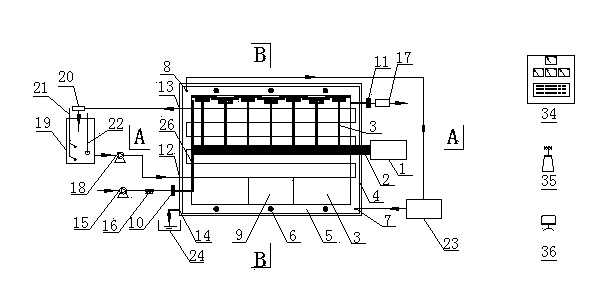

Compact kitchen waste aerobic fermentation equipment

A food waste and aerobic fermentation technology, applied in the direction of organic fertilizers, climate change adaptation, etc., can solve the problems of long processing cycle and difficulty in meeting the daily production and daily clearance of food waste, and achieve the protection of fermentation heat production and internal space The effect of high utilization rate and saving steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

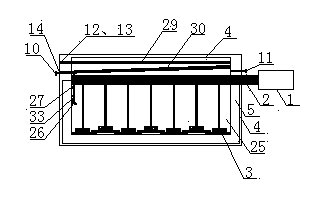

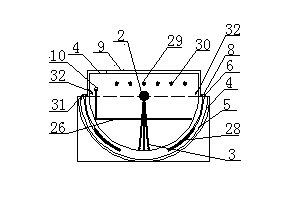

Method used

Image

Examples

Embodiment Construction

[0028] Step 1: After the fermentation equipment is installed on site, it should be connected with water and electricity, and the water bath cavity 5, the cooling water tank 19 and the hot water tank / water heater 23 should be filled with water, and then the man-machine dialogue interface of the intelligent control system 34 will automatically The run button is pressed;

[0029] The second step: open the feed port 9, put the wet material of the kitchen waste drained of water into the reaction chamber 25, close the feed port 9 after feeding, and this step can be repeated every day according to actual needs;

[0030] Step 3: Under the control of the intelligent control system 34, the whole set of fermentation equipment system starts to carry out aerobic fermentation and degradation of kitchen waste, and all electromechanical equipment operates according to the established procedures. The specific procedures are as follows:

[0031] (1) The rotating shaft 2 is driven by the reducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com