Preparation method of graphene aerogel powder and graphene aerogel powder

A graphene aerogel, graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems affecting processing and use performance, powder density increase, pore structure collapse, etc., and achieve a wide range of applications Value and Market Prospect, Effects of Low Density, Process Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the preparation method of the present invention, the graphene-based aerogel in the form of powder particles is directly obtained by freezing the graphene-based slurry or dispersion liquid, pulverizing, sieving and freeze-drying, which can avoid pulverized graphene oxide aircondensation The risk of explosion during the glue process can also increase the drying rate of the freeze-drying process and shorten the production time, and the obtained product has the advantages of good structural stability, high porosity, and low tap density; at the same time, the production process is simple and the operation It is convenient, low in cost, superior in performance, broad in prospect and suitable for mass production. Going further:

[0034] In terms of technology, using this method to treat graphene-based materials can increase the drying surface area of the material to be dried, and increase the freeze-drying rate by 45% to 100%; There is a risk of explosion.

[0035] In t...

Embodiment 1

[0060] A preparation method of graphene airgel powder, comprising the following steps:

[0061] 2kg10mg / mL graphene oxide slurry was frozen at -40°C to make ice cubes to obtain frozen samples; the frozen samples were crushed in the cold storage, and the crushed ice slag could be sieved through a 10-mesh sieve. Put the sieved smoothie into the tray of the freeze dryer, and dry it with gradient temperature rise under the vacuum degree of 20Pa, and the whole process is completed in 32 hours.

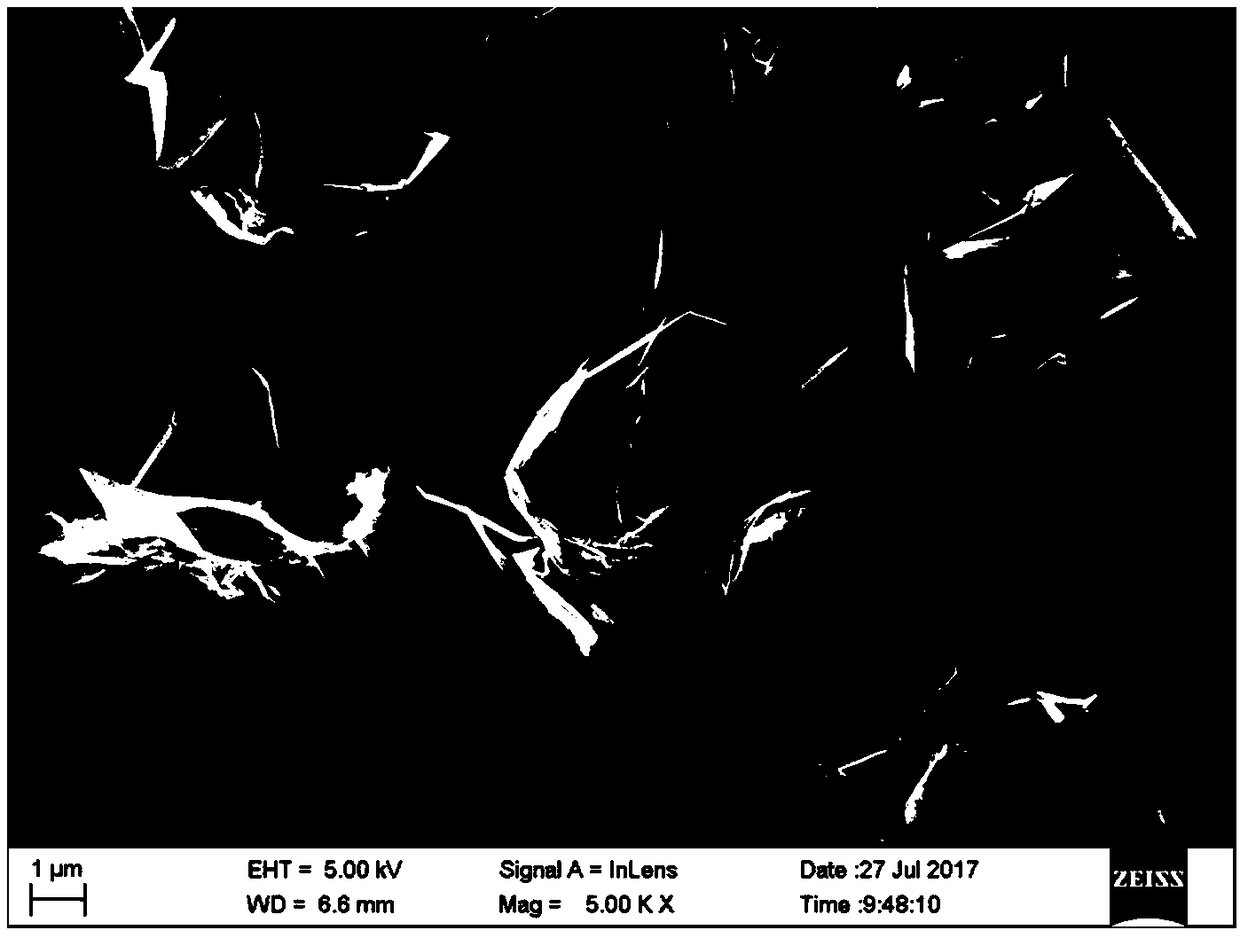

[0062] After freeze-drying, directly obtain the airgel powder material of graphene oxide, such as figure 1 As shown; the airgel material has excellent dispersibility in aqueous solution, its tap density is 12 mg / mL, and its porosity is 99.2%.

Embodiment 2

[0068] A preparation method of graphene airgel powder, comprising the following steps:

[0069] 2kg20mg / mL graphene slurry was frozen at -40°C to make ice cubes to obtain frozen samples; the frozen samples were crushed in the cold storage, and the crushed ice slag could be sieved through a 10-mesh sieve. The sieved smoothie is put into the tray of the freeze dryer, under the condition of vacuum degree of 30Pa, the gradient temperature rises and dries, and the whole drying time is 18h.

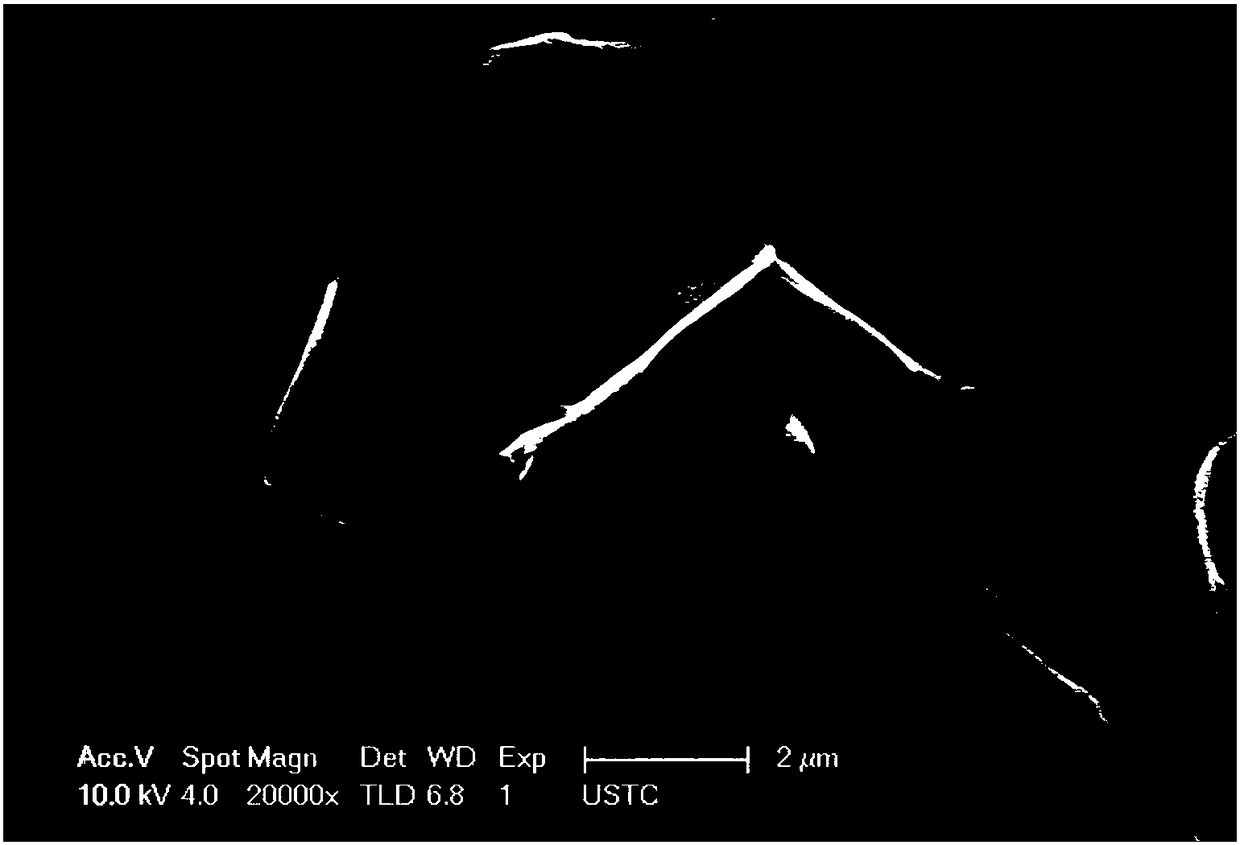

[0070] The airgel powder material of graphene is directly obtained after freeze-drying, and its corresponding microstructure is as follows: figure 2 Shown; its tap density is 21mg / mL, and the porosity is 99%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com