Rural household waste incineration method and device

A technology for domestic waste incineration and villages and towns, applied in the combustion method, incinerator, combustion type, etc., can solve the problems of incomplete combustion, less than 850 ° C, low organic content, etc., to reduce NOx generation and disposal costs. , the effect of eliminating secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

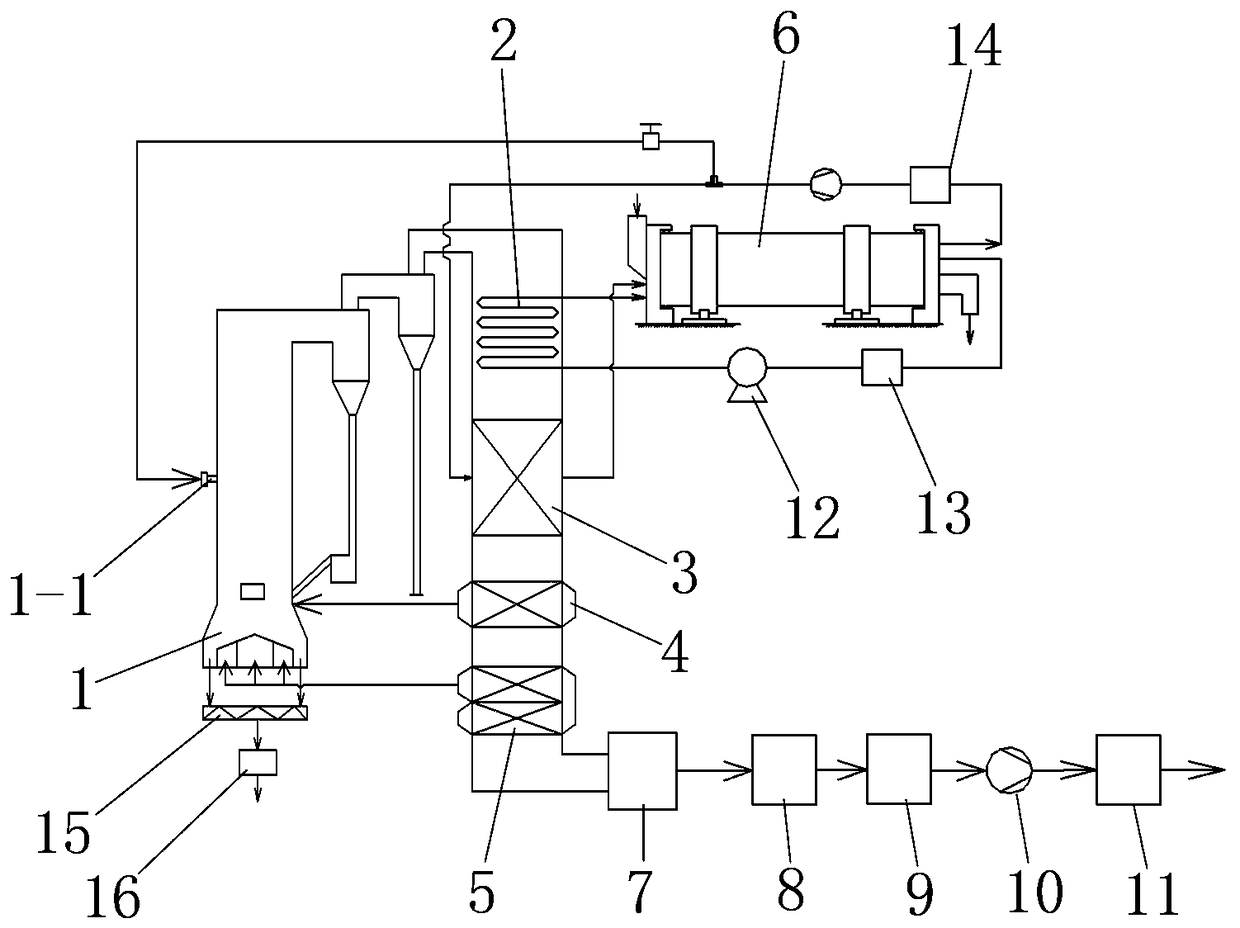

[0009] refer to figure 1 , a method for incineration of domestic waste in villages and towns, which includes utilizing a circulating fluidized bed incinerator 1 to incinerate waste dried to a moisture content of less than 15%, the auxiliary fuel is coal, and the odor in the waste pool is induced once during the incineration process The tuyere and the secondary tuyere are sent into the furnace for combustion, and the harmful gas generated by the odor is purified by the purification device at the end of the circulating fluidized bed incinerator 1, so there is no need to separately treat the odor; The water vapor released from the garbage is sprayed into the furnace to cool down. Because the moisture content of the dried garbage is low and the furnace temperature is high, the temperature of the furnace can be easily controlled at 850-950°C after the steam is injected; the heat source of the dry garbage is the heat of the flue gas generated by garbage incineration .

[0010] A de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com