Method and device for testing delay of detonator delay element

A technology of time-delay testing and procrastination, which is applied in the direction of weapon accessories, fuzes, offensive equipment, etc., can solve the problems of low efficiency, high test cost, and long time-consuming period, and achieve safe and convenient operation, improve work efficiency, and short time-consuming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

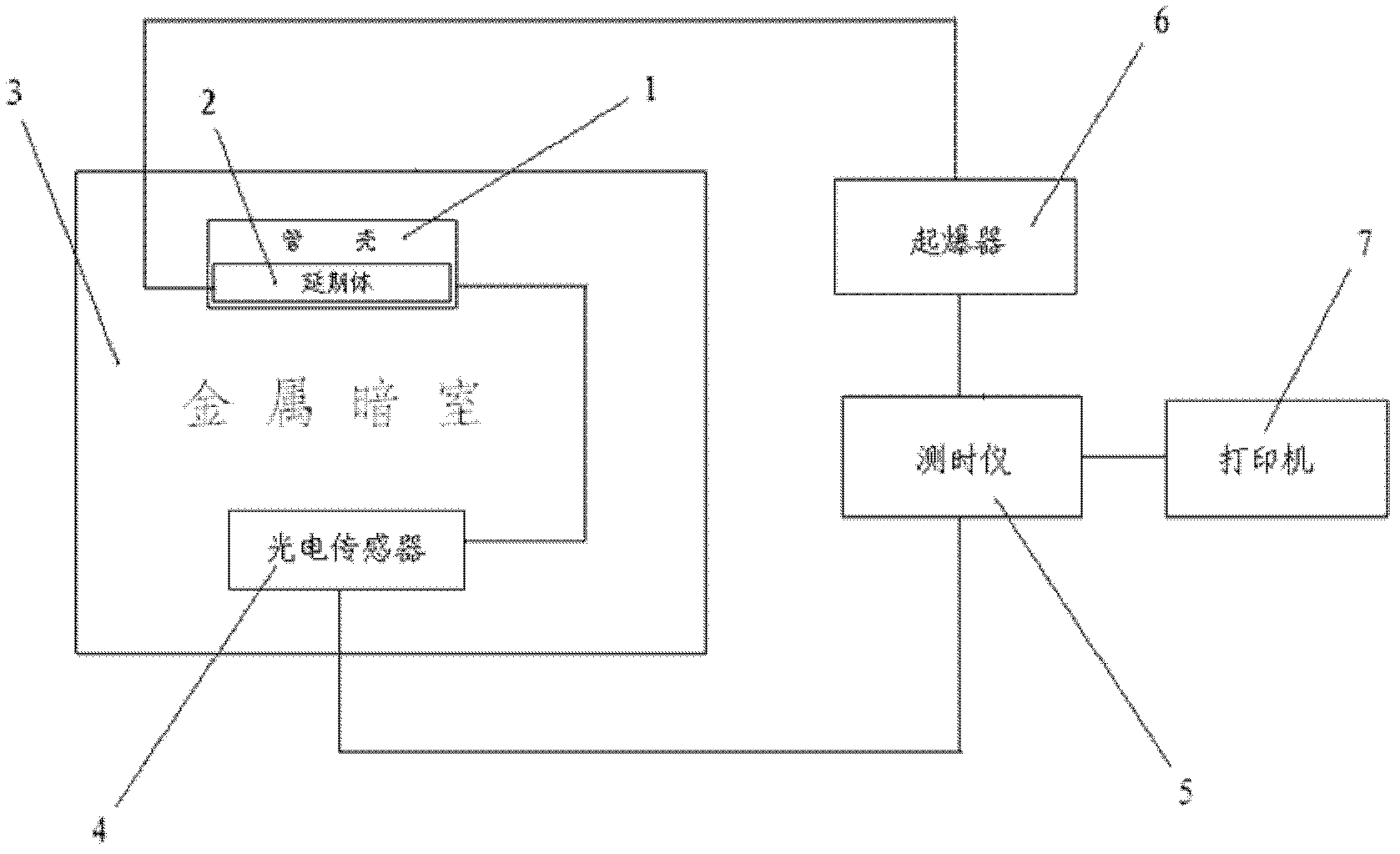

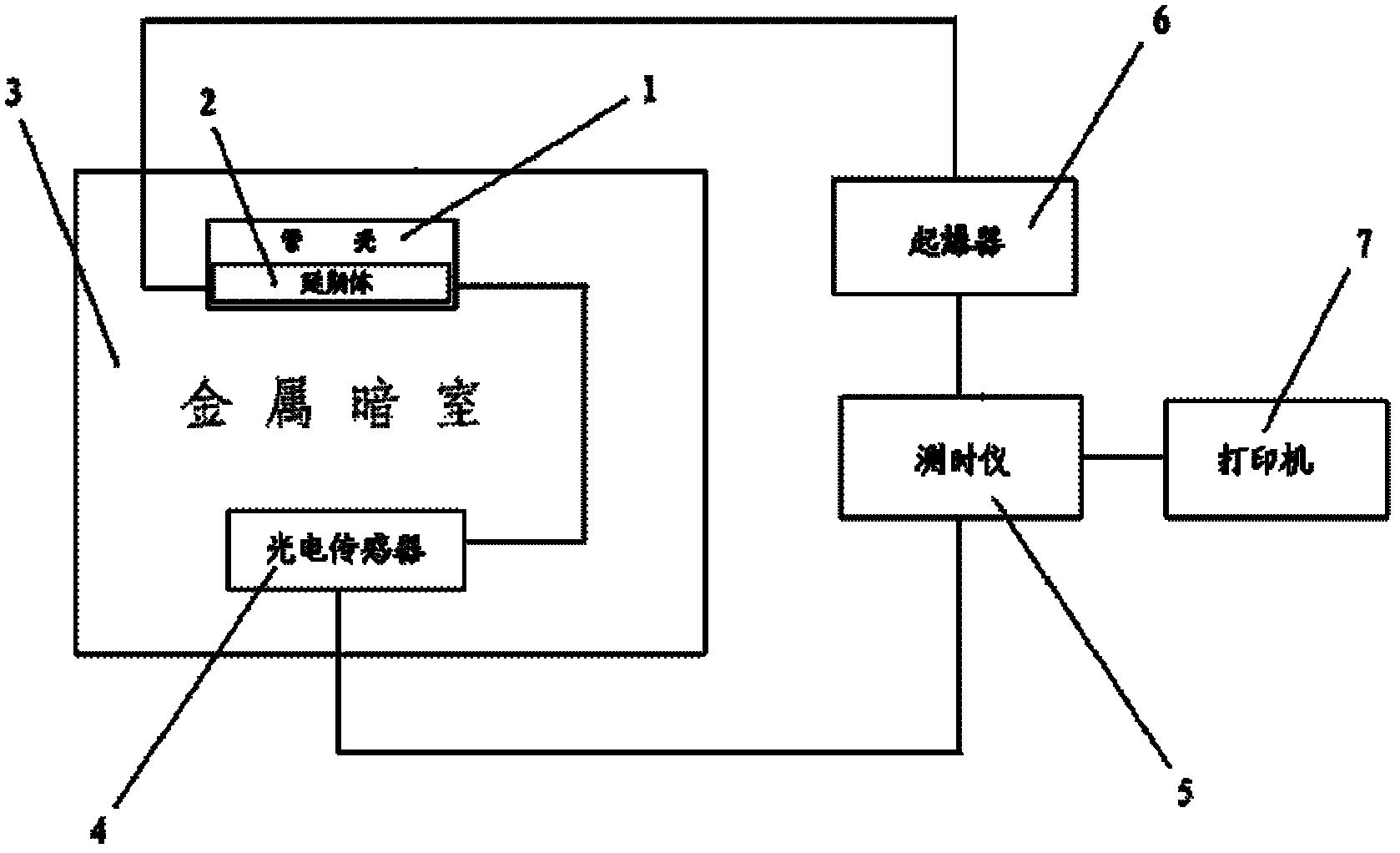

[0023] Such as figure 1 As shown, a method for testing the time delay of a detonator delay body comprises the steps of: putting the cut lead delay body 2 into a steel pipe with both ends open and a length of 50 mm to 80 mm (the length of the shell is determined according to the length of the lead delay body). In the detonator shell 1, fix the position of the delay body 2 in the tube shell; load onto the detonator 6 (electric ignition element or detonator) at one end of the delay body 2 for exciting the delay 2; the delay body 2 will be housed Put the tube shell 1 into the metal darkroom 3; install the photoelectric sensor 4 on the other end of the extension body 2; install the time meter 5, connect the initial signal end to the detonator 6, and connect the termination signal end to the photoelectric sensor 4; use the detonator 6. Activate the delay body 2; read the data di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com