Efficient energy-saving environment-friendly steam generator

A steam generator, high-efficiency and energy-saving technology, applied in the direction of steam generation, steam generation method using pressure combustion, steam boiler, etc., can solve the problems of high harmful gas content, high exhaust gas temperature, low thermal efficiency, etc., to achieve cost reduction and The equipment takes up space, solves the effect of tube explosion under long-term high temperature, and reduces the temperature of the furnace outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

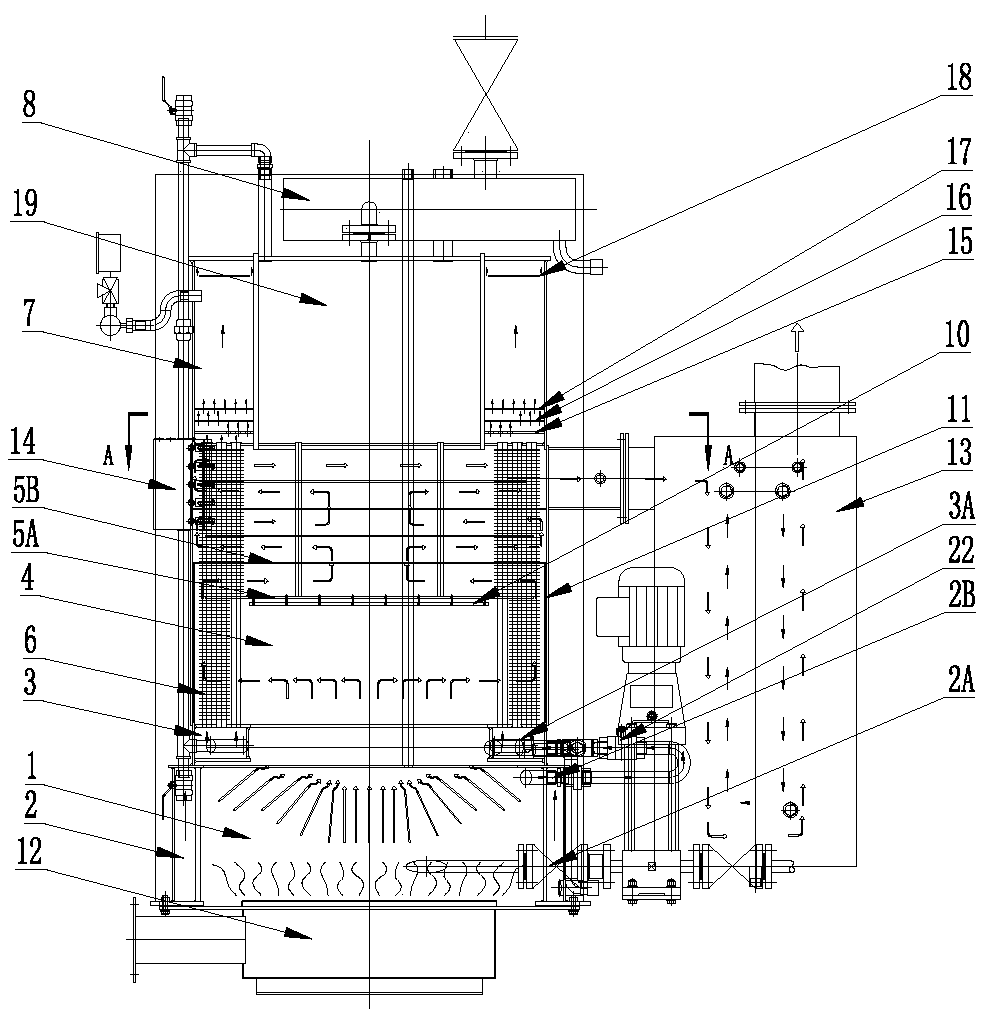

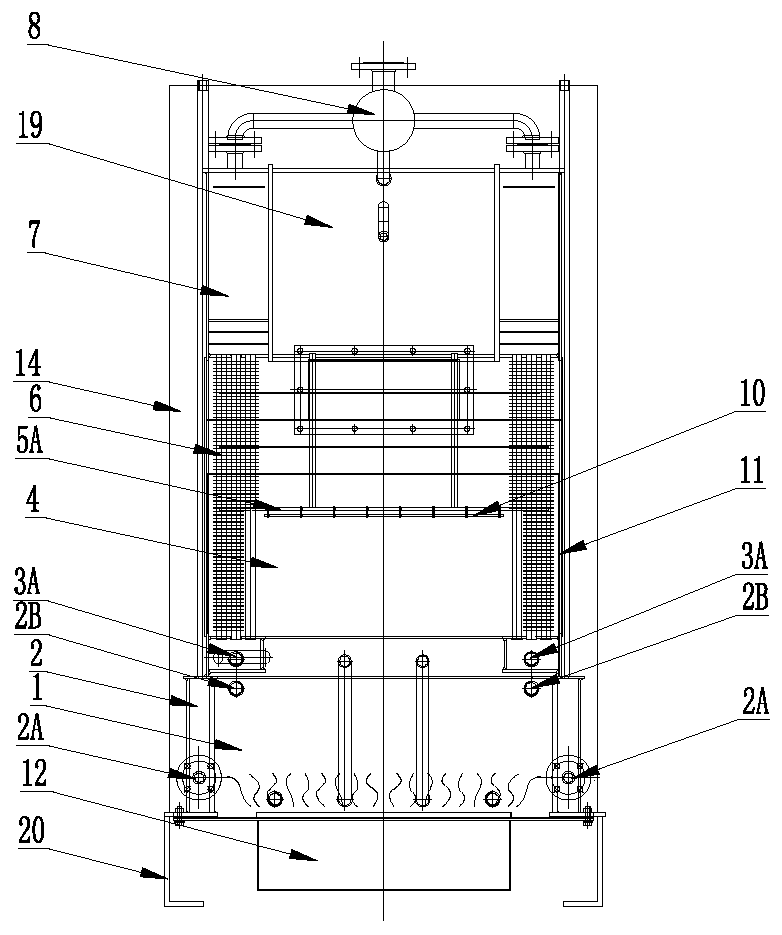

[0023] Such as Figure 1-3 The high-efficiency, energy-saving and environment-friendly steam generator shown includes a combustion chamber 1, and a flat full premix burner 12 is arranged at the bottom of the combustion chamber 1. The planar fully premixed burner 12 is accommodated in the support base 20 located in the combustion chamber 1, which saves space, avoids interference during use, and is safe and reliable. The outer ring of the side wall of the combustion chamber 1 is provided with a lower pressure-bearing water jacket 2 . The top ring of the combustion chamber 1 is provided with an upper pressurized water jacket 3 . The center of the top of the combustion chamber 1 communicates with the bottom of the heat exchange chamber 4. A smoke partition is arranged horizontally in the heat exchange chamber 4. A heat exchange tube 6 is arranged around the inner side of the heat exchange chamber 4. The lower end of the heat exchange tube 6 is connected to the upper pressurized w...

Embodiment 2

[0029] Such as Figure 4 The high-efficiency, energy-saving and environment-friendly steam generator shown has the same structure as figure 1 The embodiments are basically the same, the only difference is: the setting position and type of the burner. In this embodiment, the burner 12 is arranged on one side of the combustion chamber 1, and the burner 12 adopts a cylindrical fully premixed burner (ordinary low-nitrogen side-fired low-nitrogen burner can also be used), and the working end of the burner 12 extends into the combustion chamber 1. The bottom of the inner wall of the combustion chamber 1 is provided with a refractory cement layer 21 .

Embodiment 3

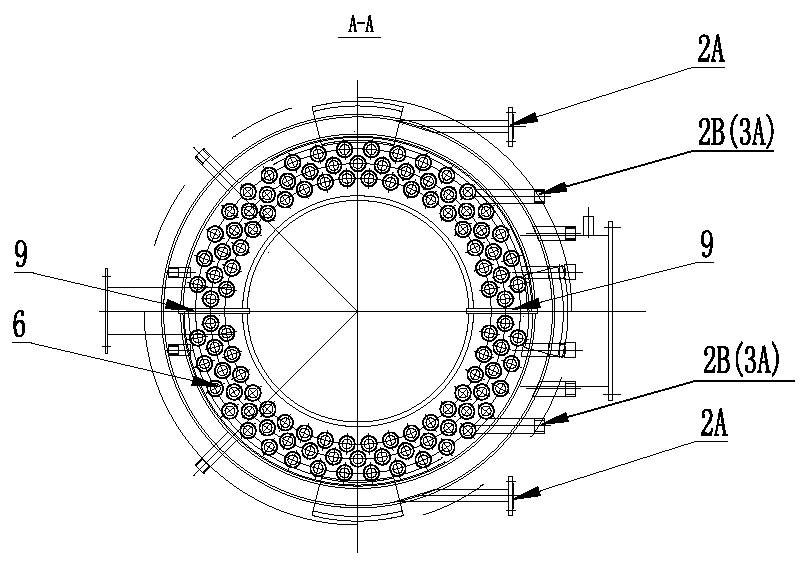

[0031] The high-efficiency, energy-saving and environment-friendly steam generator structure and figure 1 The embodiments are basically the same, the difference lies in: the number of sub-steam generators. Figure 5 The structure of the high-efficiency energy-saving and environment-friendly steam generator of embodiment 3 and figure 1 The high-efficiency, energy-saving and environment-friendly steam generator structure shown in the same position (ie figure 1 Sectional view at A-A). It can be seen from the figure that in this embodiment, the lower pressurized water jacket 2, the upper pressurized water jacket 3, the heat exchange tube 6 and the steam uniform chamber 7 are divided into three parts by three vertical partitions 9, so that Three sub-steam generators are formed. Correspondingly, there are 3 groups of water jacket water inlet 2A, water jacket water outlet 2B, and boiler water inlet 3A. Compared with Example 1, this structure further increases the design water cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com