Method for manufacturing electric arc furnace fume heat insulating pipe and electric arc furnace fume heat insulating pipe

A production method and technology of heat preservation pipes, which are applied in the direction of heat insulation protection of pipes, heat preservation, pipes/pipe joints/pipe fittings, etc., which can solve the problems of insufficient strength of heat preservation materials, reduced efficiency of power generation by waste heat of flue gas, and reduction of flue gas temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

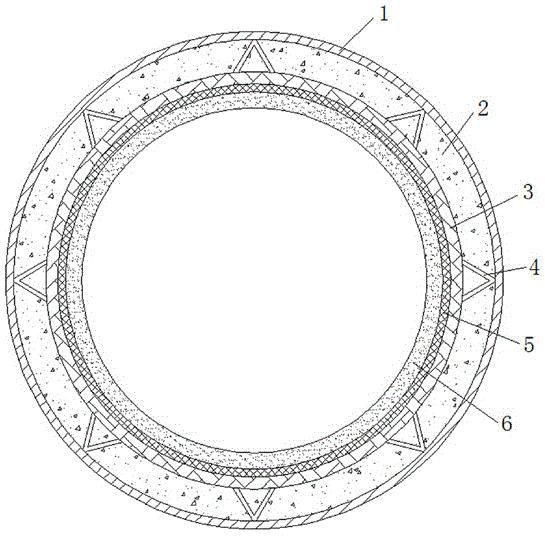

[0015] Such as figure 1 As shown, the flue gas pipe 1, the aluminum silicate layer 2, the barbed wire 3, the anchor 4, the asbestos board 5, and the ceramic fiber layer 6.

[0016] The manufacturing method of the flue gas insulation pipe of the submerged arc furnace comprises the following steps:

[0017] Firstly, the V-shaped screw nails used as anchors 4 are uniformly welded on the inner wall of the flue gas pipe 1, and then the inside of the flue gas insulation pipe is cleaned, mainly to remove welding slag and rust, and brush the V-shaped screw nails on the inner wall of the pipe and the V-shaped screw. Coal paint. After the paint is dry, the aluminum silicate layer 2 is laid twice in the flue gas pipe 1. During the construction, two layers of aluminum silicate layers are laminated with staggered joints. The inside shall prevail. After the two layers of aluminum silicate layers are laid, barbed wire 3 shall be laid on the aluminum silicate layer. The choice of wire mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com