Sludge low-temperature drying machine and using method thereof

A drying machine and sludge technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc. Problems such as difficulty in maintenance and repair, to achieve the effect of good sludge forming effect, beneficial to sludge drying, and improving the processing capacity of a single unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

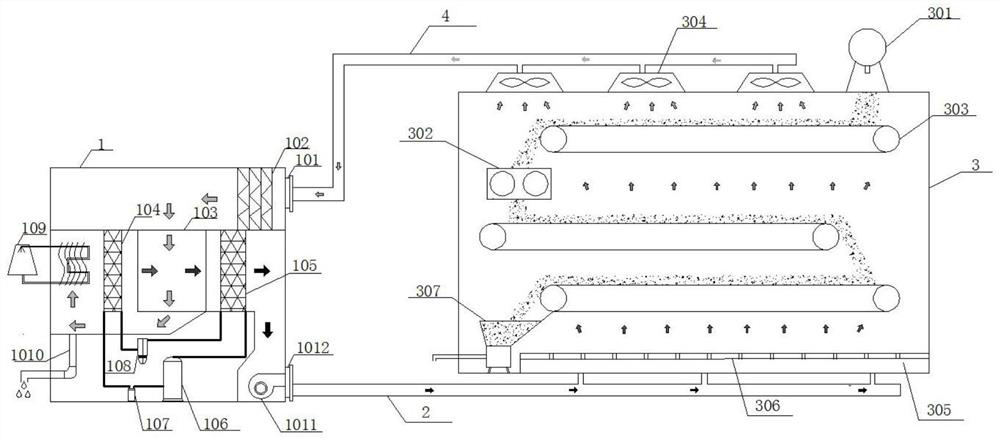

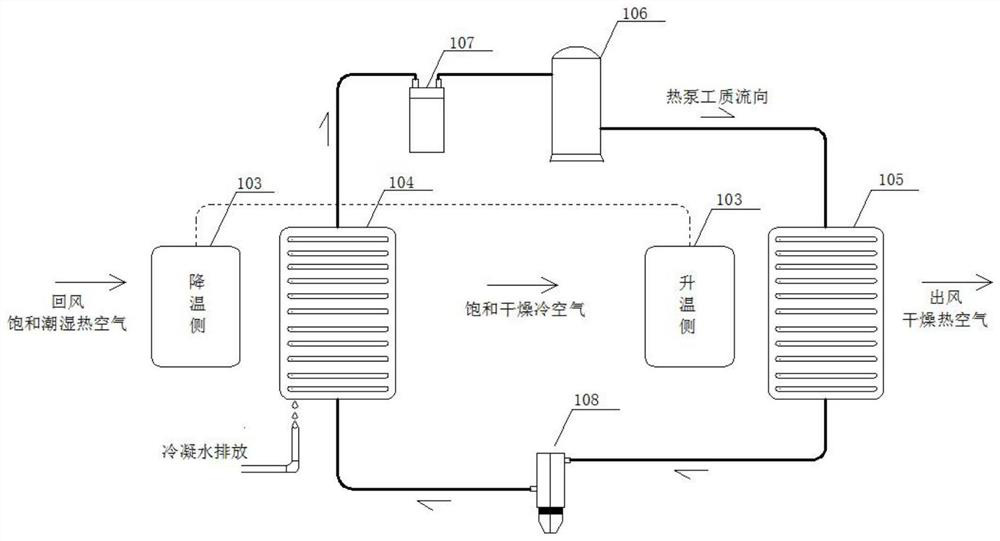

[0036] The technical solution in the present invention will be clearly and completely described in conjunction with the drawings of the embodiments below, and the direction in the figure is marked as the wind flow direction or the flow direction of the working fluid in the heat pump.

[0037] A low-temperature sludge drying machine is composed of a heat pump chamber 1 and a sludge drying chamber 3, wherein the heat pump chamber 1 and the sludge drying chamber 3 are separately placed in two boxes, and the two are relatively independent. The heat pump chamber 1 is composed of compressor 106, evaporator 104, condenser 105, regenerator 103, expansion valve 108, gas-liquid separator 107, heat dissipation water cooling tower 109, condensed water drainage pipe 1010, heat pump room air supply fan 1011, dust removal filter device 102, heat pump chamber air supply port 1012 and heat pump chamber return air port 101; the sludge drying chamber 3 is composed of primary sludge forming device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com