Furnace for combined combustion of methane of garbage leachate and garbage

A landfill leachate and mixed combustion technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of mixed combustion, no auxiliary burner matching structure, and no other problems, so as to avoid coking, simple structure, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

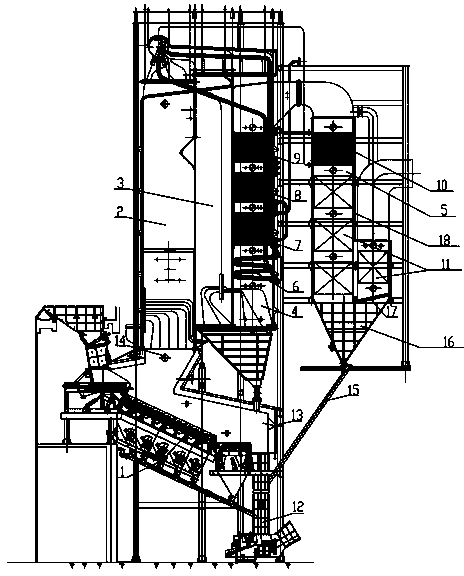

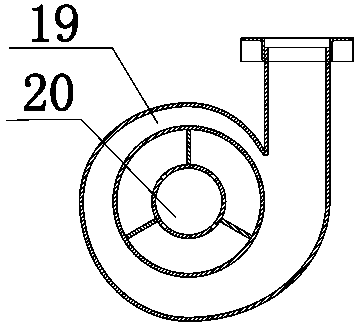

[0024] like Figure 1-2 Shown, the boiler of the methane of a kind of landfill leachate of the present invention and rubbish mixed combustion comprises steel frame, fire grate 1, furnace chamber and tail flue 5, and described furnace chamber connects tail flue 5, and furnace chamber is composed of Composed of a furnace 2, an ember chamber 3 and three flues 4, the fire grate 1 is arranged at the lower part of the furnace chamber, and a slagging and ash-discharging device 12 is arranged below the fire grate 1, which is characterized in that the fire grate 1 It is a two-stage reciprocating fire grate. A biogas burner 14 for landfill leachate is installed on the lower part of the furnace 2 and on the side wall above the fire grate 1. The rear wall of the lower part of the biogas burner 14 is also provided with an ignition burner 13. The biogas burner 14 is a vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com