Boiler drum longitudinally arranged chain grate hot water boiler

A chain grate and hot water boiler technology, which is applied in the field of hot water boilers, can solve the problems of easy blockage of pipes, low heat efficiency of boilers, large coal consumption, etc. large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

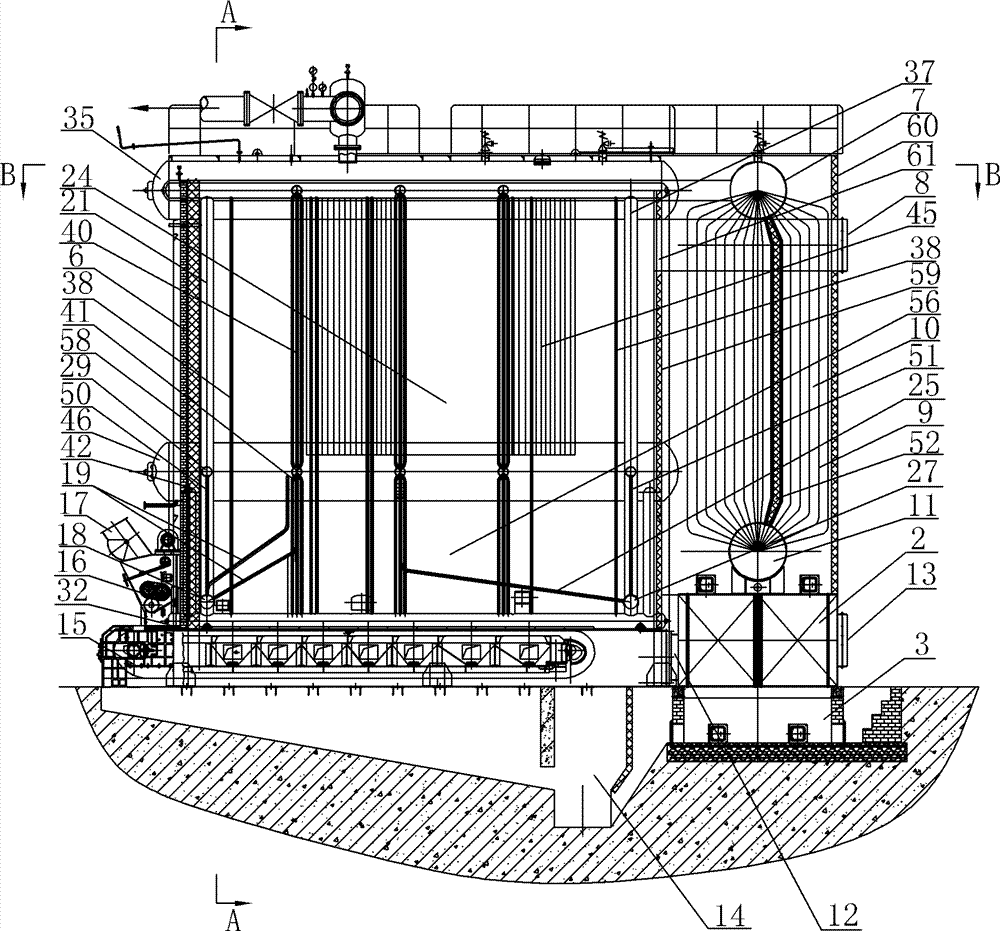

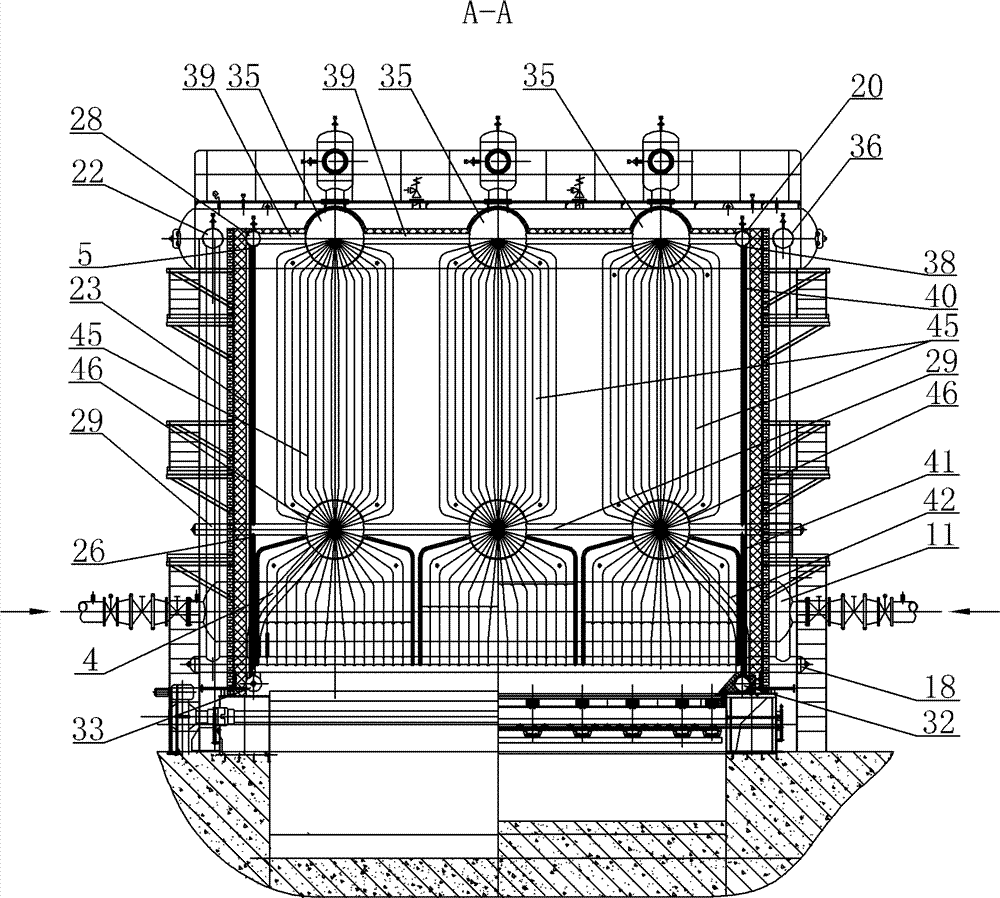

[0015] Specific implementation mode one: combine Figure 1 ~ Figure 4Describe this embodiment, the drum vertical chain grate hot water boiler in this embodiment includes a furnace body 6, a layered coal feeder 16, a coal feeder 17, a large beam chain grate 15, a front arch 57, and a rear arch 54 , the left anti-coking box 33, the right anti-coking box 32, a plurality of upper drums 35 and a plurality of lower drums 46 consistent with the number of the upper drums, the bottom of a plurality of upper drums 35 is the furnace 24, the The lower rear end of the large beam chain grate 15 is provided with a slag outlet 14, and the coal feeder 17 is arranged in front of the front wall 58 of the furnace body and directly above the input end of the large beam chain grate 15, and the layered coal feeder 16 is set between the coal feeding hopper 17 in front of the front wall 58 of the furnace body and the input end of the large beam chain grate 15, and the output end of the large beam chai...

specific Embodiment approach 2

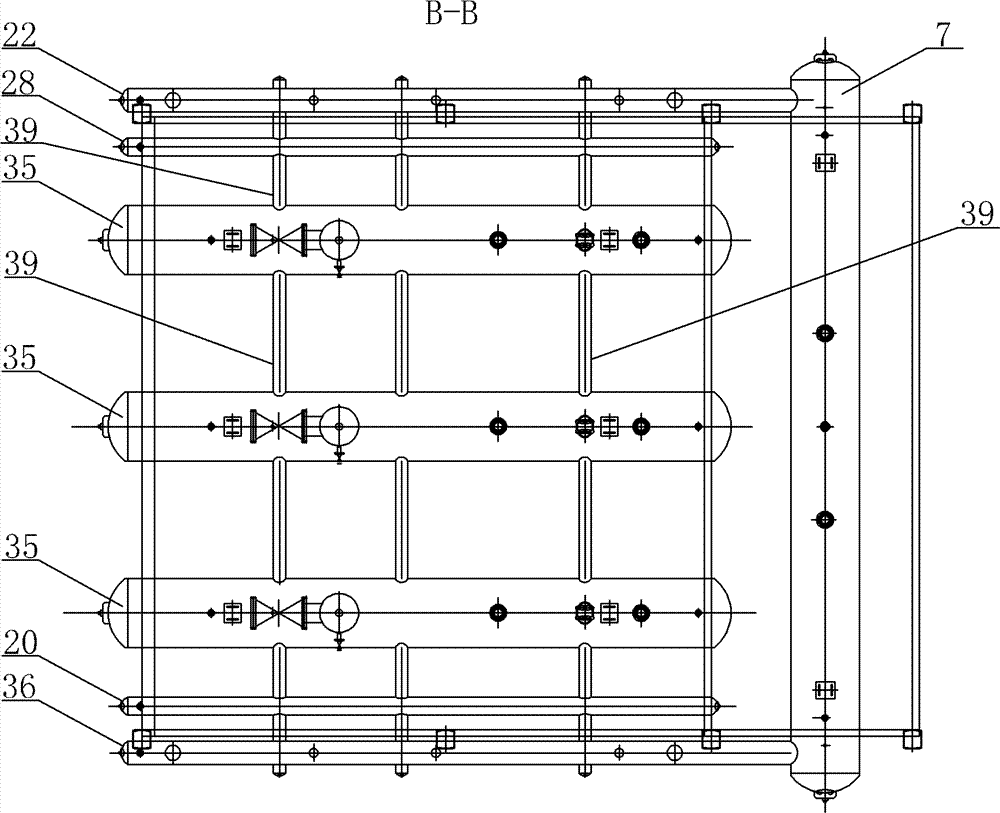

[0016] Specific implementation mode two: combination figure 1 Describe this embodiment, the convection economizer 9 described in this embodiment includes an upper cylinder 7, a lower cylinder 11 and a set of convection tube bundles 10, the upper end of the convection tube bundle 10 communicates with the upper cylinder 7, and the convection tube bundle 10 The lower end communicates with the lower cylinder 11, the lower cylinder 11 at the bottom of the convection economizer 9 communicates with the pipe network water collector, and the upper cylinder 7 of the upper part of the convection economizer 9 is respectively connected to one end of the left longitudinal water pipe 22 and One end of the right vertical water pipe 36 is connected, and a second baffle wall 52 is arranged longitudinally between the upper cylinder body 7 and the lower cylinder body 11 . With such a setting, the heating surface is large, it is not easy to deposit carbon and dust outside the convection tube bundl...

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 and image 3 Describe this embodiment, the quantity of the upper drum 35 of this embodiment is 3-6. With such a setting, the heating area is large, the thermal efficiency of the boiler is high, and it is not easy to deposit carbon and dust outside the convection tube bundle, and there is no dirt in the convection tube bundle, avoiding the blockage of the convection tube bundle, and at the same time meeting the design requirements. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com