Smoke recycling rubbish incineration boiler

A technology of flue gas recirculation and waste incineration, applied in incinerators, combustion methods, combustion types, etc., to achieve the effects of improving thermal efficiency, reducing dust volume, and extending operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

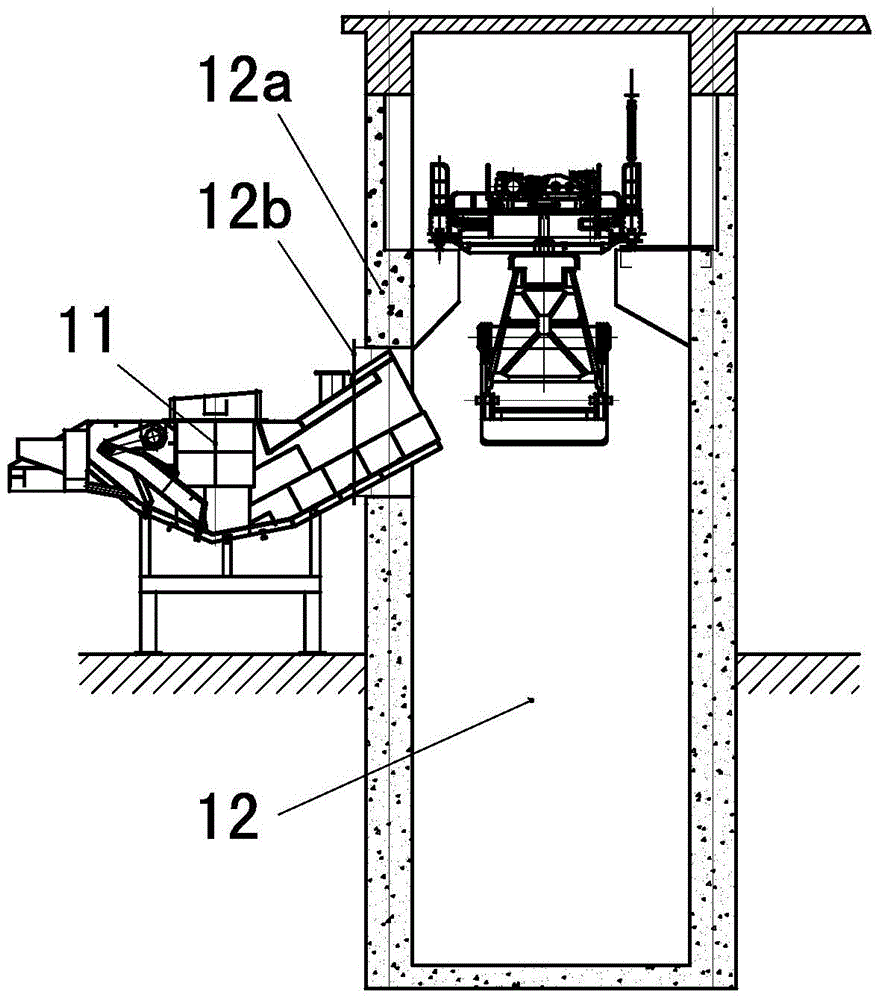

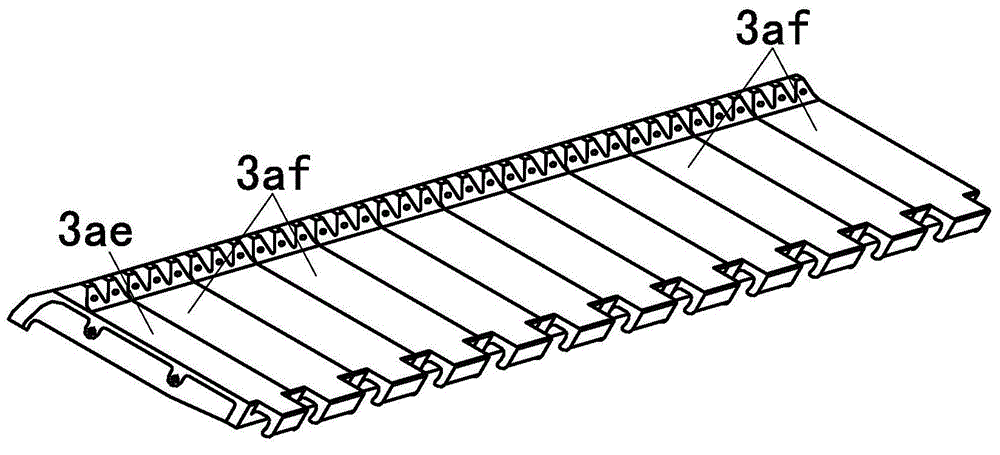

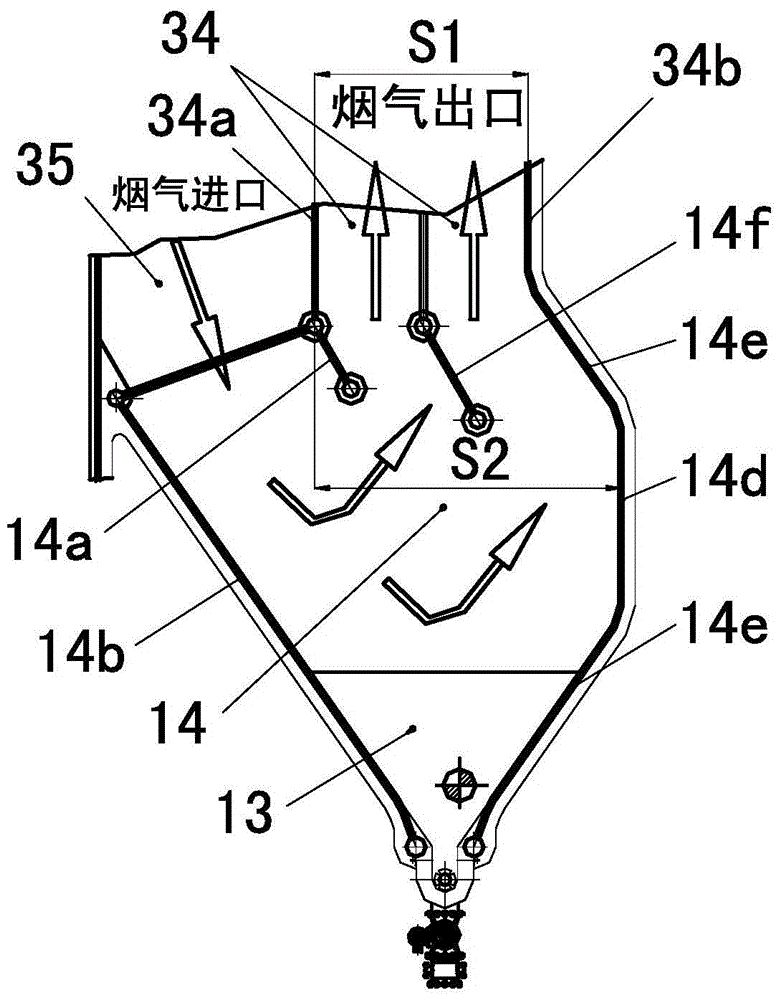

[0035] The schematic diagram of the structure of the flue gas recirculation waste incineration boiler in this embodiment is as follows Figure 1-15 As shown, the flue gas recirculation waste incineration boiler includes a boiler steel frame 26 and a furnace 2 installed on the boiler steel frame; a grate mounting bracket 39 is arranged below the furnace 2, and a reciprocating mechanical grate is installed on the grate mounting bracket 39 3; After the flue gas outlet at the top of the furnace 2, the first shaft flue 1, the second shaft flue 35, the third shaft flue 34, the horizontal flue 30, the first vertical tail flue 24 and the first shaft flue 24 connected in sequence are arranged. The second vertical tail flue 19; the second vertical shaft flue 35 and the third vertical shaft flue 34 below are provided with a dust-reducing flue gas chamber 14, and the inlet end and the outlet end of the dust-reducing flue gas chamber 14 are connected with the second vertical shaft flue 35 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com