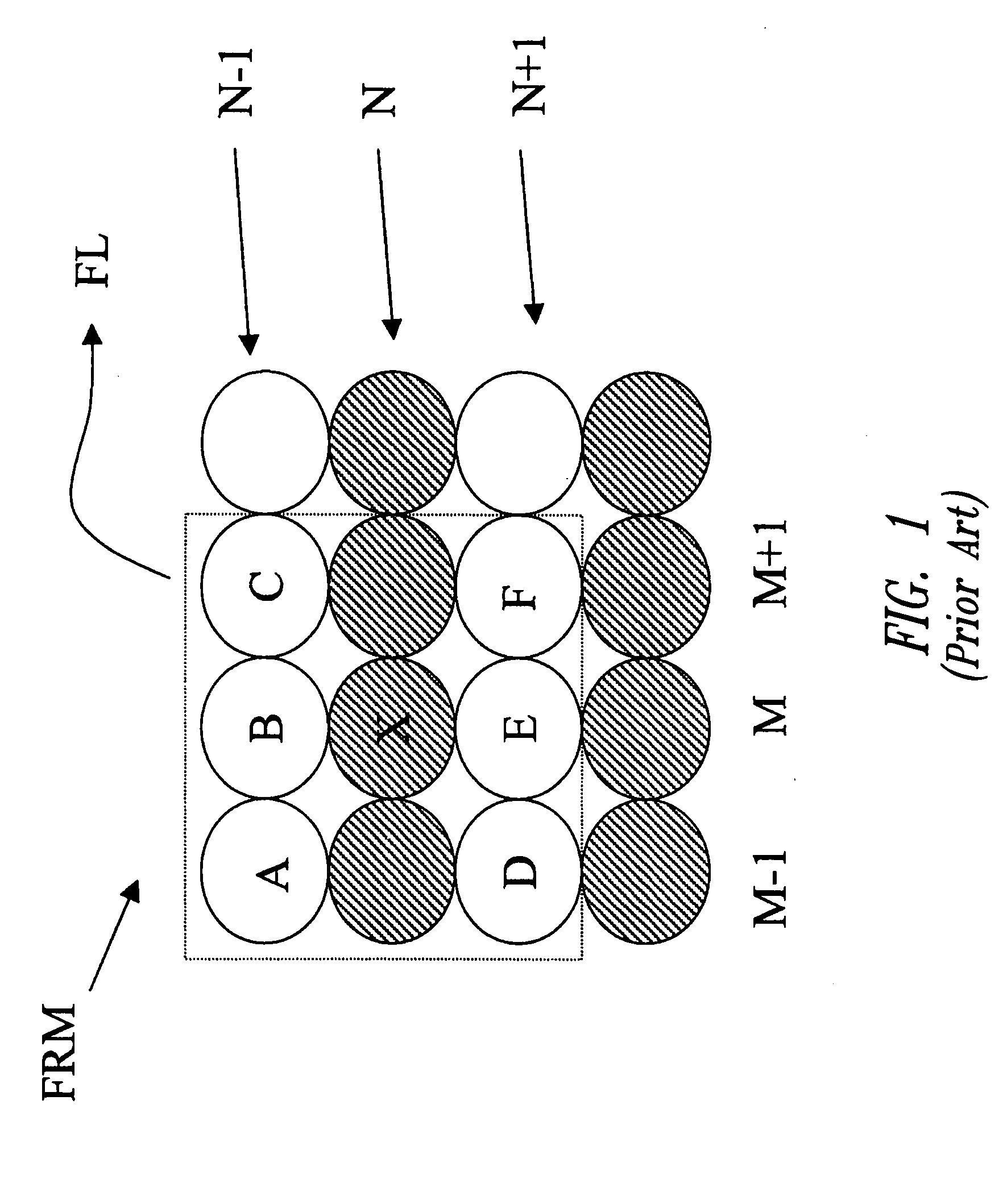

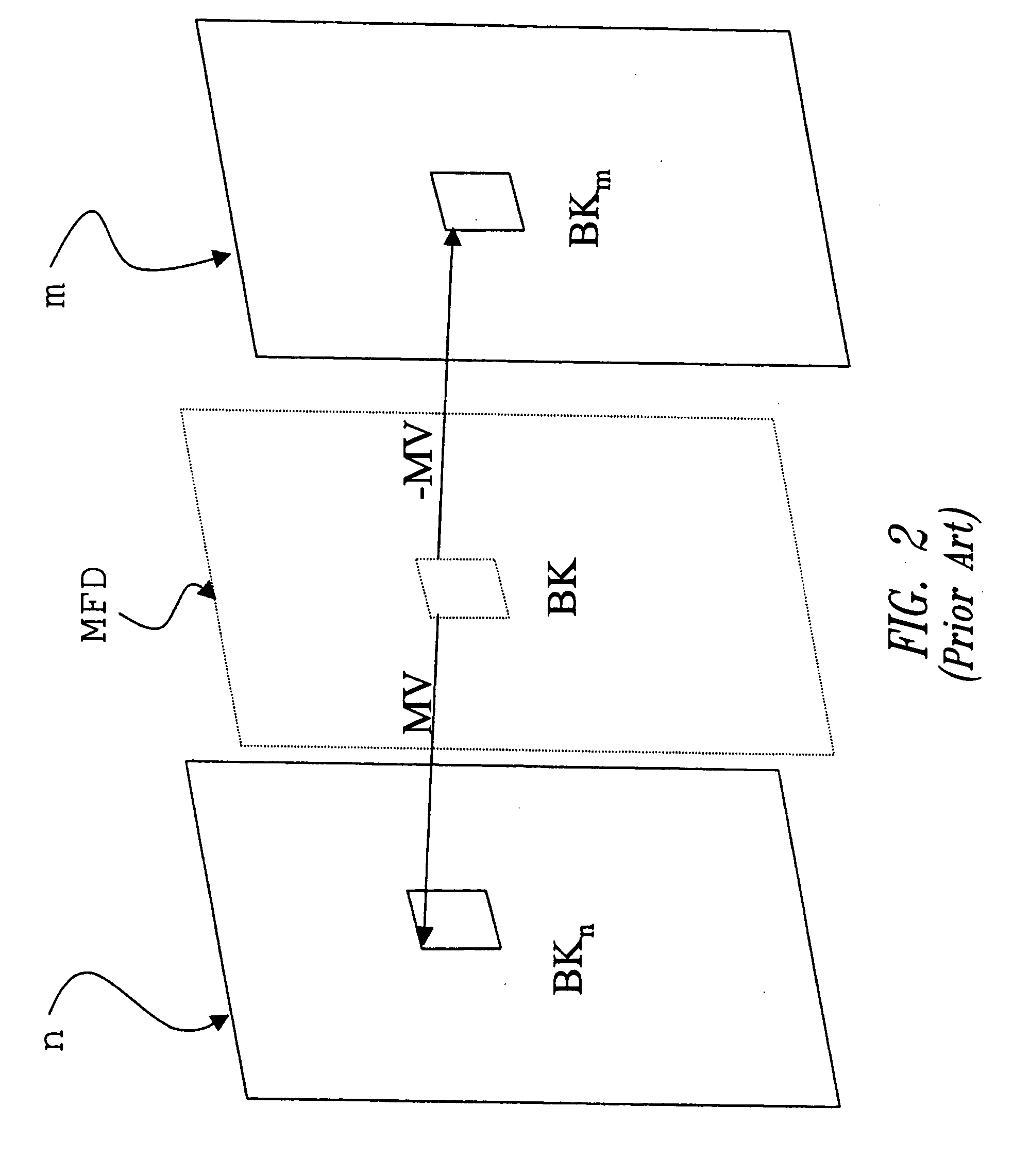

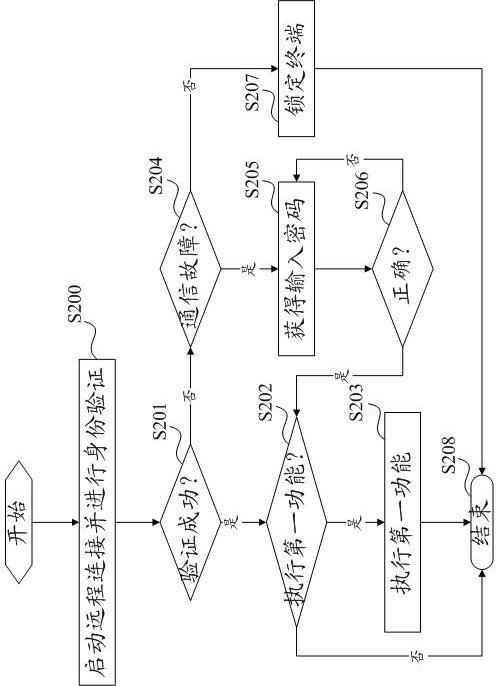

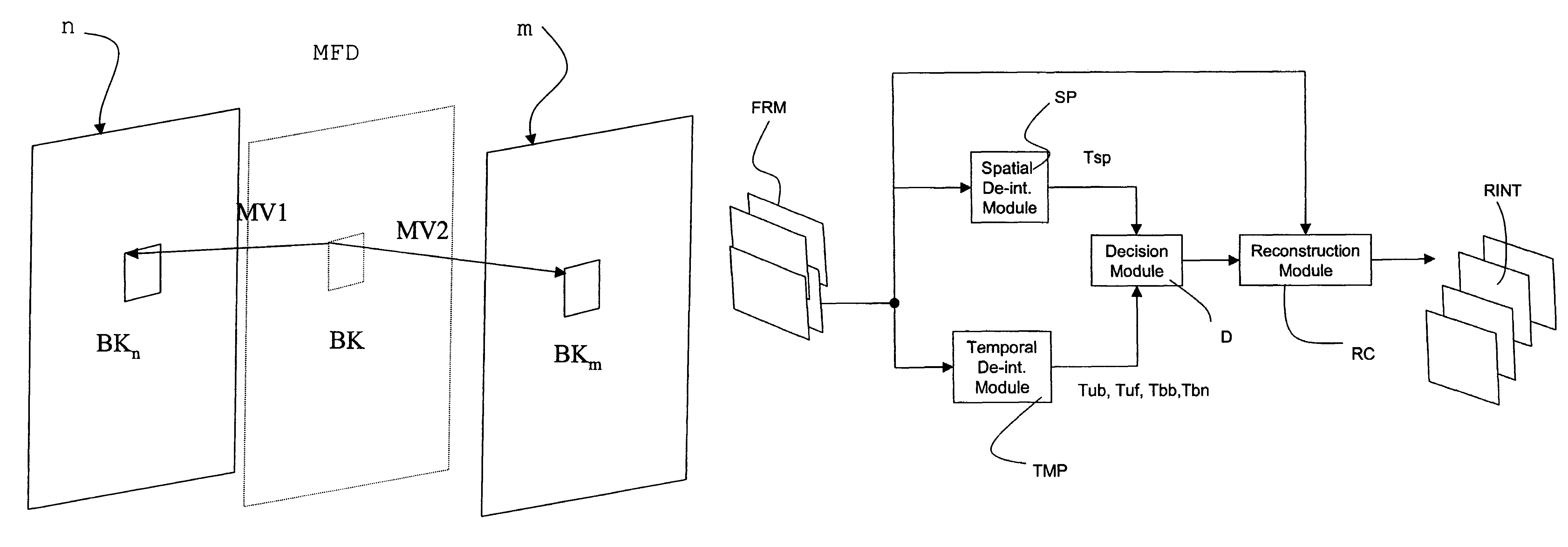

Method and system for de-interlacing digital images, and computer program product therefor

InactiveUS20050179814A1Easy to operateGood Performance GuaranteedTelevision system detailsPicture reproducers using cathode ray tubesProgressive scanDigital image

A spatial-type de-interlacing process to be applied to a digital image for obtaining a spatial reconstruction. Furthermore, to the digital image there are also applied one or more temporal-type motion compensation de-interlacing processes for obtaining one or more temporal reconstructions, and the spatial reconstruction and the one or more temporal reconstructions are sent to a decision module. The decision module applies a cost function to the spatial reconstruction and the temporal reconstructions and chooses from among the spatial reconstruction and the temporal reconstructions the one that minimizes the cost function. Preferential application is to display systems, in particular displays of a cathode-ray type, liquid-crystal type, and plasma type which use a mechanism of progressive scan.

Owner:STMICROELECTRONICS SRL

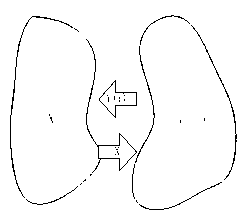

Smart phone photographing guiding method based on image matching

InactiveCN102801857AGood Performance GuaranteedTelevision system detailsColor television detailsFlashlightImage matching

The invention provides a smart phone photographing guiding method based on image matching, which can solve the problem of difficulty in framing when one person carries out self-photographing by adopting a postpositional phone camera in the prior art. The smart phone photographing guiding method comprises the steps of: presetting a closed region X on a phone photographing interface before photographing, so as to be used for displaying an expected position (of a person to be photographed) on a final image; and then photographing a dynamic image of the person to be photographed by using a phone camera, carrying out image outline Y(i) extraction on each frame of the dynamic image by adopting a sobel operator, directly or indirectly guiding the camera to rotate or the person to be photographed to move according to the distance between the closed region X and the center point of an image outline Y(i) region of each frame and a position correlation between the closed region X and the image outline Y(i) through a voice prompt module or the flicker frequency of a flashlight until that the closed region X is basically coincident with the image outline Y(i), and extracting the fame of image as a final image to be stored.

Owner:北京知势技术服务有限公司

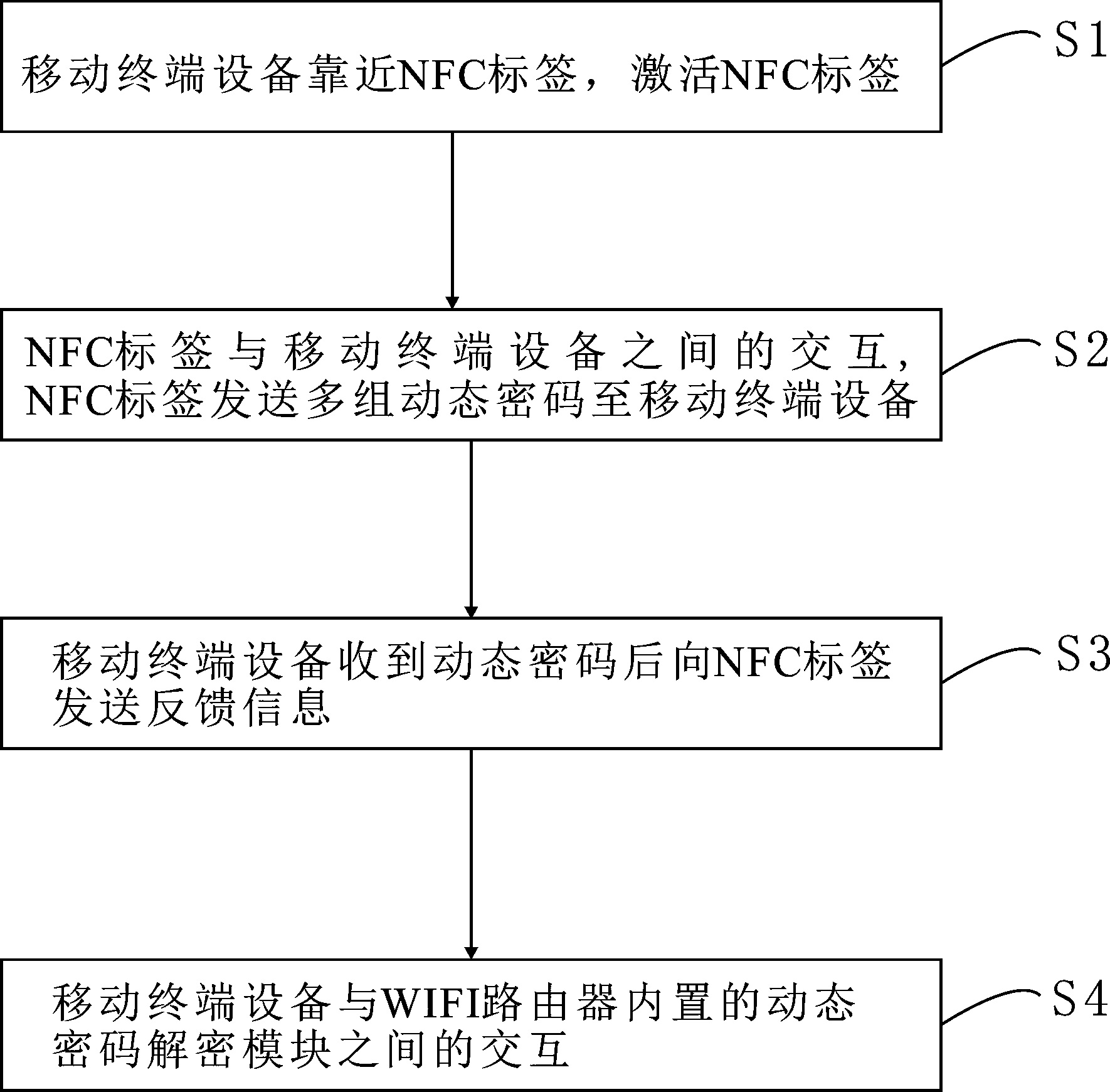

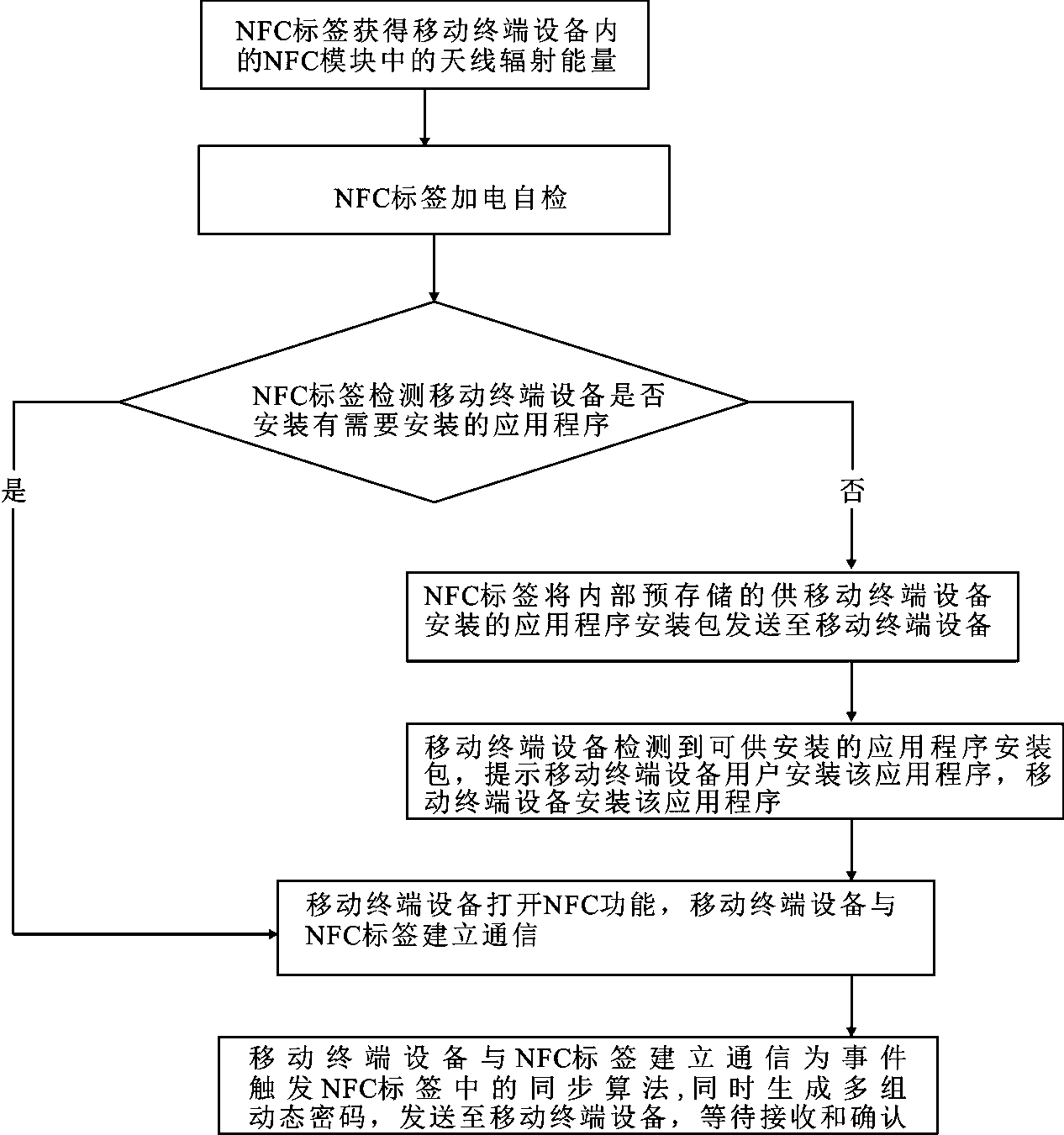

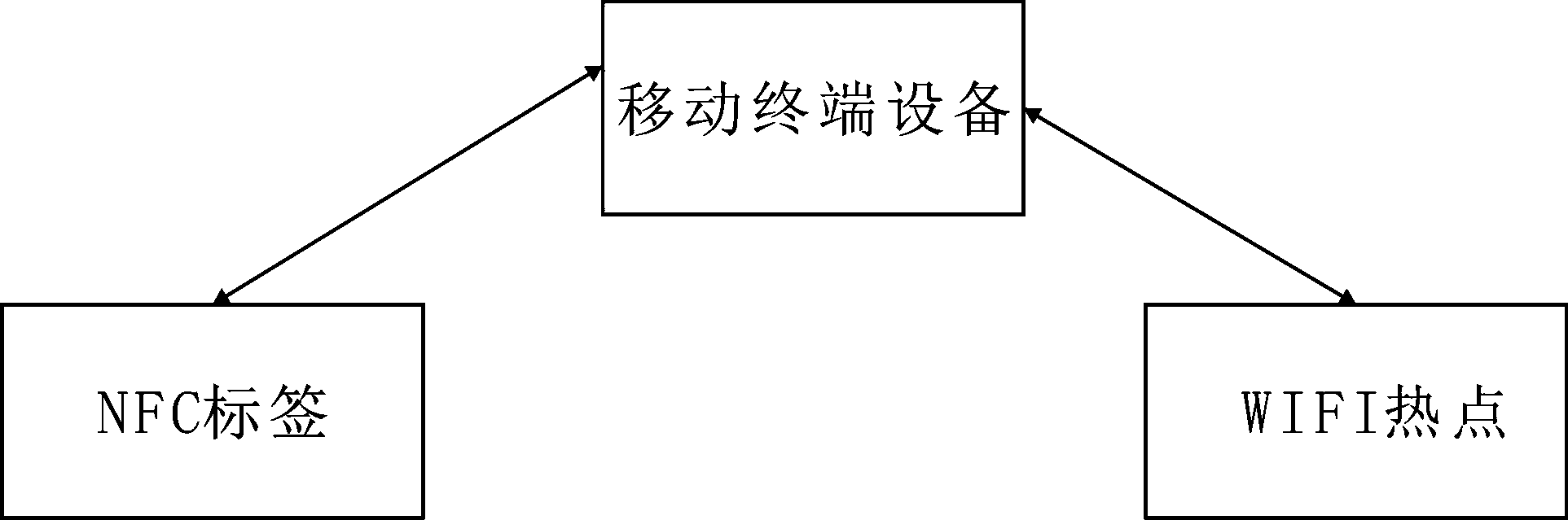

Method and system for connecting to WIFI (Wireless Fidelity) by NFC (Near Field Communication) and mobile terminal equipment

ActiveCN103874164AQuick connectionGood Performance GuaranteedAssess restrictionConnection managementPasswordNetwork packet

The invention discloses a method for connecting to WIFI (Wireless Fidelity) by NFC (Near Field Communication). The method comprises the steps that mobile terminal equipment is close to an NFC label, the NFC label is activated, an application program which is prestored in the NFC label is installed in the mobile terminal equipment, the NFC label starts a synchronization algorithm which is synchronized by events, a plurality of groups of dynamic passwords are generated to be sent to the mobile terminal equipment, the mobile terminal equipment sends the obtained dynamic password data package to a WIFI router, a synchronization algorithm which is operated in a dynamic password decoding module built-in the WIFI router is consistent with the synchronization algorithm in the NFC label, base band information which is received is dynamically decoded, an SSID (Service Set Identifier) and a login password of a WIFI hot spot are decoded, a communication channel between the mobile terminal equipment and the WIFI hot spot is built, and the interconnection and the data interaction of two pieces of equipment are completed. According to the method, a user does not need to input a password when WIFI connection is carried out, and the WIFI can be connected by a dynamic password mode through an NFC technology.

Owner:上海升途智能系统有限公司

Method and system for de-interlacing digital images, and computer program product therefor

ActiveUS7375763B2Good Performance GuaranteedAccelerated programTelevision system detailsColor signal processing circuitsProgressive scanDisplay device

To carry out de-interlacing of digital images there is provided a spatial-type de-interlacing process to be applied to a digital image for obtaining a spatial reconstruction. Furthermore, to the digital image there are also applied one or more temporal-type de-interlacing processes for obtaining one or more temporal reconstructions, and the spatial reconstruction and the one or more temporal reconstructions are sent to a decision module. The decision module applies a cost function to the spatial reconstruction and the temporal reconstructions and chooses from among the spatial reconstruction and the temporal reconstructions the one that minimizes the cost function. Preferential application is to display systems, in particular displays of a cathode-ray type, liquid-crystal type, and plasma type which use a mechanism of progressive scan.

Owner:STMICROELECTRONICS SRL

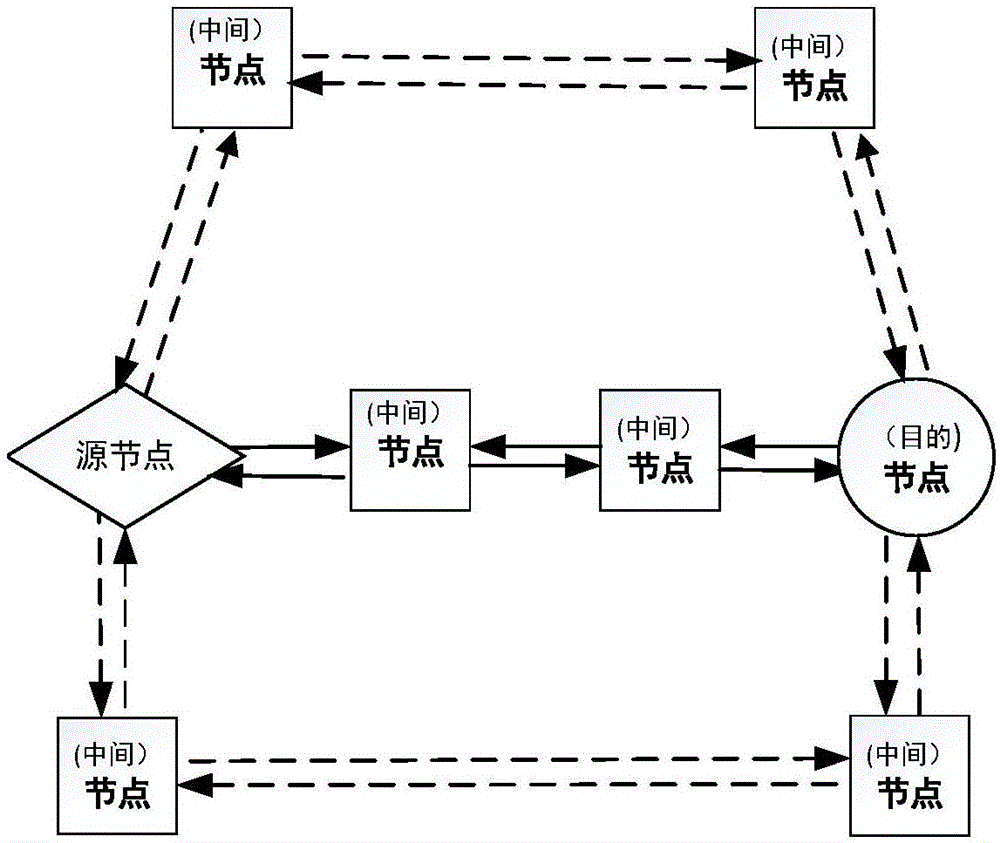

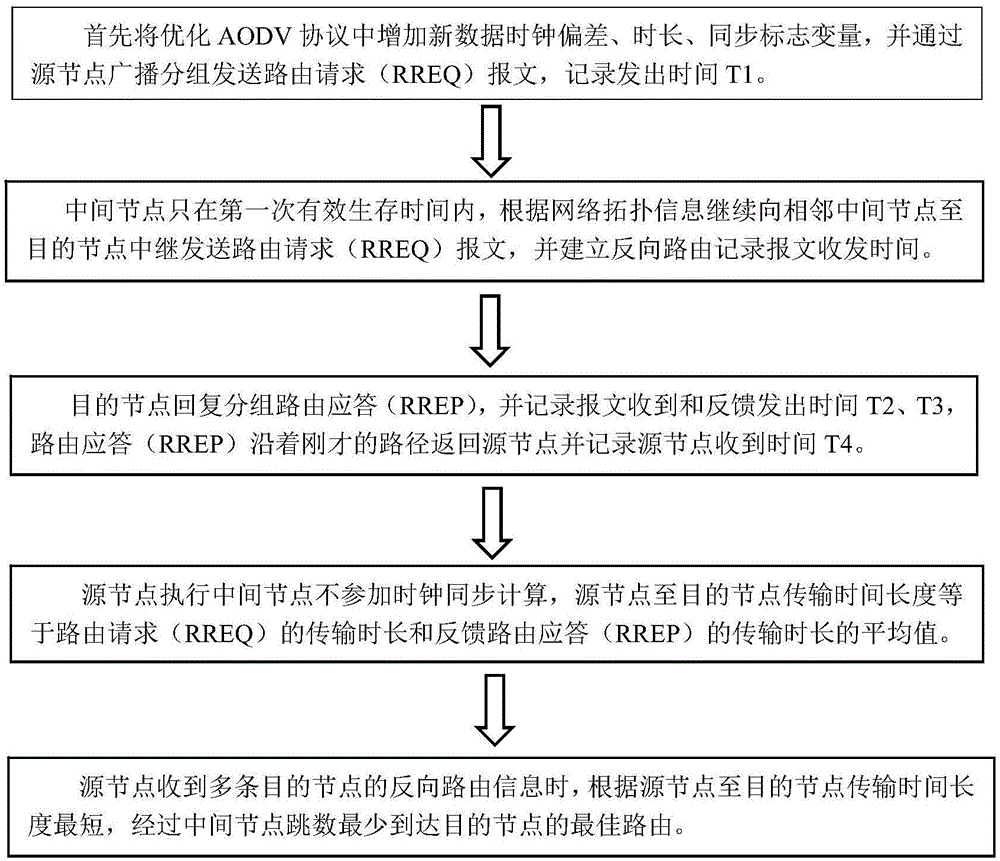

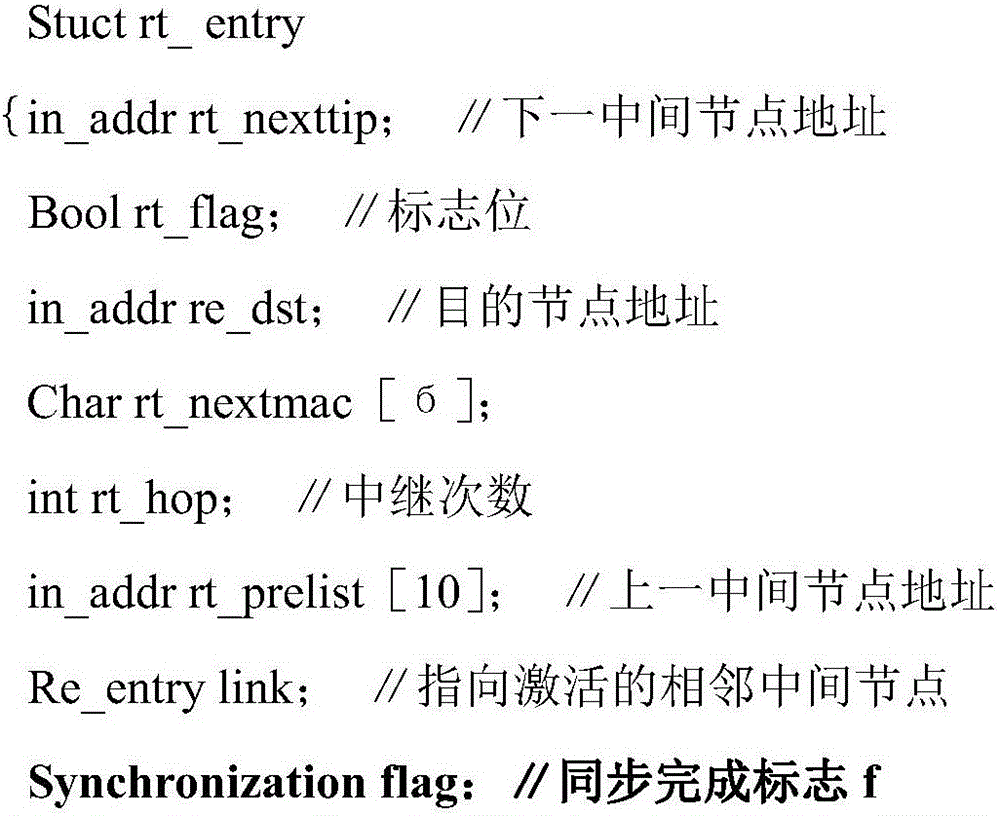

Method for determining optimal route based on transmission time length

ActiveCN106385701AGood Performance GuaranteedOptimal Power ControlSynchronisation arrangementNetwork topologiesPower controlReal-time computing

The invention discloses a method for determining an optimal route based on transmission time length. The method comprises the following steps: establishing a communication channel route by using an AODV routing protocol via a source node; simultaneously establishing a reverse route in a process of enabling route to request message packet broadcast to pass from an intermediate node to a destination node, wherein the reverse route comprises information such as transmission time length from the source node to the destination node; determining an optimal route capable of passing from the intermediate node to the destination node through minimum hop count according to the shortest transmission time length from the source node to the destination node if the source node receives a plurality of reverse route messages reaching the destination node. Through the method for determining the optimal route based on transmission time length, the conventional method for selecting a route according to minimum hop count based on AODV protocol is optimized; the method is capable of ensuring that the source node can determine the optimality of the route when receiving a plurality of same reverse route messages with minimum hop count, and achieving optimal route control overhead, link stability and power control.

Owner:上海灵信数字技术有限公司

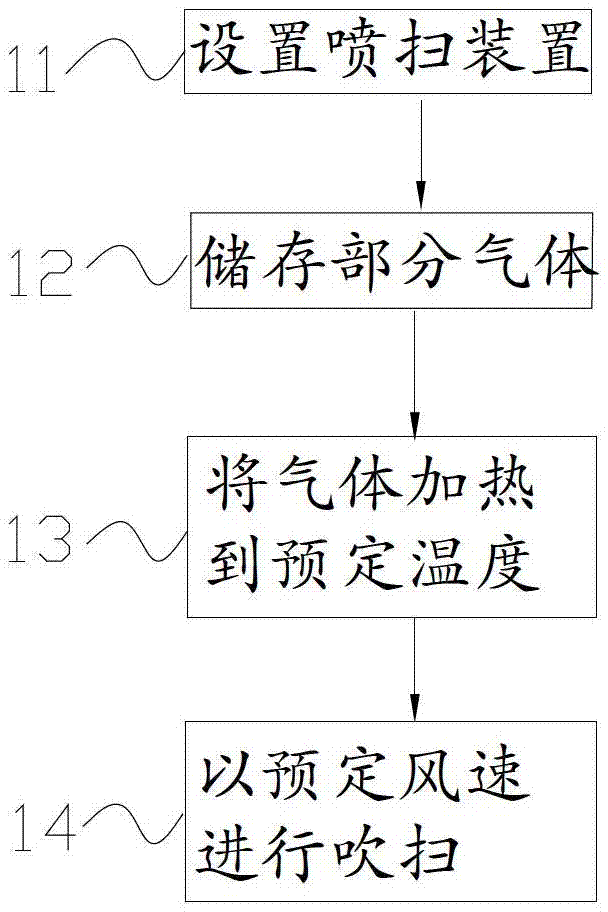

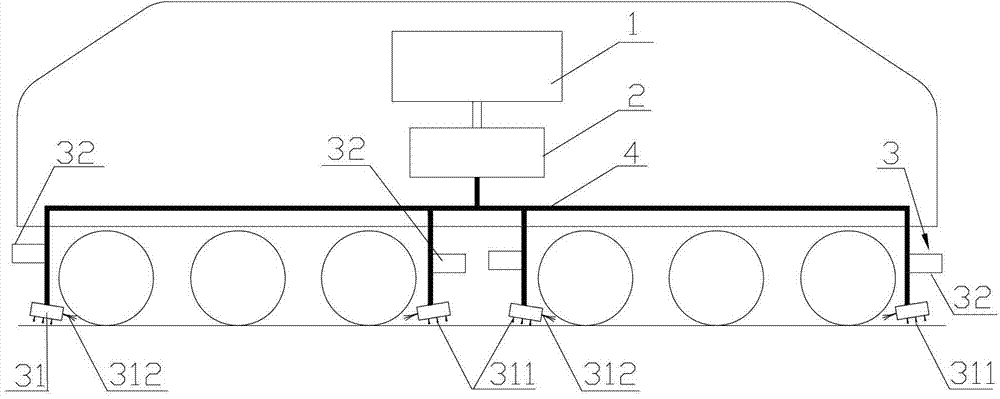

Method and device for tackifying rail train and wheel rail

InactiveCN103112470AAchieve Viscosity SettingGood viscosity increasing effectRailway wheel guards/bumpersEngineeringMechanical engineering

The invention provides a method and a device for tackifying a rail train and a wheel rail. By the method and the device, tackifying of the wheel rail under a clean dry state can be realized, tackifying effect is good, and control is simpler and easier to implement. The tackifying method includes: 11), setting a jetting and sweeping device capable of generating jetting air and sweeping the wheel rail; 12), heating gas forming the jetting air in the jetting and sweeping device to a preset temperature; and 13), enabling the jetting and sweeping device to move along with the rail train and sweep a rail face and a contact area of the wheel tail and the wheel rail at a preset air speed. The tackifying device comprises the jetting and sweeping device capable of jetting air and sweeping and a heater for heating the gas forming the jetting air in the jetting and sweeping device to the preset temperature, and an air jetting position of the jetting and sweeping device is arranged correspondingly to the contact area and the rail face. By the method and the device for tackifying the rail train and the wheel rail, the contact area of the wheel rail and the rail face can be swept through air energy, good contact adhesiveness of the wheel rail can be guaranteed to enable the wheel rail to normally run, and control of the device is simpler and easier to implement.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

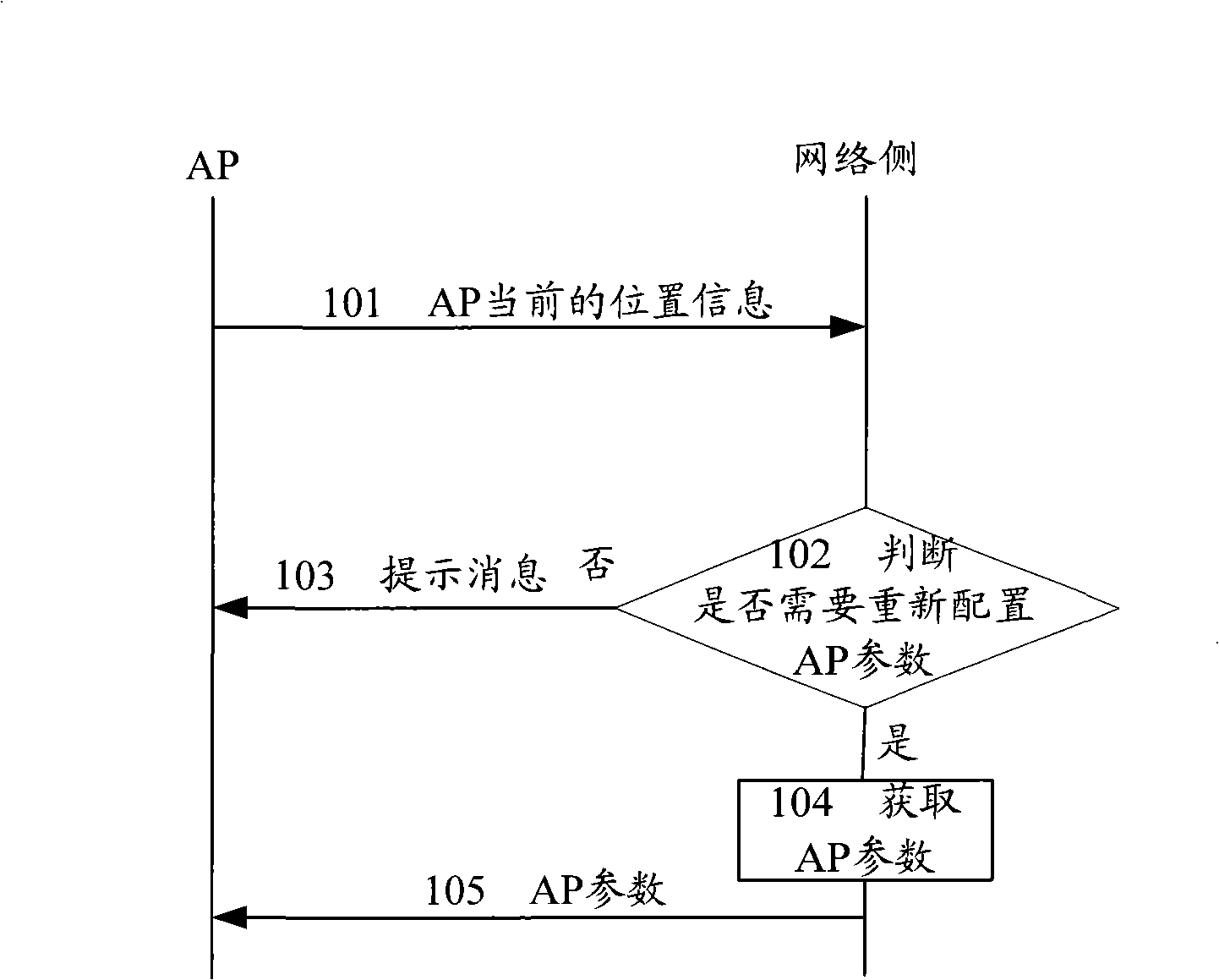

Access equipment parameter configuration method, device and system

ActiveCN101272617AGood Performance GuaranteedReduce maintenance costsData switching by path configurationRadio/inductive link selection arrangementsCollocationAuto-configuration

The invention discloses a method for collocating parameters of access equipment, a device and a system thereof. The network side of the technical proposal of the invention can, according to the current location information of the access equipment, send the parameters of the access equipment corresponding to the current location information of the access equipment to the assess equipment and rapidly realize auto-configuration of the parameters of the access equipment; no man power is needed in the process of parameter collocation; therefore, the consistency of the parameters and geographical position of the access equipment after roaming is ensured and the best performance of the access equipment is ensured as well, meanwhile, the maintenance cost is greatly saved for operators; besides, users of the access equipment do not need to initiatively notify the operators any more and consult whether the parameters of the access equipment need to be modified, which can facilitate users.

Owner:SHANGHAI HUAWEI TECH CO LTD

Method and system for de-interlacing digital images, and computer program product therefor

ActiveUS20050110901A1Easy to operateGood Performance GuaranteedTelevision system detailsColor signal processing circuitsProgressive scanDisplay device

To carry out de-interlacing of digital images there is provided a spatial-type de-interlacing process to be applied to a digital image for obtaining a spatial reconstruction. Furthermore, to the digital image there are also applied one or more temporal-type de-interlacing processes for obtaining one or more temporal reconstructions, and the spatial reconstruction and the one or more temporal reconstructions are sent to a decision module. The decision module applies a cost function to the spatial reconstruction and the temporal reconstructions and chooses from among the spatial reconstruction and the temporal reconstructions the one that minimizes the cost function. Preferential application is to display systems, in particular displays of a cathode-ray type, liquid-crystal type, and plasma type which use a mechanism of progressive scan.

Owner:STMICROELECTRONICS SRL

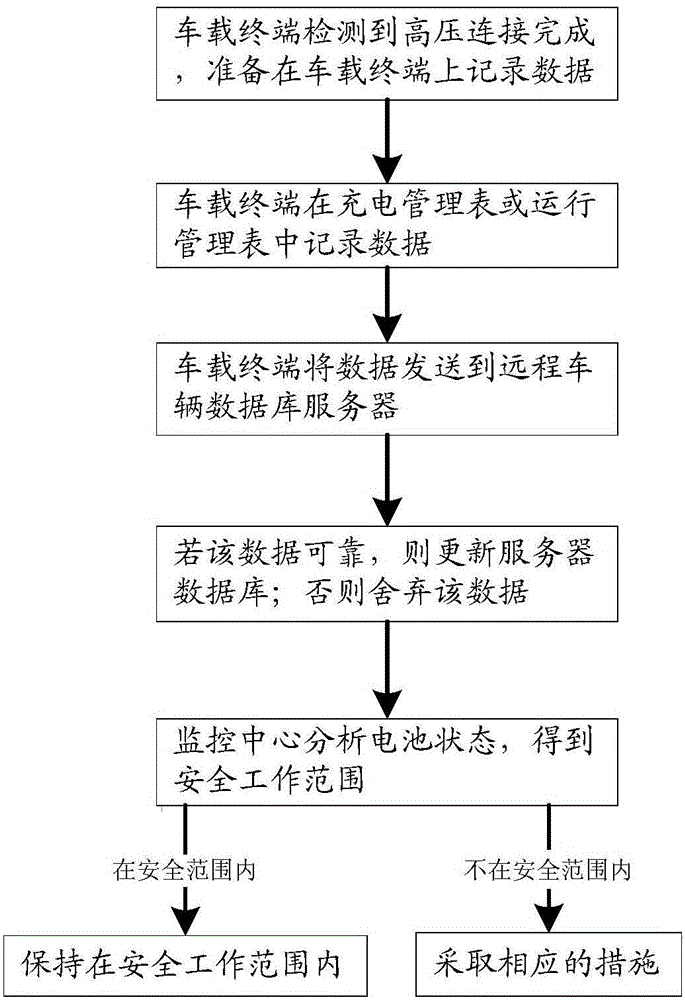

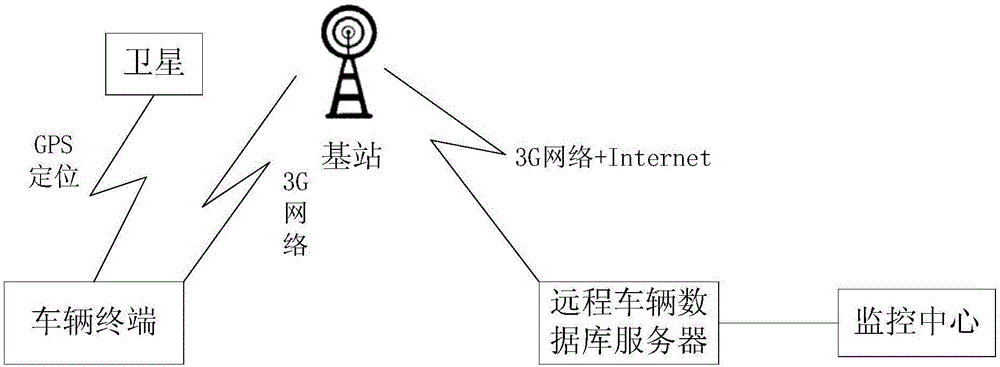

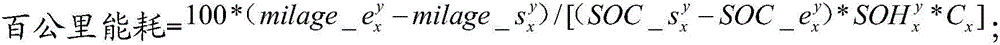

Vehicle battery performance testing method and vehicle battery performance testing system

ActiveCN106324514AGood Performance GuaranteedElectrical testingElectric vehicle charging technologyData packElectrical battery

The invention discloses a vehicle battery performance testing method and a vehicle battery performance testing system. The vehicle battery performance testing method comprises the following steps of S1, on the condition that an on-vehicle terminal detects finishing of high-voltage connection, recording data on the on-vehicle terminal; S2, on the condition that the on-vehicle terminal detects vehicle charging or normal driving, performing recording in a charging management table or operation management table; S3, after the on-vehicle terminal finishes data recording, performing data packing and transmitting data packages to a remote vehicle database server; S4, after the server receives the data, checking the data for determining whether the data are effective and reliable, if yes, updating the server database, and otherwise, abandoning the data; S5, analyzing the battery state by a monitoring center, obtaining a safe operation range, when the battery state is not in the safe operation range, performing a next step, and otherwise, keeping the battery state in the safe operation range; and S6, if the battery state of a certain vehicle is not in the safe operation range, taking a corresponding measure. The vehicle battery performance testing method and the vehicle battery performance testing system can perform comprehensive analysis on the battery performance of an electric vehicle, thereby better ensuring performance of the electric vehicle.

Owner:CHONGQING CHANGAN SUZUKI AUTOMOBILE

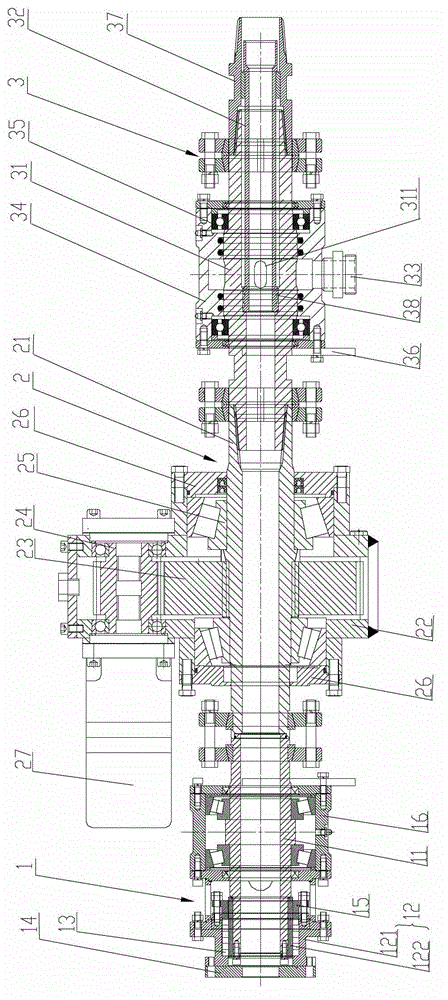

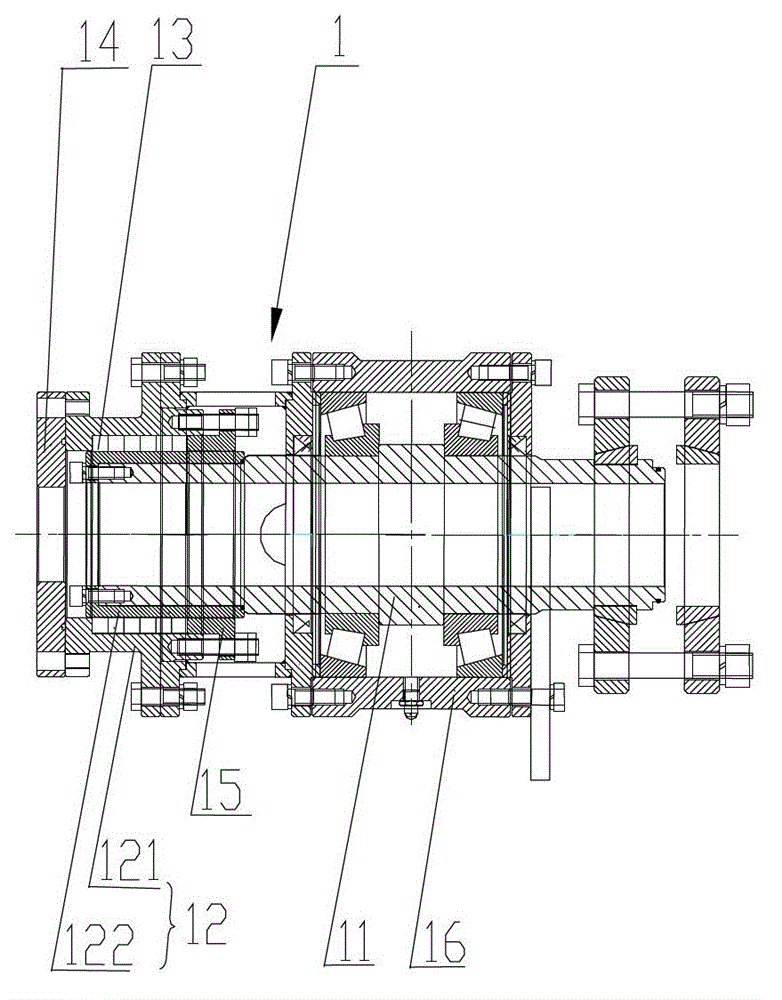

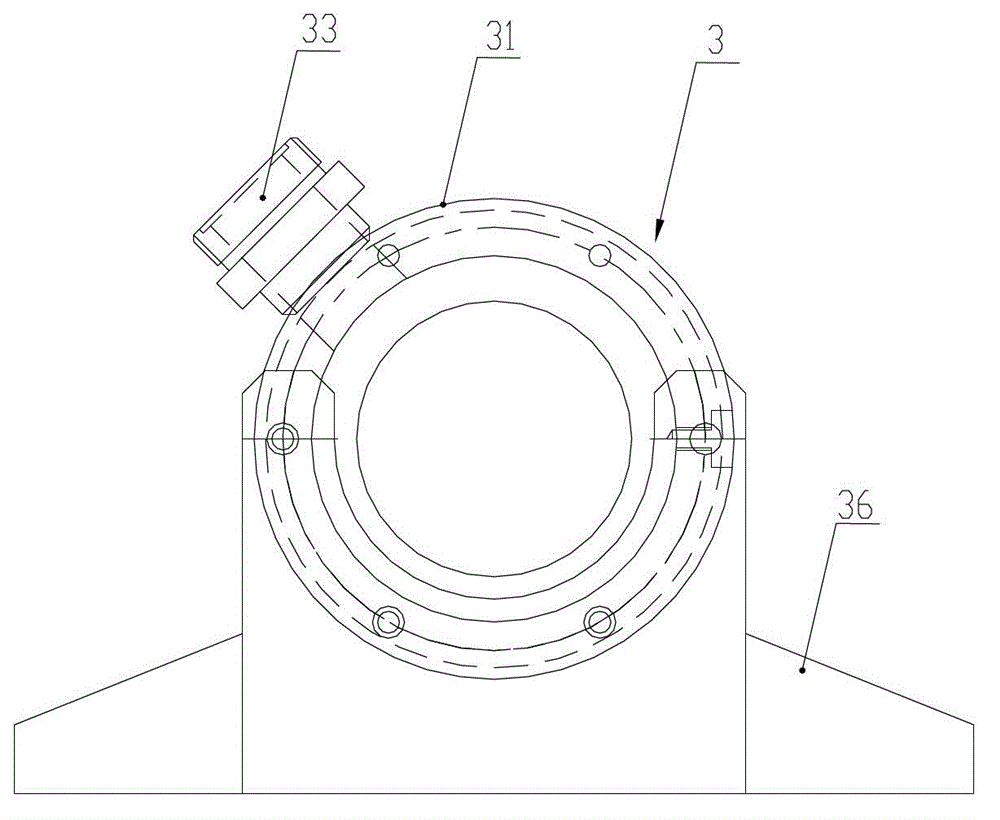

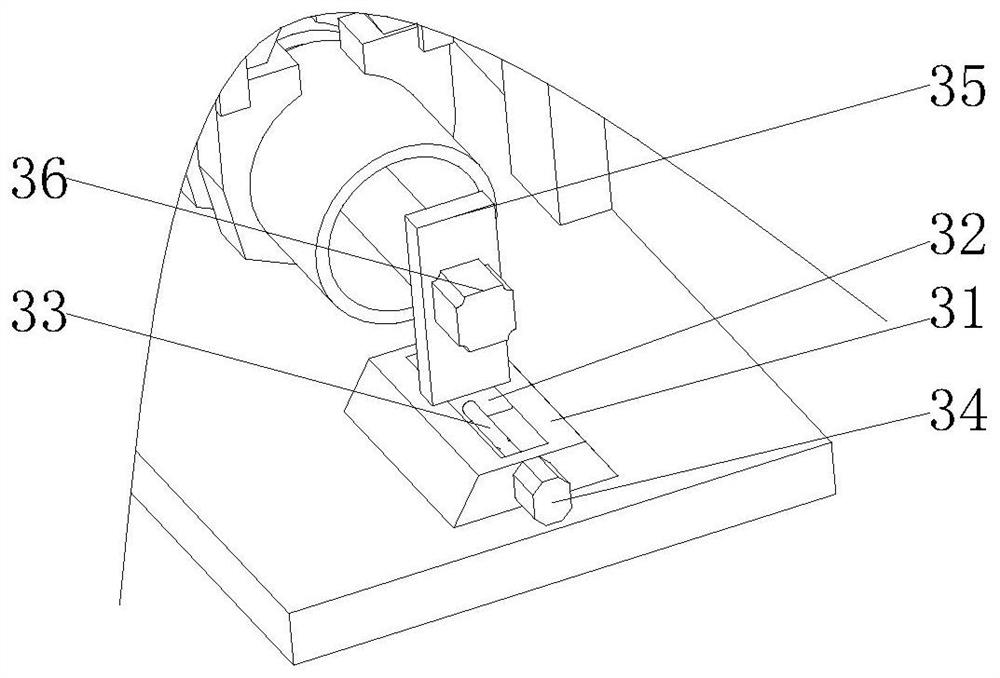

Reverse circulation drill for geological prospecting, and power head thereof

The invention provides a reverse circulation drill for geological prospecting, and a power head of the reverse circulation drill. The reverse circulation drill for geological prospecting is high in drilling efficiency. The power head comprises a rotating joint, a rotary box and a gas distributor, wherein the rotating joint, the rotary box and the gas distributor respectively comprise a rotating shaft, a main shaft and a mandrel which are hollow shafts arranged in a coaxial through way and are sequentially connected in a sealing way; the outer end of the rotating shaft is provided with a slag discharge hole; the main shaft is connected with a driving motor; the mandrel is internally provided with an inner tube in a coaxial way; the inner end of the inner tube is connected with the inner wall of the mandrel in a sealing way; the inner end of the inner tube is communicated with a hollow part of the main shaft is through; the outer diameter of the inner tube is smaller than the inner diameter of the mandrel; and at least one air inlet is arranged along the circumferential direction of the inner end of the mandrel, and compressed air enters the mandrel from through the air inlet. All the parts of the power head are independent of one another, so that the power head is convenient to assemble and disassemble; therefore, the sampling process is simplified, the quality of a sample is guaranteed, and the exploration efficiency is improved.

Owner:张家口市宣化正远钻采机械有限公司

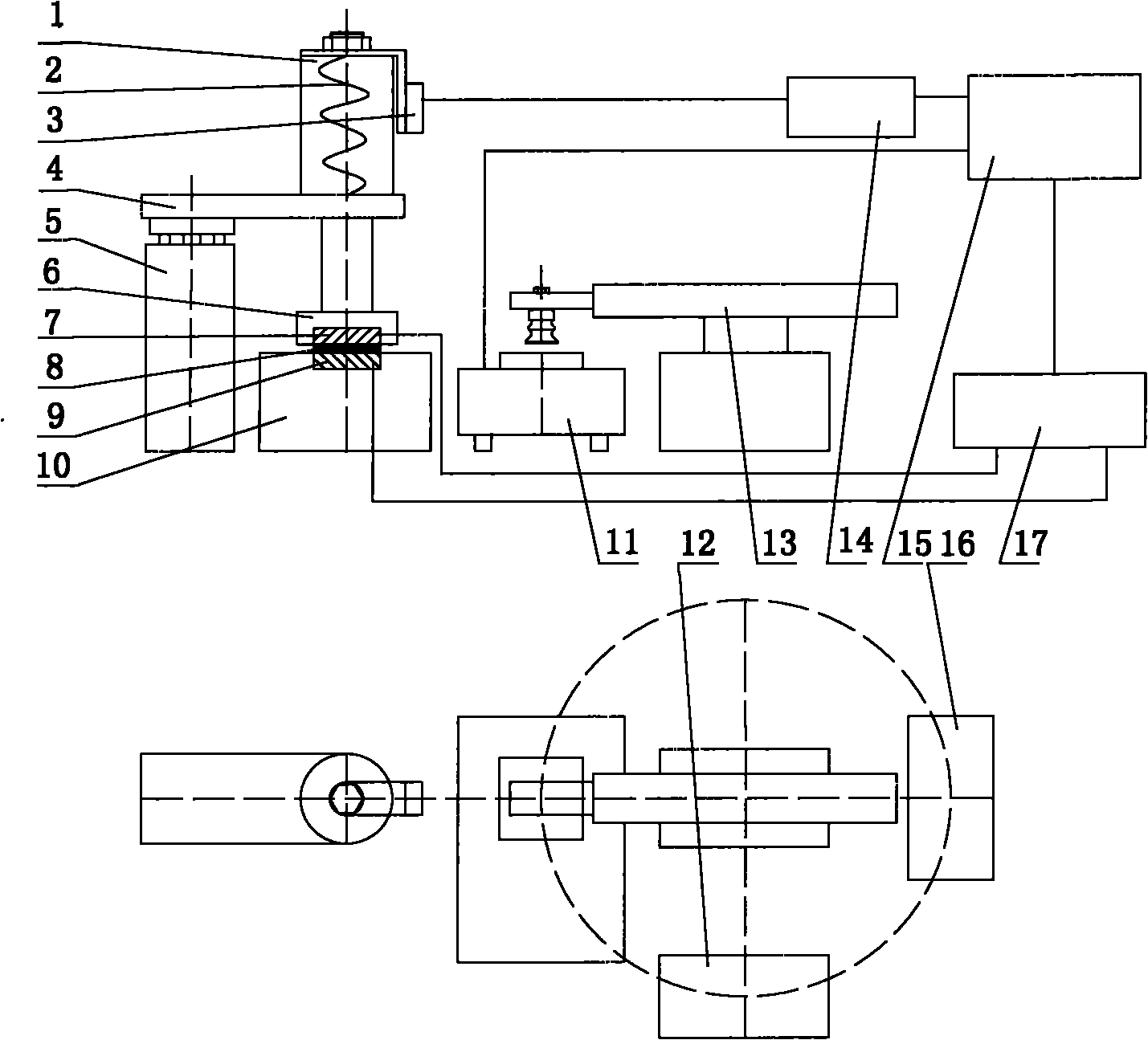

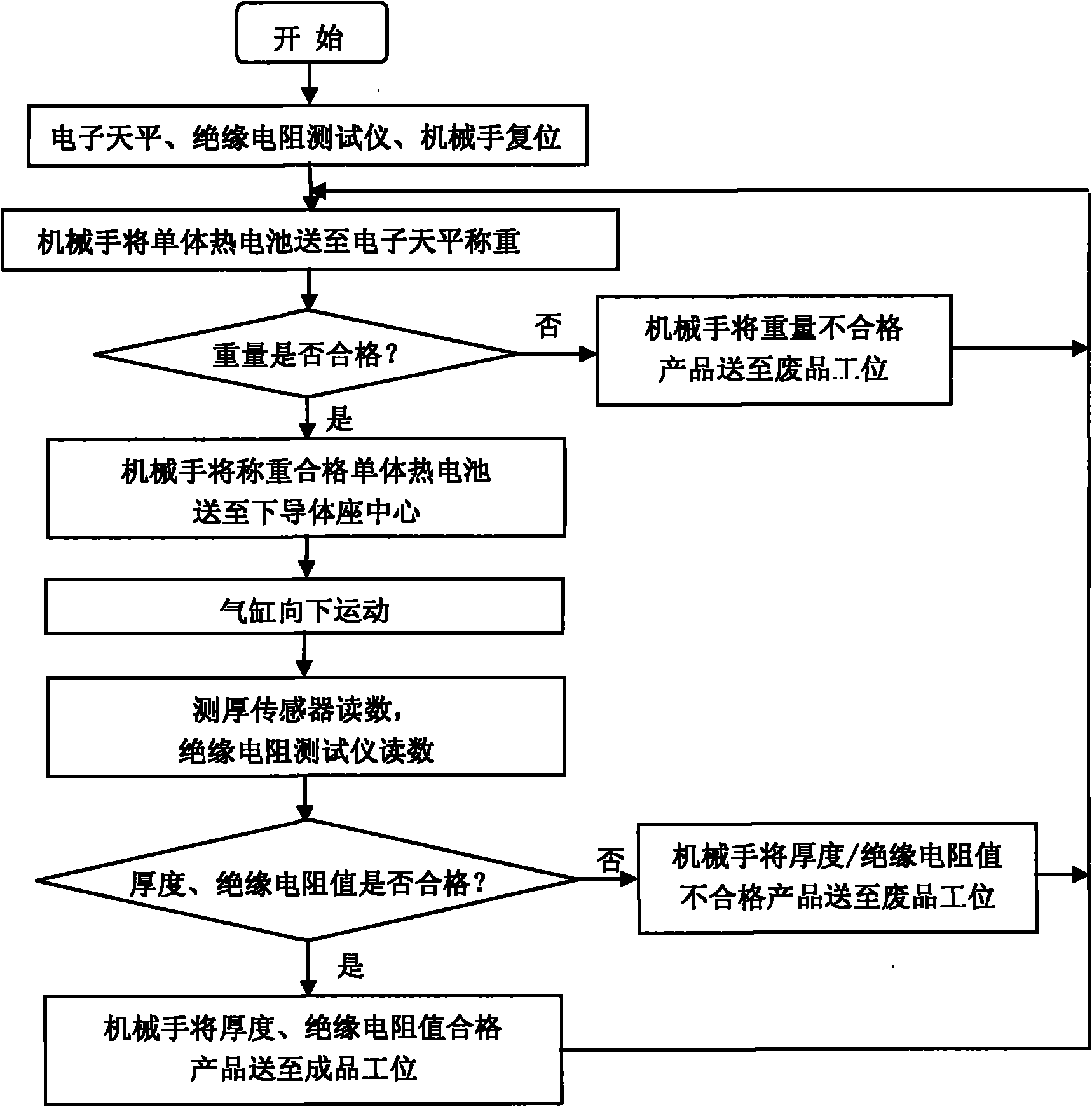

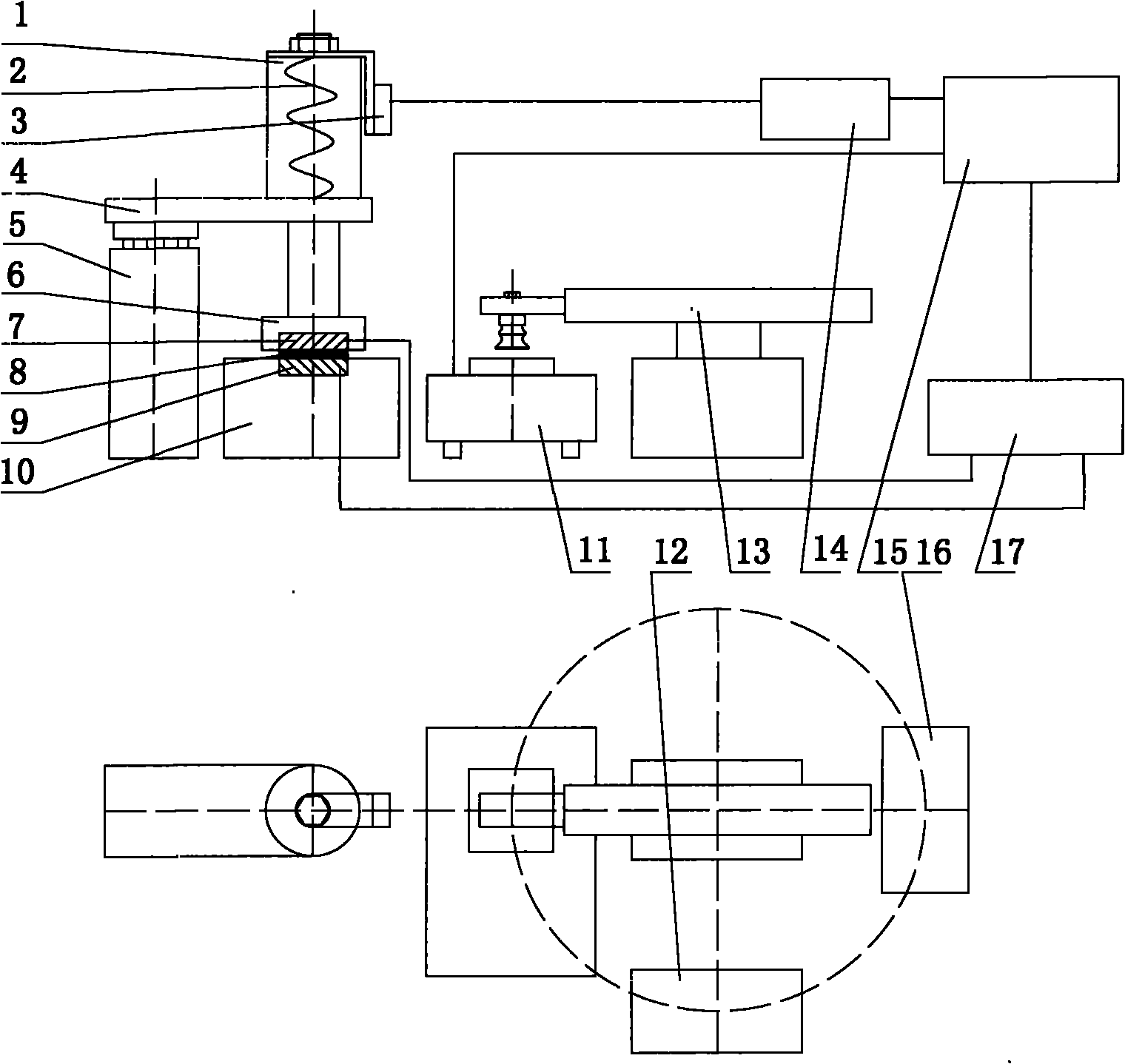

Monomer thermoelectric cell parameter automatic detecting device and control method thereof

InactiveCN101936765AAvoid subjective errorAvoid damageResistance/reactance/impedenceUsing optical meansElectrical resistance and conductanceControl system

The invention relates to a monomer thermoelectric cell parameter automatic detecting device and a control method thereof, belonging to the technical field of thermoelectric cell automatic detection. The monomer thermoelectric cell parameter automatic detecting device comprises a control system, a weighting system, and an insulation resistance and thickness measuring system, wherein a computer of the control system controls a manipulator via a multifunction board to respectively send monomer thermoelectric cells to the weighting system and the insulation resistance and thickness measuring system to get the weight, the insulation resistance value and the thickness; and the three technical parameters are compared with preset values to respectively send qualified products and unqualified products to a finished product station and a waste product station. The monomer thermoelectric cell parameter automatic detecting device and control method thereof can measure the weight, thickness and insulation resistance of monomer thermoelectric cell quickly and accurately.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

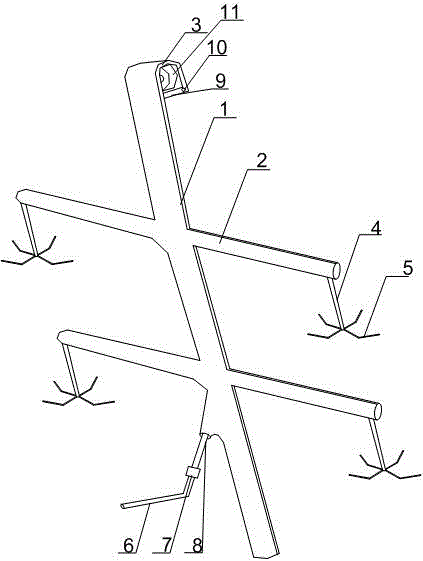

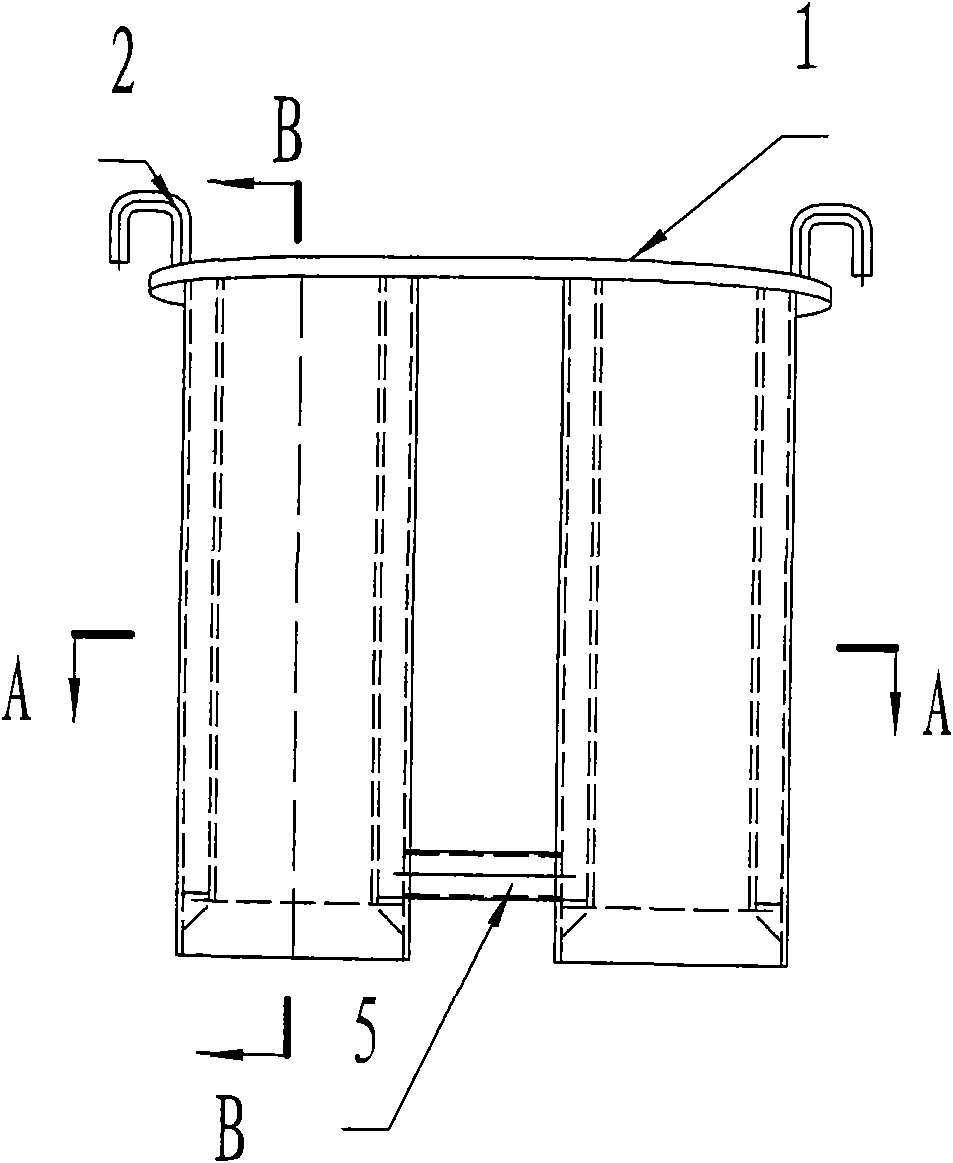

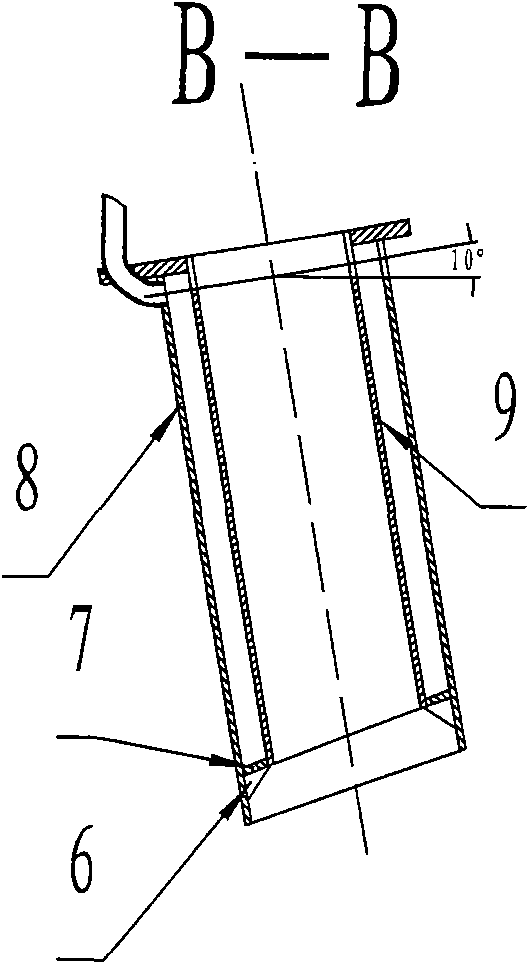

Electrophoresis part suspension device

InactiveCN104630868AIncrease contact areaGoodness GuaranteedElectrolysis componentsElectrophoretic coatingsHinge angleElectrophoresis

The invention discloses an electrophoresis part suspension device. The electrophoresis part suspension device comprises a supporting rod and a lifting hook, wherein multiple auxiliary struts are symmetrically and vertically arranged at the two sides of the supporting rod, the auxiliary struts are welded on the supporting rod, a suspension shaft and a hook which are connected with each other are arranged on each auxiliary strut, each suspension shaft is connected with the two end parts of the corresponding auxiliary strut, the lifting hook is arranged at the top of the supporting rod, a sealing body is arranged on the lifting hook, the sealing body is rotatably fixed at an opening of the lifting hook by virtue of a hinge pin, and the hinge pin is connected with the lifting hook by virtue of a torsional spring; each hook is mainly designed to be of an eta shape, the supporting rod is generally designed to have a rectangular cross section, and a shrapnel is additionally arranged in each eta-shaped hook, so that a rack can be effectively fixed and contact area between each hook and the supporting rod can be increased, and good conductivity is guaranteed; and the supporting rod can be firmly fixed on an external support by virtue of the arranged sealing body, so that the external support does not shake when moved, the supporting rod can not fall off, and an electrophoresis part can not be damaged.

Owner:CHENGDU FENGFAN TECH

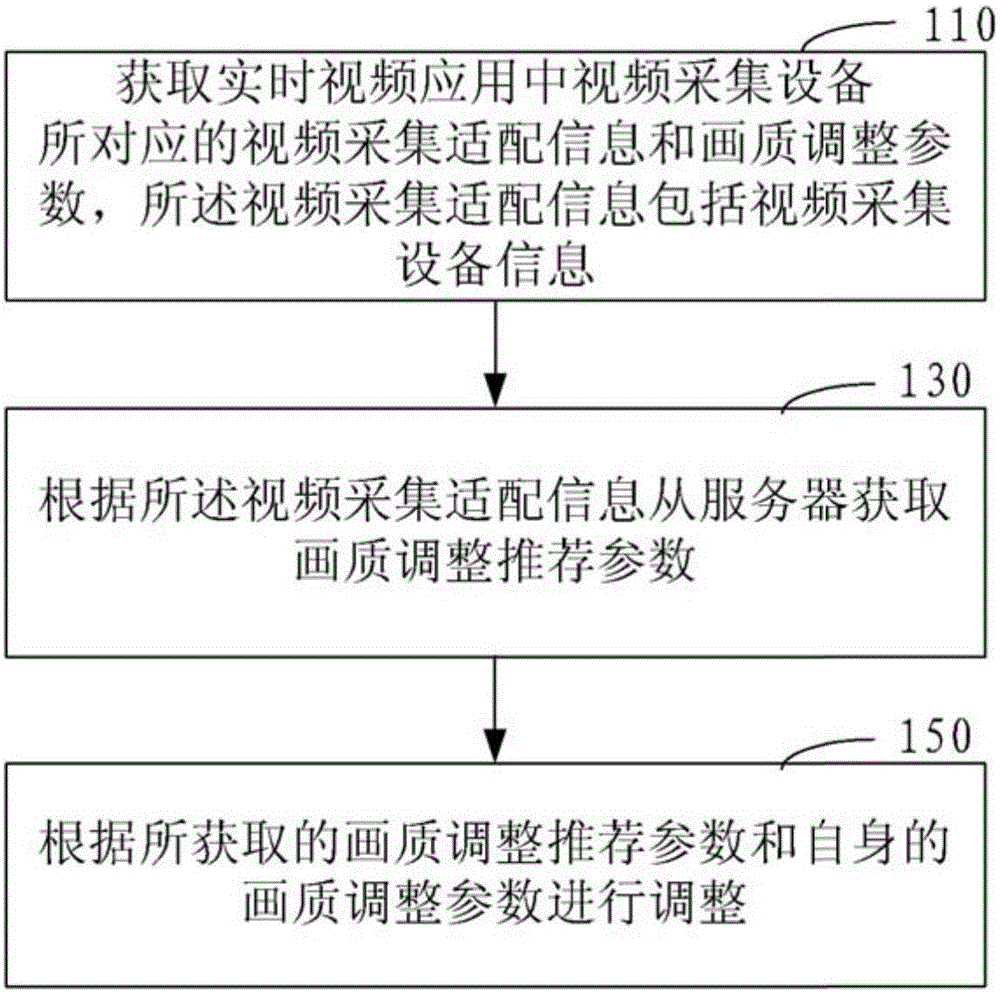

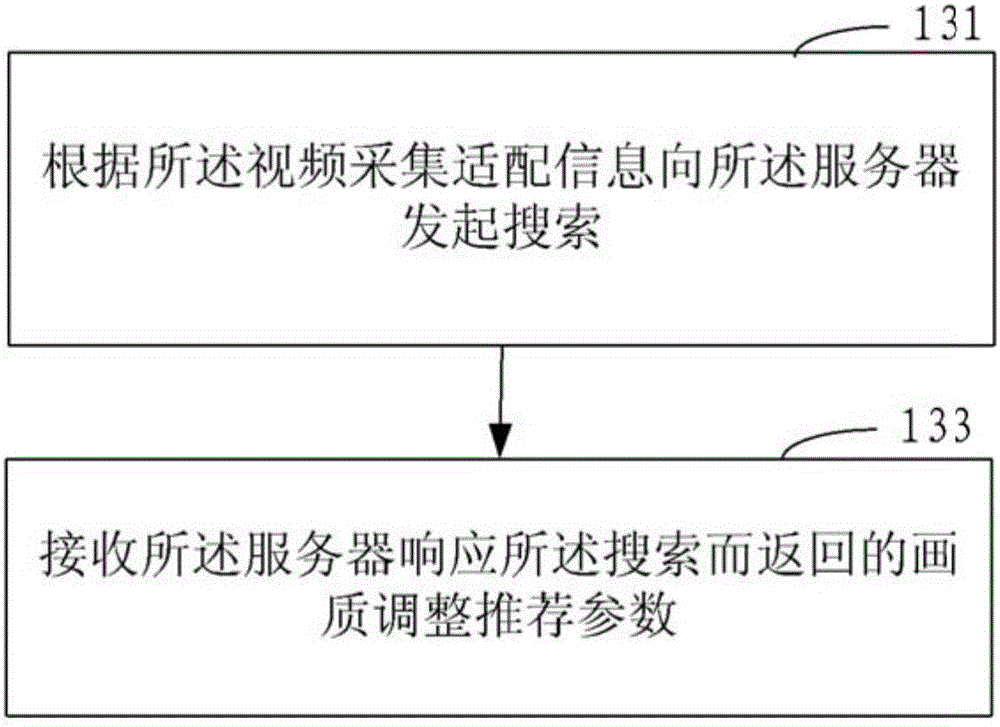

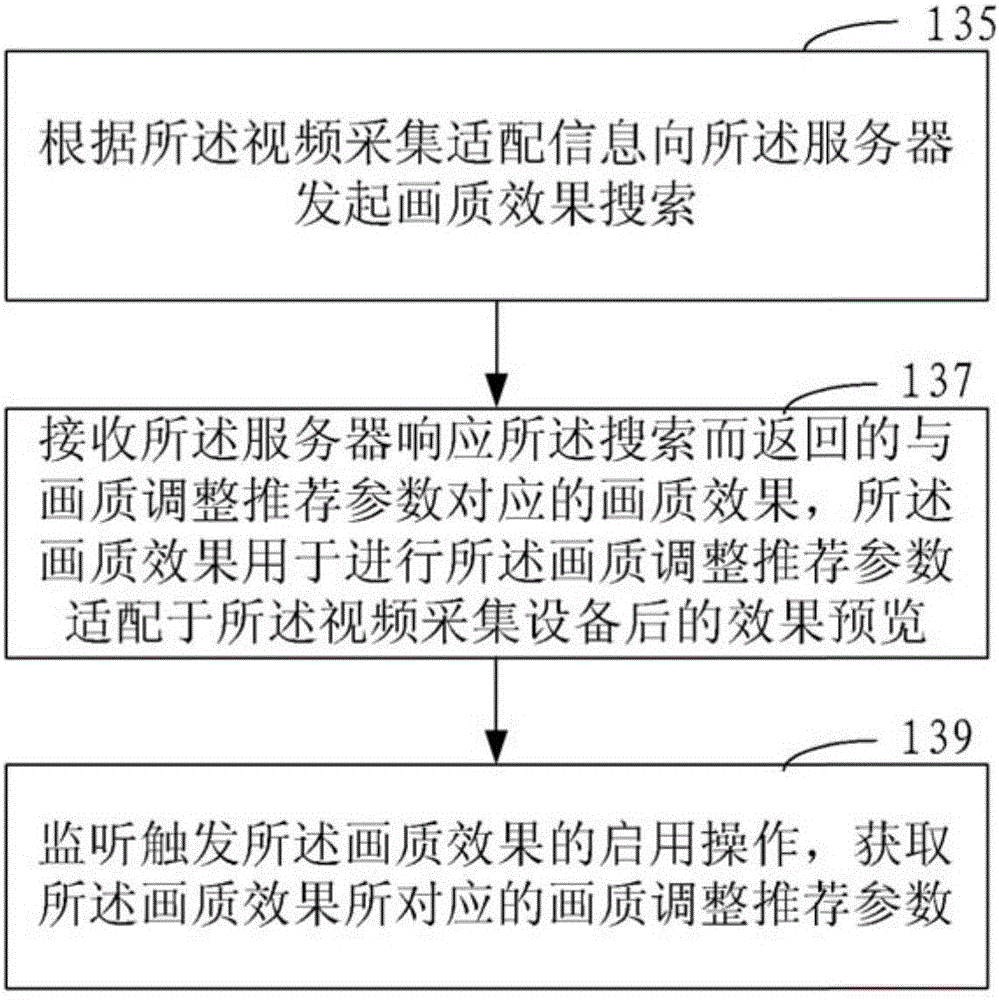

Picture quality processing method and device in real-time video application

ActiveCN105721888AImprove the defect of poor image qualityAvoid cumbersome operationsSelective content distributionQuality adjustmentComputer graphics (images)

The invention provides a picture quality processing method and device in a real-time video application. The method comprises the following steps: obtaining video collection adaptation information and a picture quality adjustment parameter corresponding to video collection in the real-time video application, wherein the video collection adaptation information comprises video collection equipment information; obtaining a picture quality adjustment recommendation parameter from a server according to the video collection adaptation information; and carrying out adjustment according to the obtained picture quality adjustment recommendation parameter and the own picture quality adjustment parameter. According to the picture quality processing method provided by the invention, by means of the cooperation of the real-time video application and the server, the recommendation of the picture quality adjustment parameter is realized, namely the picture quality adjustment parameter recommended by the server is obtained according to the own video collection adaptation information, the adjustment is carried out according to the picture quality adjustment parameter, so the real-time video application can automatically adjust the corresponding picture quality in an operation process, in this case, the defect of relatively poor picture quality in a released real-time video does not exist anymore, and an optimal effect of live broadcast is guaranteed.

Owner:徐文波

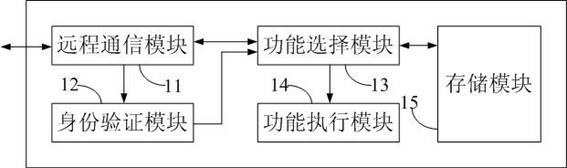

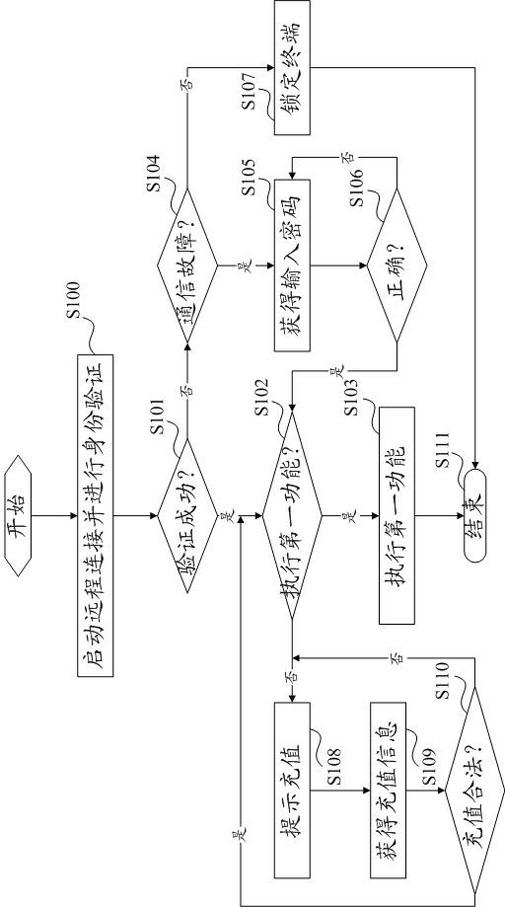

Soya-bean milk machine and remote control method thereof

InactiveCN102098329AGood Performance GuaranteedSimple management workBeverage vesselsTransmissionRemote controlStatus changed

The invention discloses a remote control method of a soya-bean milk machine, comprising the steps: a. starting a remote connection, carrying out authentication and executing the step b if the authentication is successful; b. judging whether a first function is executed, and if yes, executing the step c; and c. executing the first function. The invention provides the remote control method of the soya-bean milk machine and the soya-bean milk machine, so that the management work and maintenance work are very simple.

Owner:JOYOUNG CO LTD

Method and system for de-interlacing digital images, and computer program product therefor

InactiveUS7663695B2Good Performance GuaranteedAccelerated programTelevision system detailsPicture reproducers using cathode ray tubesProgressive scanComputer graphics (images)

Owner:STMICROELECTRONICS SRL

Titanium white fritted glaze and preparation method thereof

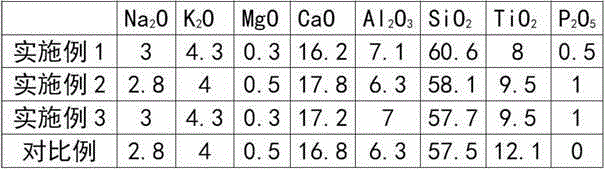

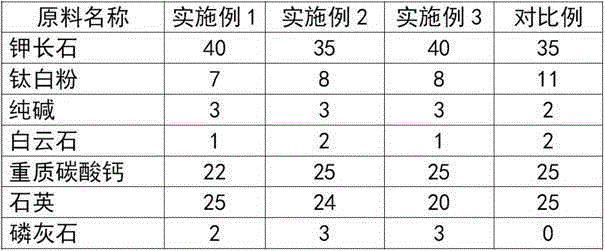

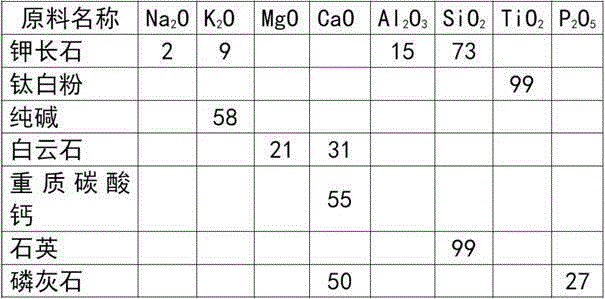

The invention discloses titanium white fritted glaze which is prepared from, by mass, 2-3% of Na<2>O, 4-5% of K<2>O, 0-1% of MgO, 16-18% of CaO, 6-8% of Al<2>O<3>, 56-62% of SiO<2>, 0.5-1.2% of P<2>O<5> and 8-10% of TiO<2>. The invention further discloses a preparation method of the titanium white fritted glaze. According to the titanium white fritted glaze, a defined amount of apatite is added, a phosphorus split phase is formed in the glaze at a high temperature, and the glaze emulsion turbidity is improved through the refractive index difference between liquid phrases; meanwhile, on the premise that a good glaze surface is guaranteed, the consumption of titanium dioxide is lowered, and the emulsion turbidity, whiteness and fatness can be further improved.

Owner:肇庆市高要区恒纯非金属材料有限公司

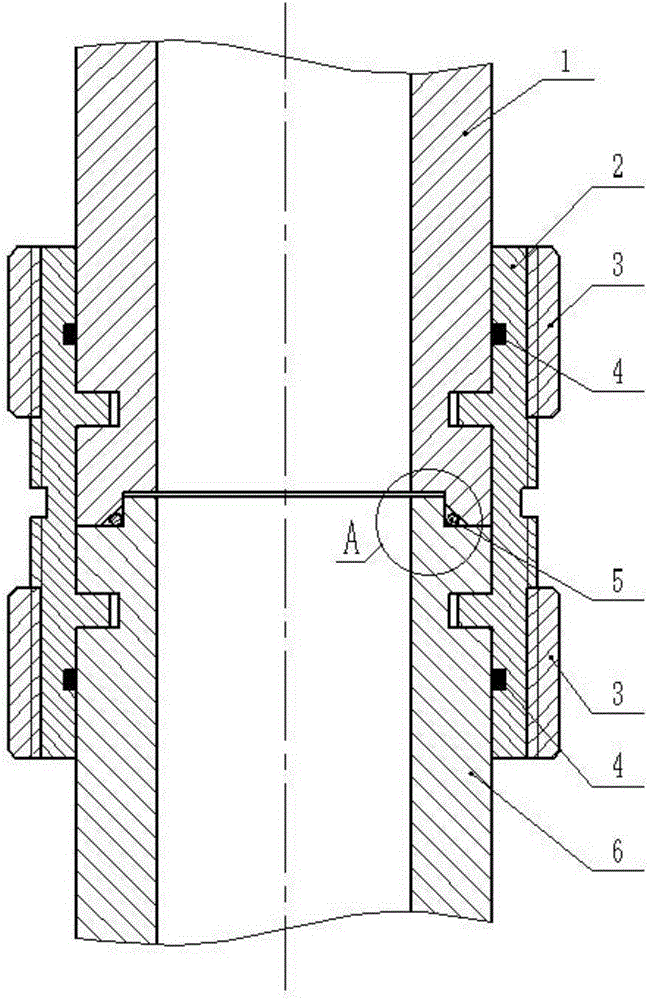

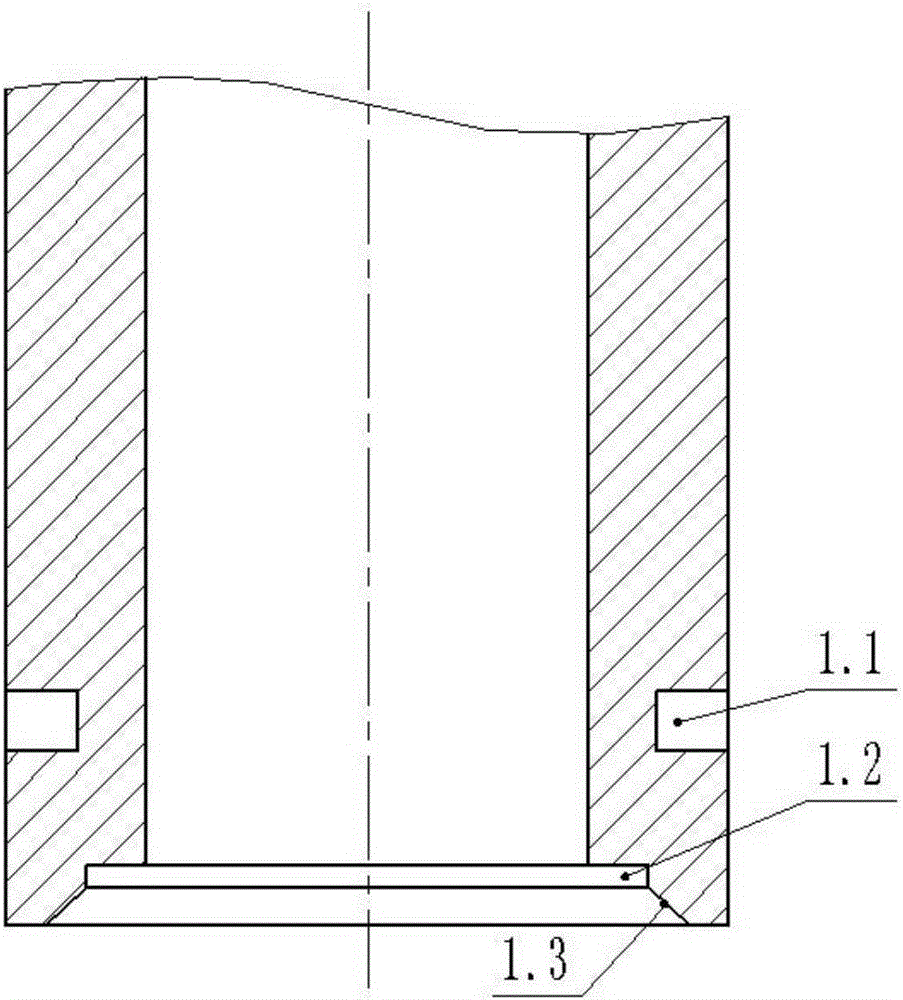

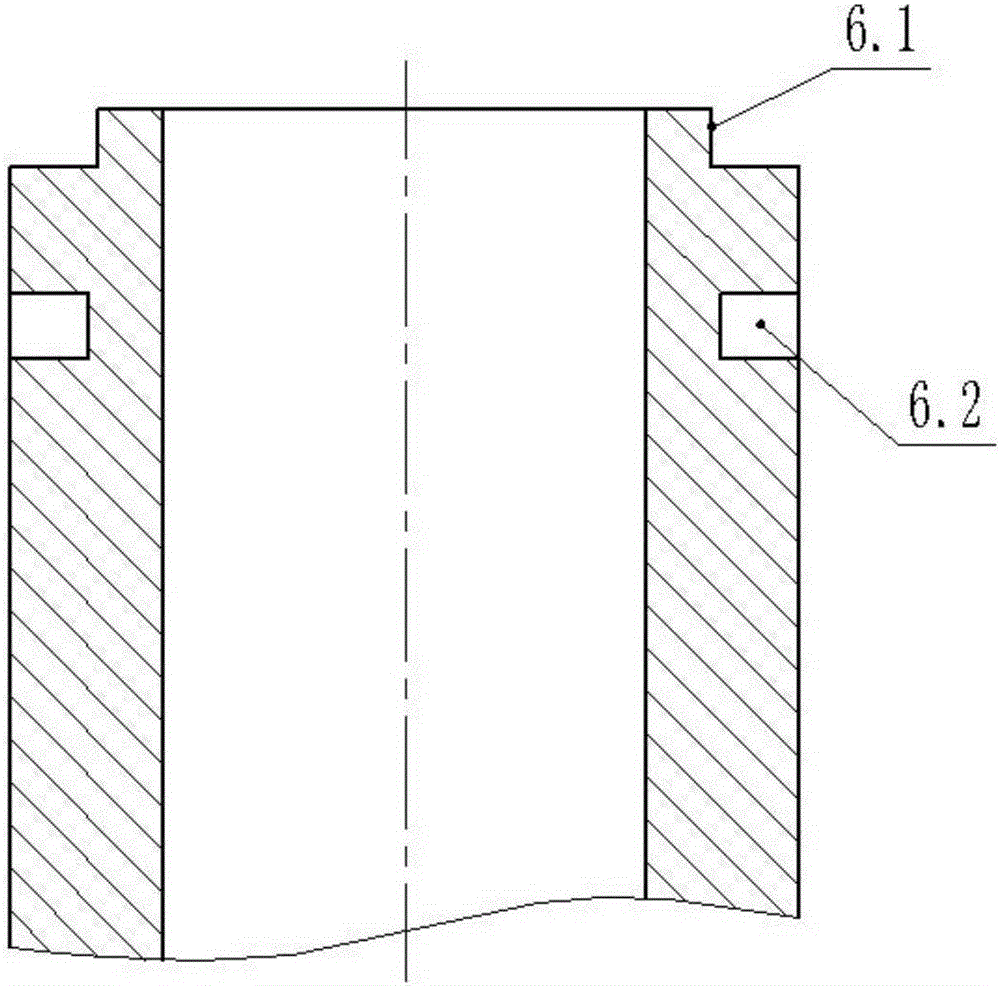

Drill rod connector

ActiveCN105298410ABurst evenlyReliable sealingDrilling rodsDrilling casingsDrill pipePetroleum engineering

The invention discloses a drill rod connector which comprises a male drill rod, a female drill rod, a snap ring and nuts. An inner spigot is arranged on the lower end face of the male drill rod, chamfers are formed in orifices of the inner spigot, grooves are formed in the outer wall of the periphery of the male drill rod, an outer spigot matched with the inner spigot of the male drill rod is arranged on the upper end face of the female drill rod, grooves which are the same as those formed in the male drill rod are formed in the outer wall of the periphery of the female drill rod, two outer threads are formed in the outer wall of the periphery of the snap ring, the inner wall of the periphery of the snap ring is provided with sealing grooves and protruding blocks which are both symmetric up and down, the male drill rod is in location fit with the female drill rod through the inner spigot and the outer spigot, the snap ring is inserted into the grooves formed in the outer wall of the periphery of the male drill rod and the grooves formed in the outer wall of the periphery of the female drill rod through the protruding blocks, the male drill rod, the female drill rod and the snap ring are connected into a whole, and the two nuts are installed on the two outer threads of the outer wall of the periphery of the snap ring. The drill rod connector has the advantages of being reliable in sealing, capable of bearing forward and reverse rotating torque and convenient to assemble and disassemble.

Owner:CHTC JOVE HEAVY IND

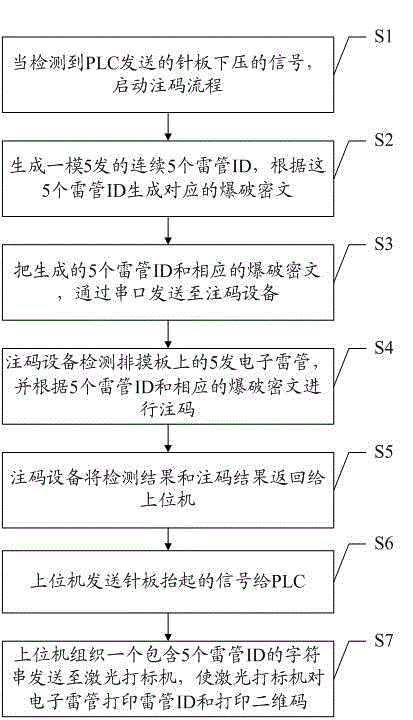

Upper computer realization method of code marking device used for production of electron detonators

ActiveCN105216454AImprove yield rateImprove testing standardsDuplicating/marking methodsTypewritersDetonatorTechnical standard

The invention discloses an upper computer realization method of a code marking device used for production of electron detonators. The method comprises the steps that five produced detonator IDs and corresponding explosion cryptographs are sent to the code marking device through a serial port; the code marking device detects five electron detonators on a row template and carrying out code marking according to the five produced detonator IDs and the corresponding explosion cryptographs; the code marking device returns a detection result and a code marking result to an upper computer; the upper computer sends a pin plate lifting signal to a PLC; the upper computer organizes a character string containing the five detonator IDs and sends the character string to a laser marking machine, and the laser marking machine is enabled to print the detonator IDs and two-dimensional codes to the electron detonators. According to the invention, the production yield of the electron detonators is improved, automatic detection and code marking are realized, the detection standard of the electron detonators leaving a factory is improved, and the good performance of the electron detonators leaving the factory are ensured. Real time management and control over the electron detonators are realized.

Owner:SHENZHEN DACHENG CHUANGANDA ELECTRONICS SCI & TECH DEV

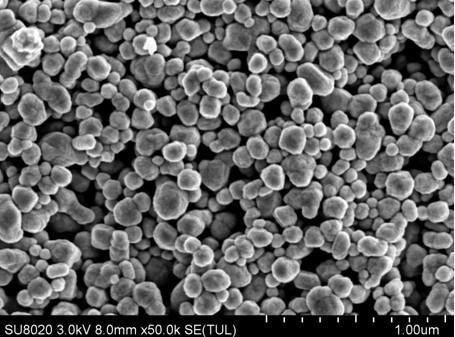

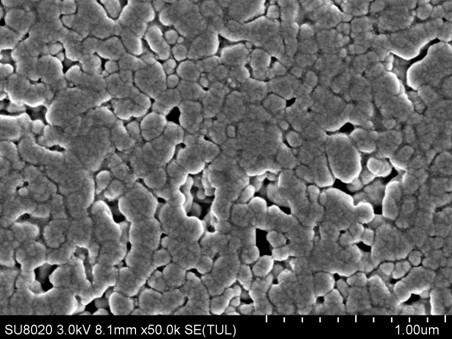

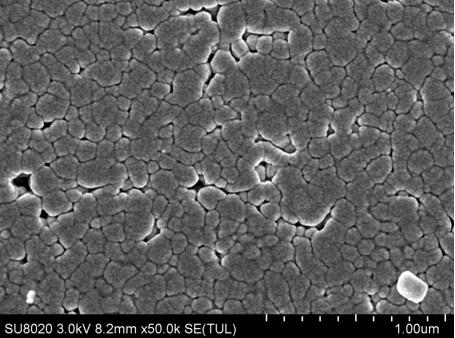

Method for preparing high-concentration nano-silver particle conductive ink through two-step method and conductive ink

InactiveCN109370316AImprove production efficiencyGood Performance GuaranteedInksHigh concentrationMicrowave

The invention discloses a method for preparing high-concentration nano-silver particle conductive ink through a two-step method and the conductive ink. The method comprises the following steps: (1) completely dissolving 1 part by mass of silver nitrate in 30 parts by mass of glycol, and completely dissolving 1 part by mass of polyvinylpyrrolidone in a glycol solution, so as to prepare a conductiveink precursor; and (2) carrying out microwave heating on the glycol solution containing silver nitrate and polyvinylpyrrolidone for 90 seconds, cooling the heated mixed liquid to the room temperature, carrying out centrifugal concentration, and removing supernate, so as to obtain the conductive ink containing high-concentration nano-silver particles. The preparation steps in a traditional three-step method are replaced with the two steps of microwave heating and centrifugal concentration for preparing the conductive ink, so that the process steps are reduced, the preparation time and cost aresaved, and the preparation efficiency is improved; and a nano-silver lead prepared by virtue of the method preserves good electrical properties, and the preparation efficiency of the conductive ink is improved.

Owner:JIAXING UNIV

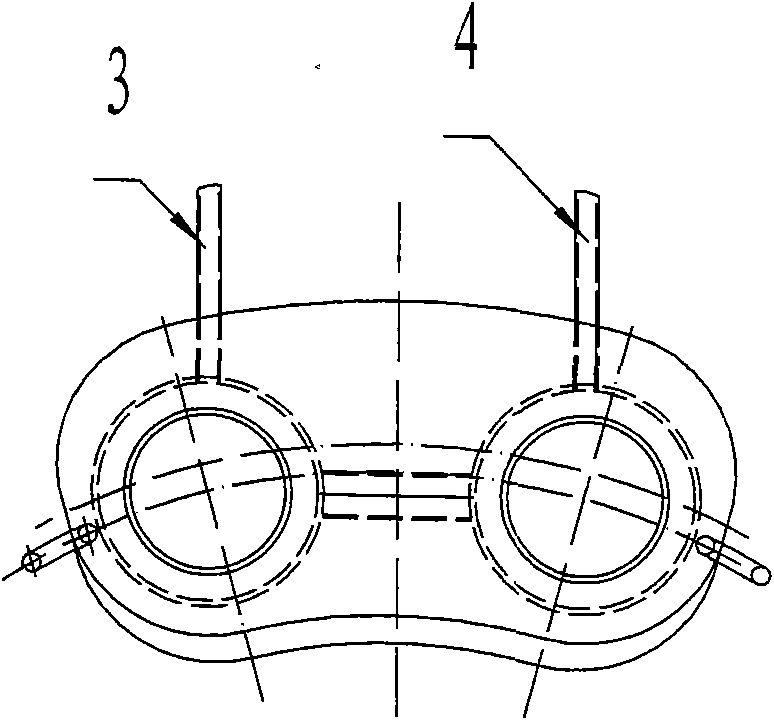

Closed type calcium carbide furnace charging nozzle and process for producing same

InactiveCN101526309AImprove the quality structure of the material layerImprove furnace conditionArc welding apparatusCharge manipulationEnergy consumptionCrucible

The invention provides a closed type calcium carbide furnace charging nozzle and a process for producing the same. The charging nozzle mainly comprises two groups of seamless external casings, seamless internal casings, water inlet pipes, water outlet pipes, communication pipes and bottom edge embedded flanges; the seamless internal casings are arranged in the seamless external casings; the bottom edge embedded flanges, the water inlet pipes and the water outlet pipes are arranged on the two groups of the seamless external casings respectively; and the two groups of seamless external casings are communicated with the communication pipes. The charging nozzle has the advantages of solving the problems of water leakage due to frequent breakage and frequent shut-down of the furnace for exchange, meeting the requirements on the charging production of a closed type calcium carbide furnace, effectively improving quality structure of material layers around electrodes, greatly improving furnace conditions (avoiding piling of materials on the outer side of the charging nozzle), making the materials keep a steamed bread-shaped charge surface around the electrodes, further effectively reducing thermal loss, alleviating the insufficiency of the materials in the central region of the furnace, reducing the temperature of the charge surface, reducing exposing areas of the electrodes, reducing the thermal loss of electrode resistances, improving the quality structure of the material layers, contributing to improving the pre-heating of the furnace materials and forming a big crucible region, ensuring good furnace conditions, avoiding frequent occurrence of material stamping and material throwing, and further facilitating the technical operation and control of the furnace and high yield, high quality and low energy consumption of the furnace.

Owner:YUNNAN YUNWEI CO LTD

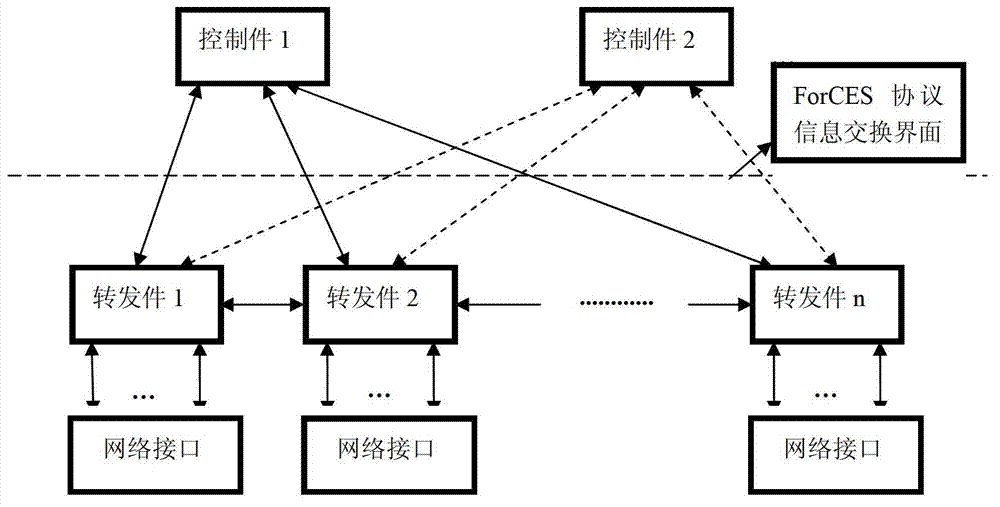

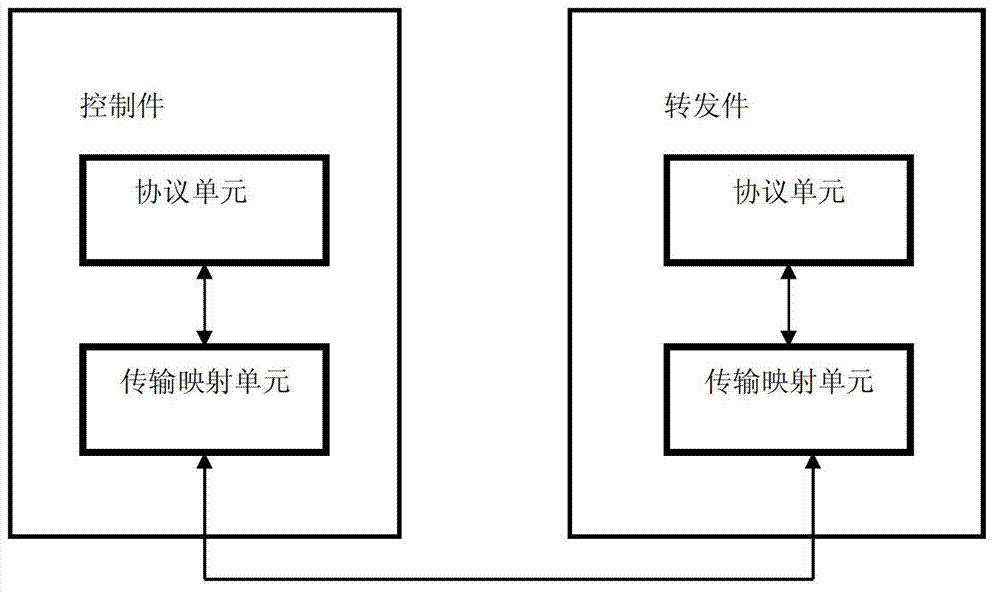

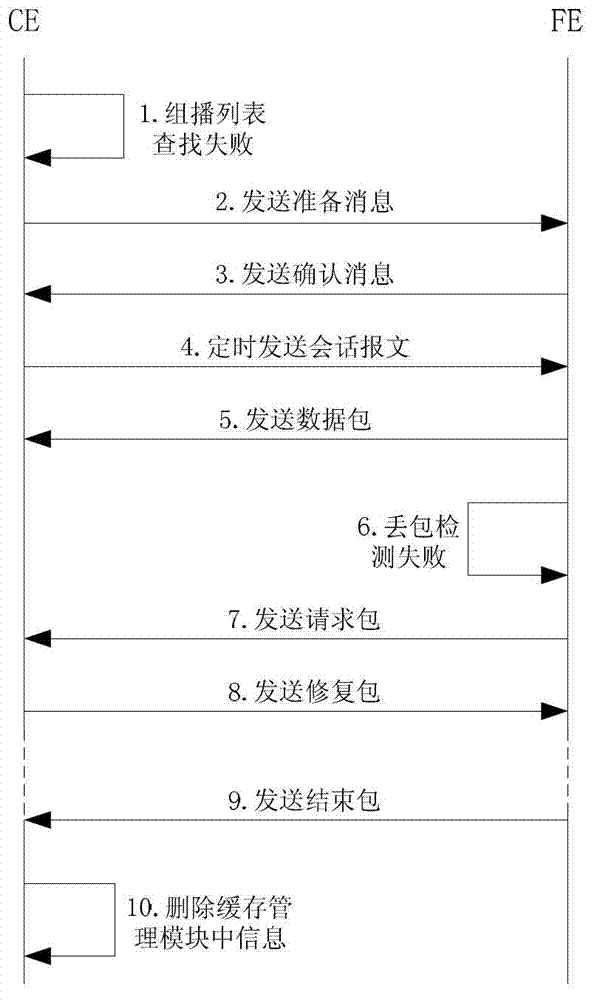

Reliable multicast transmission method for ForCES protocol information

InactiveCN102761491AGood Performance GuaranteedReliable transmissionSpecial service provision for substationReliable transmissionReliable multicast

The invention discloses a reliable multicast transmission method for ForCES protocol information. The method comprises the following steps: adding a reliable multicast module in a transmission mapping unit of a ForCES networkware; carrying out packet loss detection by a reliable multicast module in a forwarding element; and carrying out packet loss recovery by a reliable multicast module in a controlling element. Due to the adoption of the method, the reliable multicast transmission of control protocol information between ForCES networks is realized. Moreover, less control protocol information is processed by the controlling element in the ForCES networkware, the network bandwidth is saved, the reliable transmission of the control protocol information is ensured, and excellent performance of the ForCES networkware is guaranteed.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

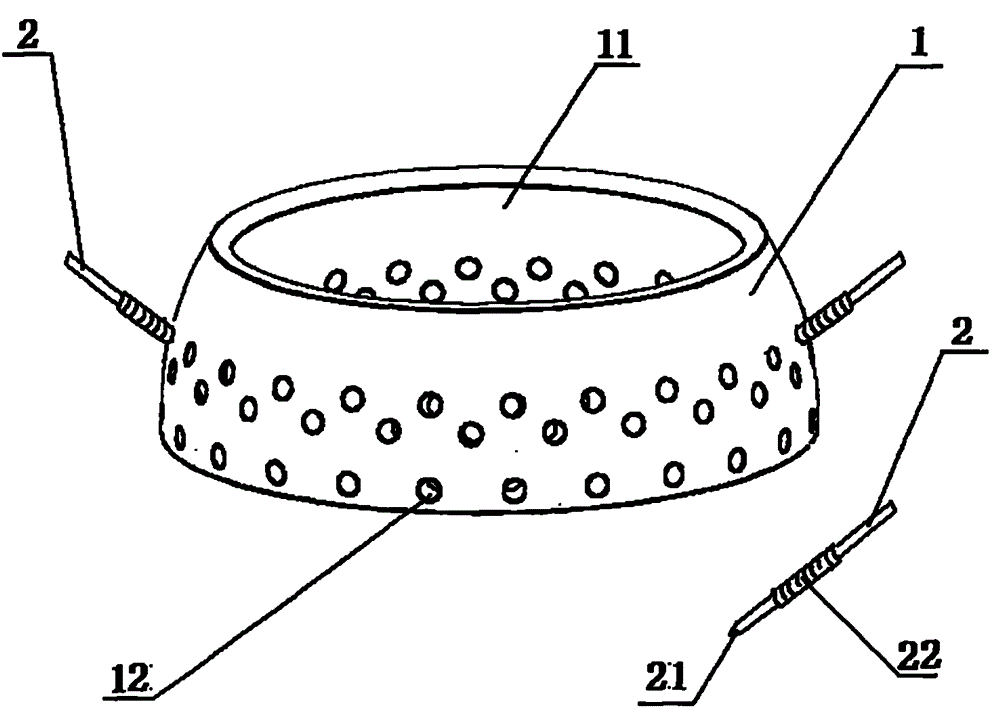

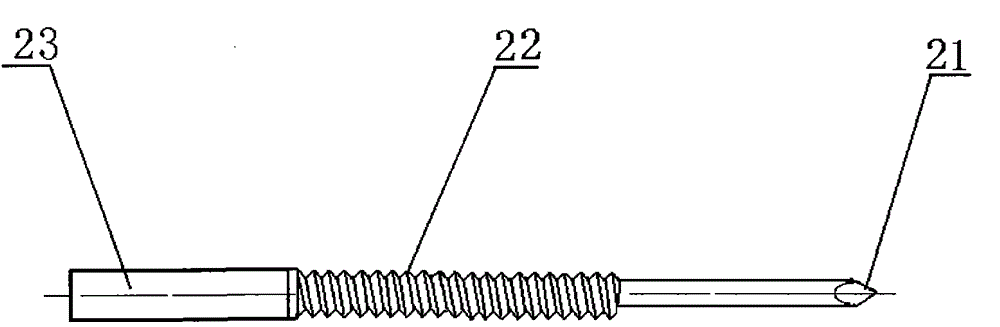

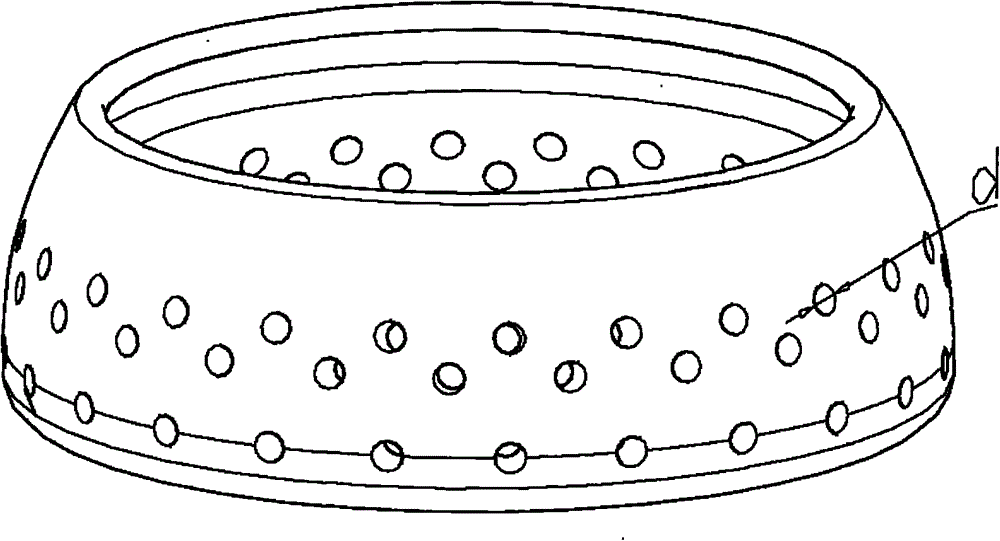

Patella external fixing support

ActiveCN103948421AGood Performance GuaranteedReduce difficultyExternal osteosynthesisScrew threadPatellar fracture

The invention discloses a patella external fixing support, which comprises a fixing support main body and a plurality of metal bone needles, wherein the fixing support main body is a partially-hollow spherical housing gradually shrunk from the bottom surface to the top surface and is provided with a spherical center; a plurality of threaded holes are evenly distributed around the spherical center on the circumferential surface of the fixing support main body; the metal bone needles can penetrate through the threaded holes for bolt fixing. The patella external fixing support provided by the invention can externally fix all kinds of patellar fracture in a comprehensive way, has excellent stability, and avoids all sorts of defects of internal fixing.

Owner:TIANJIN XINZHONG MEDICAL DEVICES

Production technology of high-surface quality thin-gauge hot-rolled pickling galvanized sheet

InactiveCN109797355ARemove internal distortionGood Performance GuaranteedHot-dipping/immersion processesMetal rolling arrangementsDistortionThin slab

The invention belongs to the technical field of iron and steel processing, and particularly relates to a production technology of a high-surface quality thin-gauge hot-rolled pickling galvanized sheet. The production technology of the thin-gauge hot-rolled pickling galvanized sheet includes the following steps that a raw material coil is produced by endless and continuous casting and rolling process of strip steel, then pickling, drain, first drying, leveling, water washing, electromagnetic induction heating, galvanizing, air knife blowing, cooling in rear section, water cooling, middle loop,finishing, straightening, passivating, second drying, outlet loop, inspection, oiling, and coiling into a hot-dip galvanized coil are carried out through the pickling technology, and the product thickness is 0.8mm-4.0mm. The production technology of the thin-gauge hot-rolled pickling galvanized sheet can reduce or eliminate defects of leak plating, pits and the like on the surface of the strip steel, alleviate the surface leak plating problem of the thin plate hot-rolled pickling galvanized sheet, further eliminate a part of internal distortion, and is conducive to subsequent cross-cutting, longitudinal cutting and forming processing and production, and improves the yield of products of the company and customer.

Owner:RIZHAO BAOHUA NEW MATERIAL CO LTD

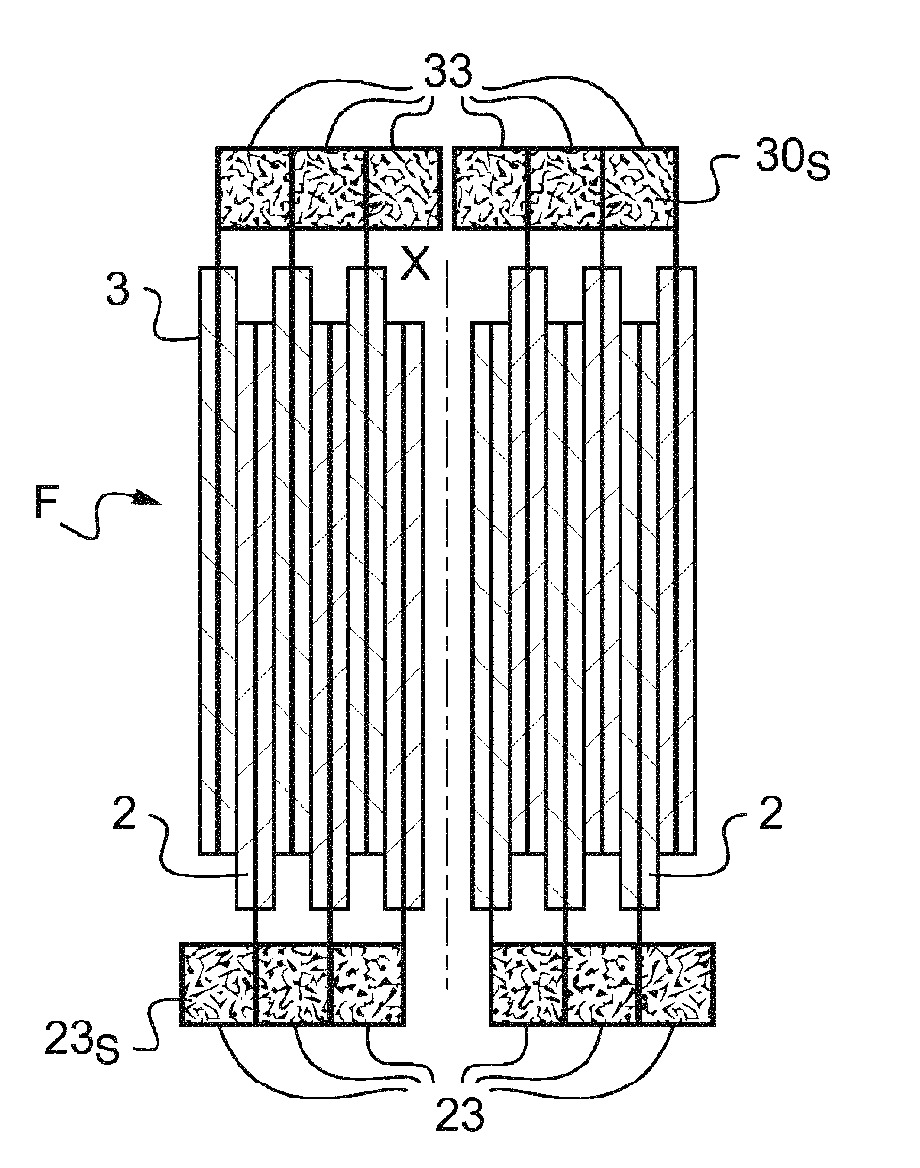

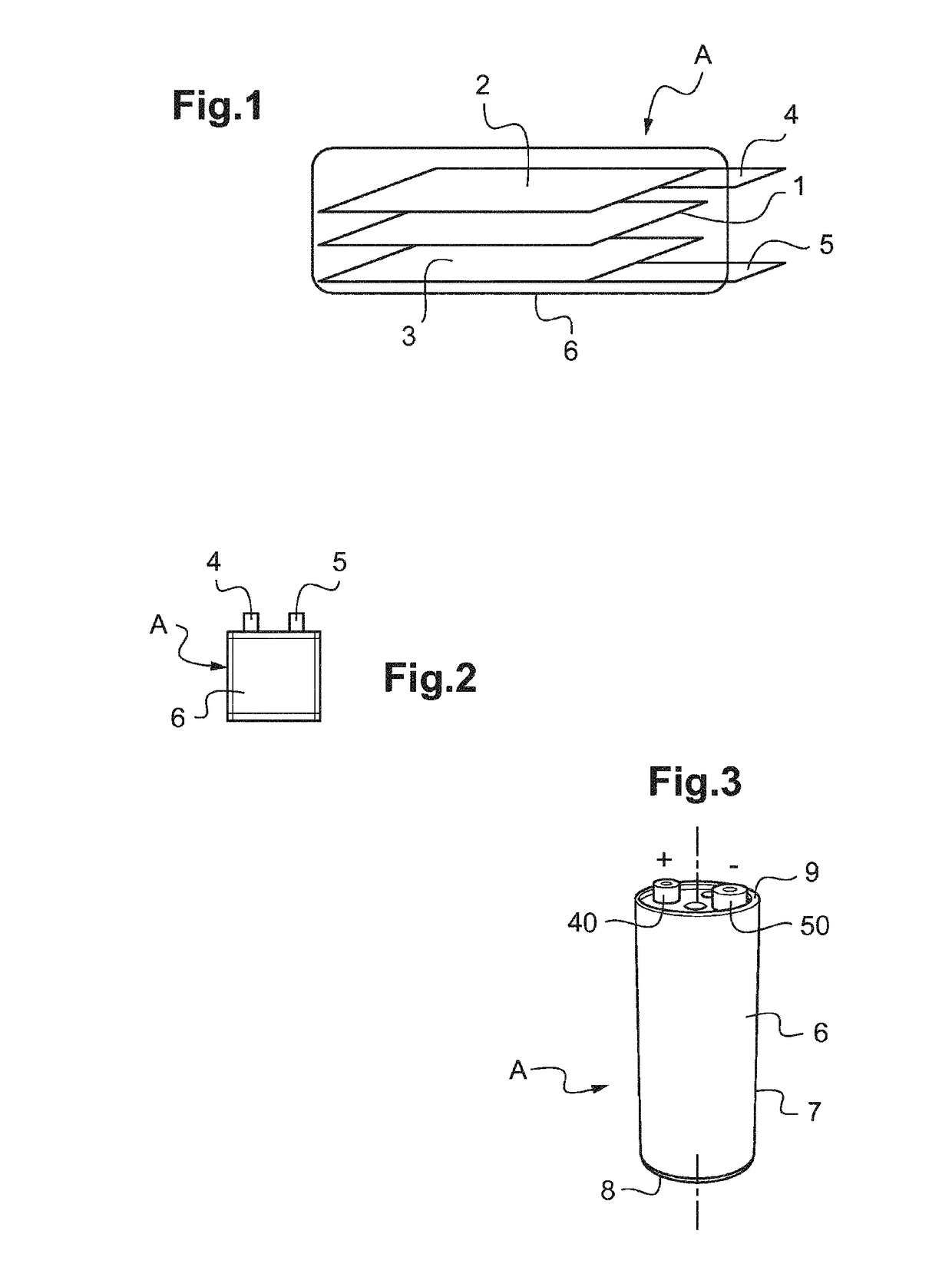

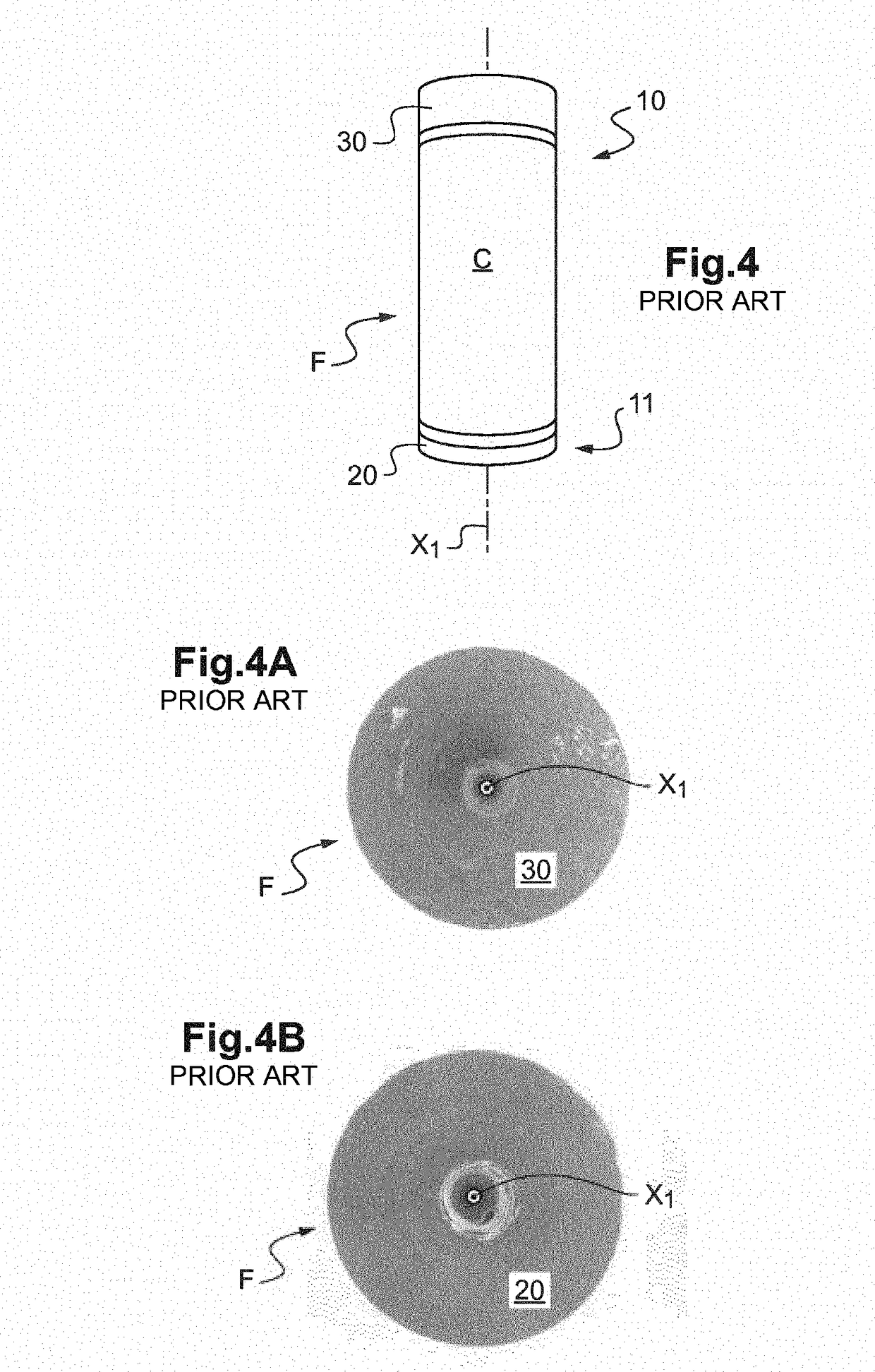

Method for producing an electrochemical bundle for a metal-ion accumulator comprising metal foam at the ends of foils

InactiveUS20180175359A1High quality weldingAvoid burnsFinal product manufactureCell electrodesElectricityElectrical connection

One subject of the invention is a process for producing an electrochemical bundle of a metal-ion accumulator, with a view to its electrical connection to the output terminals of the accumulator, which is characterized by the addition of a strip of metal foam to the margins with a view to welding with a current collector.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

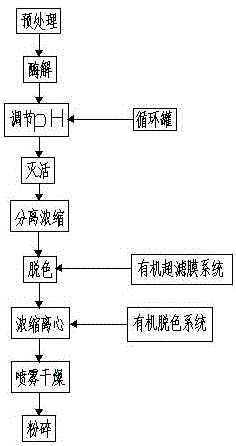

Naringin extraction process

InactiveCN106543247AAvoid destructionReduce energy consumptionSugar derivativesSugar derivatives preparationNaringinCentrifugation

The invention discloses a naringin extraction process, which comprises: 1, crushing; 2, enzymolysis; 3, PH value adjusting; 4, inactivation; 5, separating and concentrating; 6, decoloration; 7, concentrating centrifugation; 8, spray drying; and 9 crushing. According to the present invention, the filtration precision is high so as to fundamentally ensure the good purity and good quality of the filtrate; the membrane process is the purely physical process without the phase change, the energy consumption is low, the system performs the operations at the room temperature, the damage of the heat on the active substance in the enzyme preparation product is overcome; and compared to traditional filtration process, the extraction process of the present invention has the following advantages that the product quality is improved, and the product yield and the production efficiency are significantly increased.

Owner:HEFEI XINDA MEMBRANE TECH

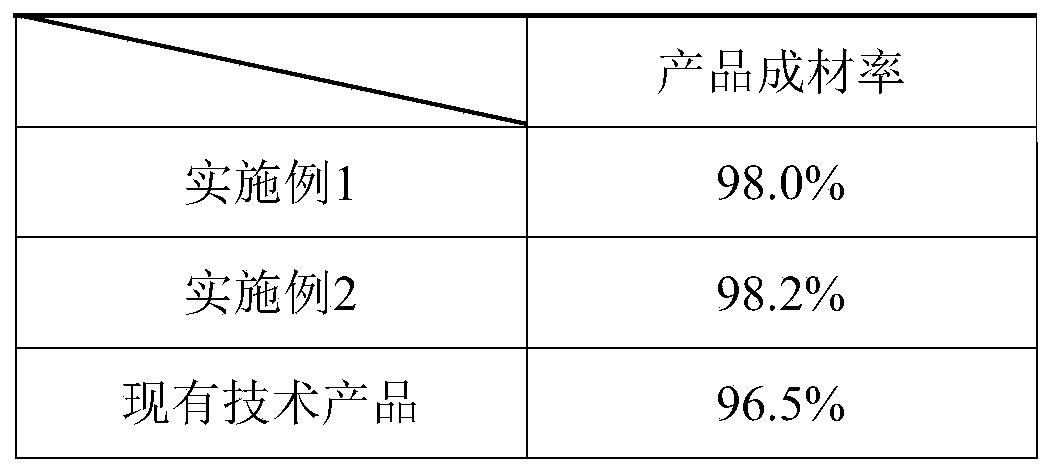

Internal formation lead plaster preparation process

The invention discloses an internal formation lead plaster preparation process. The internal formation lead plaster preparation technology comprises the following steps in sequence: step one. adding water so as to prepare preparatory liquid; step two. adding lead powder; and step three. adding dilute sulphuric acid so as to form the lead plaster. According to the internal formation lead plaster preparation technology, pure water is used as a solvent and a dispersing agent so as to completely and uniformly disperse materials, so that the uniformity and the consistency of components in the lead plaster are improved, and by adopting a wet-process addition process, the pollution of dust generated during the addition of powder materials to environments is avoided. Compared with a dry-process technology, the internal formation lead plaster preparation process has the advantages that the non-uniform stirring caused by the difference of the powder materials in specific gravity can be solved, meanwhile, the stirring time can aslo be shortened, the production efficiency is improved, as the stirring time is shortened, the good effect of the lead plaster is ensured, and the difficulty in application of the lead plaster is avoided. The self discharge of storage batteries prepared from the lead plaster is obviously reduced, and the heavy current cycle life is obviously prolonged.

Owner:CHAOWEI POWER CO LTD

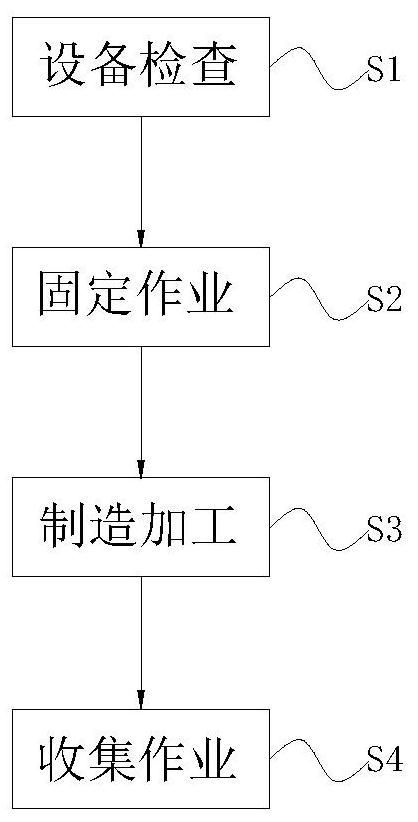

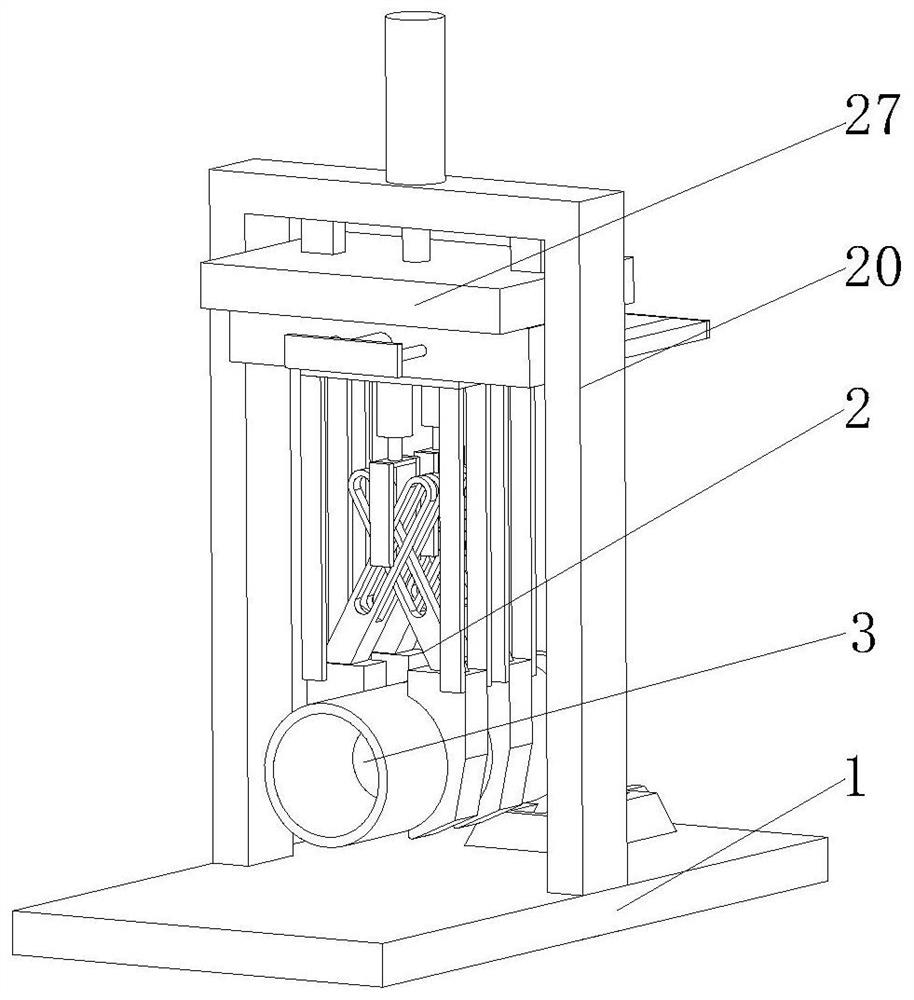

Chemical vulcanization tower production and manufacturing system

ActiveCN112496748AQuality assuranceGuaranteed pass rateEdge grinding machinesWelding/cutting auxillary devicesVulcanizationPipe fitting

The invention provides a chemical vulcanization tower production and manufacturing system. The chemical vulcanization tower production and manufacturing system comprises a bottom plate, a clamping device and a welding device. The clamping device is fixedly mounted on the bottom plate, and the welding device is fixedly connected to the bottom plate and located below the clamping device. According to the chemical vulcanization tower production and manufacturing system, the clamping device can clamp a tubular iron tower, and the stability of a pipe fitting before welding is guaranteed; secondly,the welding position of the pipe fitting can be polished, secondary treatment is not needed, and the production cost is effectively reduced; and finally, the welding quality can be effectively improved, the quality of a vulcanization tower is guaranteed, and meanwhile the production efficiency can be improved.

Owner:三门峡市宏基机械有限公司

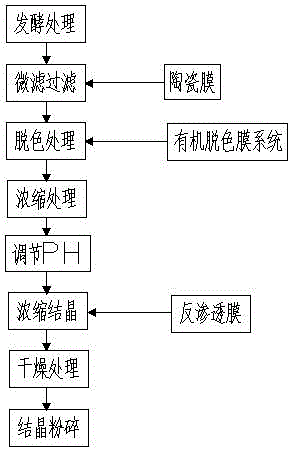

Soybean isoflavone separating technology

InactiveCN106282258AGuaranteed purityGood Performance GuaranteedOrganic chemistryFermentationMicrofiltrationIsoflavones

The invention discloses a soybean isoflavone separating technology. An extraction process comprises the steps of 1 fermentation treatment, 2 microfiltration filtering, 3 decolorizing treatment, 4 concentration treatment, 5 PH regulating, 6 concentration and crystallization, 7 rinsing treatment, 8 drying treatment and 9 crystallizing and crushing. The soybean isoflavone separating technology is a production process which can be safely and efficiently used for a long term and is convenient to maintain, the production process is simple, and meanwhile the production cost is reduced.

Owner:HEFEI XINDA MEMBRANE TECH

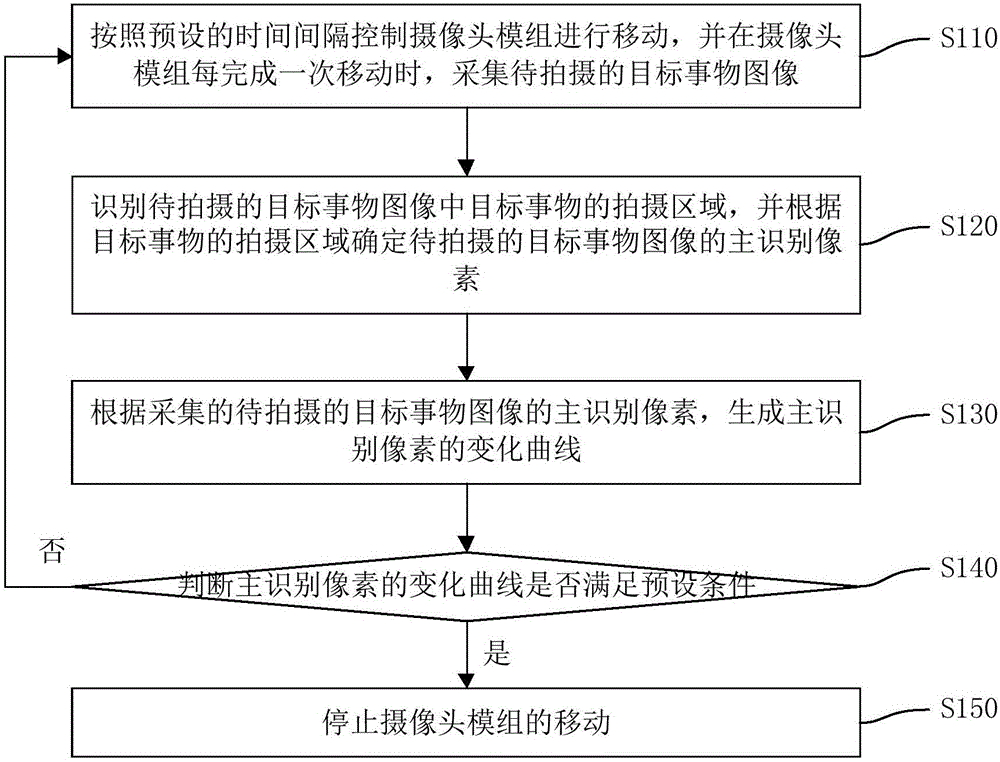

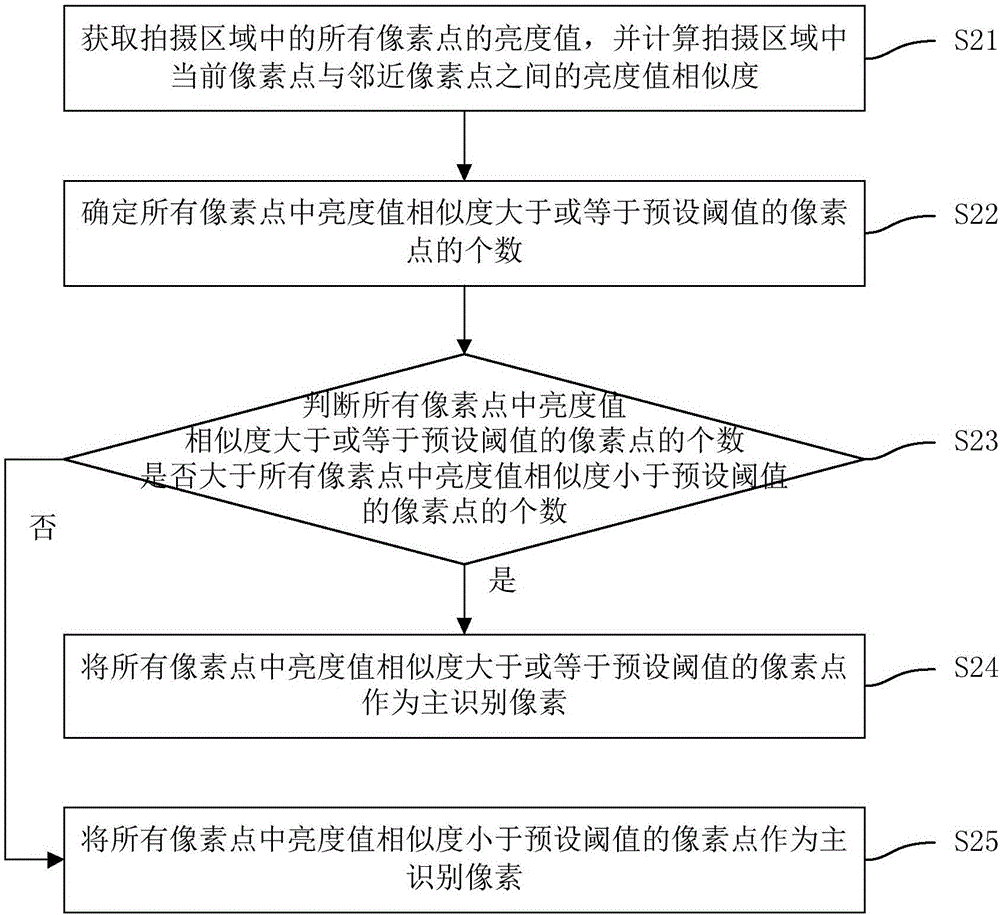

Shooting method and device of mobile terminal

ActiveCN106210529AGuaranteed shooting qualityGood Performance GuaranteedTelevision system detailsColor television detailsShooting methodCamera module

The invention discloses a shooting method and device of a mobile terminal. The shooting method comprises the following steps: controlling a camera module to move according to a preset time interval, and collecting a to-be-shot target object image when the camera module completes motion every time; identifying a shooting area of a target object in the to-be-shot target object image, and determining a main identification pixel of the to-be-shot target object image according to the shooting area of the target object; generating a changing curve of the main identification pixel according to the acquired main identification pixel of the to-be-shot target object image; judging whether the changing curve of the main identification pixel satisfies preset conditions or not; and if the changing curve of the main identification pixel satisfies preset conditions, stopping moving the camera module. By adopting the shooting method disclosed by the invention, the shooting quality of the image can be ensured, and meanwhile, a purpose of rapidly aligning the target object image through a high-precision mode can be achieved, and good effects of a final image can be guaranteed.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com