Method for using numerically-controlled pipe bender to process heating constant temperature bending pipe

A tube bending machine and constant temperature technology, which is applied in the field of plastic processing, can solve the problems of low forming precision, repeated preheating of the mold, and difficult temperature control, etc., and achieve the effect of high forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

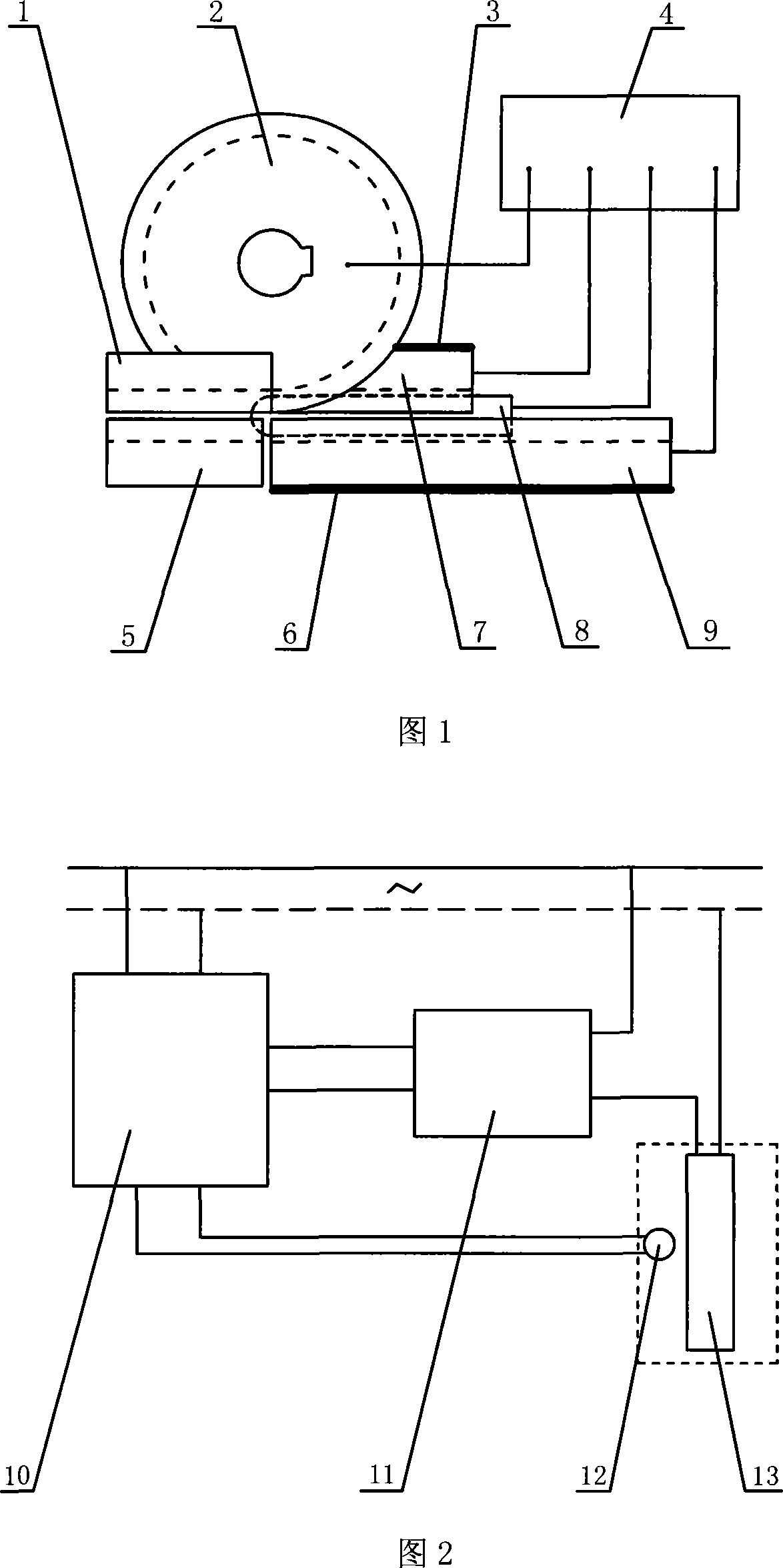

Method used

Image

Examples

Embodiment 1

[0027] In this example, a mold with a bendable diameter of Φ25mm and a wall thickness of 1.9mm is used. The bending radius is 75mm. The selected pipe is an AZ31 magnesium alloy shunt extruded pipe. The bending temperature is set at 150°C and the bending angle is 90°. The bending speed is 3r / min. When the temperature of the mold reaches 150°C, install the pipe. Within 3 minutes, the surface temperature of the pipe reaches 150°C. Start the pipe bender to complete the bending process. No cracking, no wrinkles on the inner arc surface, the maximum wall thickness reduction rate is 13%, the maximum ellipticity of the cross-section is 2.5%, and the rebound rate is 3.5% when released, which meets the use requirements.

Embodiment 2

[0029]In this example, a mold with a bendable diameter of Φ42mm and a wall thickness of 4mm is used. The bending radius is 84mm. The selected pipe is AM30 magnesium alloy shunt extruded pipe. The speed is 5r / mim, the mold is heated from room temperature to 200°C within 5 minutes, the pipe is installed and kept warm, and the surface temperature of the pipe reaches 200°C within 3 minutes, and the bending process is completed by starting the pipe bender. Sliding, no cracking on the outer side of bending, no wrinkling on the inner side, the maximum wall thickness reduction rate is 11.6%, the maximum ellipticity of the cross-section is 1.6%, and the rebound rate when released is 2%, which meets the use requirements.

Embodiment 3

[0031] In this example, a die with a bendable diameter of Φ42mm and a wall thickness of 2mm is used. The bending radius is 84mm. The selected pipe is AZ31 magnesium alloy shunt extruded pipe. The speed is 1r / mim, the mold is heated from room temperature to 250°C within 6 minutes, the pipe is installed and kept warm, and the surface temperature of the pipe reaches 250°C within 3 minutes, the bending process is completed by starting the pipe bender, and the inner and outer surfaces of the pipe are bent and deformed No slipping, no cracking on the curved outer arc surface, no wrinkling on the inner arc surface, the maximum wall thickness reduction rate is 12.8%, the maximum ellipticity of the cross-section is 1%, and the rebound rate when released is 1.2%, which meets the use requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com