Compound-type waste incineration boiler

A waste incineration and compound technology, which is applied in the boiler field to achieve the effects of improving heat exchange efficiency, reducing height, and evenly distributing flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

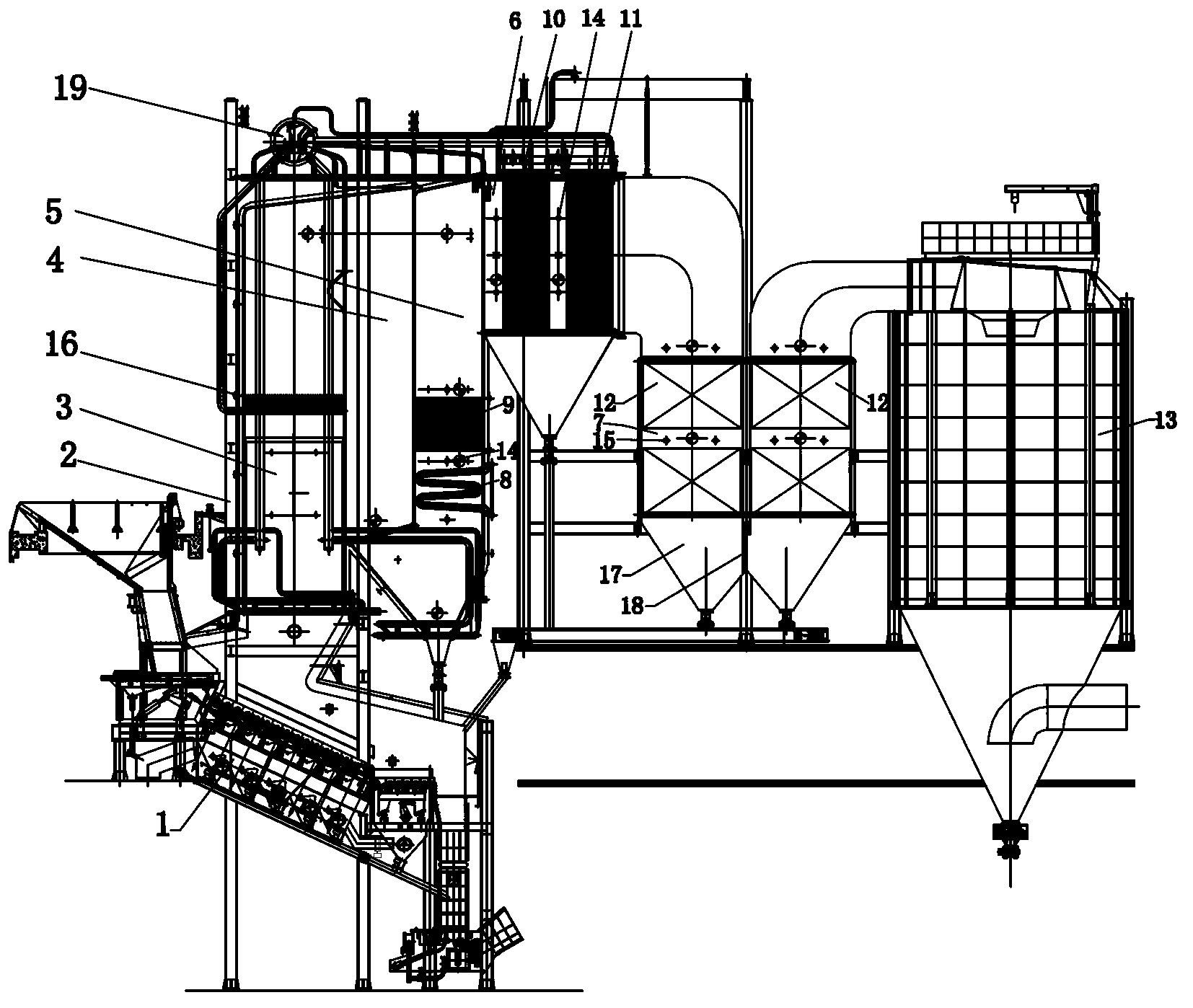

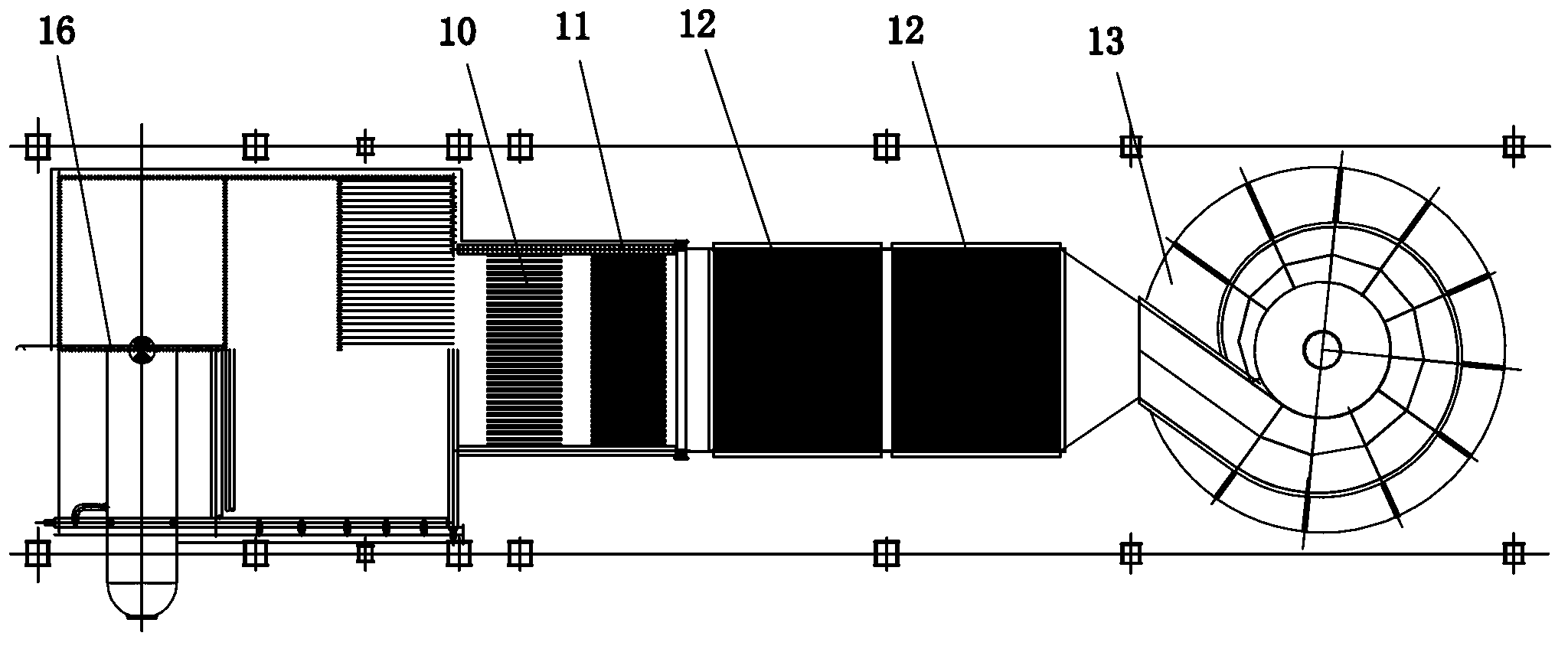

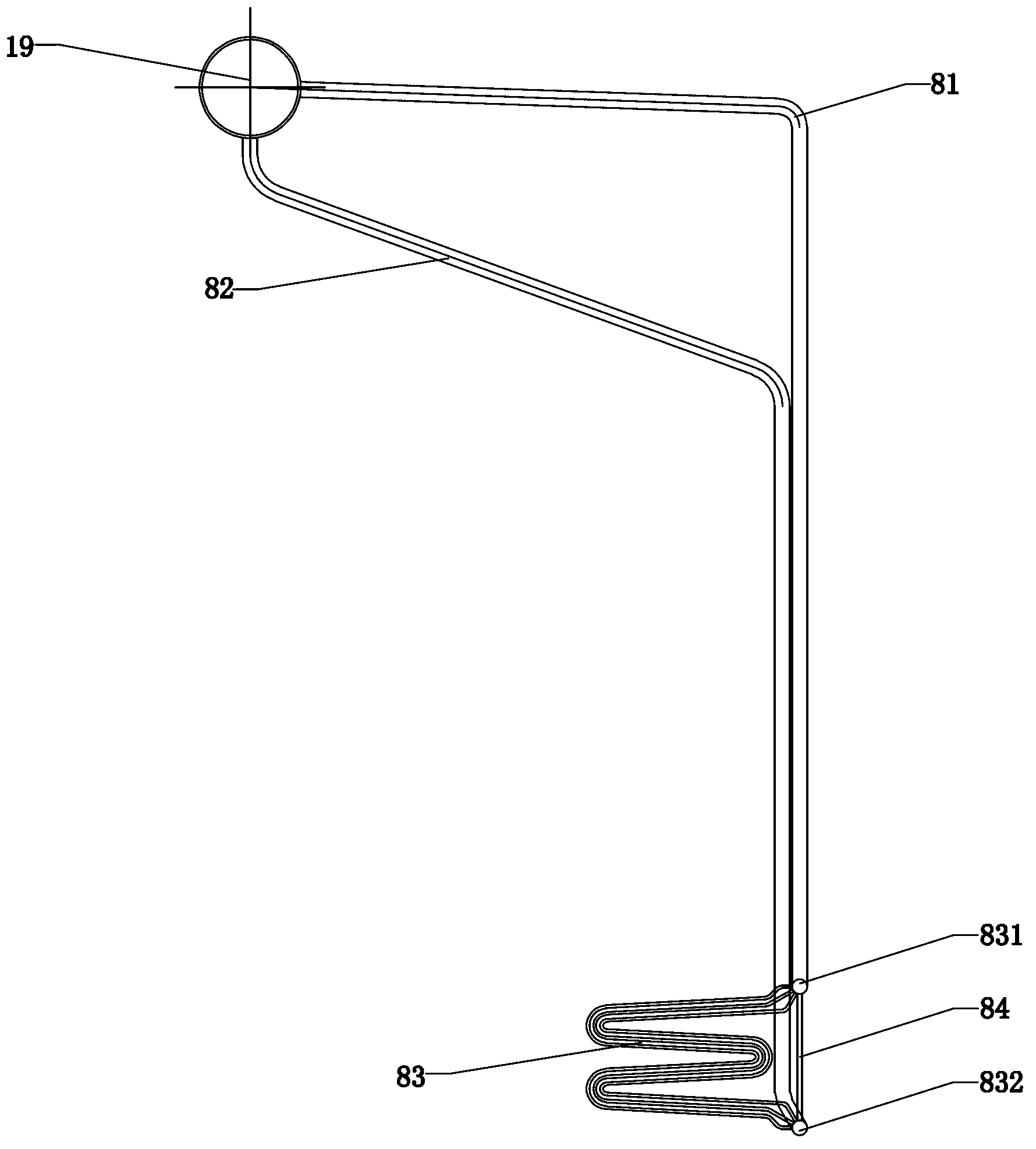

[0018] As shown in the figure: 1 is the grate, 2 is the steel frame, 3 is the hearth, 4 is the ember chamber, 5 is the three flues, 6 is the horizontal flue, 7 is the tail U-shaped flue, and 8 is the Σ-shaped convection Tube device, 9 is high temperature superheater, 10 is medium temperature superheater, 11 is low temperature superheater, 12 is economizer, 13 is neutralization reaction tower, 14 is steam soot blower, 15 is shock wave soot blower, 16 17 is a lower ash hopper, 18 is a trough separator, 19 is a drum, 81 is an ascending pipe, 82 is a descending pipe, 83 is a convection pipe bundle, and 84 is a recirculation pipe.

[0019] Such as figure 1 , figure 2 and image 3 As shown, a composite waste incineration boiler includes a steel frame 2, a fire grate 1, a furnace chamber, a horizontal flue 6 and a tail U-shaped flue 7, and the furnace chamber includes a furnace 3, an ember chamber 4 and three Flue 5. A water-cooled partition wall 16 is arranged on the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com