Method for preparing nano particle modified chemical fibre

A nanoparticle and chemical fiber technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of cumbersome and high cost of composite materials, achieve improved tensile properties, low production cost, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

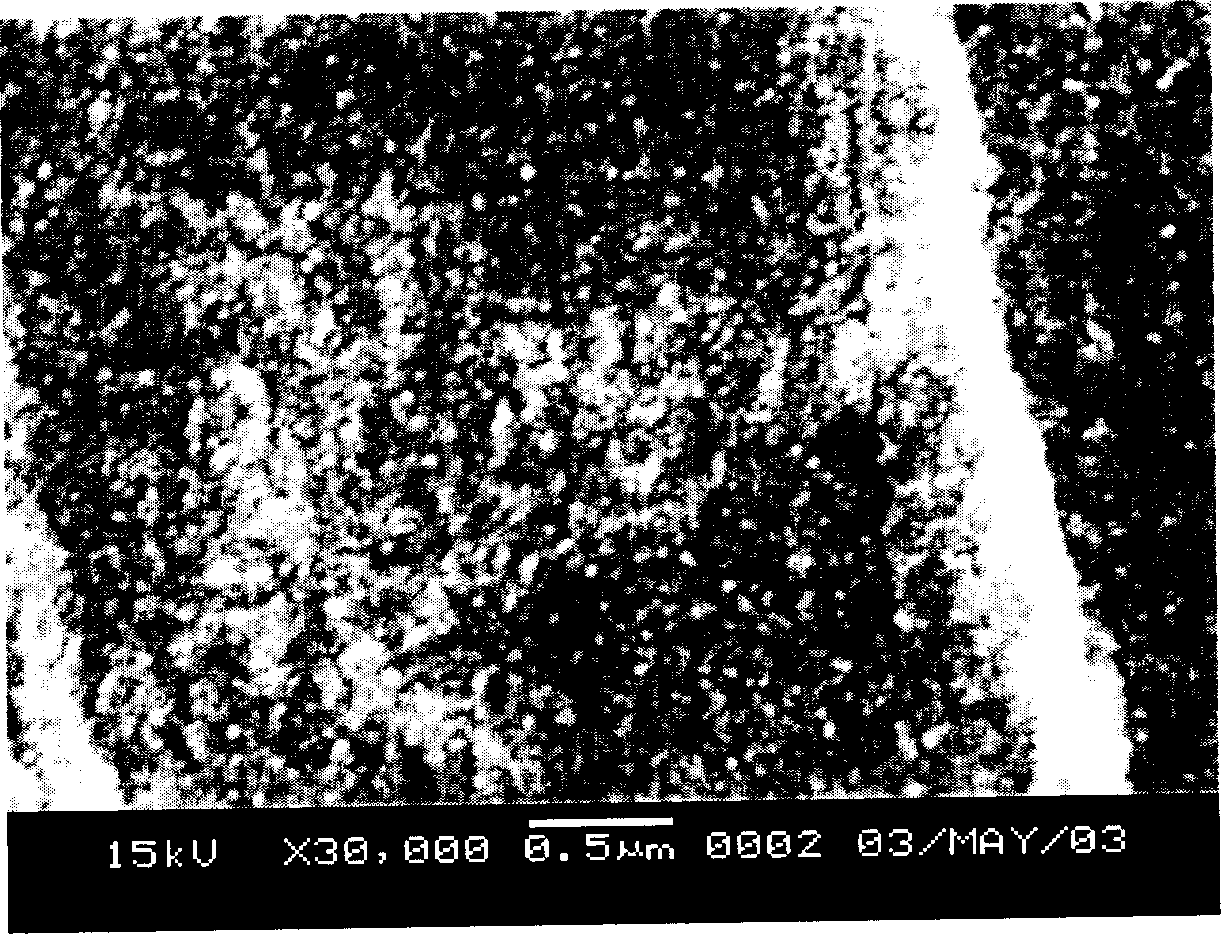

[0028] Add the surface-treated nano-silica and xylene into a container with an ultrasonic generator at a ratio of 1:100 and stir at a high speed for 20 minutes to make an extract with evenly dispersed nanoparticles. Put the polyethylene jelly fiber in In it, the extraction was carried out twice for a total of 20 minutes in a static state, and then dried at room temperature. The dry jelly fiber is stretched 12 times at 100°C, 2 times at 110°C, and 1.4 times at 120°C. The strength of the obtained fiber is 30.5cN / dtex, the modulus is 1720cN / dtex, and the elongation at break is 3.31%. However, the polyethylene jelly fiber is extracted under the same conditions in an extraction bath not containing nanoparticles and then dried and stretched under the same conditions. The fiber strength obtained is 29.6cN / dtex, and the modulus is 1170cN / dtex. The elongation was 3.83%. The scanning electron micrograph of the cross-section of the fiber after one-stage stretching is as follows: figu...

Embodiment 2

[0030] Add 2 parts each of surface-treated nano-tourmaline particles and nano-titanium dioxide particles to 98 parts of an aqueous solution containing 3% sodium thiocyanate, and stir at high speed under ultrasonic conditions for 20 minutes to prepare a preheating bath for uniform dispersion of nanoparticles.

[0031] The polyacrylonitrile primary fiber coming out of the coagulation bath enters the above-mentioned preheating bath, the bath temperature is 55°C, stretched 1.5 times under the ultrasonic state, the fiber stays in the preheating bath for 1min, and then carries out secondary stretching and water washing and other post-treatment processes to make acrylic fibers containing nanoparticles. The average number of negative oxygen ions released by the tested final product is 150 / cm 3 , the far-infrared emission rate is 83%, its antibacterial rate to Escherichia coli is 81%, and the antibacterial rate to Staphylococcus aureus is 77%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com