Air supply system for lime kiln

An air supply system and air supply technology, applied in the field of lime kiln, can solve the problems of small central air volume, low lime quality, deterioration, etc., and achieve the effect of uniform air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

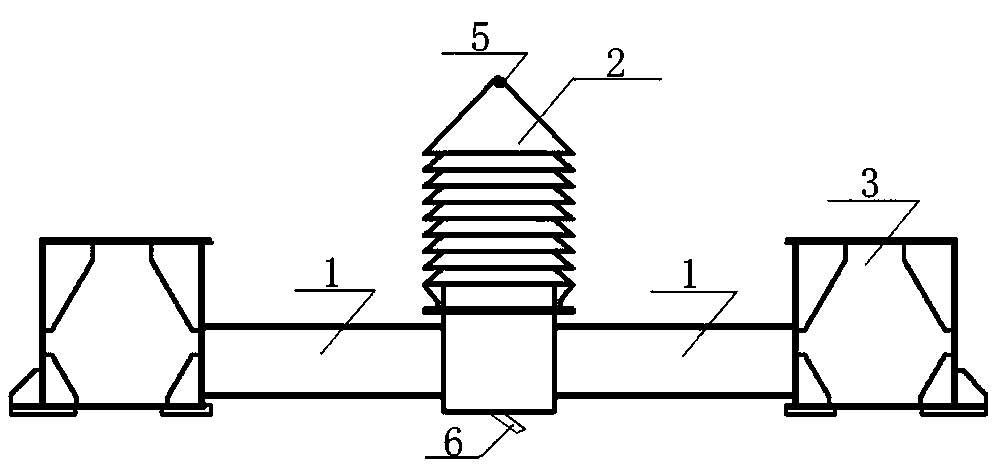

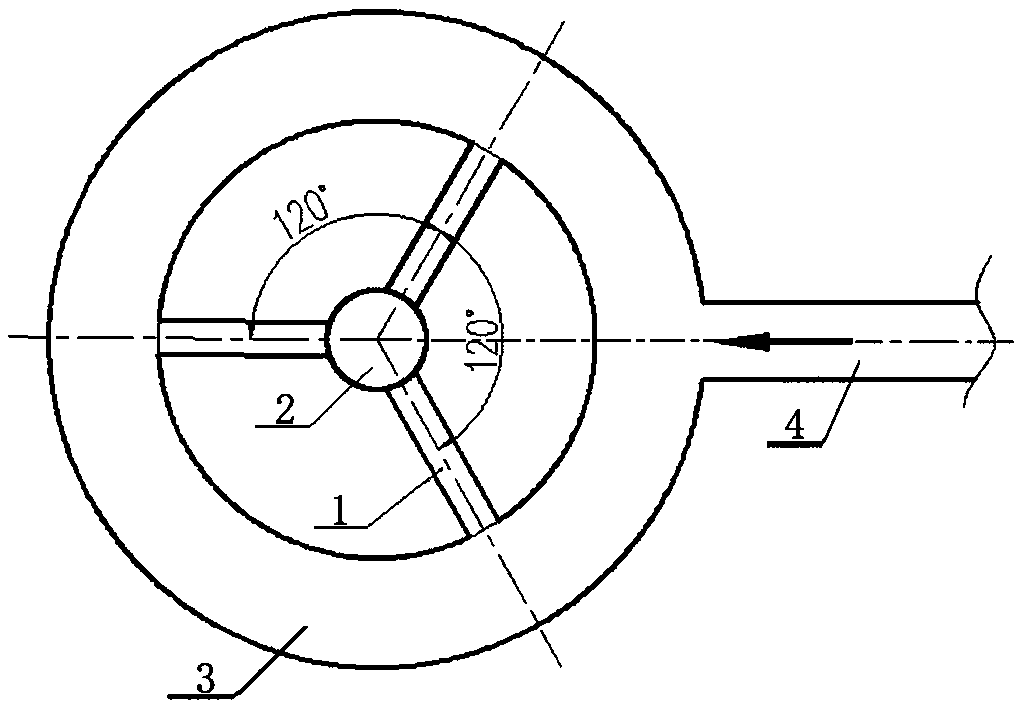

[0019] A kind of lime kiln air supply system of the present invention, as Figure 1~2 As shown, it includes an exhaust fan, an air supply pipeline 4, and an air collecting box 3, and the exhaust fan is fixedly connected with the air supply pipeline 4, and the described air collecting box 3 is circular, and the air collecting box 3 is fixedly connected with the air supply pipeline 4, Three air supply branch pipes 1 are provided on the circular inner wall of the air collection box 3, and the included angles between the three air supply branch pipes 1 are all 120°, and the other ends of the three air supply branch pipes 1 are intersected with a wind cap 2 , the hood 2 is a multi-layer tower structure with the same diameter, and each layer of the hood 2 is evenly arranged with a plurality of air supply holes every week, and each layer of the hood 2 is evenly arranged with a plurality of air outlets every week; the hood 2 is A 10-story tower structure with the same diameter; the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com