Leather tanning chromium-containing waste treatment method

A treatment method and waste technology, which is applied in the field of roasting treatment of chromium-containing waste from leather tanning, can solve the problems of high recovery rate, less secondary hazardous waste, and difficult disposal of hazardous waste, and achieve the chromium content of waste residue The effect of reducing toxicity, saving production cost, and reducing chromium content in waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

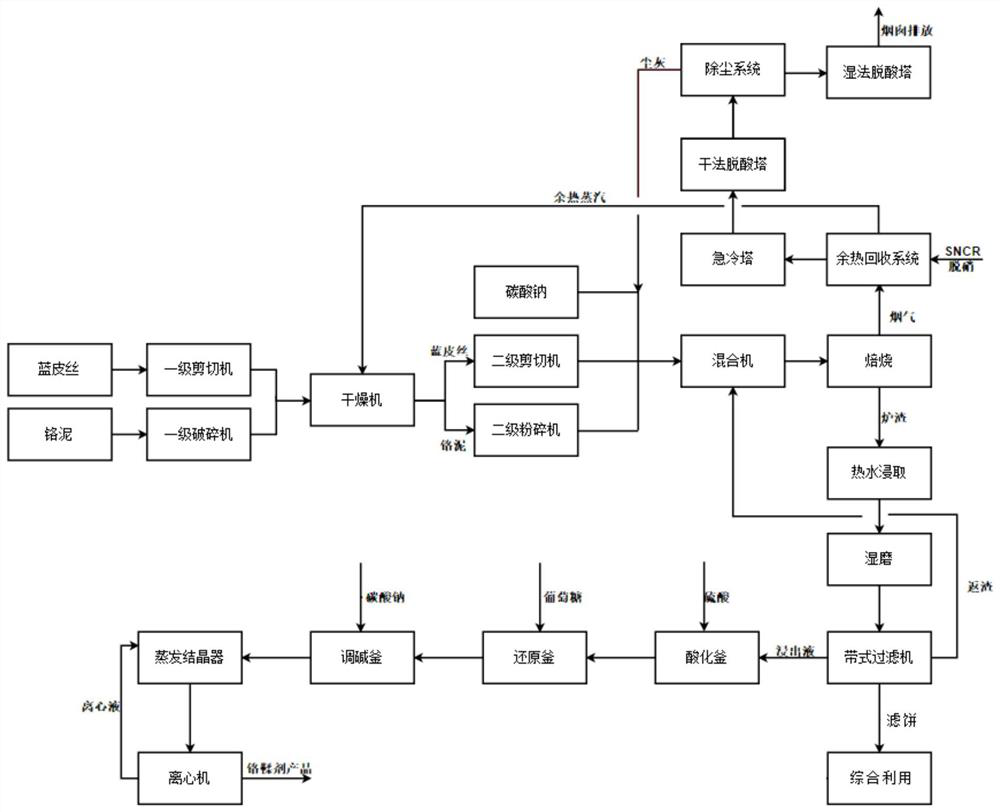

[0033] refer to figure 1 A method for treating chromium-containing waste from leather tanning of the present embodiment includes four sections of pretreatment, roasting, posttreatment and flue gas treatment, and the specific steps are as follows:

[0034] (1) Pretreatment of the raw materials to be processed: (1) Processing of raw chrome leather scraps: pass the raw chrome leather scraps to be processed through a shearing machine, and coarsely crush large pieces of extruded chrome leather scraps to obtain coarsely crushed chrome leather Chips; Drying: Coarsely crushed chrome leather chips are dried with a belt dryer at a temperature of 60-70°C to reduce the moisture content to 13%, and then enter the secondary grinder to be crushed into particles with a particle size of no more than 140 μm. Leather powder, stored in the chrome leather shavings silo; (2) Processing of raw material chrome sludge: Large pieces of chromium sludge are coarsely crushed through a primary crusher to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com