Substrate etching method and etching disposal device

A technology for etching processing and substrates, which can be used in optics, instruments, electrical components, etc., to solve problems such as defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

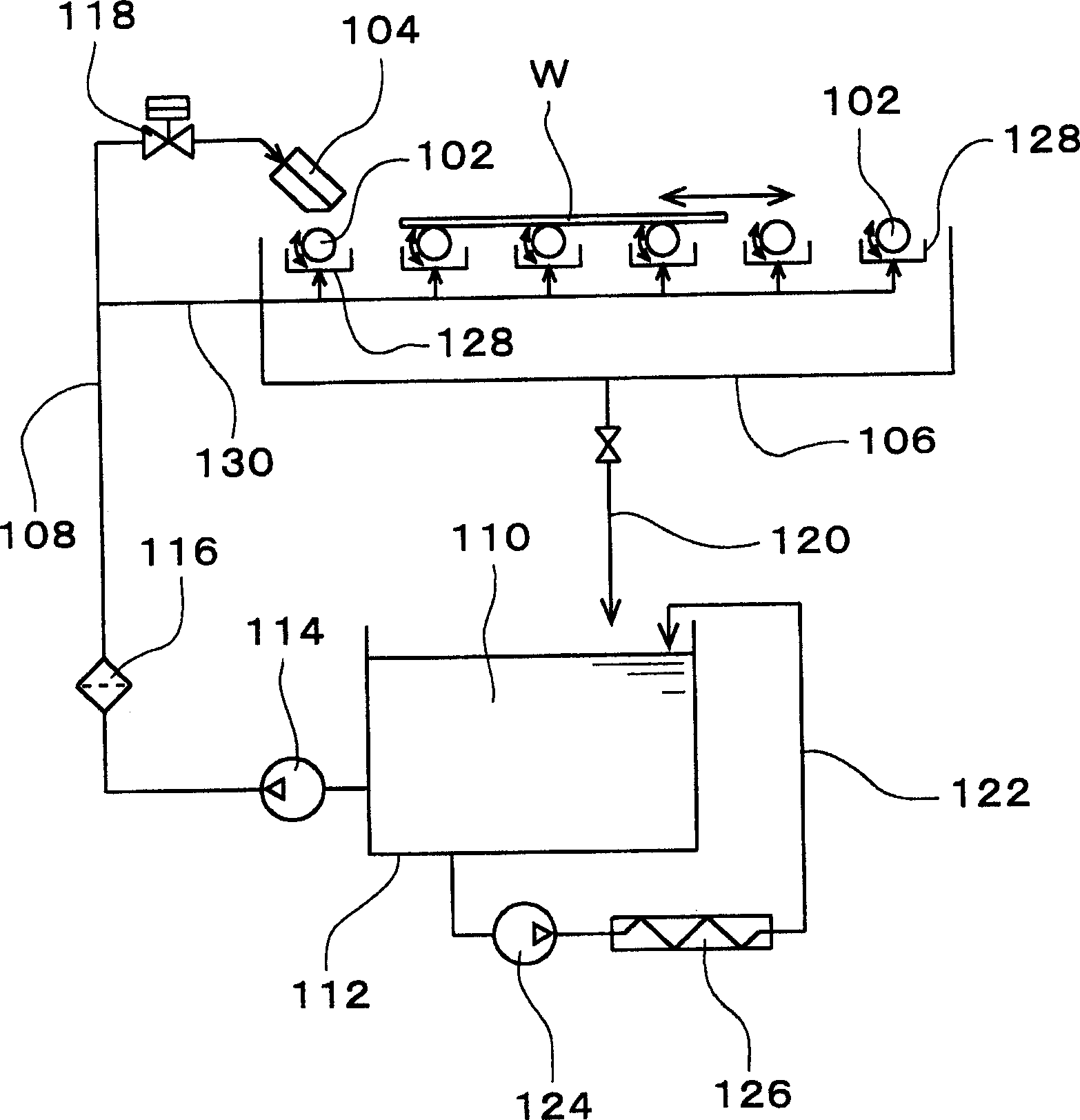

[0060] Below, refer to Figure 1 to Figure 8 The best mode for carrying out the present invention will be described.

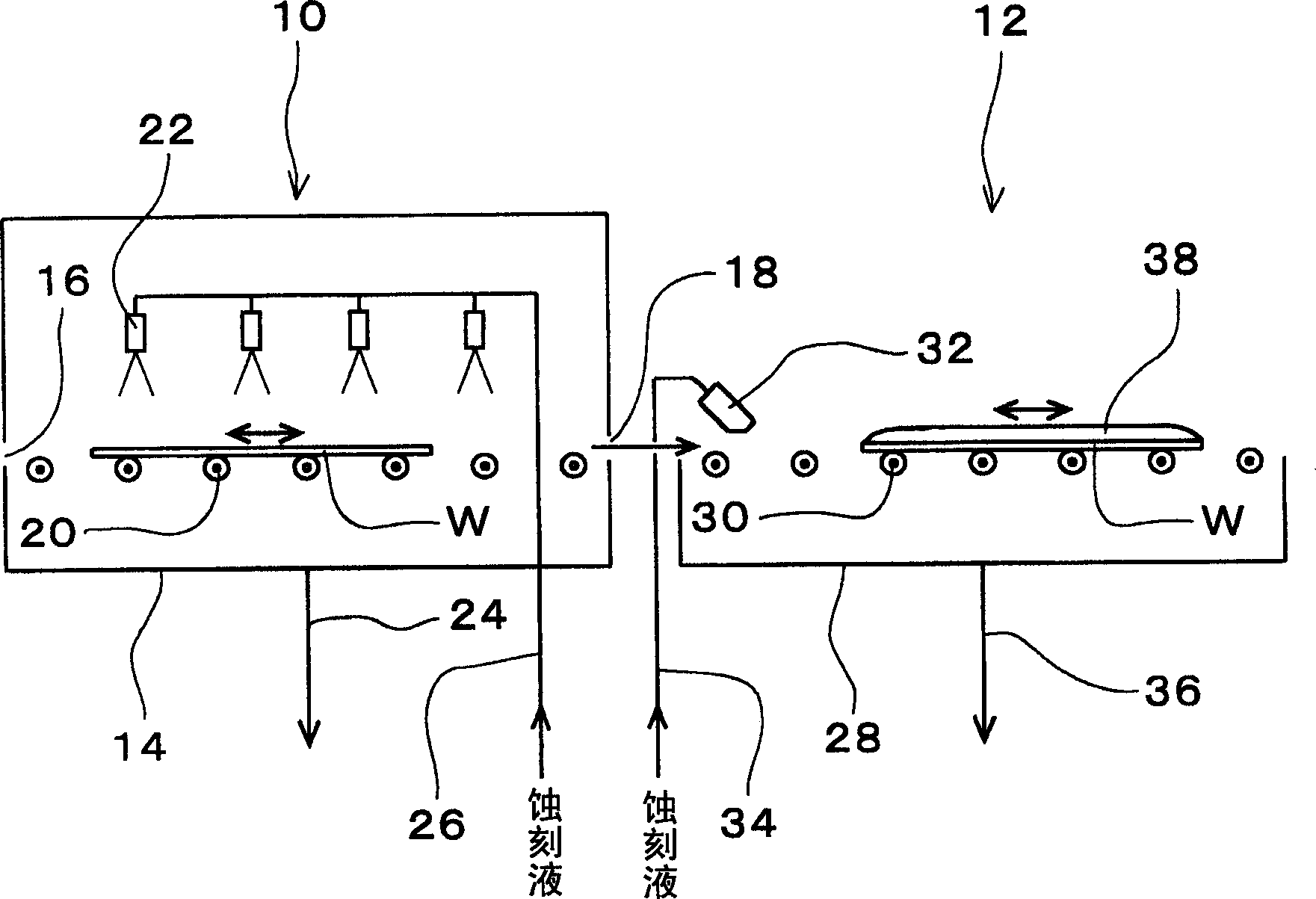

[0061] figure 1 One embodiment showing the first invention is a schematic side view showing an example of a schematic structure of a substrate etching processing apparatus. This etching processing apparatus is configured by connecting a jet etching processing unit 10 and an agitating etching processing unit 12 .

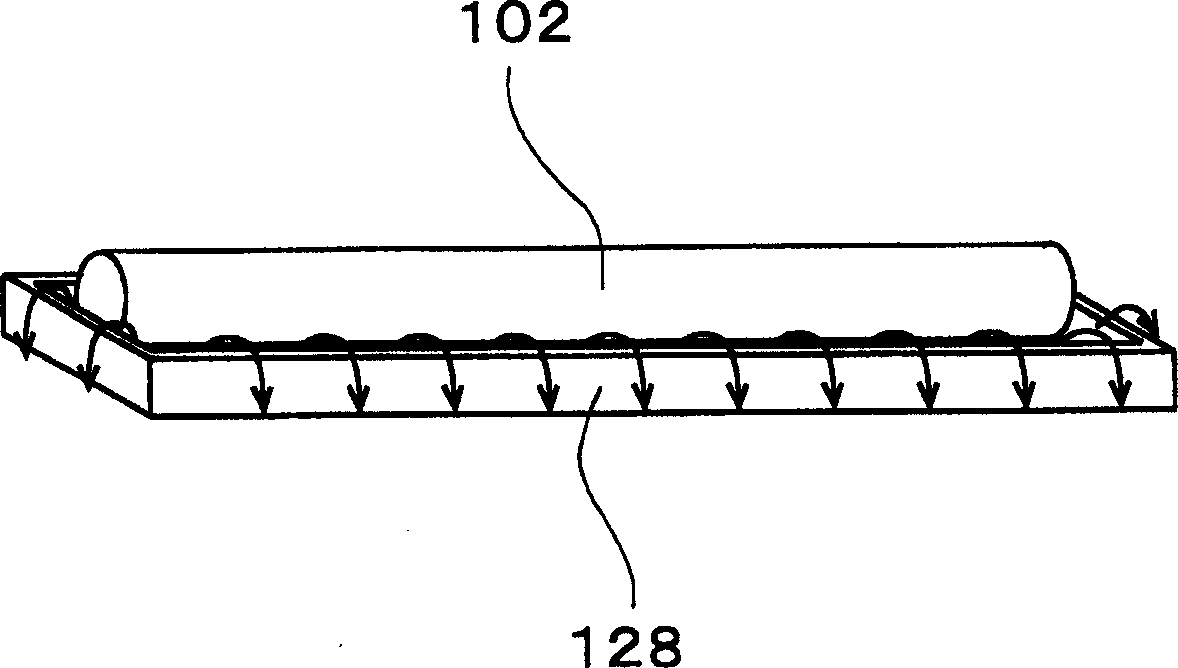

[0062]The jet etching processing unit 10 includes a sealed first processing tank 14 having a loading-side opening 16 and a loading-side opening 18 . Inside the first processing tank 14 , a plurality of conveying rollers 20 capable of normal and reverse rotations that support the substrate W and convey in the horizontal direction are arranged in parallel to each other along the substrate conveyance path. The substrate W is reciprocated in the processing tank 14 by these conveyance rollers 20 . In addition, above the substrate conveyance path, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com