Oil smoke cleanse extraction device

A technology of exhaust device and oil fume purification, which is applied in the fields of oil fume removal, chemical instruments and methods, and household heating, etc., can solve the problems of oil fume gas purification, increased noise, and large working noise of range hoods, and achieves the elimination of pollution, The effect of silently eliminating oil fume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

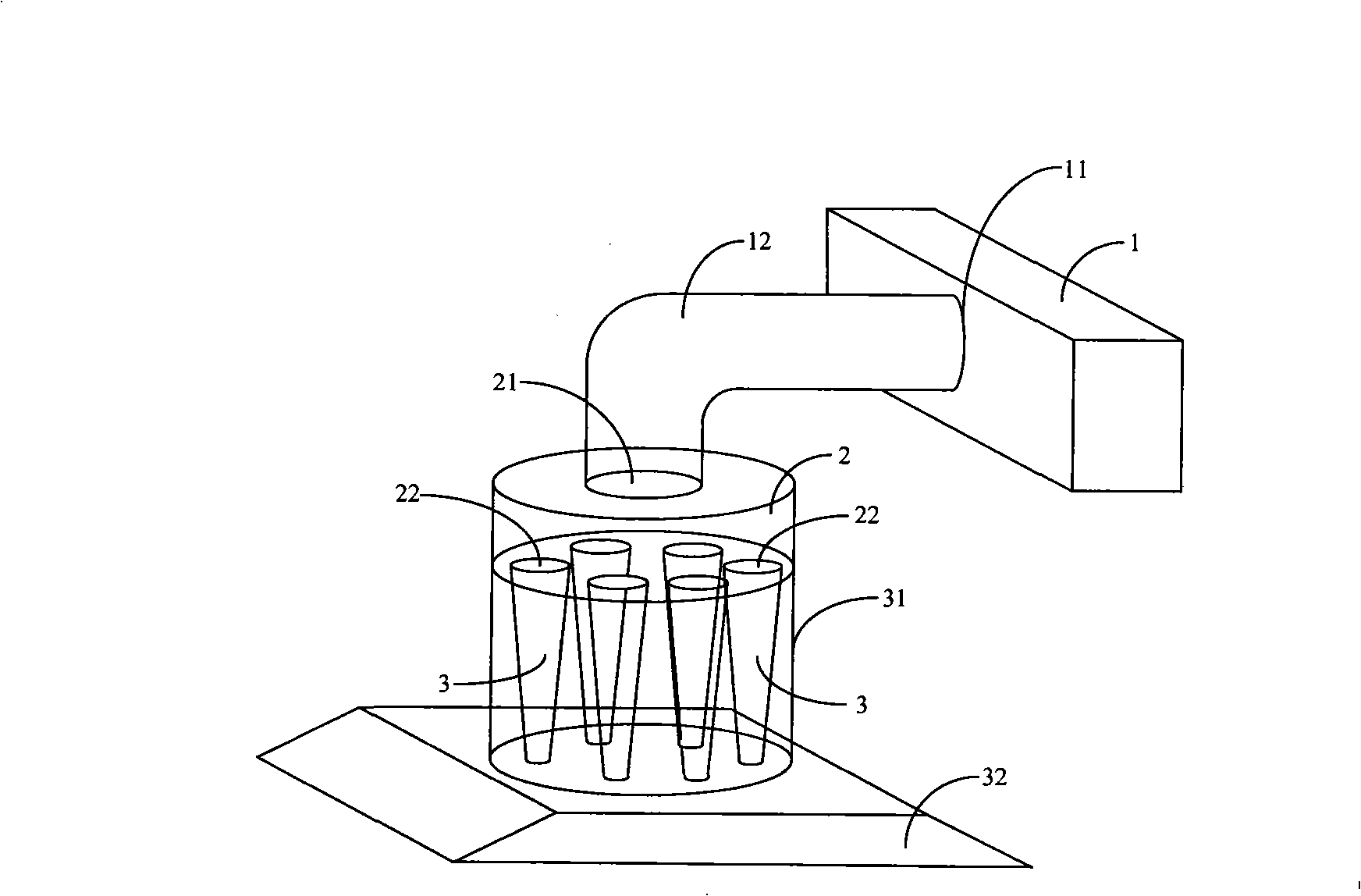

[0054] Such as figure 1 As shown, this embodiment includes a blower 1 for exhausting gas, the inlet 11 of the blower 1 is connected with the outlet 21 of a box-shaped air flow controller 2 through a pipe 12 . The airflow controller 2 is provided with a plurality of air intake holes 22 . Each air inlet 22 is respectively connected to the larger diameter end of a conical cyclone pipe 3 . Several cyclone pipes 3 are placed in a cabinet casing 31 , and an oil fume hood 32 is also provided below the cabinet casing 31 .

[0055] During work, the cabinet box body 31 with a plurality of cyclone tubes 3 inside, the oil fume hood 32 and the air flow controller 2 are installed above the cooktop together, and the end of the cyclone tube 3 with a smaller diameter is exhausted by the fan 1 The inhaled gas forms a negative pressure area in the fume hood 32 , so that the fume gas generated on the stove is sucked into the cyclone pipe 3 . The conical cyclone pipe 3 is a reducing pipe. The ...

Embodiment 2

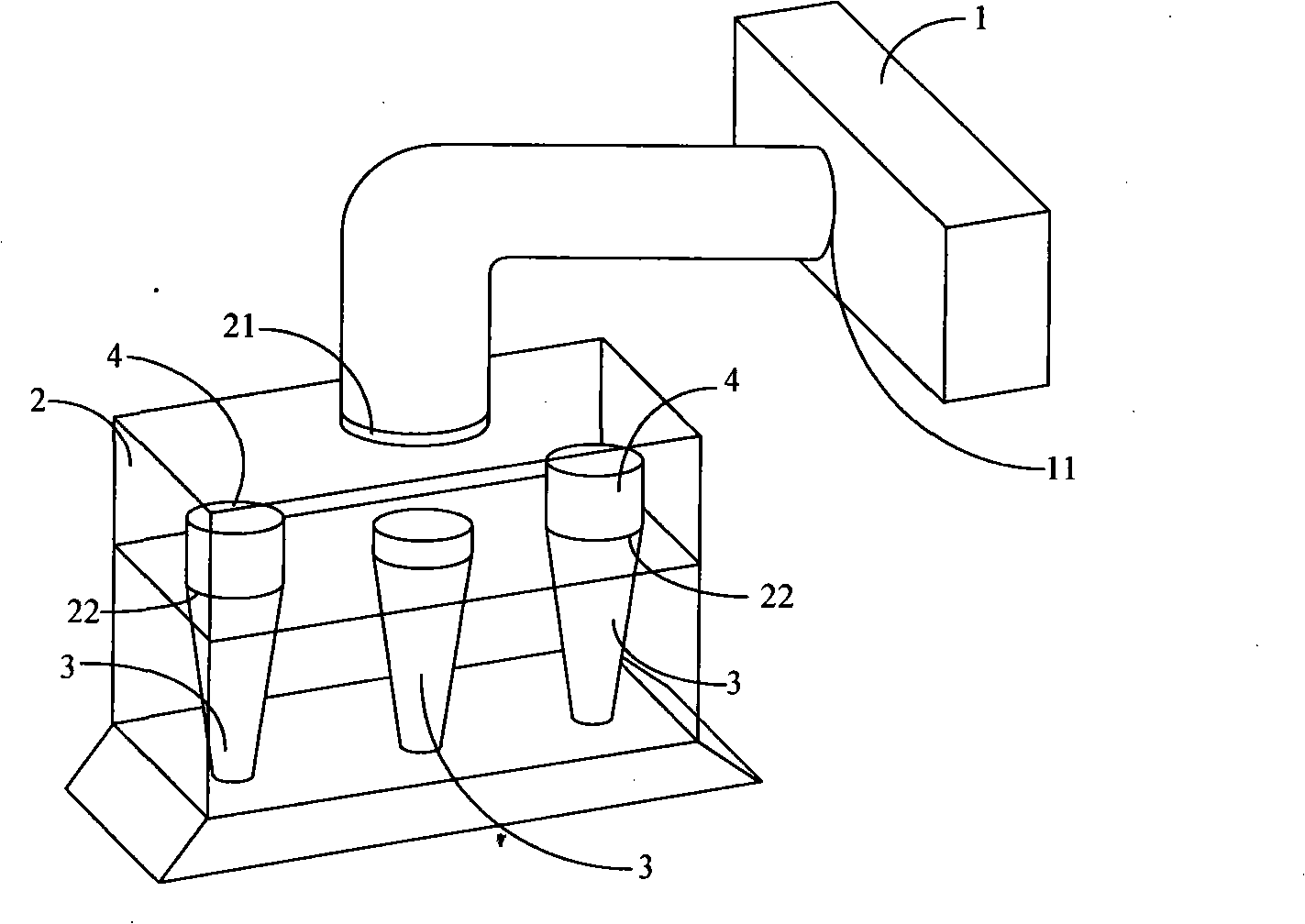

[0059] Such as figure 2 As shown, this embodiment also includes a blower 1 for exhausting gas, the inlet 11 of the blower 1 is connected with the outlet 21 of a cuboid airflow controller 2 . Three circular air intake holes 22 are arranged on the bottom plate of the airflow controller 2 . Each air inlet 22 is directly correspondingly connected with the larger-diameter end of a conical cyclone pipe 3 .

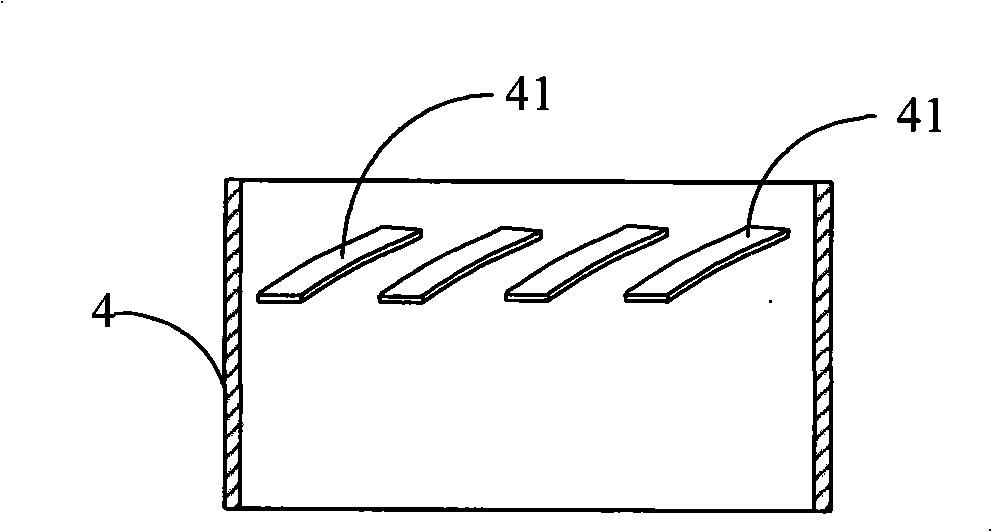

[0060] In the box-shaped body of the air flow controller 2, there are also three flow boosters 4 for controlling the flow velocity and flow direction of the fume gas, and each flow booster 4 communicates with a corresponding air inlet 22 respectively. The flow booster 4 is used to lead out the soot gas in the cyclone tube 3, and the flow rate of the soot gas sent out from the three cyclone tubes 3 can be controlled by setting the corresponding height. Since the outlet 21 of this embodiment is located in the upper middle of the airflow controller 2, in order to balance the thr...

Embodiment 3

[0071] Such as Figure 7 As shown, the difference between this embodiment and the above-mentioned second embodiment is that two inclined partitions 23 are also arranged in the box of the airflow controller 2, and the space in the airflow controller 2 is divided by the partitions 23. Up and down two floors. A hole 231 is opened on the partition plate 23 for connecting with the flow booster 4 .

[0072] In this embodiment, there are altogether four flow enhancers 4, and the number of cyclone tubes 3 is five. The cyclone tube in the middle is not connected with a flow booster, and the remaining four cyclone tubes 3 are respectively connected with a flow booster 4 symmetrically. The flow boosters 4 on the same side have different heights, and their tops are flush with the surface of the partition 23 .

[0073] For the scheme in which the outlet 21 on the airflow controller 2 is arranged at the upper middle, this embodiment has a good oil fume flow distribution control function,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com