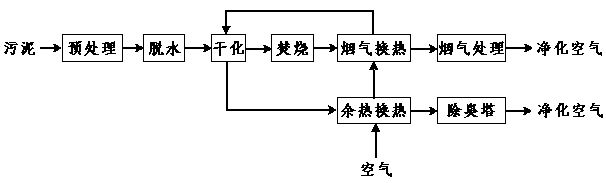

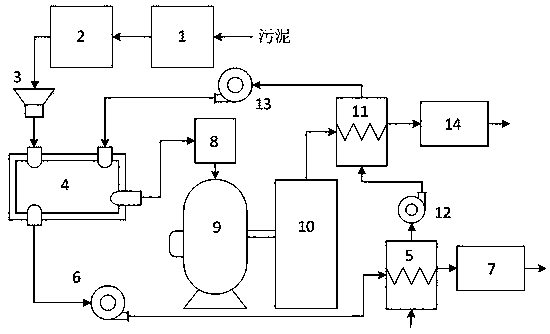

Sludge incineration treatment method and device

A technology of sludge incineration and treatment method, applied in the fields of sludge treatment, water/sludge/sewage treatment, combustion method, etc., can solve the problems of waste of resources, increase of pollutants, low calorific value of domestic sludge, etc., to save energy Good heat and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Sludge pretreatment: A certain domestic sludge has a moisture content of 85% and a calorific value of 1100kcal / kg. Adjust the sludge moisture content to 90%, stir for 2 hours, add inorganic dilute acid to the sludge solution, and adjust the sludge solution The pH is 1, stirred for 30 minutes, and settled for 1 hour. The precipitated sludge enters the desanding device, and quicklime is added to the desanded organic sludge to make the pH of the sludge solution neutral. After mixing evenly, add 1‰ of PAM to form Organic sludge flocs.

[0054] Sludge drying and incineration: The pretreated organic sludge is dehydrated by plate and frame. The moisture content of the dewatered sludge is 55%, and the dry basis heat value is 2450kcal / kg. After the dehydrated sludge is granulated, it enters the drying device and is dried The temperature of the hot air at the air inlet of the device is 100°C, the moisture content of the dried sludge is 25%, the humidity of the hot steam after dry...

Embodiment 2

[0056] Sludge pretreatment: A certain domestic sludge has a moisture content of 83% and a calorific value of 2300kcal / kg. Adjust the sludge moisture content to 95%, stir for 1 hour, add inorganic dilute acid to the sludge solution, and adjust the sludge solution The pH is 5, stirred for 1 hour, and settled for 2 hours. The precipitated sludge enters the desanding device, and quicklime is added to the desanded organic sludge to make the pH of the sludge solution neutral. After mixing evenly, add 1‰ of PAM to form Organic sludge flocs.

[0057] Sludge drying and incineration: The pretreated organic sludge is dehydrated by plate and frame. The moisture content of the dewatered sludge is 75%, and the dry basis heat value is 3500kcal / kg. After the dehydrated sludge is granulated, it enters the drying device and is dried. The temperature of the hot air at the air inlet of the device is 150°C, the moisture content of the dried sludge is 20%, the humidity of the hot steam after drying...

Embodiment 3

[0059] Sludge pretreatment: A certain domestic sludge has a moisture content of 86% and a calorific value of 2600kcal / kg. Adjust the sludge moisture content to 95%, stir for 1 hour, add inorganic dilute acid to the sludge solution, and adjust the sludge solution The pH is 4, stirred for 1 hour, and settled for 2 hours. The precipitated sludge enters the desanding device, and quicklime is added to the desanded organic sludge to make the pH of the sludge solution neutral. After mixing evenly, add 1‰ of PAM to form Organic sludge flocs.

[0060] Sludge drying and incineration: The pretreated organic sludge is dehydrated by plate and frame. The moisture content of the dewatered sludge is 70%, and the dry basis heat value is 3700kcal / kg. After the dehydrated sludge is granulated, it enters the drying device and is dried The temperature of the hot air at the air inlet of the device is 200°C, the moisture content of the dried sludge is 15%, the humidity of the hot steam after drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com