Preparation method for positive electrode material of iron, lithium and manganese phosphate battery

A cathode material, lithium iron phosphate technology, applied in the field of electrochemical power supply, can solve the problems that cannot meet the application requirements of cathode materials for power lithium-ion batteries, insufficient mixing of reactants, and poor uniformity of reaction products, etc., to shorten the drying time , saving preparation time, and suppressing the effect of hindering charge transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

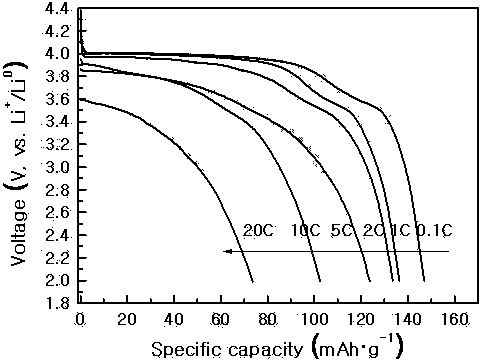

Embodiment 1

[0016] Example 1 Select lithium hydroxide, ferrous oxalate, manganese oxalate, phosphoric acid, magnesium nitrate and glucose as lithium source, iron source, manganese source, phosphorus source, metal salt and carbon source respectively, according to the elemental molar ratio Li: Fe: Mn :P:Mg=1.07:0.75:0.25:1:0.02 Weigh and set aside. Lithium hydroxide was added to ethanol, heated and stirred at 40°C for 2h. Sol A was formed by adding ferrous oxalate, manganese oxalate and magnesium nitrate. The complexing agent citric acid was added to the phosphoric acid-containing ethanol aqueous solution to obtain solution B, and glucose was added to solution B (converted into carbon and the mass fraction of the total mass of raw materials was 4%). Sol A and solution B were mixed and heated to 60°C, and the pH was adjusted with ammonia water to form gel C. Gel C was microwave-dried for 10 minutes to obtain a powder precursor. The precursor is ground into fine components, and the obtaine...

Embodiment 2

[0017] Example 2 Lithium hydroxide, iron phosphate, manganese oxalate, phosphoric acid, magnesium nitrate and glucose are selected as lithium source, iron source, manganese source, phosphorus source, metal salt and carbon source respectively, according to the elemental molar ratio Li:Fe:Mn: P: Mg=1.07:0.75:0.25:1:0.02 Weigh and set aside. Lithium hydroxide was added to ethanol, heated and stirred at 50°C for 2h. Sol A was formed by adding iron phosphate, manganese oxalate and magnesium nitrate. The complexing agent citric acid was added to the phosphoric acid-containing ethanol aqueous solution to obtain solution B, and glucose was added to solution B (converted into carbon and accounted for 5% of the total mass of raw materials). Sol A and solution B were mixed and heated to 60°C, and the pH was adjusted with ammonia water to form gel C. Gel C was microwave-dried for 10 minutes to obtain a powder precursor. The precursor is ground into fine components, and the obtained pow...

Embodiment 3

[0018] Embodiment 3 selects lithium hydroxide, ferromanganese phosphate, phosphoric acid, magnesium nitrate and glucose as lithium source, iron source, manganese source, phosphorus source, metal salt and carbon source respectively, wherein ferromanganese phosphate is simultaneously used as iron source and manganese source, It can also be used as a phosphorus source, weighed according to the elemental molar ratio Li:Fe:Mn:P:Mg=1.05:0.5:0.5:1:0.02 and then used. Lithium hydroxide was added to ethanol, heated and stirred at 40°C for 2h. Sol A was formed by adding ferromanganese phosphate and magnesium nitrate. The complexing agent citric acid was added to the phosphoric acid-containing ethanol aqueous solution to obtain solution B, and glucose was added to solution B (converted into carbon and the mass fraction of the total mass of raw materials was 2%). Sol A and solution B were mixed and heated to 60°C, and the pH was adjusted with ammonia water to form gel C. Gel C was micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com