Boiler with water pipes and fire pipes with flow in opposite directions

A positive and negative, water and fire technology, applied in the combustion chamber, combustion method, combustion equipment and other directions, can solve the problems of poor ignition performance of the furnace, low mixing performance, excessive smoke and dust emissions, etc., to reduce the amount of ash and increase labor. Intensity, combustion stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

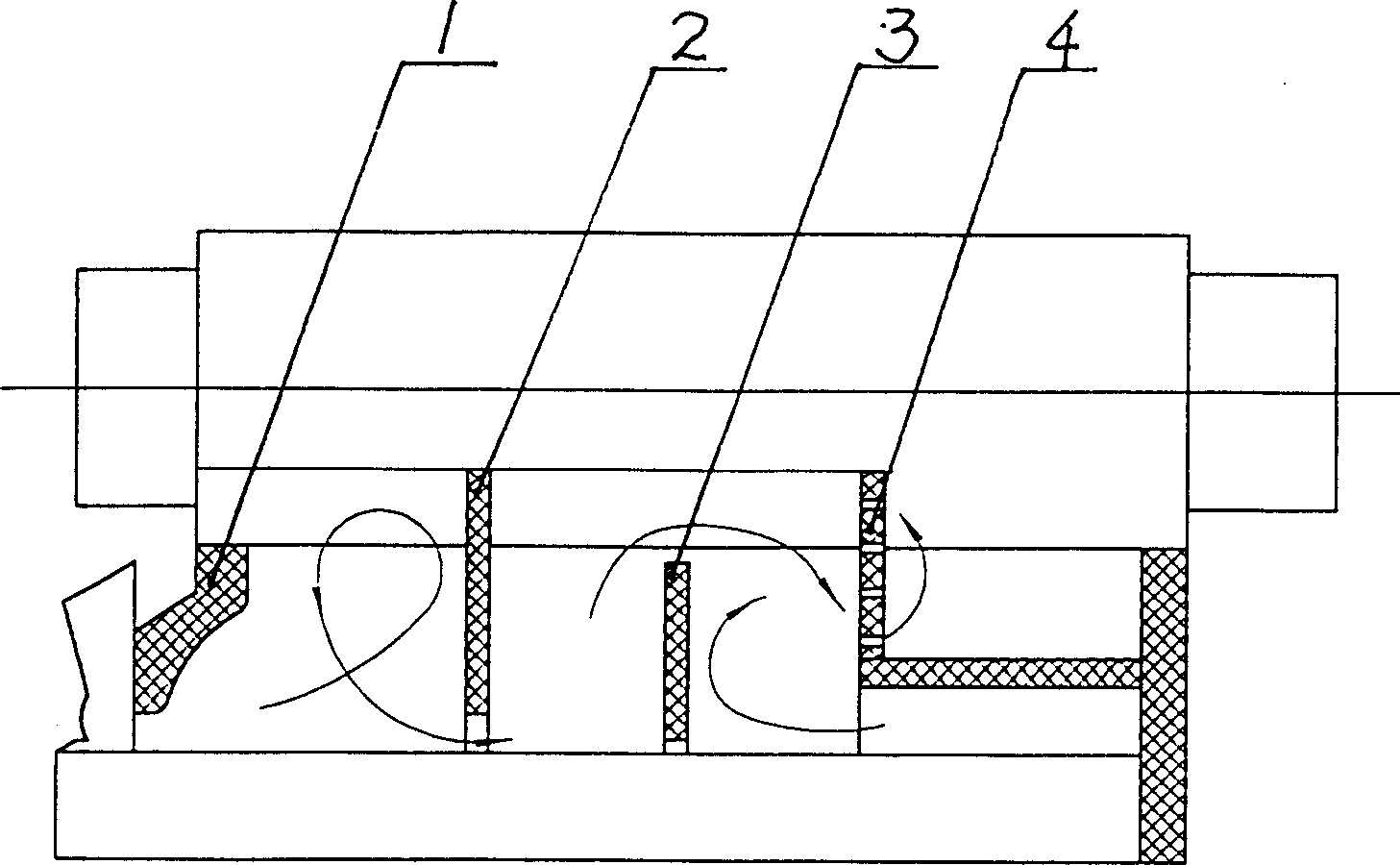

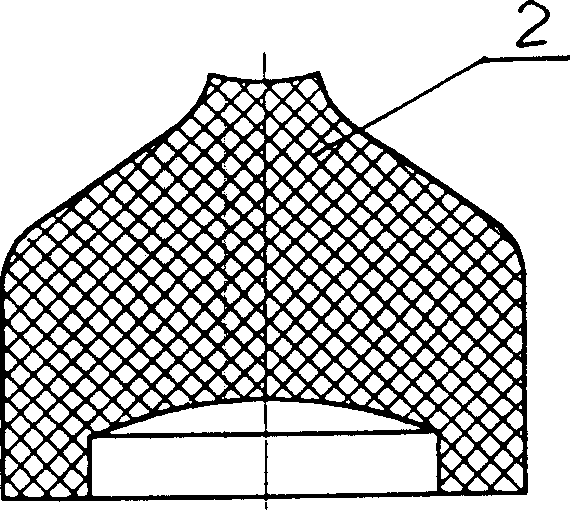

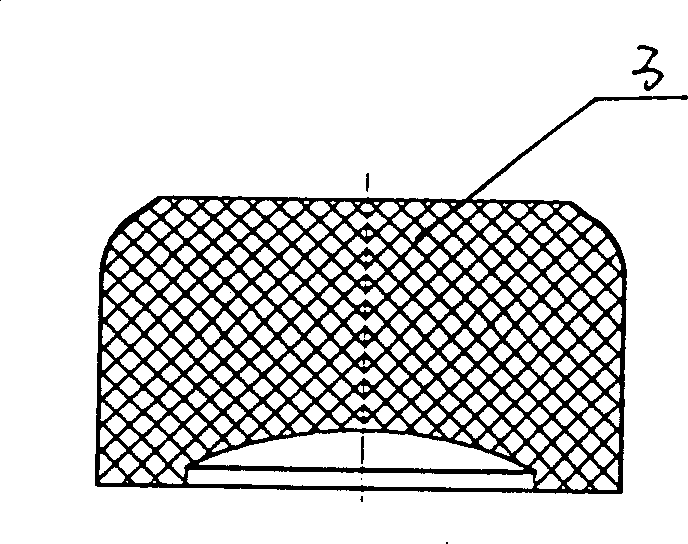

[0011] Water and fire tubes are facing countercurrent combustion boilers such as Figure 1~5 As shown, it is composed of a drum, a combustion chamber and a fire grate. In the combustion chamber, a front arch 1, an I-type arch 2, a II-type arch 3 and a III-type arch 4 are set, and a fire burner is provided on the arch. The lower part of the Type I vertical arch has a flame burner, the lower part of the Type II vertical arch has a flame burner, and the upper part of the Type II vertical arch has a gap with the top surface of the combustion chamber. All have fire burners, and the through-hole type III vertical arch has fire burners in the middle and upper parts, and the flow curve of the flue gas in the combustion chamber is as follows: figure 1 indicated by the arrow. It can be produced by using normal boiler processing technology to meet various index requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com