Production technology of high-surface quality thin-gauge hot-rolled pickling galvanized sheet

A hot-rolled pickling and production process technology, which is applied in hot-dip plating process, metal material coating process, metal rolling, etc., to achieve the effect of eliminating missed plating, eliminating internal distortion, and improving the company's product and customer yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

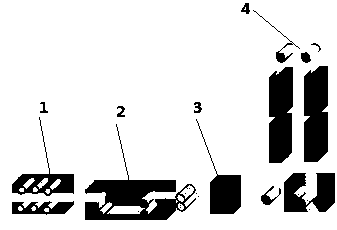

Image

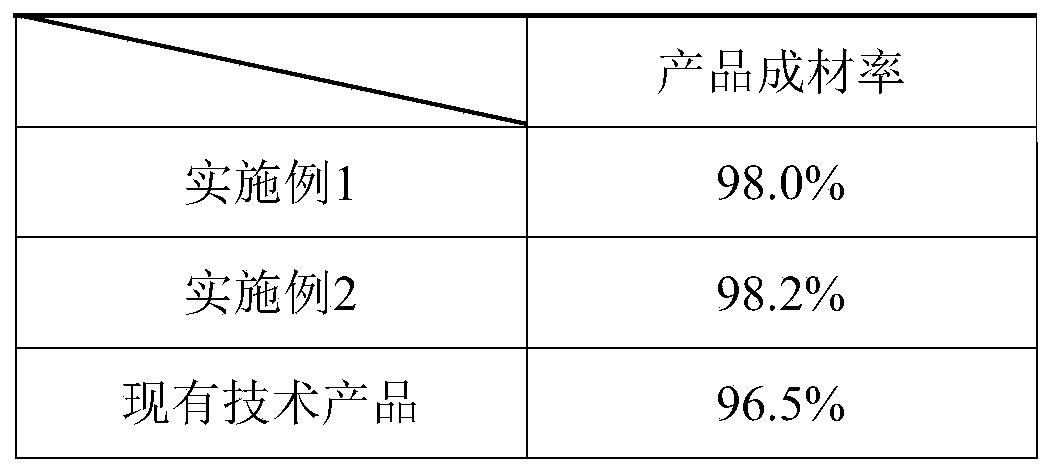

Examples

Embodiment 1

[0025] A production process of high surface quality thin-gauge hot-rolled pickling galvanized sheet, comprising the following steps:

[0026] The raw material coils are produced through the endless continuous casting and rolling process of strip steel, and then pickling, squeezing, first drying, smoothing, water washing, electromagnetic induction heating, galvanizing, air knife purging, and subsequent stage Cooling, water cooling, intermediate looper, skin pass, tension leveling, passivation, second drying, export looper, inspection, oiling, coiling into hot-dip galvanized coil, product thickness 0.8mm-4.0mm.

[0027] The wringing process uses wringing rollers, and two pairs of wringing rollers are set.

[0028] The water washing process steps are sequentially going through the upper and lower brush rollers, spraying water washing, and squeezing the drying rollers.

[0029] The steps of the pickling process are: uncoiling, welding, inlet looper, scale breaking, pickling, rins...

Embodiment 2

[0036] A production process of high surface quality thin-gauge hot-rolled pickling galvanized sheet, comprising the following steps:

[0037] The raw material coils are produced through the endless continuous casting and rolling process of strip steel, and then pickling, squeezing, first drying, smoothing, water washing, electromagnetic induction heating, galvanizing, air knife purging, and subsequent stage Cooling, water cooling, intermediate looper, skin pass, tension leveling, passivation, second drying, export looper, inspection, oiling, coiling into hot-dip galvanized coil, product thickness 0.8mm-4.0mm.

[0038] The wringing process uses wringing rollers, and two pairs of wringing rollers are set.

[0039] The water washing process steps are sequentially going through the upper and lower brush rollers, spraying water washing, and squeezing the drying rollers.

[0040] The reduction process uses an induction heating furnace for induction heating, and the temperature of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com