Integrated pump valve module

An integrated, pump-valve technology, used in cardiac catheterization, massage aids, physical therapy, etc., can solve the problems of difficult to guarantee the accuracy of measurement data, difficult to guarantee sealing and reliability, unstable cuff airflow, etc. Low cost, meet the requirements of sealing, excellent rigidity and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

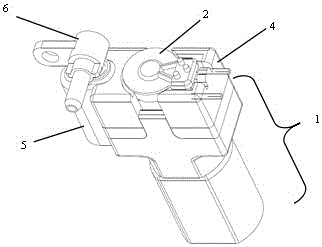

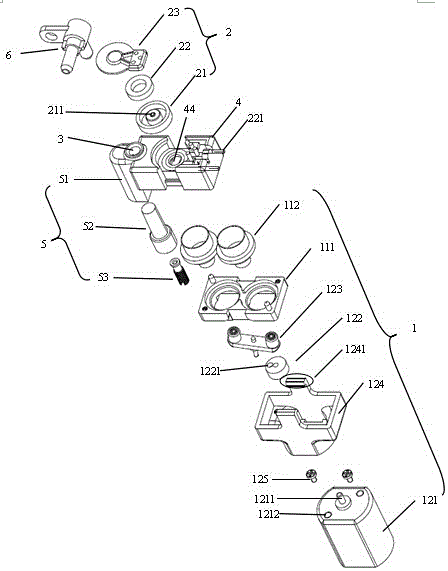

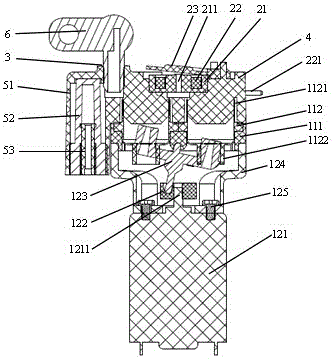

[0024] Such as figure 1 , figure 2 with image 3 As shown, the integrated pump valve of the present invention includes a booster pump 1 , an air release valve 2 , an air outlet 3 and an upper cover 4 , wherein the air outlet 3 and the air release valve 2 are both arranged on the upper cover 4 . The deflation valve 2 is a solenoid valve. The bottom of the upper cover 4 includes two annular grooves 41, 42, and the annular grooves 41, 42 open downward. Two pistons 112 corresponding to the annular grooves 41 , 42 are provided in the booster pump 1 . The inner surfaces of the two annular grooves 41, 42 are in close contact with the upper ends 1121 of the two pistons, and the opposite side 43 of the two annular grooves 41, 42 is directly connected to the opening 44 at the top of the upper cover at the bottom of the grooves. The opening 44 is located below the deflation valve 2, and the bottom end of one annular groove 41 on the side 45 away from the other annular grooves 42 dir...

Embodiment 2

[0033] On the basis of Embodiment 1, a slow air release valve 5 is also provided on the side of the upper cover 4 close to the air outlet 3 , and the air flow channel of the slow air release valve 5 communicates with the air flow channel of the upper cover 4 . The slow release valve 5 can be a normally open small hole arranged on the upper cover 4; the following structure can also be adopted: the slow release valve 5 is composed of a core seat 51, a rubber core 52 and a copper core 53, and the core seat 51 There is an air core chamber for the passage of gas, the air core chamber communicates with the air flow channel in the upper cover, the rubber core 52 is placed in the air core chamber, one end of the rubber core 52 is closed and the other end is open, the rubber core 52 The open end of the core seat 51 is interference fit with the end of the core seat 51. There is a cutout 54 on the side wall of the rubber core 51. The length of the cutout 54 in the radial direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com