Automatic water distribution system for brick manufacturing device

An automatic water distribution and equipment technology, applied in auxiliary molding equipment, manufacturing tools, ceramic molding machines, etc., can solve the problems of brick making machines that are difficult to achieve extrusion molding, water loss, etc., and achieve the effect of increasing the pass rate and controlling accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

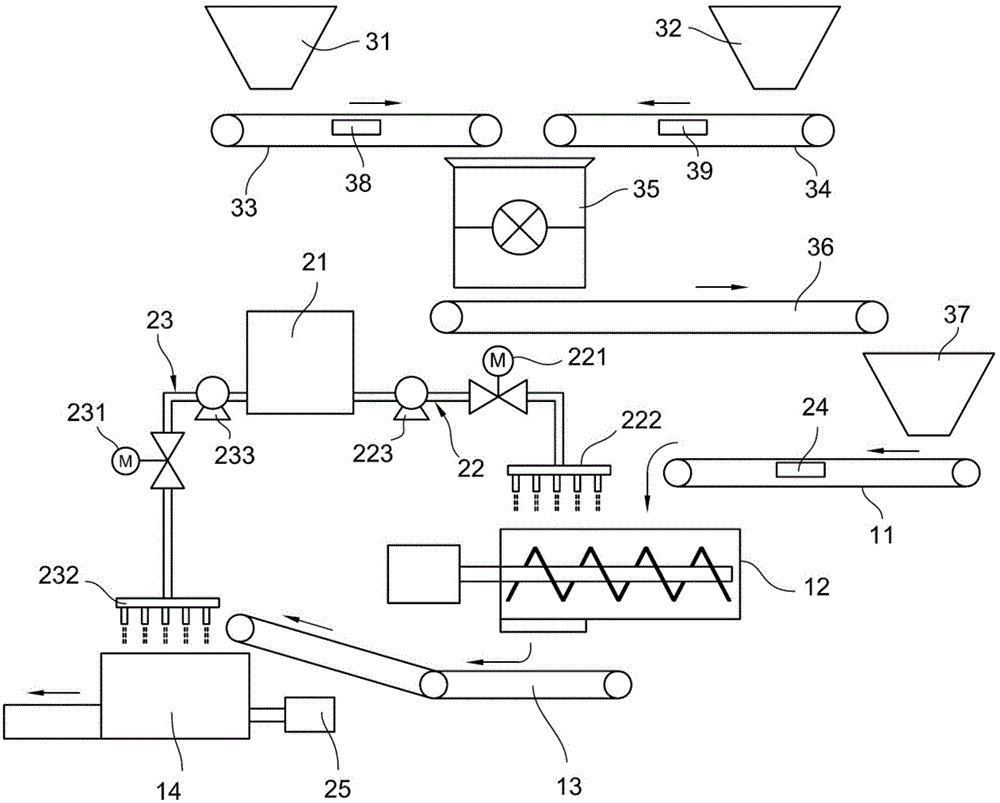

[0026] refer to figure 1 , figure 2 , an automatic water distribution system for brick-making equipment according to the present invention. The water distribution system is mainly used to include a brick-making raw material conveyor belt 11, a mixer 12, a final material conveyor belt 13 and a brick-making machine arranged in sequence along the material conveying direction. 14 brick making equipment.

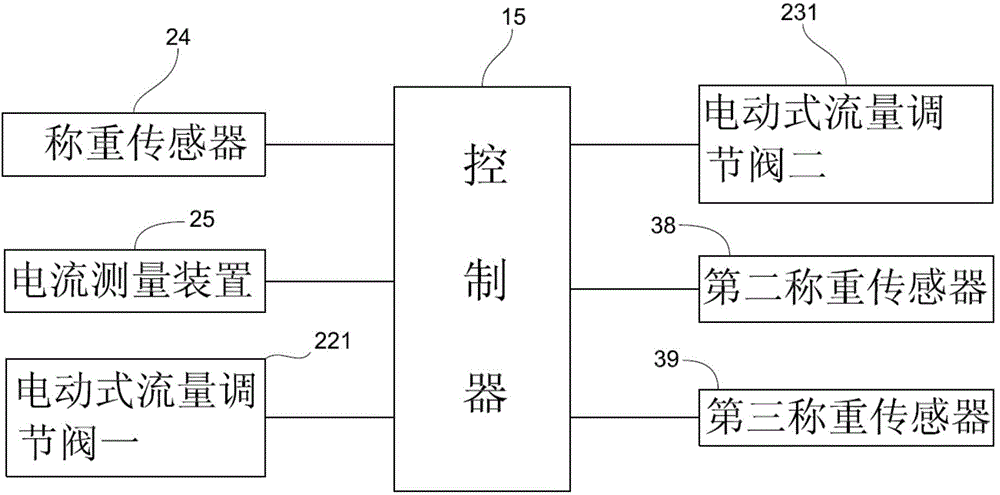

[0027] The automatic water distribution system includes: a water tank 21 , a main water supply part 22 , an auxiliary water supply part 23 , a weighing sensor 24 , a current measuring device 25 and a controller 15 . The main water supply part 22 is connected with the water tank 21 for adding water to the mixer 12 . The auxiliary water supply part 23 is connected with the water tank 21 and is used for adding water to the brick making machine 14 described above. The weighing sensor 24 is arranged on the brick-making raw material conveyor belt 11 for detecting the material flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com