Horizontal combined fuel oil and gas biomass steam generator

A steam generator and combined technology, which is applied in steam generation, steam boilers, steam boiler accessories, etc., can solve the problems of ineffective use, less flue gas return, and low combustion efficiency, so as to improve heating efficiency and increase Large radiant heating surface and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

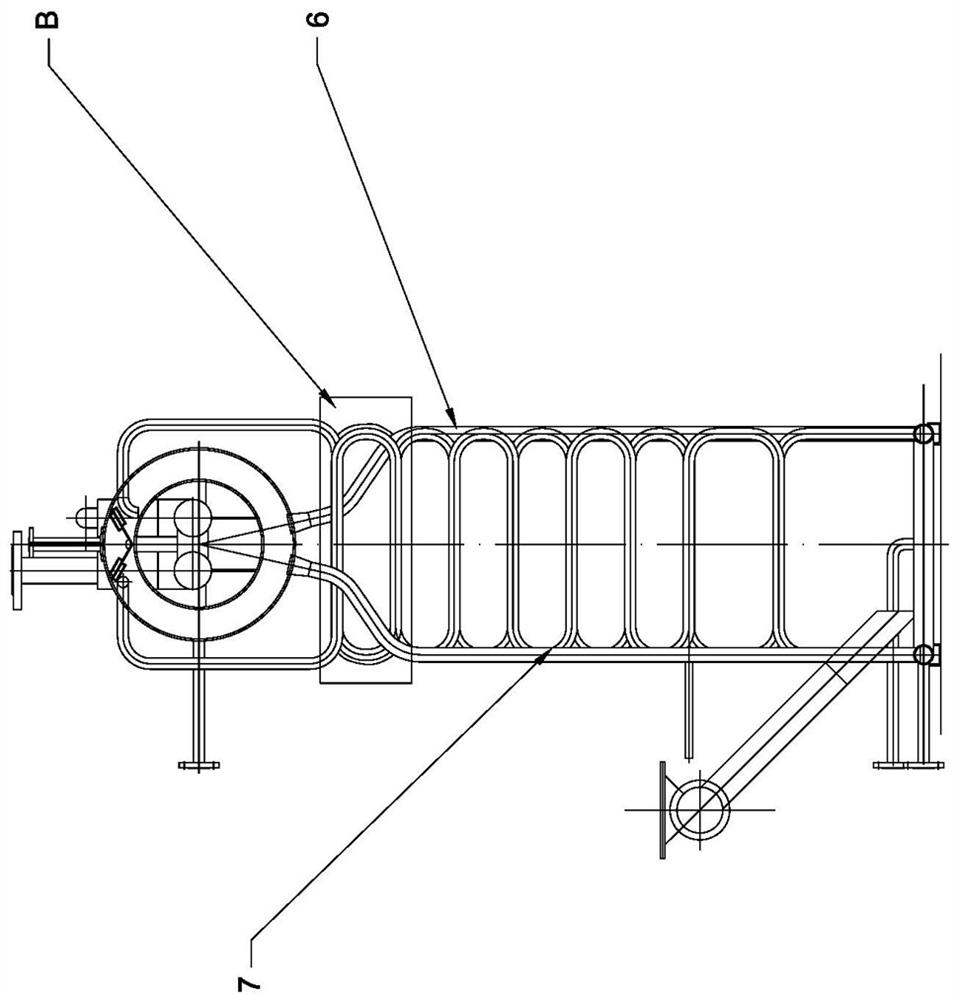

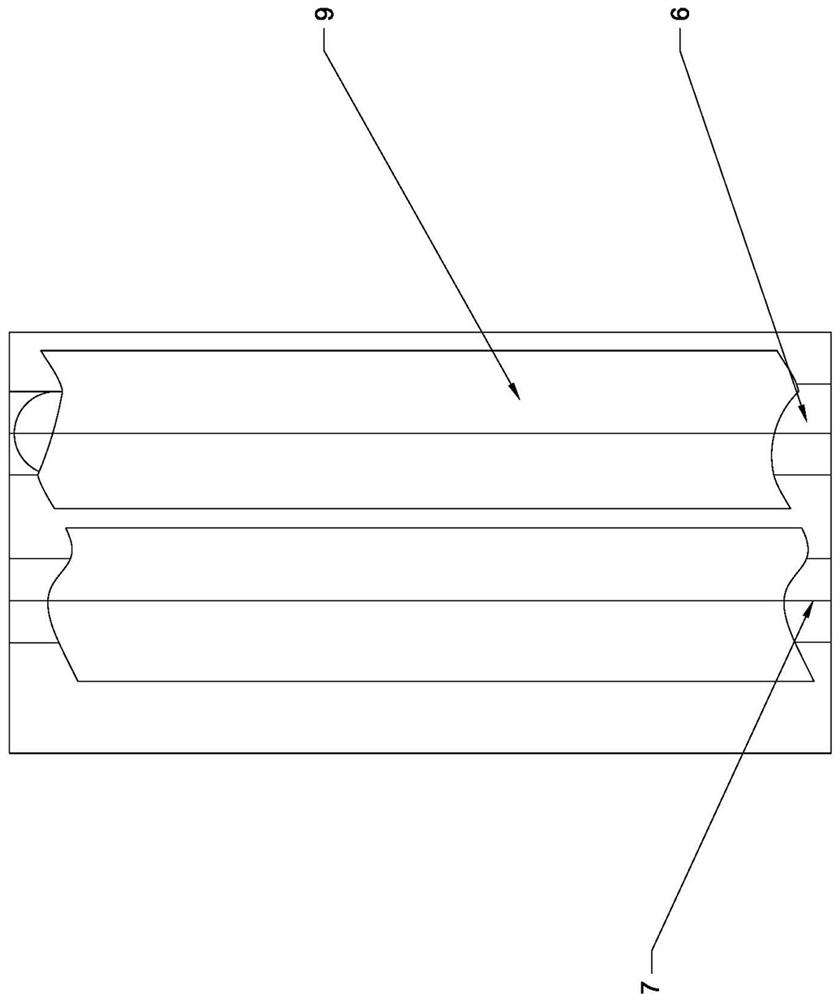

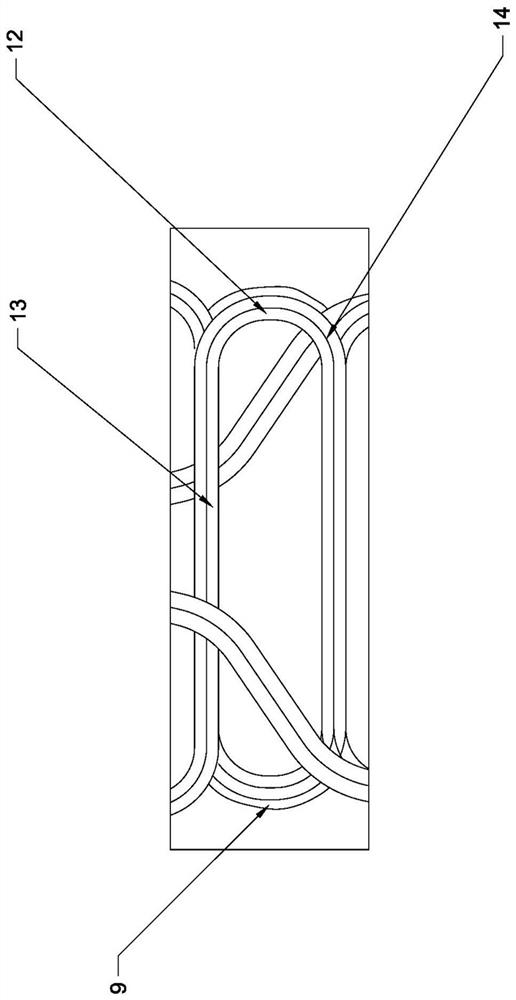

[0021] Such as Figure 1-6 As shown, the object of the present invention is achieved as follows: a horizontal combined fuel-fired biomass steam generator includes an evaporator body 5, the evaporator body 5 includes a base 4, and a lower set arranged on the base 4 Box, located in the hearth 10 on the lower header, the hearth 10 is provided with a boiler drum 1 correspondingly, a downcomer 2 is also provided between the boiler tube 1 and the lower header; between the boiler tube 1 and the lower header is provided Several groups of heating surface tube assemblies 16, which are located between the lower header and the drum 1. The drum 1 is equipped with a steam-water separator and an annular reheating tube 11; the annular reheating tube 11 is correspondingly arranged There is a main steam valve; the drum 1 is also equipped with a safety valve and a pressure gauge respectively; a feeder 17 is provided beside the furnace 10; the heating surface tube assembly 16 is provided with seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com