Household waste sorting and drying system

A sorting system and domestic waste technology, applied in the direction of chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problem that environmental sanitation enterprises cannot do classified collection and classified transportation, the implementation effect is not satisfactory, and there is no Pay attention to waste classification and other issues to achieve the effect of reducing the amount of slag and fly ash, reasonable structure design and stable incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

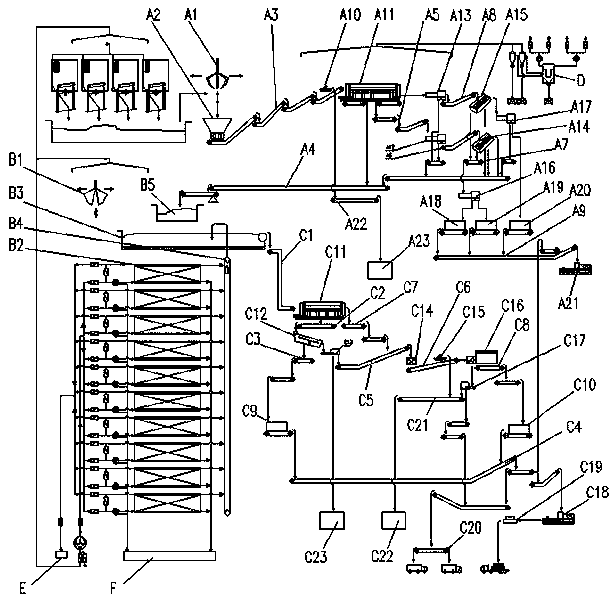

[0023] see figure 1 , the embodiment of the present invention includes a garbage pre-sorting system A, a garbage drying system B and a garbage post-sorting system C.

[0024] The pre-garbage sorting system A is used for material shaping and resource recovery before the incoming materials are dried, and the particle size of the materials is controlled within an appropriate range to achieve the best drying effect; at the same time, the dried materials are easily Resources that are more difficult to recover after deterioration or drying are sorted out in advance.

[0025] Garbage pre-sorting system A includes primary garbage grab crane A1, bag breaker A2, front sorting conveyor one A3, front sorting conveyor two A4, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com