Method for lowering quantity and toxicity of flying ash of household garbage incineration plant

A domestic waste incineration and domestic waste technology, applied in the field of solid waste treatment, can solve the problems of uncompetitive economic costs, achieve good environmental and social benefits, improve the ecological environment, and simplify the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

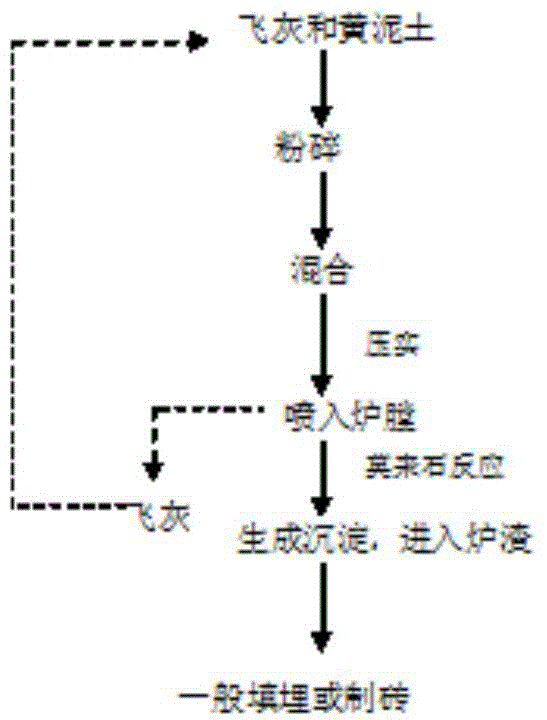

[0055] Step 1, using beige mud and fly ash produced by normal incineration of a domestic waste incineration plant as raw materials, the beige mud is a kind of beige clay, and its main mineral component is quartz (SiO 2 ), illite (K(Al,Fe,Mg)(Si,Al) 4 o 10 (OH) 2 ) and kaolinite (Al 2 Si 2 o 5 (OH) 4 ).

[0056] Mix according to the mass ratio of fly ash: beige mud = 40:60, and crush to a particle size of 0.1mm.

[0057] Then mix the three with the mass ratio of fine grinding medium: mixture of fly ash and beige mud: water=5:0.5:1, and carry out fine grinding with a stirring ball mill, and the fine grinding medium is corundum pellets. In the finely ground material, the mass proportion of particles with a particle size of ≤100 μm is 50%.

[0058] Step 2: Compress the ground fly ash and beige mud into a cylindrical sample under a pressure of 20 MPa.

[0059] Step 3, during the incineration process of domestic waste, put the prepared sample into the incineration furnace a...

Embodiment 2

[0062] Step 1. The beige mud and the fly ash produced by the normal incineration of a domestic waste incineration plant are used as raw materials. The main mineral components of the beige mud are quartz, illite and kaolinite.

[0063] Mix according to the mass ratio of fly ash:beige mud=50:50, and crush to a particle size of 0.5mm.

[0064] The corundum bead is the fine grinding medium again, with the fine grinding medium: the mixture of fly ash and beige mud: the mass proportion of water=6.5:1.2:1 the three are mixed, carry out fine grinding with stirring ball mill; After fine grinding In the material, the mass proportion of particles with a particle size of ≤100 μm is 60%.

[0065] Step 2, pressing the ground fly ash and beige mud into a cylindrical sample under a pressure in the range of 60 MPa.

[0066] Step 3, during the incineration process of domestic waste, the prepared sample is put into the incineration furnace at a certain rate, and the input amount of the sample i...

Embodiment 3

[0069] Step 1. The beige mud and the fly ash produced by normal incineration of a domestic waste incineration plant are used as raw materials. The beige mud is a kind of beige clay, and its main mineral components are quartz, illite and kaolinite.

[0070] Mix according to the mass ratio of fly ash:beige mud=60:40, and crush to a particle size of 1mm.

[0071] Then use the corundum quality ball as the fine grinding medium, mix the three with the fine grinding medium: the mixture of fly ash and beige mud: water=8:2:1 with the fine grinding medium, and carry out fine grinding with a stirring ball mill . In the finely ground material, the mass proportion of particles with a particle size of ≤100 μm is 70%.

[0072] In step 2, the ground fly ash and beige mud are pressed into a cylindrical sample under a pressure ranging from 100 MPa.

[0073] Step 3: During the incineration process of domestic garbage, the prepared samples are put into the incineration furnace at a certain rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com