Sludge drying burning combination treatment method

A sludge drying and combined treatment technology, which is applied in combustion methods, dehydration/drying/thickened sludge treatment, incinerators, etc., can solve the problem of wear and corrosion of the heating surface at the tail, narrow applicability of wet sludge, and pollution of heat transfer working fluid etc. to achieve the effects of reducing the amount of fly ash, reducing energy consumption, and simplifying the working fluid heat transfer system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

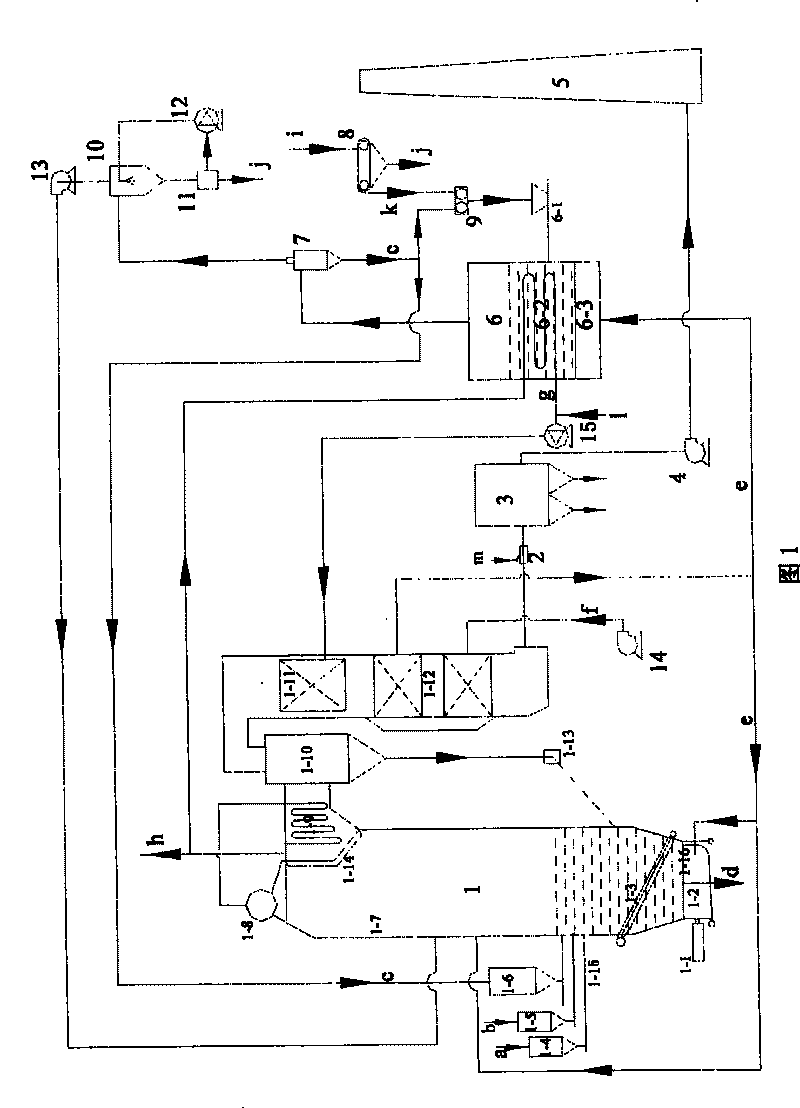

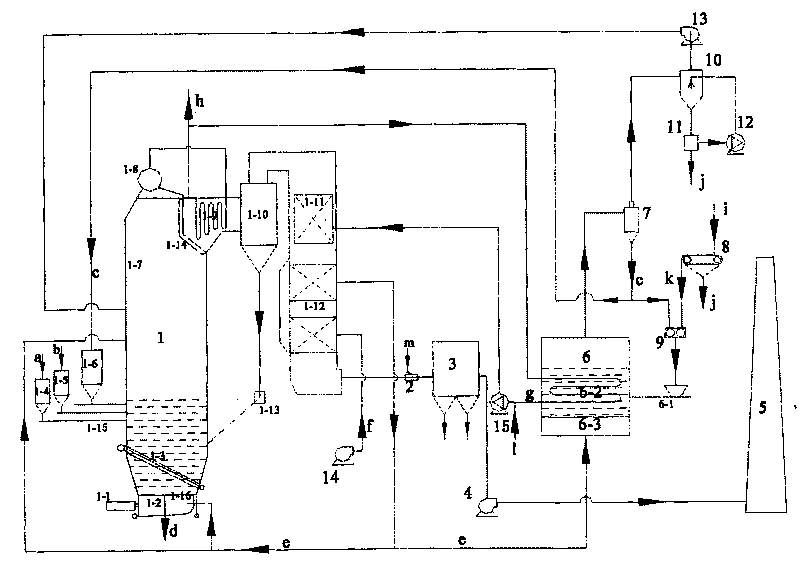

[0026] specific implementation plan

[0027]The present invention adopts a low-magnification circulating fluidized bed incinerator, the circulation rate is 2-3, and the cross-sectional state flow velocity in the incinerator is 1.5-3m / s, mainly based on the following considerations: ①The dry sludge has a small particle size and a critical fluidization velocity Small; ②The wear rate of the buried pipe in the dense-phase area of the incinerator is proportional to the cube of the flow velocity, and reducing the flow rate is conducive to reducing the wear of the buried pipe by particles in the dense-phase area and prolonging the service life of the buried pipe; ③Increasing solid particles and gas The residence time in the incinerator is conducive to the combustion of sludge and the decomposition of dioxins; ④ In the case of ensuring the residence time of the gas, the height of the incinerator can be effectively reduced; Reduce the amount of fly ash, reduce the workload of the cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com