Naringin extraction process

An extraction process, the technology of naringin, applied in the field of naringin extraction process, can solve the problems that the production environment is difficult to meet the production requirements of food additives, the heavy economic burden of enterprises and the pressure of environmental protection, the consumption of water resources and chemical raw material resources, etc. Achieve the effect of easy operation and maintenance, reduce the loss of active ingredients, and overcome the damage of active substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

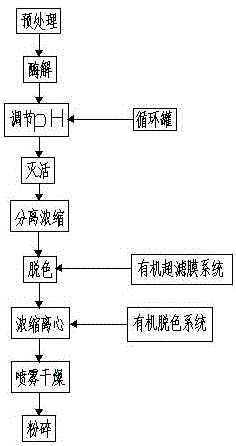

[0029] now attached figure 1 The present invention will be further described in detail with specific embodiments.

[0030] Concrete embodiment manufacturing steps are as follows:

[0031] A kind of naringin extraction process is characterized in that, extraction process step comprises:

[0032] Step 1, pretreatment: crush pomelo peel into slurry with slag and then sieve to obtain crude pomelo peel pulp;

[0033] Step 2, enzymatic hydrolysis: adding enzymes to enzymatically hydrolyze the crude pomelo peel pulp and then sieving to obtain pomelo peel pulp;

[0034] Step 3, adjust PH: adjust the PH of the obtained pomelo peel pulp to ensure that there is a certain buffer in the pulp;

[0035] Step 4, inactivation: adjust the temperature, and inactivate the enzymes that have been put into the pomelo peel pulp;

[0036] Step 5, separation and concentration: put the inactivated pomelo pulp into the organic ultrafiltration membrane to separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com