Formed carbon dioxide absorbing material and preparation method thereof

An adsorption material, carbon dioxide technology, applied in the direction of adsorption, chemical instruments and methods, separation methods, etc., can solve the problems of inconvenient use, loss, and affecting adsorption efficiency, etc., achieve high efficiency, high stability, and facilitate storage and recycling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

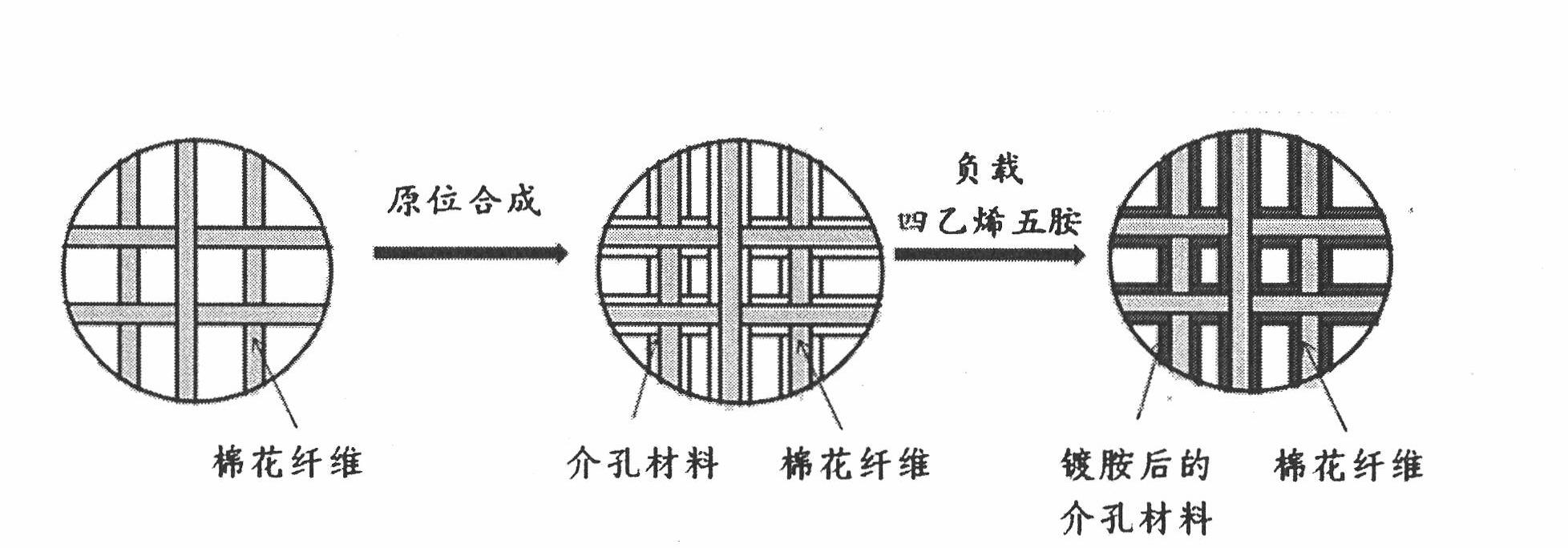

[0023] At room temperature, 2g P123(EO 20 PO 70 EO 20 ) was dissolved in a solution of 60g 2Mol / L HCl and 15g water, slowly added 4.25g tetraethyl orthosilicate while stirring at 40°C, stirred for two minutes, added 8g cotton, and stood at 40°C for 48h. Cool, wash and dry at room temperature to obtain a formed mesoporous molecular sieve-cotton fiber composite material, referred to as S1 / C. Take 0.2g of S1 / C sample and add it to 0.2g of tetraethylenepentamine in 10g of ethanol solution, stir and reflux at 80°C for 2h, then evaporate to dryness at 80°C to obtain a sample loaded with 50% (wt) amine. Samples with different loadings of tetraethylenepentamine were prepared in the same way. The obtained sample is denoted as S1 / C-X, and X represents the weight percent content of tetraethylenepentamine in the sample. The obtained samples were subjected to gas chromatography for CO 2 Adsorption measurements, the adsorption data are listed in Table 1.

Embodiment 2

[0032] At room temperature, dissolve 2g of P123 in a solution of 60g of 2Mol / L HCl and 15g of water, slowly add 4.25g of tetraethyl orthosilicate while stirring at 40°C, stir for two minutes, add 8g of cotton, and let stand at 40°C 24h, then stand at 60°C for 24h. Cool, wash and dry at room temperature to obtain a formed mesoporous molecular sieve-cotton fiber composite material, referred to as S2 / C. Take 0.2g of S2 / C sample and add it into 0.2g of tetraethylenepentamine in 10g of ethanol solution, stir and reflux at 80°C for 2h, then evaporate to dryness at 80°C to obtain a sample loaded with 50% (wt) amine. Samples with different loadings of tetraethylenepentamine were prepared in the same way. The obtained sample is denoted as S2 / C-X, and X represents the weight percent content of tetraethylenepentamine in the sample. The obtained samples were subjected to gas chromatography for CO 2 Adsorption measurements, and the adsorption data are listed in Table 3.

Embodiment 3

[0038] At room temperature, dissolve 2g of P123 in a solution of 60g of 2Mol / L HCl and 15g of water, slowly add 4.25g of tetraethyl orthosilicate while stirring at 40°C, stir for two minutes, add 9g of cotton, and stand at 40°C 24h, then stand at 80°C (or 100°C) for 24h. Cool, wash and dry at room temperature to obtain a mesoporous molecular sieve-cotton fiber composite material, referred to as S3 / C (S4 / C). It was found that under these two conditions, the cotton fibers had been hydrolyzed and the samples had a powdery appearance and were not effectively shaped.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com