Patents

Literature

61results about How to "Control Precise Control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

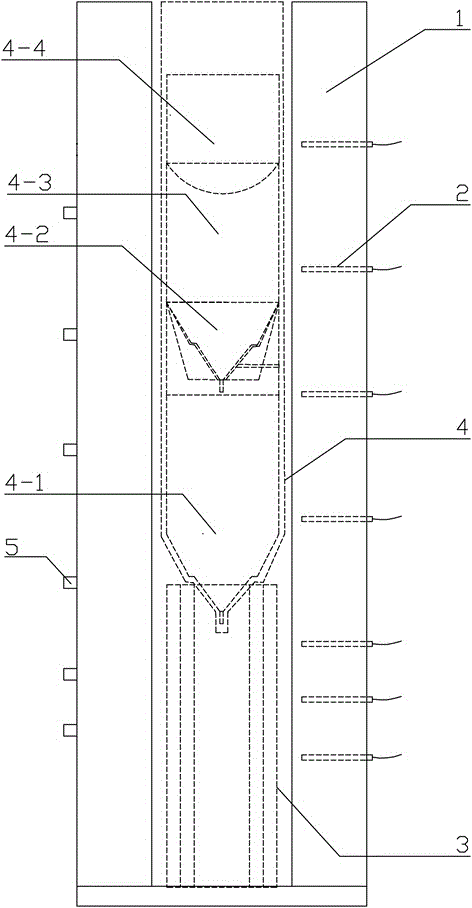

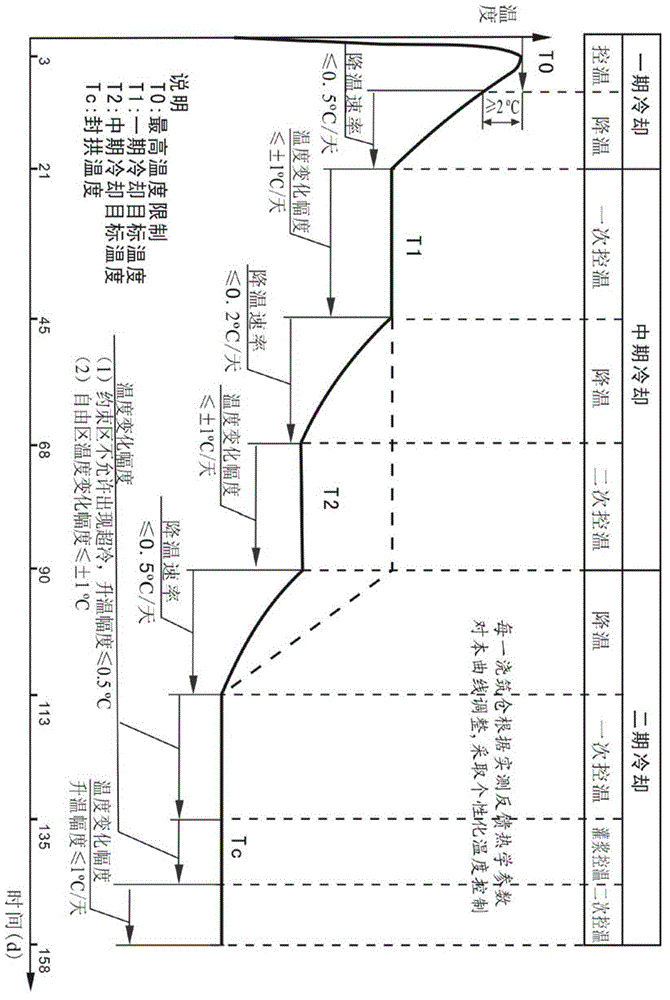

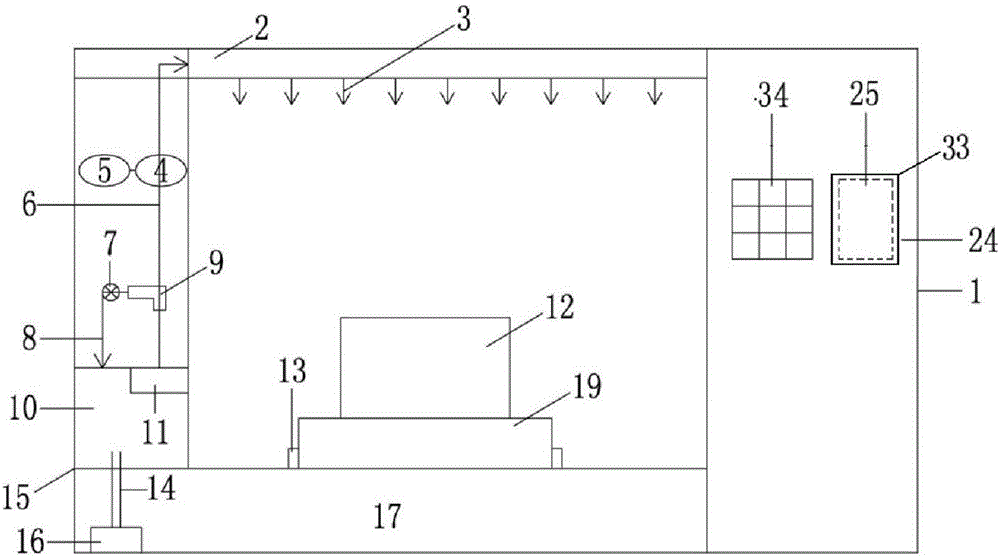

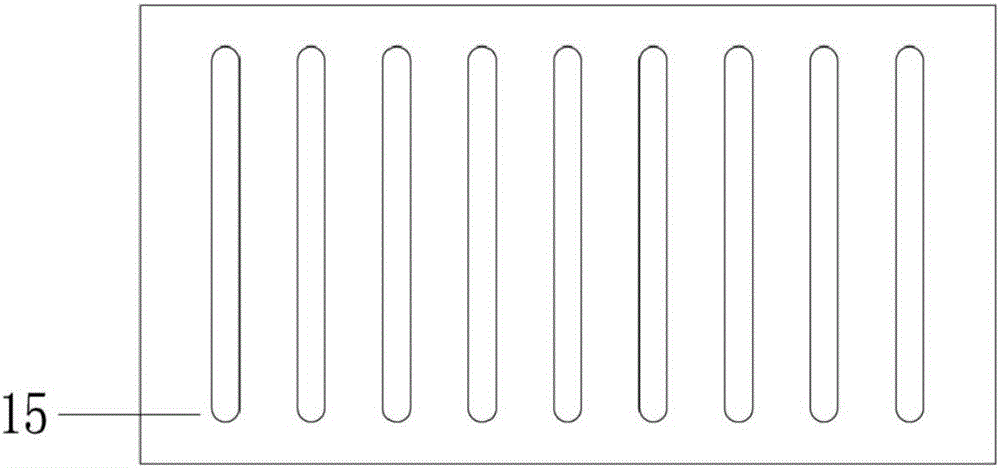

Method and system for intelligently controlling temperature of concretes of dam under construction

InactiveCN102852145AEasy to controlControl precise controlFoundation engineeringTemperature controlWater flow

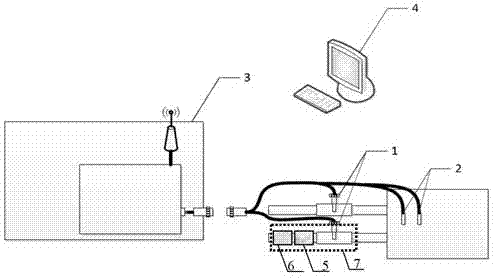

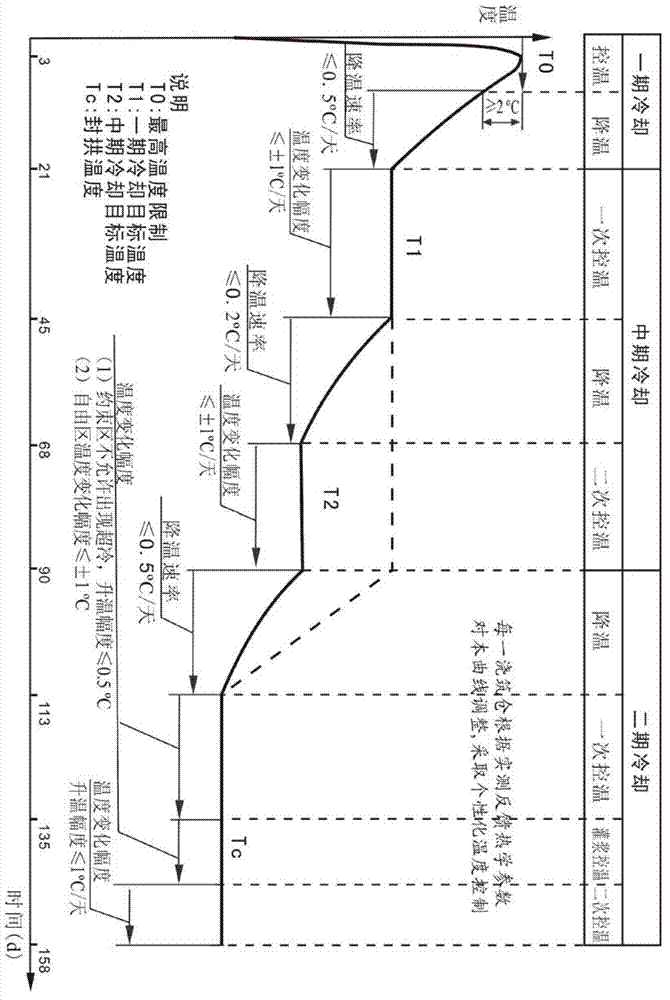

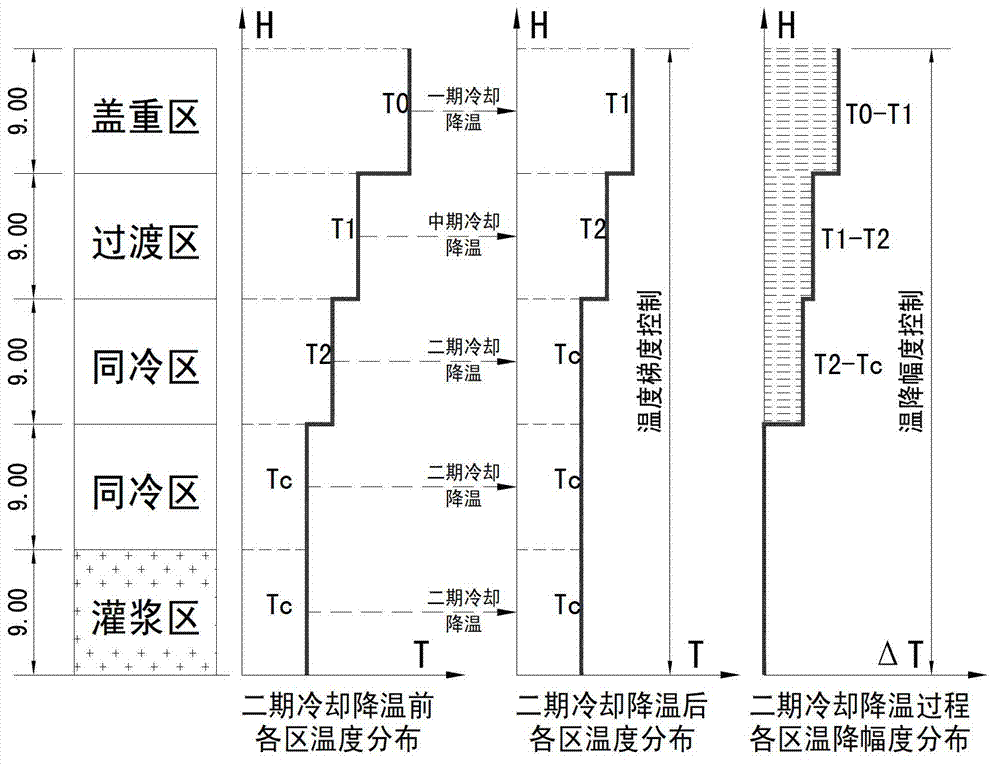

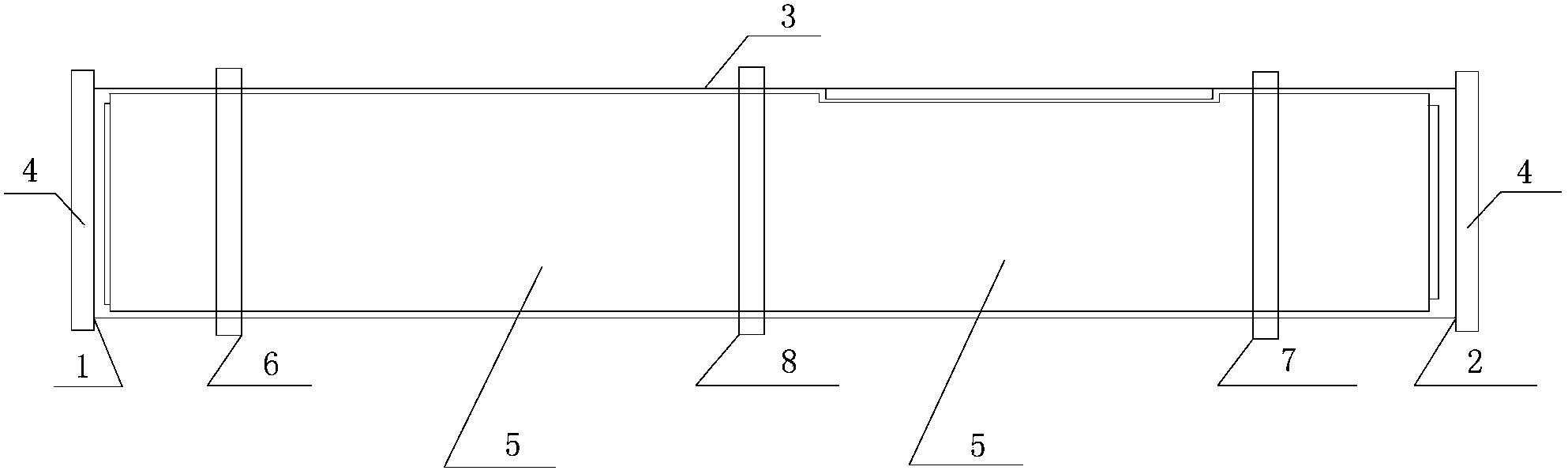

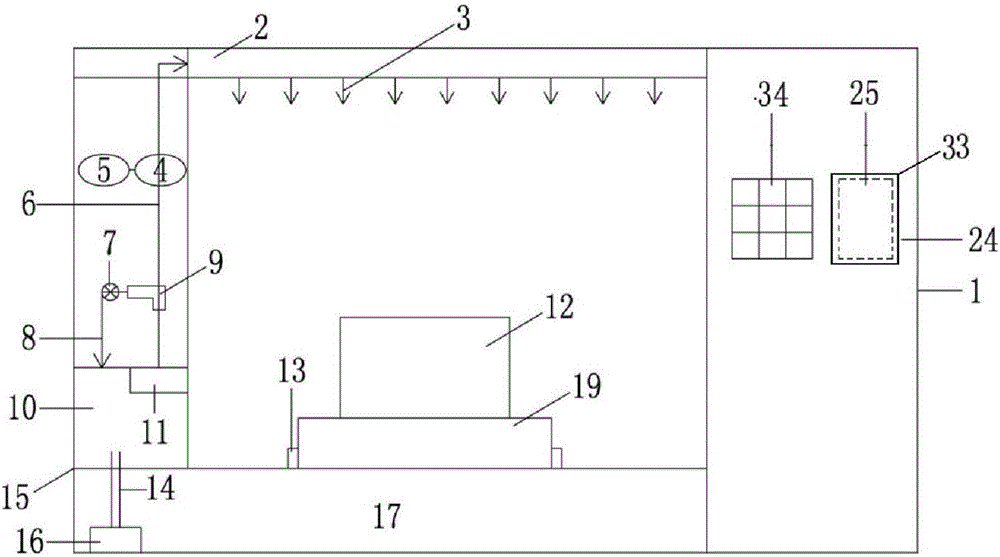

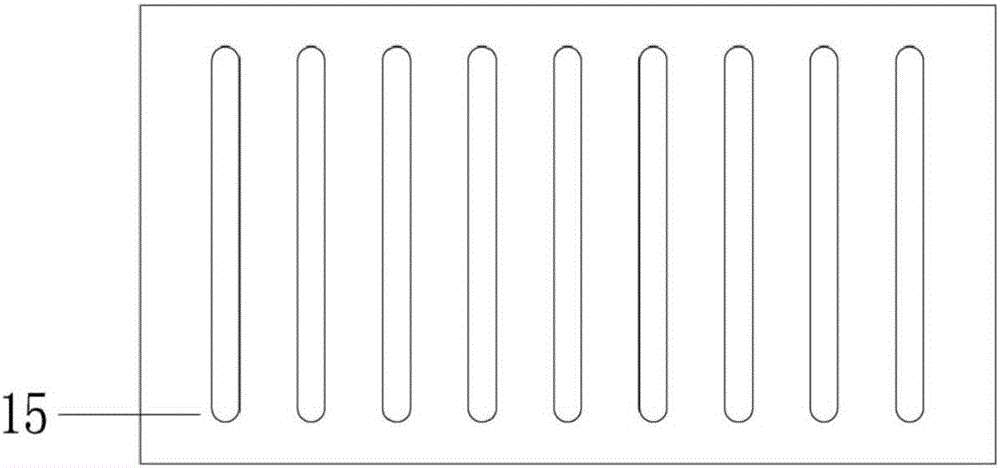

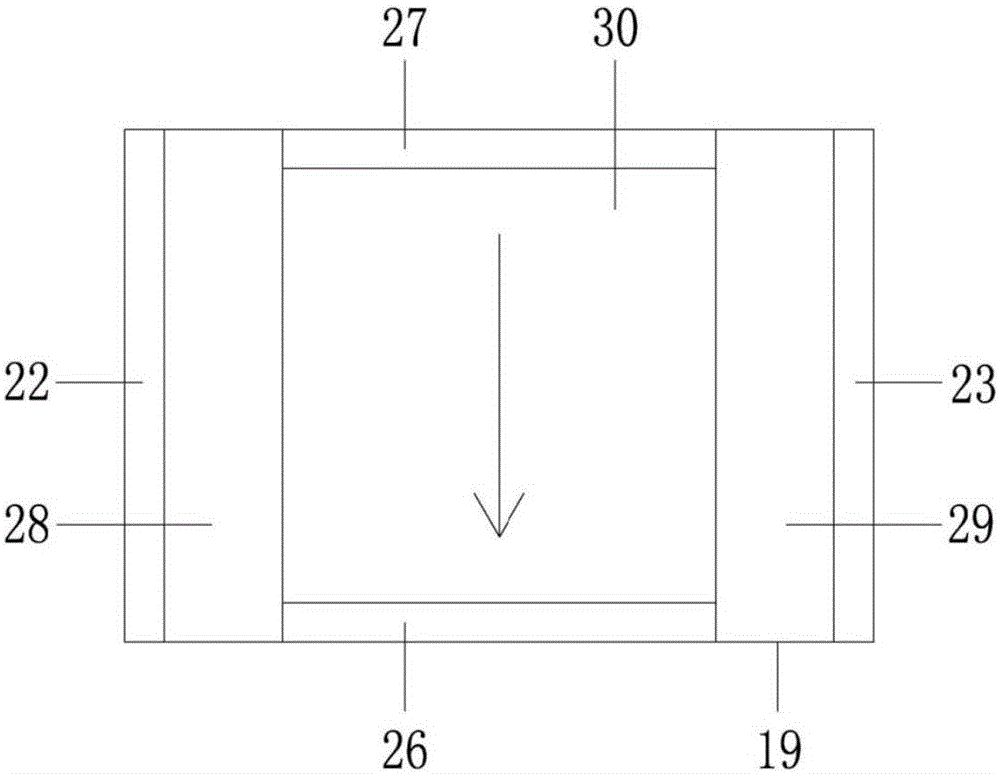

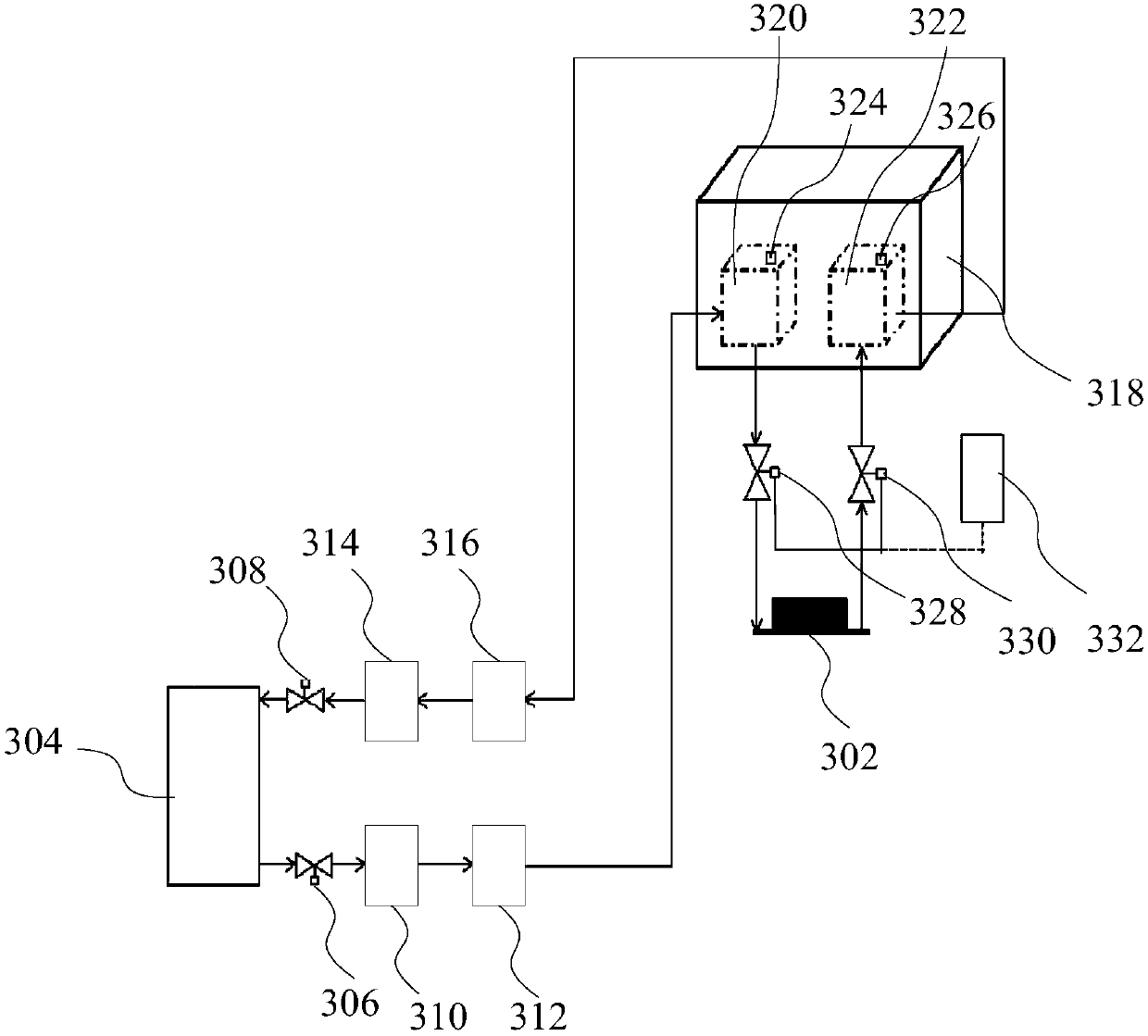

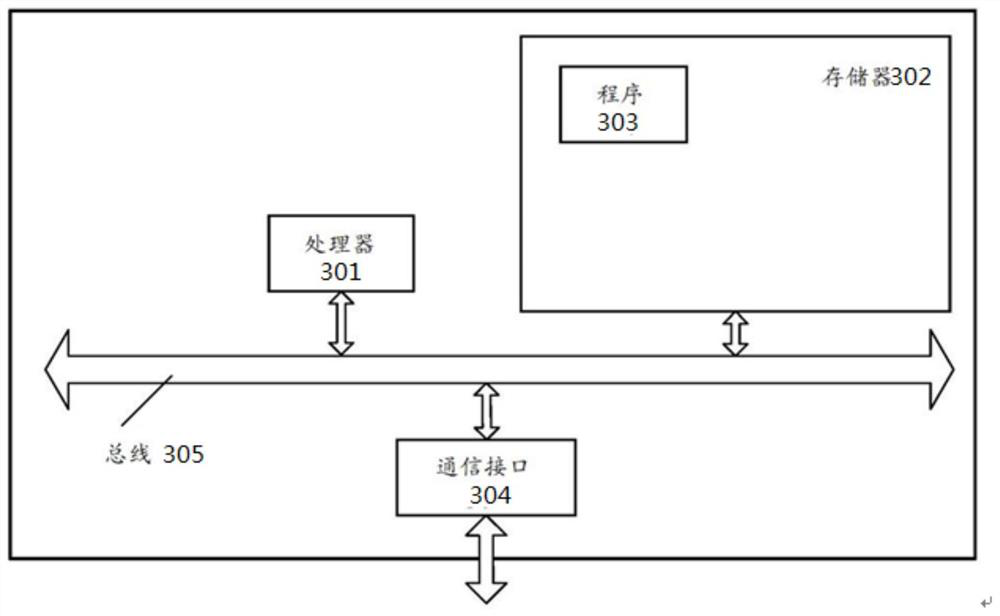

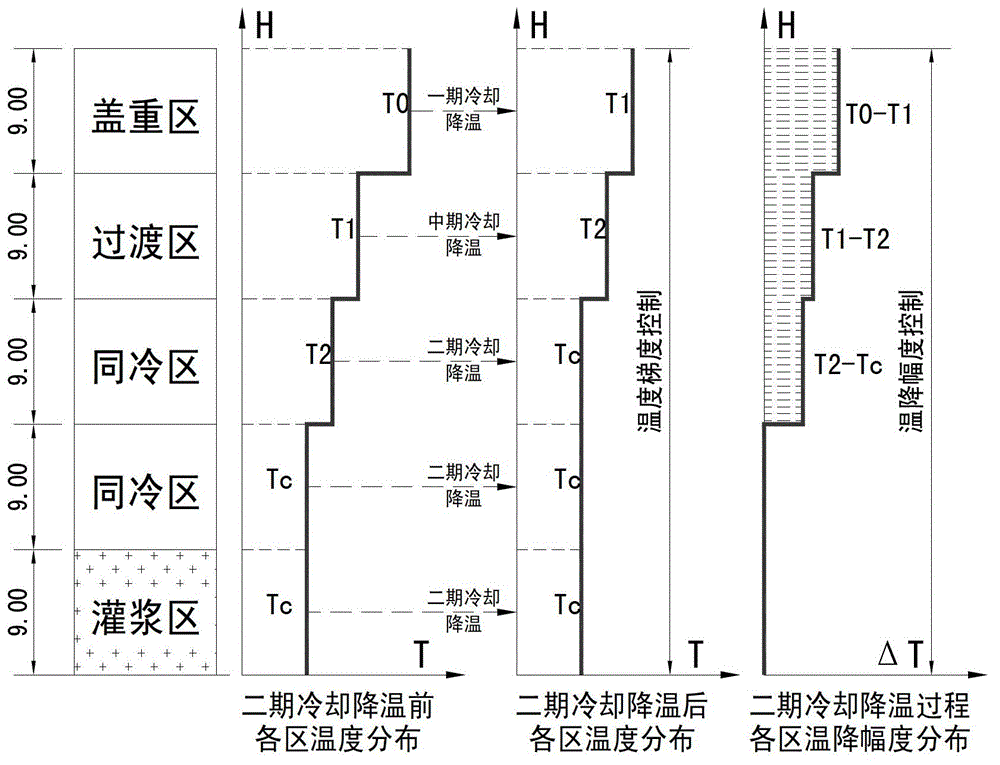

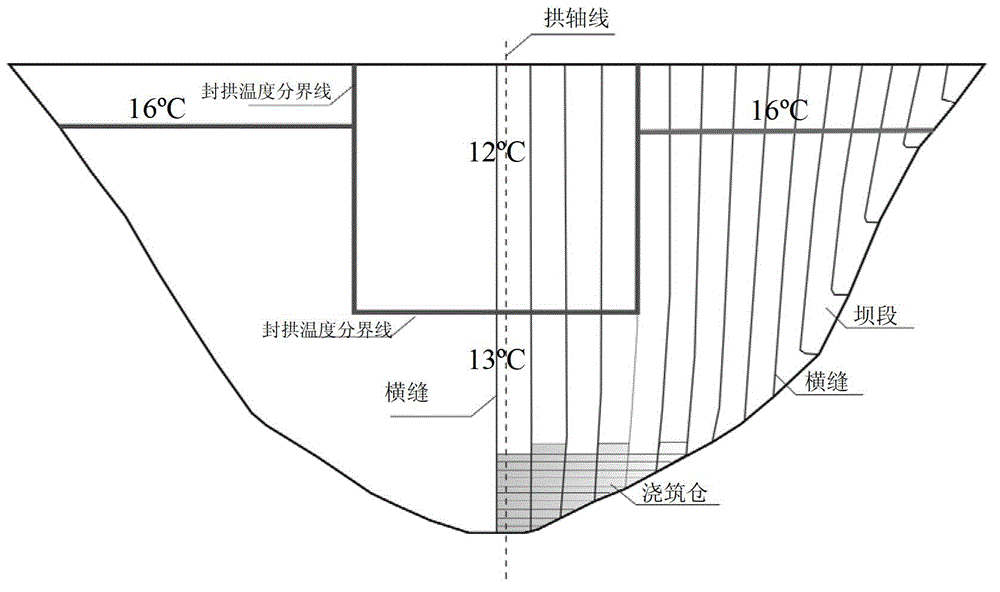

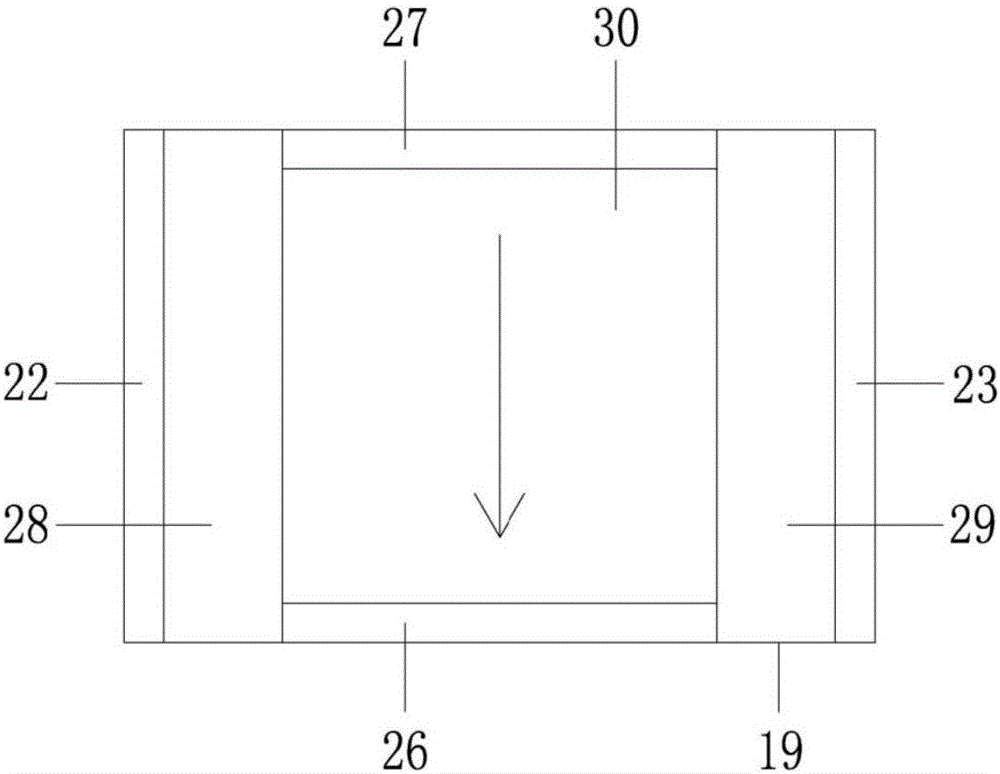

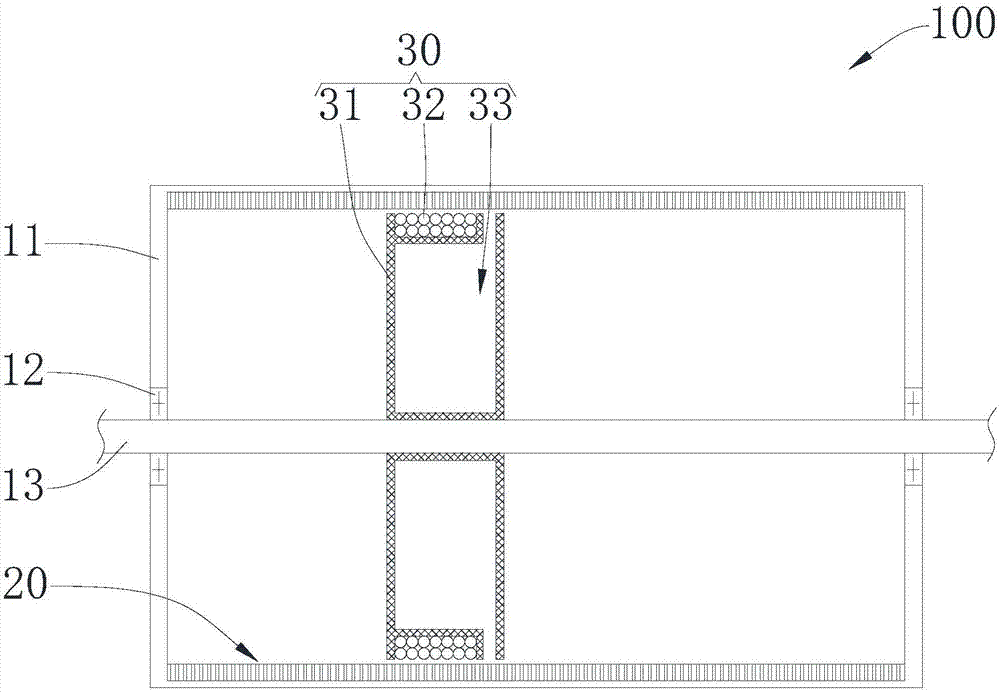

The invention discloses a method and system for intelligently controlling temperature of concretes of a dam under construction. The system comprises a control device which communicates with a heat exchanging device and a heat exchanging auxiliary device, wherein the heat exchanging device is arranged at inner part or surface of the concrete dam, and is used for exchanging heat with the concrete dam and transmitting collected temperature information of the concrete dam to the control device; the heat exchanging auxiliary device inputs a heat exchanging medium to the heat exchanging device and outputs the medium from the heat exchanging device after the heat exchange; the control device is used for controlling the heat exchanging auxiliary device; and the control device can input a temperature control strategy of each casting bin. By the system and method disclosed by the invention, the temperature of the concrete dam can be detected in real time automatically, individualized temperature control strategies are provided to different casting bins, intelligent learning is performed according to actual conditions on site, and concrete thermal parameters which are the most accurate and realistic are selected for each casting bin, so that the precise control on water flow capacity and / or temperature can be realized, the precision for controlling the concrete dam temperature is high, the data is reliable, labour and water costs can be greatly reduced, and the anti-cracking effect of the dam is good.

Owner:上海高千软件科技有限公司 +2

Heat treatment deformation control method of thin-wall saddle-shaped aluminum alloy casting

The invention discloses a heat treatment deformation control method of a thin-wall saddle-shaped aluminum alloy casting. The heat treatment deformation control method is suitable for large thin-wall casting aluminum alloy parts. According to the characteristics of the casting, a blocking disc and a clamp are arranged on the casting before heating, one end with a thicker wall is put into a furnace by a vertical placement way; thermal stress during heating can be reduced by heating in stages; in a solid melting stage, deformation during quenching can be reduced by adjustable tooling shape maintainance; in an aging stage a pretightening force is continued to be applied for maintainance of a tooling constraining force. The advantages of the heat treatment deformation control method are that: the heat treatment deformation control method uses an adjustable tooling shape maintainance method in heating, solid melting and aging stages to solve the heat treatment deformation control problem of the thin-wall casting aluminum alloy and avoid the problems of repeated deformation calibration and difficulties in shape, position and size control after solid melting. By application of the pretightening force before heating and after solid melting according to deformation rules, the purpose of precise deformation control can be achieved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

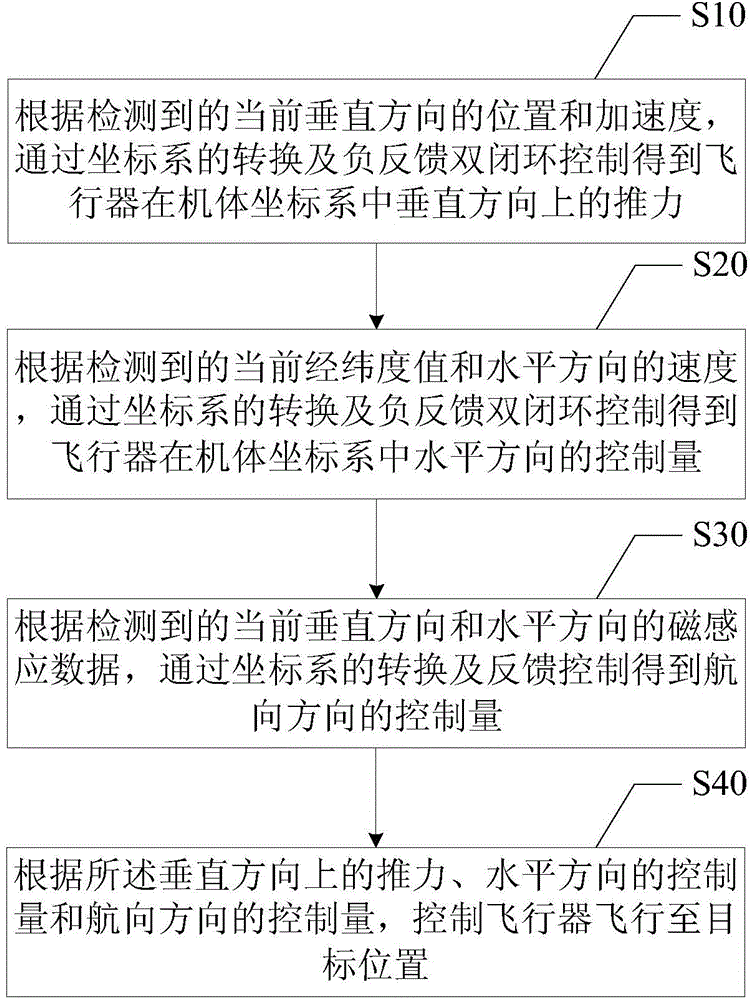

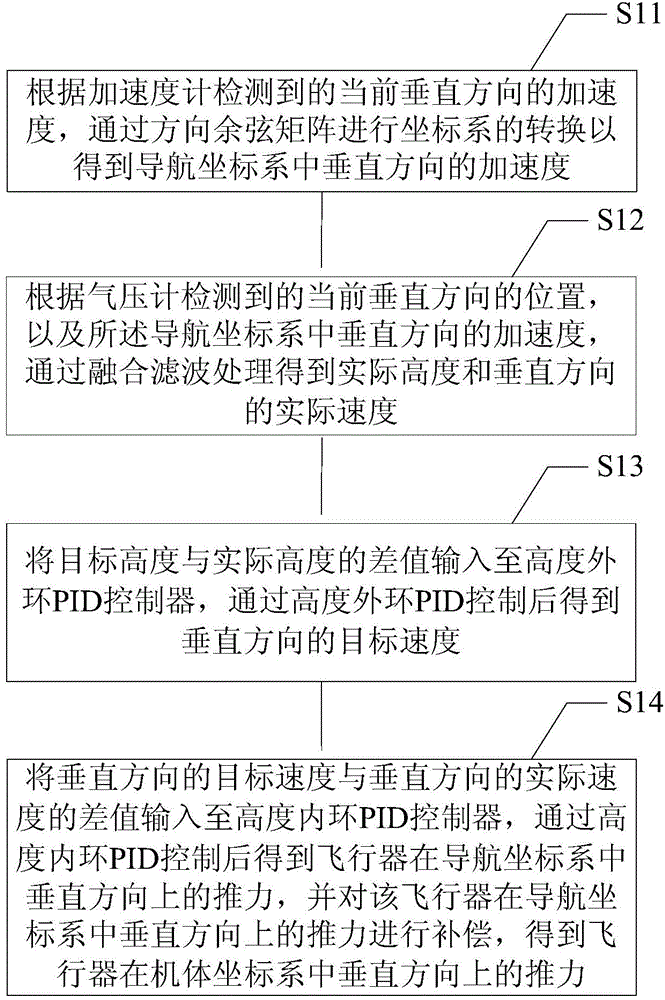

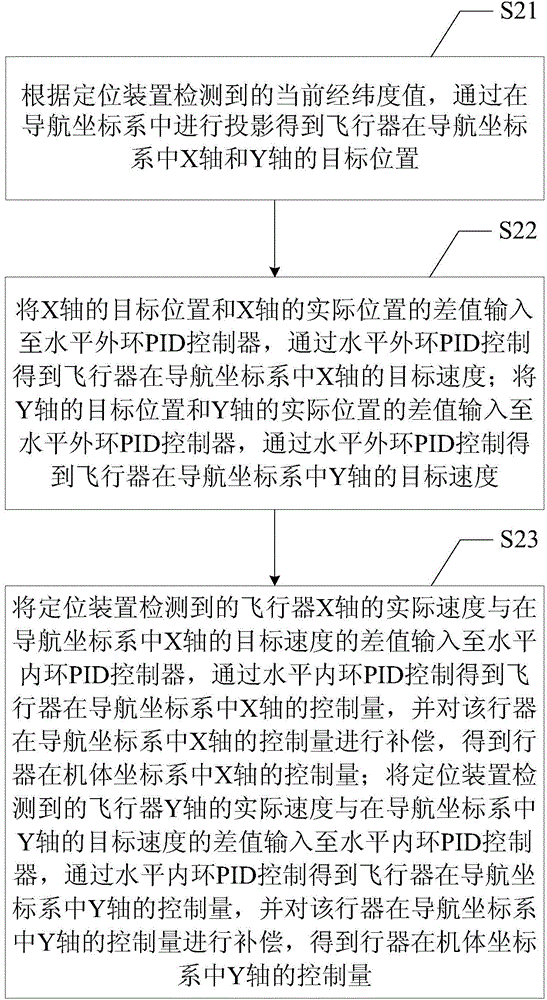

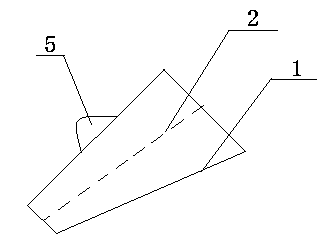

Aircraft control method and device

ActiveCN104536453AControl precise controlStable controlPosition/course control in three dimensionsNegative feedbackClosed loop

The invention discloses an aircraft control method comprising the following steps: obtaining the vertical thrust of an aircraft in an aircraft body coordinate system through coordinate system transformation and negative feedback double closed loop control according to detected current vertical position and acceleration; obtaining the horizontal controlled quantity of the aircraft in the aircraft body coordinate system through coordinate system transformation and negative feedback double closed loop control according to detected current latitude and longitude values and horizontal acceleration; obtaining the controlled quantity in the heading direction through coordinate system transformation and negative feedback double closed loop control according to detected current vertical and horizontal magnetic induction data; and controlling the aircraft to fly to a target position according to the vertical thrust, the horizontal controlled quantity and the controlled quantity in the heading direction. Aircraft control in the vertical, horizontal and heading directions can be realized, so that an aircraft can be controlled accurately to fly at a set height, and stable flight of an aircraft under complex conditions is ensured.

Owner:SICHUAN AEE AVIATION TECH CO LTD

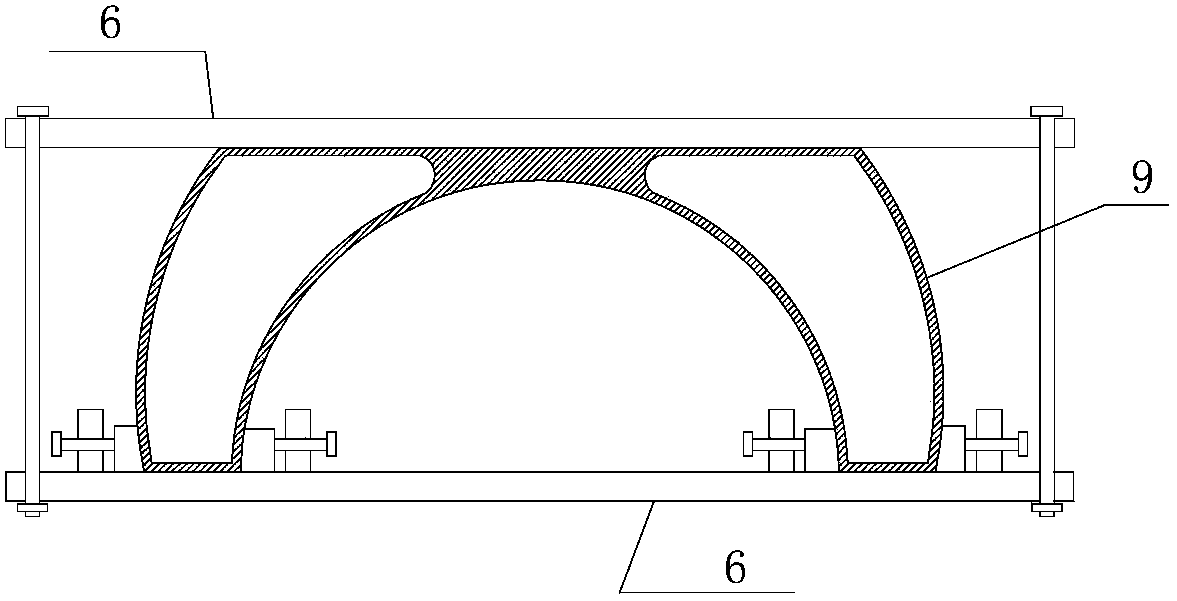

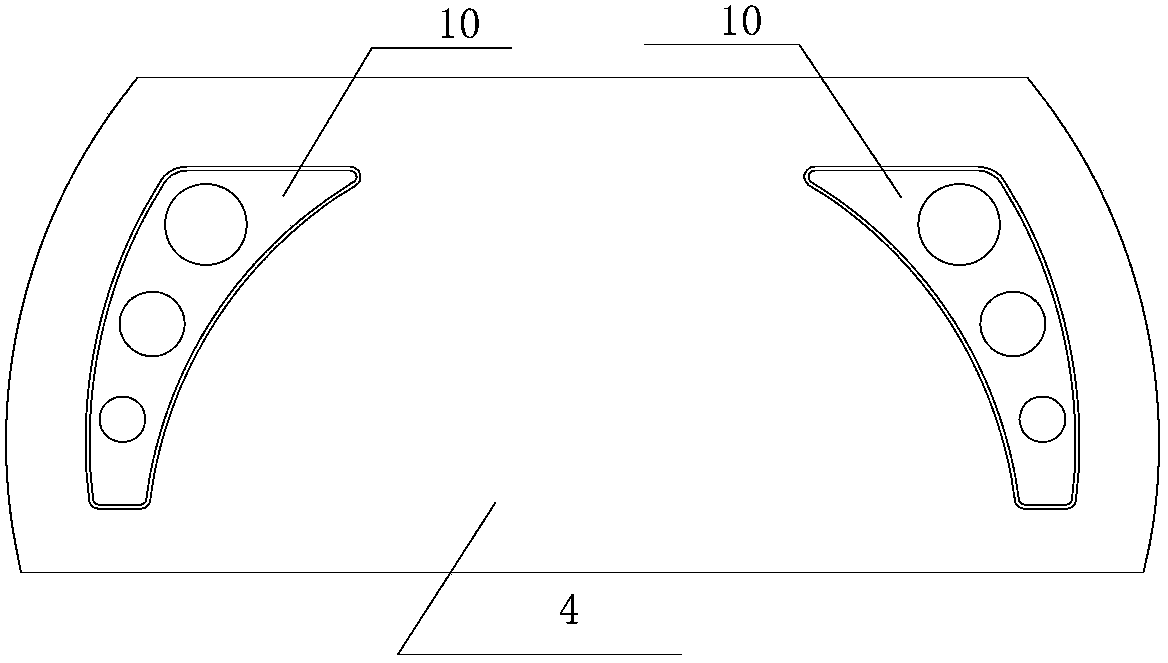

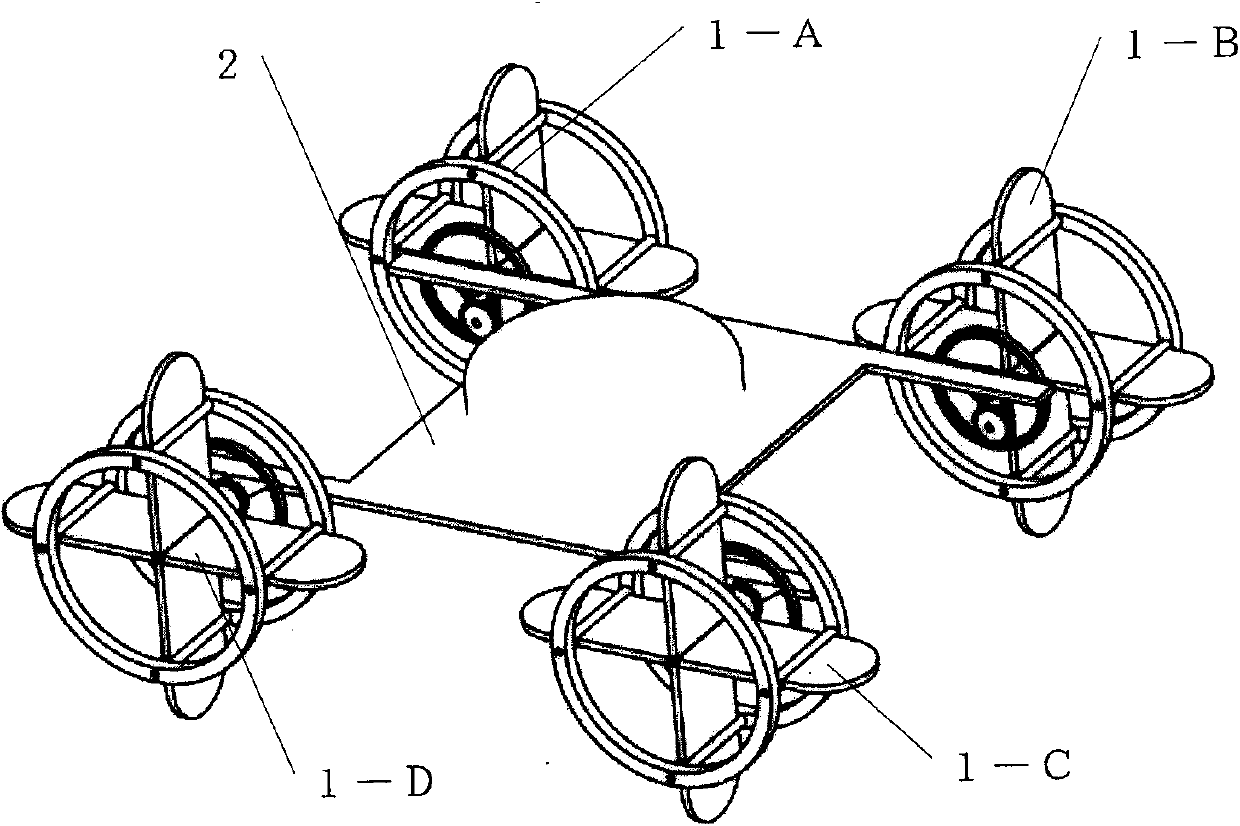

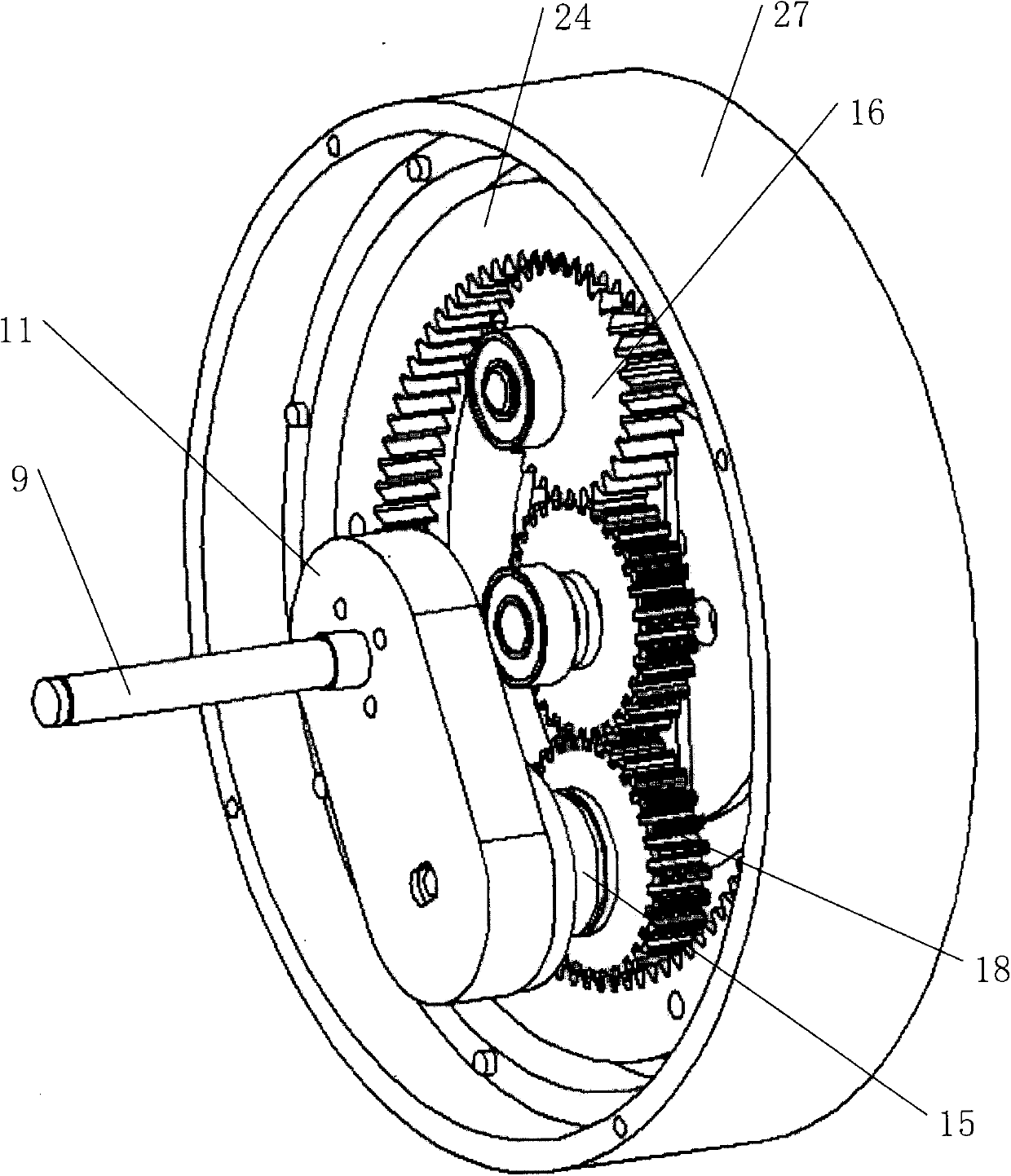

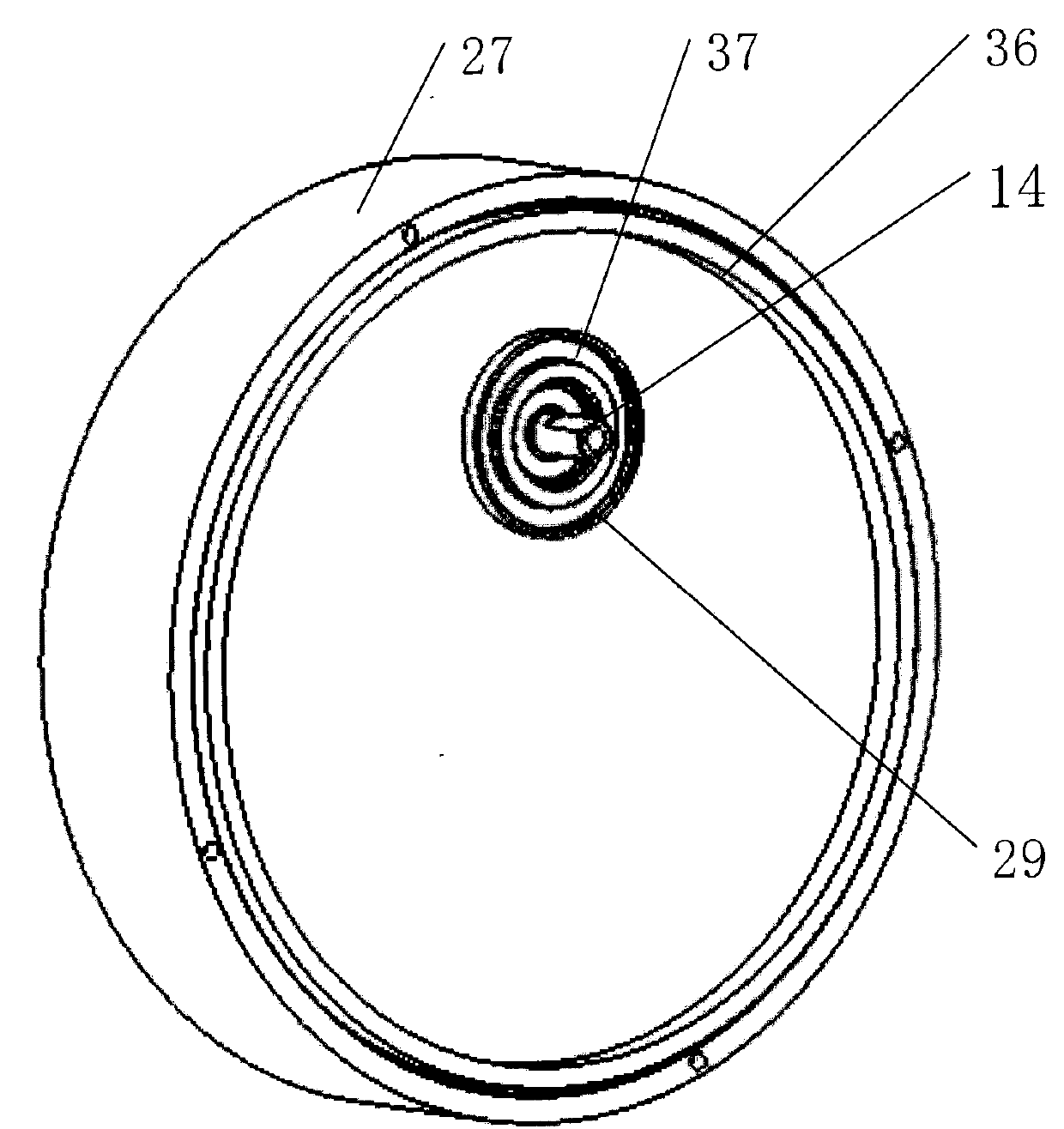

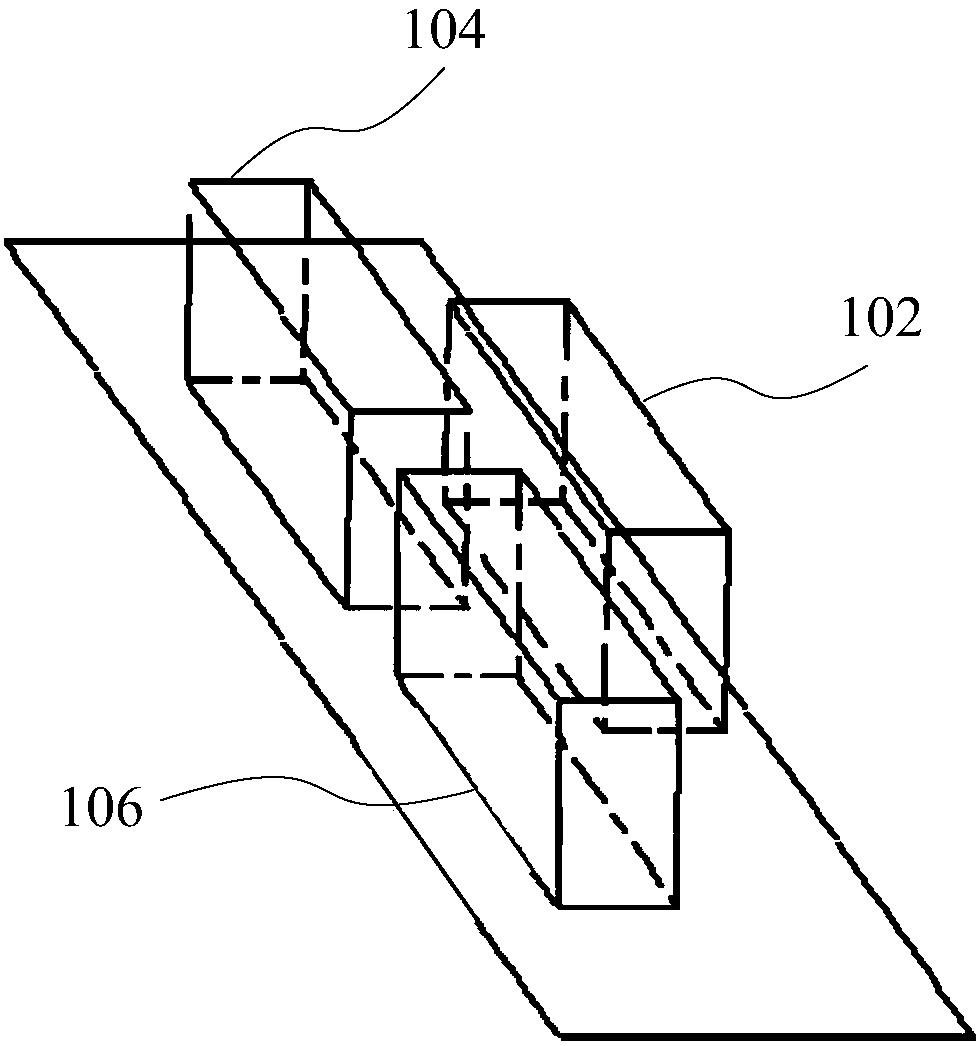

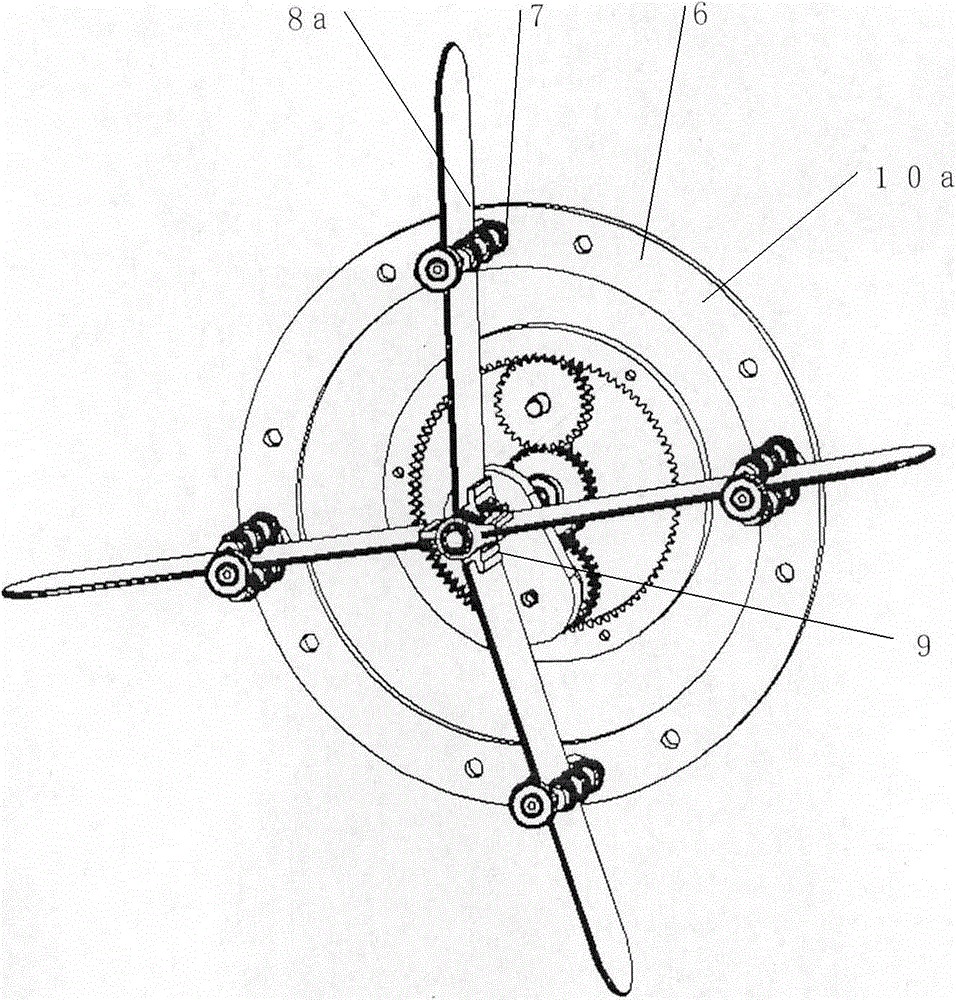

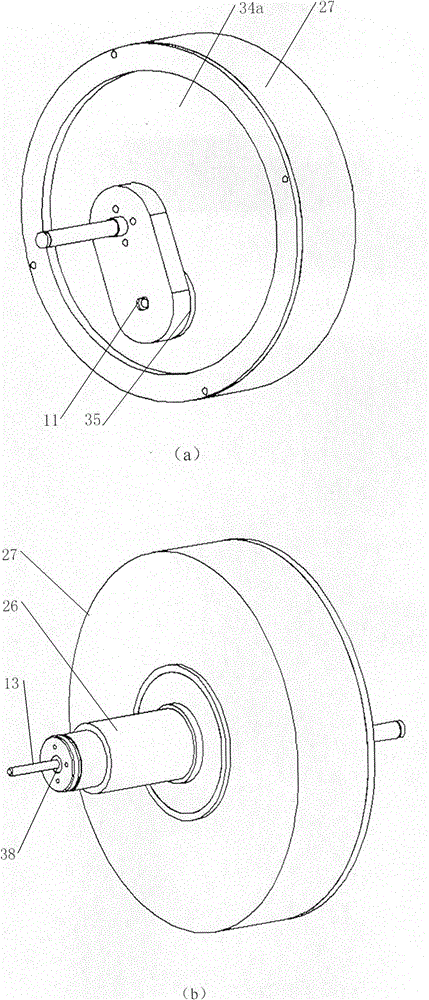

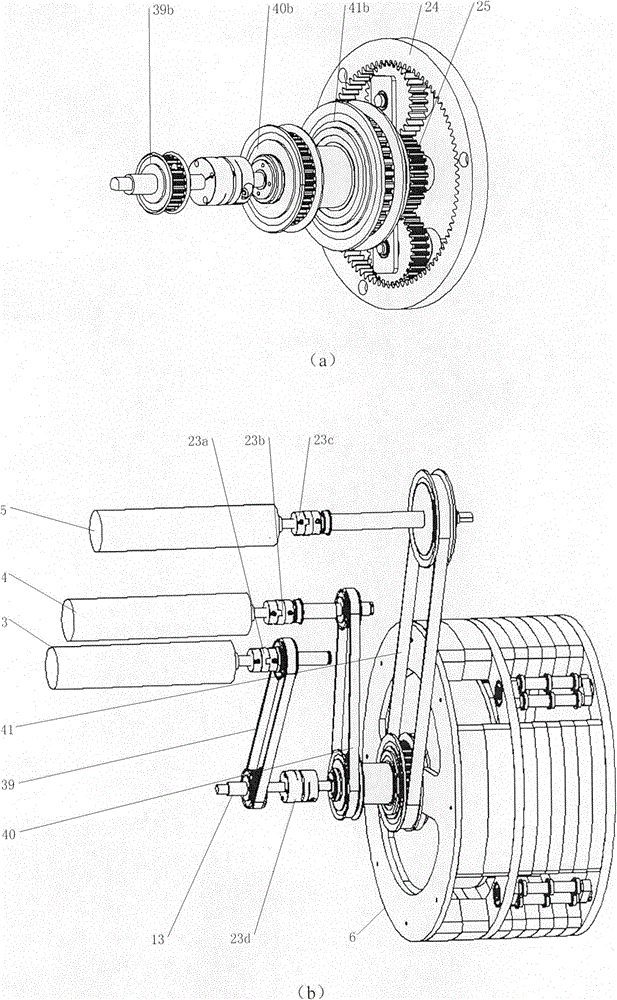

Composite configuration amphibious robot based on epicyclic gear trains and provided with wheel paddle legs

The invention discloses a composite configuration amphibious robot based on epicyclic gear trains and provided with wheel paddle legs. The robot comprises a machine frame, wheel paddle leg devices, a transmission system, a driving system and a control system, wherein the four independent wheel paddle leg devices are symmetrically arranged on two sides of the machine frame, the driving system is connected with the wheel paddle leg devices through the transmission system, each wheel paddle leg device comprises an epicyclic gear train, a paddle leg device and an outer wheel, the driving system comprises three independent driving motors, all the driving motors are connected with the control system and the rotary speed of the driving motors is controlled by the control system. A synchronous belt drive mode is adopted in the robot, and the robot has various gait motion modes and is suitable for various complex road condition environments.

Owner:青岛海艺自动化技术有限公司

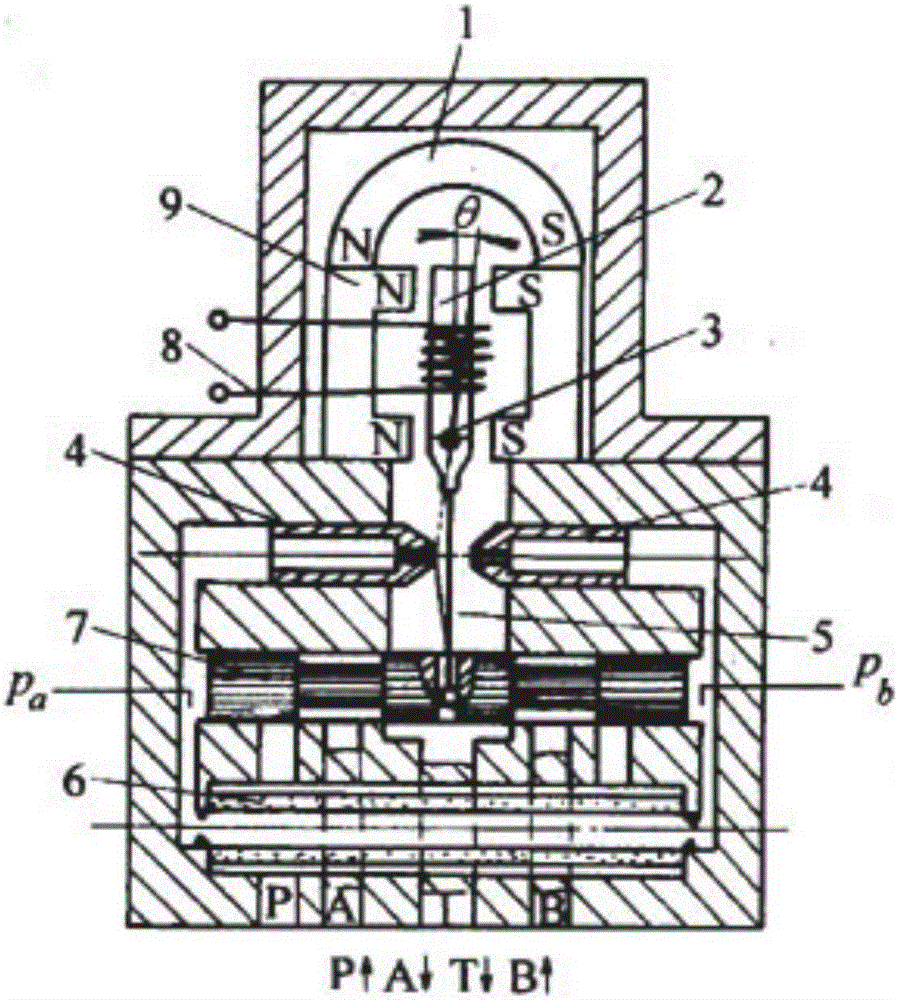

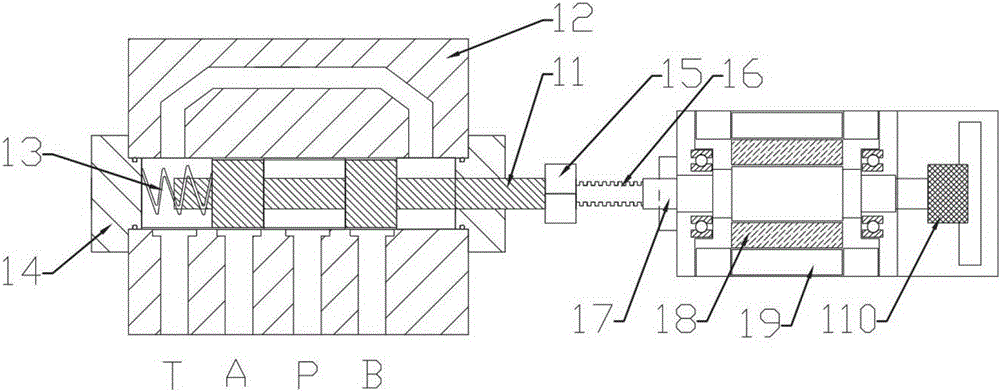

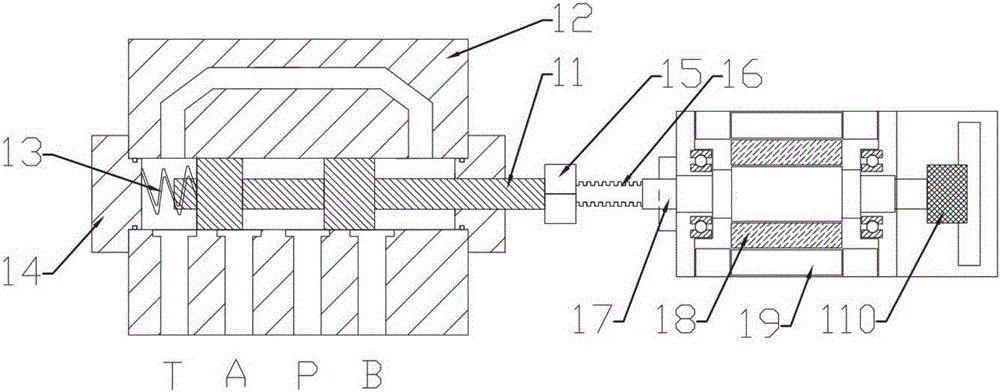

Servo motor direct-drive type servo valve

InactiveCN105221508APrecisely control the amount of axial movementPrecise control of output pressureServomotor componentsElectric machineBall screw

The invention provides a servo motor direct-drive type servo valve which has fewer stages, high system stability, good reliability, strong anti-fouling performance, low maintenance cost, a wider application occasion, and lower manufacturing difficulty and cost. The servo motor direct-drive type servo valve comprises a main valve element, a valve body, a spring, a valve body end cover, a lead screw nut, a ball screw and a servo motor, wherein the main valve element is mounted in the valve body in a sliding mode; four oil ports are arranged in the valve body; on-state among the four oil ports is regulated by virtue of changes of left, middle and right positions of the main valve element; the left end of the main valve element is resisted against the valve body end cover through the spring; the right end of the main valve element is connected with the lead screw nut; the lead screw nut is mounted on the ball screw; the servo motor comprises a servo motor shaft, a servo motor rotor, a servo motor stator and a rotary coder; the left end of the servo motor shaft is connected with the balls crew; the servo motor rotor is connected with the servo motor shaft; the servo motor stator is arranged outside the servo motor rotor in a sleeving mode; and the rotary coder is mounted at the right end of the servo motor shaft.

Owner:SHANGHAI JIJIAN PRECISION MACHINERY

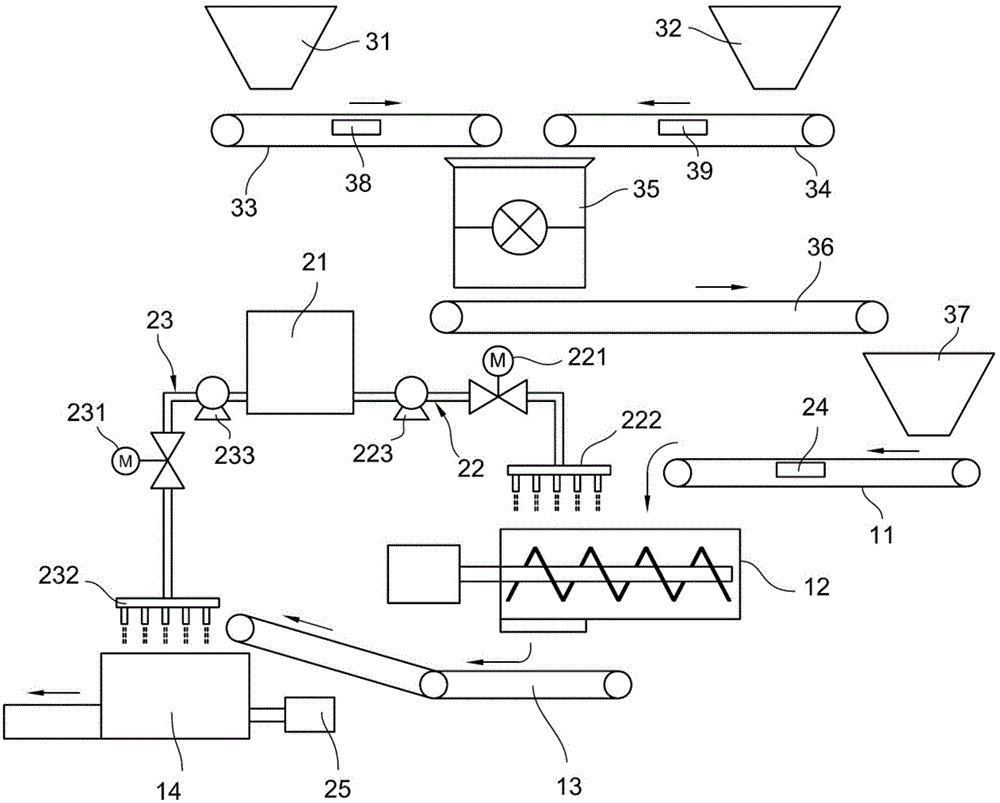

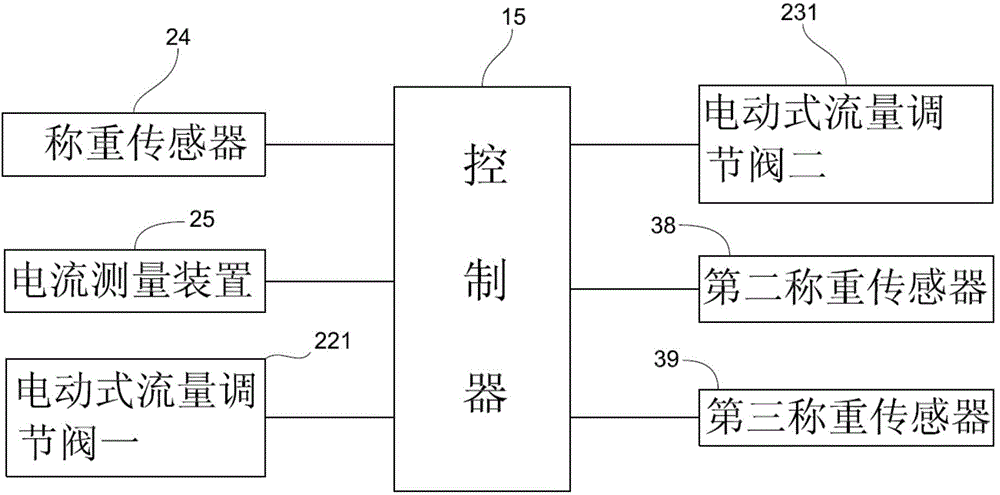

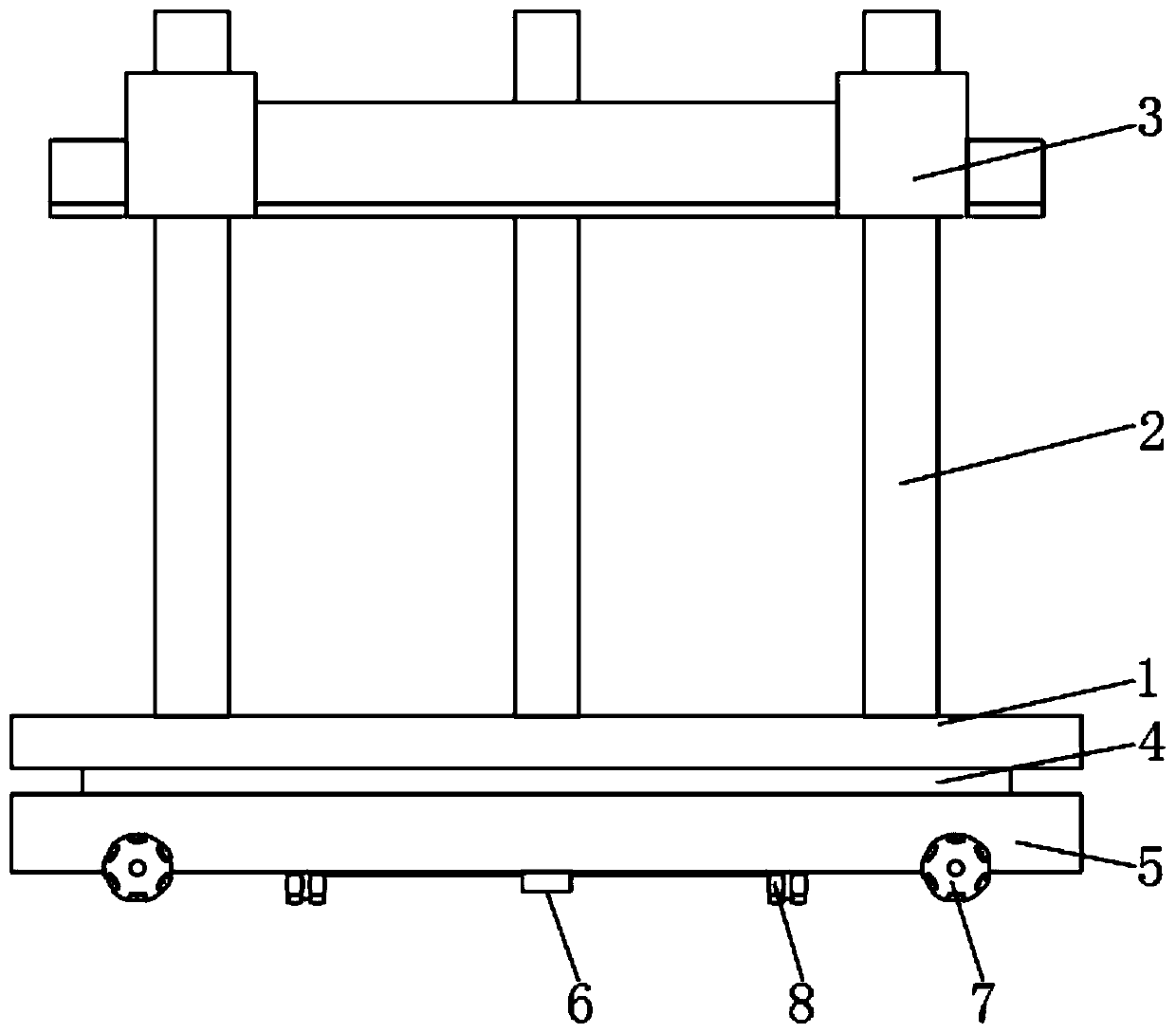

Automatic water distribution system for brick manufacturing device

ActiveCN104441209ATo achieve the purpose of auxiliary regulationTo achieve the purpose of closed-loop feedback regulationAuxillary shaping apparatusBrickMeasurement device

The invention discloses an automatic water distribution system for a brick manufacturing device. The automatic water distribution system comprises a water tank, a main water supply portion connected with the water tank, an auxiliary water supply portion connected with the water tank and used for supplying water to a brick manufacturing machine, a weighing sensor arranged on a brick manufacturing raw material conveying belt and used for detecting material flow of the brick manufacturing raw conveying belt, a current measuring device electrically connected with the brick manufacturing machine and used for detecting the actual working current of the brick manufacturing machine, a controller electrically connected with the current measuring device, the main water supply portion, the auxiliary water supply portion and the weighing sensor. The controller adjusts the water flow in the main water supply portion according to the material flow measured by the weighing sensor and the given required water proportion. The controller adjusts the water flow in the auxiliary water supply portion according to the difference value of the actual working current, measured by the current measurement device, of the brick manufacturing machine and the given working current. The water distribution system is provided with double water supply portions and capable of adjusting the water content of materials precisely to meet the forming requirement.

Owner:CHONGQING CENGTER GRAND TECH

Large-format laser cleaning device

The invention relates to a laser cleaning device, in particular to a large-format laser cleaning device, and belongs to the technical field of laser cleaning. A moving device is mounted; through the direction change of wheel brackets of the moving device, wheels can be placed on the ground or withdrawn, so that the whole laser cleaning device is convenient to move and fix; a controller respectively controls extension of extension rods of four electric cylinders to drive four laser cleaning machines to move up and down to adjust the distance from each laser cleaning machine to the surfaces of objects to be cleaned in real time, so that the objects can be always maintained in an optimal cleaning distance state for cleaning, uneven surfaces can be maintained in a more ideal cleaning effect, and the laser cleaning device can be suitable for metal workpieces with uneven surfaces; and the widths of optical fibers output by one laser cleaning machine are just in butt joint with the widths ofoptical fibers output by the adjacent laser cleaning machines, so that the four laser cleaning machines arranged side by side can be suitable for large-area cleaning of the uneven surfaces of the objects to be cleaned.

Owner:CAS LASER

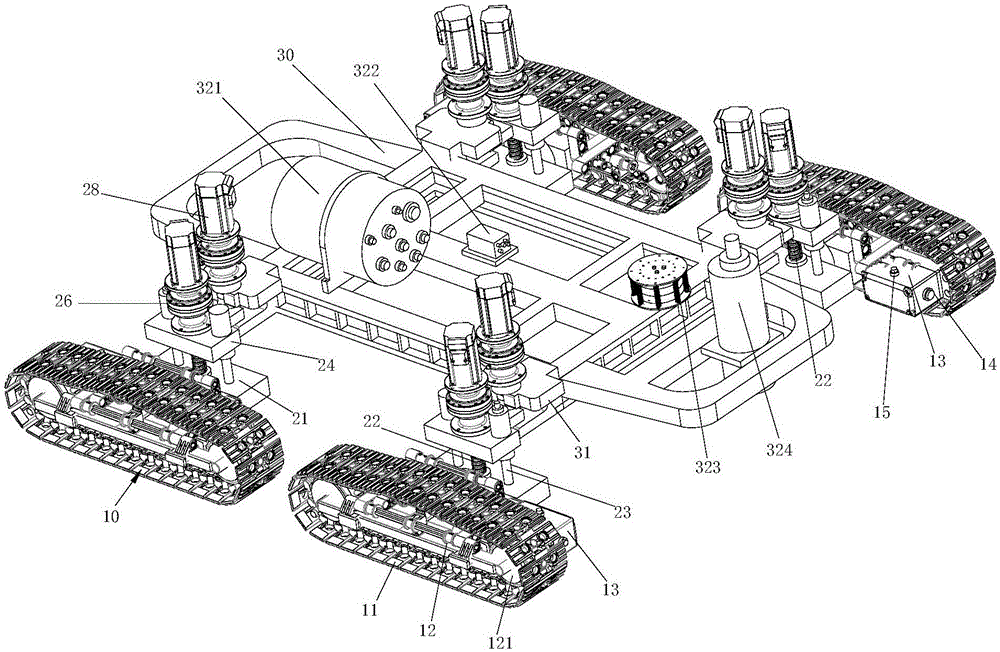

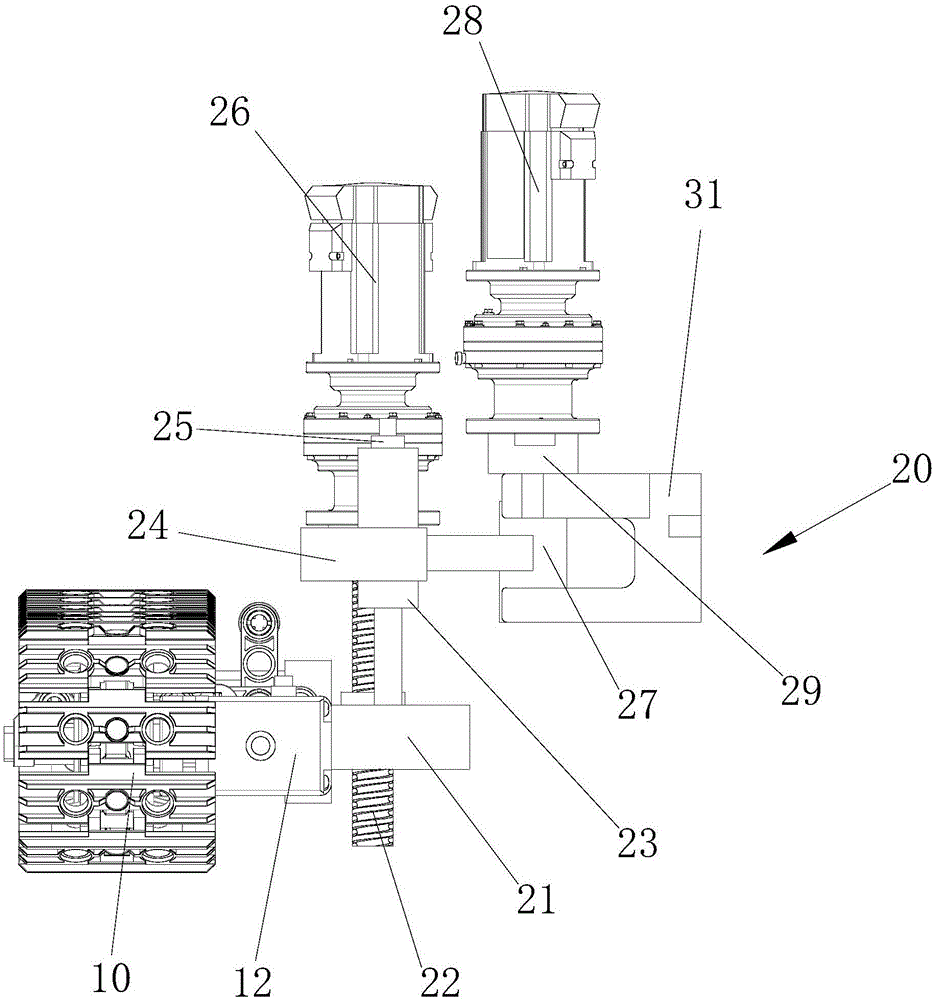

Seabed mining vehicle underpan, seabed mining vehicle and controlling method for seabed mining vehicle

ActiveCN107521643AQuick responseImprove terrain adaptabilityMineral miningEndless track vehiclesTerrainOcean bottom

The invention relates to a seabed mining vehicle underpan, a seabed mining vehicle and a controlling method for the seabed mining vehicle. The mining vehicle underpan comprises four electric-driving type caterpillar band walking mechanisms, four hanging mechanisms, an underpan frame and an underpan control system, the four electric-driving type caterpillar band walking mechanisms are mounted on the four hanging mechanisms correspondingly, and each electric-driving type caterpillar band walking mechanism is mounted on a bearing rod of the corresponding hanging mechanism through a caterpillar band frame; the bearing rods are connected with a steering lever through nuts and screw rods, and the inner ends of the steering levers are connected with hanging seats of the underpan frame through sliding bearings; and the underpan control system which is mounted on the underpan frame comprises an electronic bin, an acoustic beacon and an inertial navigation assembly. When the seabed mining vehicle is in the running process, calculating is conducted by the underpan control system according to data collected by a sensor to adjust all the caterpillar band walking mechanisms in real time, and the height of each caterpillar band walking mechanism can be adjusted independently, so that the mining vehicle keeps balance in the walking process, the terrain adaptive capacity and the over-obstacle capacity of the mining vehicle are improved, and the mining vehicle can better adapt to a complex seabed environment.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Germanium single crystal growth furnace and germanium single crystal growth temperature control method based on growth furnace

InactiveCN105951170APrecise temperature controlBreak the blockadePolycrystalline material growthFrom frozen solutionsSupporting systemTemperature control

The invention relates to the technical field of preparation of new materials, in particular to a germanium single crystal growth furnace and a germanium single crystal growth temperature control method based on the growth furnace. The germanium single crystal growth furnace is fixed on a base vertically and is characterized in that the growth furnace adopts a cylindrical stainless steel furnace body; several heating electrodes are arranged on the side wall of the furnace body from bottom to top; annular thermal insulation materials are arranged inside the furnace body; a support system is arranged at the bottom of a central shaft of the furnace body; a special-shaped quartz tube is erected on the support system; a lower crucible, a middle ring, an upper crucible and a sealing cap are sequentially arranged in the special-shaped quartz tube from bottom to top; quartz wool covers the special-shaped quartz tube. The growth furnace specific to the growth characteristics of 8-inch germanium single crystals is exquisite in structure and reasonable in design of temperature area.

Owner:云南中科鑫圆晶体材料有限公司 +2

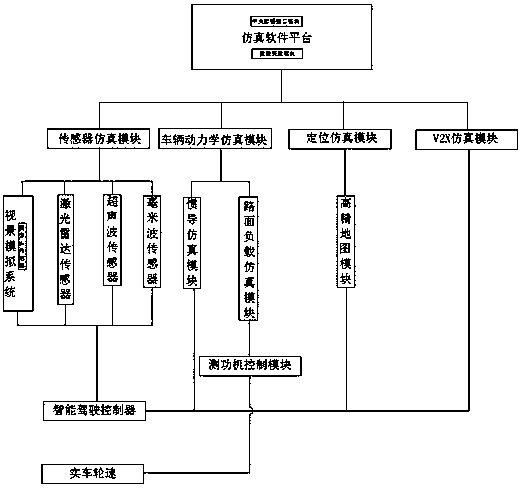

Intelligent network-connected automobile simulation test system based on whole automobile hardware-in-loop

InactiveCN110687828AImprove test accuracy and confidenceImprove test efficiencySimulator controlDriver/operatorVehicle dynamics

The invention discloses an intelligent network-connected automobile simulation test system based on whole automobile hardware-in-loop, and relates to the technical field of intelligent automobile automatic driving. The system comprises a hub dynamometer, a vehicle dynamics simulation module, a hub dynamometer control module, a sensor simulation module, a visual simulation system and a positioningsimulation module, wherein the hub dynamometer is independently mounted on wheels of a tested whole automobile; the vehicle dynamics simulation module mainly comprises an inertial navigation simulation module and a road load simulation module; the hub dynamometer control module is used for receiving parameters from the vehicle dynamics simulation module; the sensor simulation module is used for simulating the environment around the tested vehicle; the visual simulation system is connected with the output signal of the sensor simulation module and is used for simulating the visual angle of a driver; and the positioning simulation module is used for simulating the position of the vehicle in a high-precision map. According to the system, a large number of different environmental conditions can be simulated without being constrained by external conditions, compared with an actual road experiment, a large amount of time and manpower and a large number of financial resources can be saved, the safety is higher than that of the road experiment, and the test performance is greatly improved.

Owner:苏州智行众维智能科技有限公司

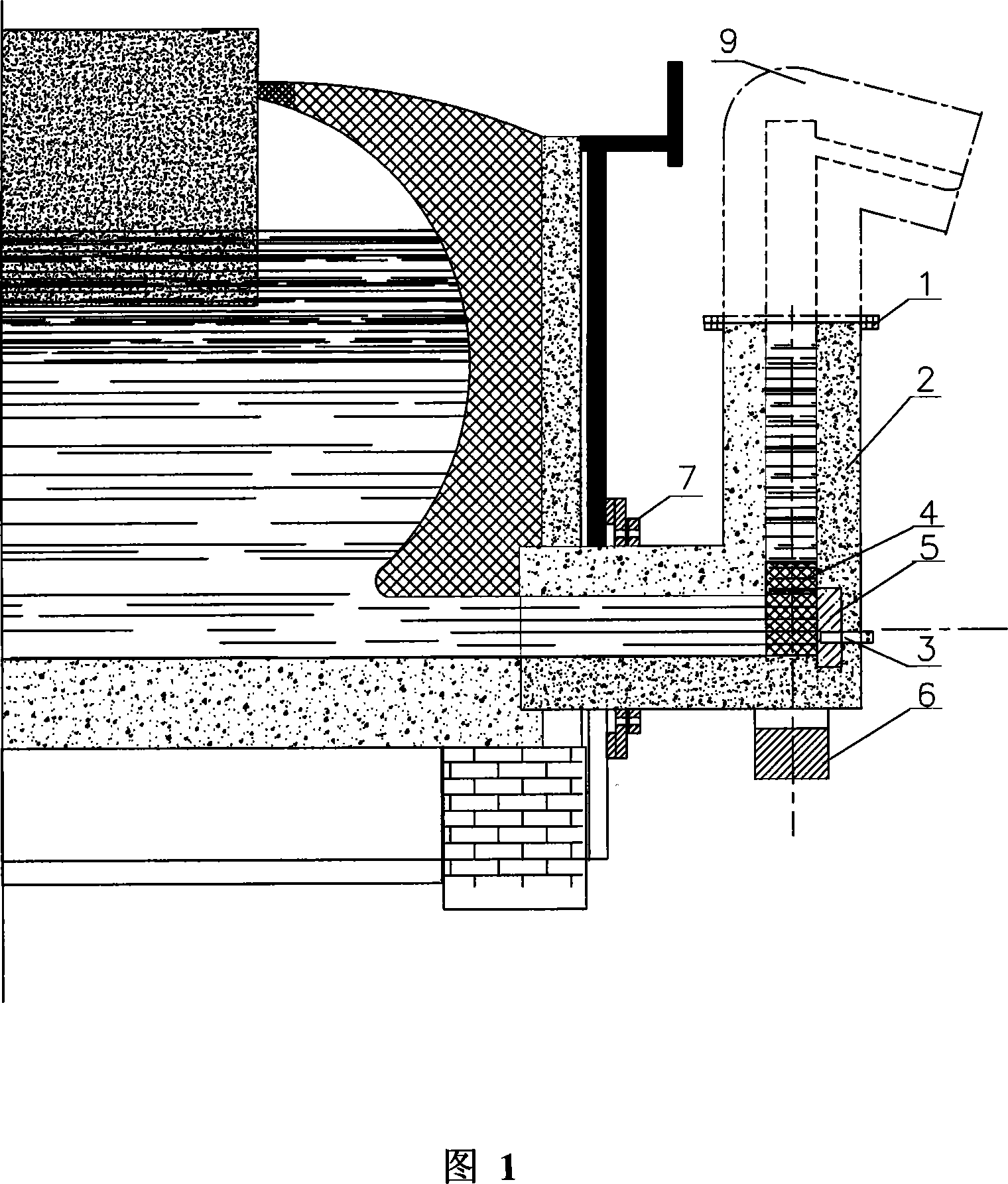

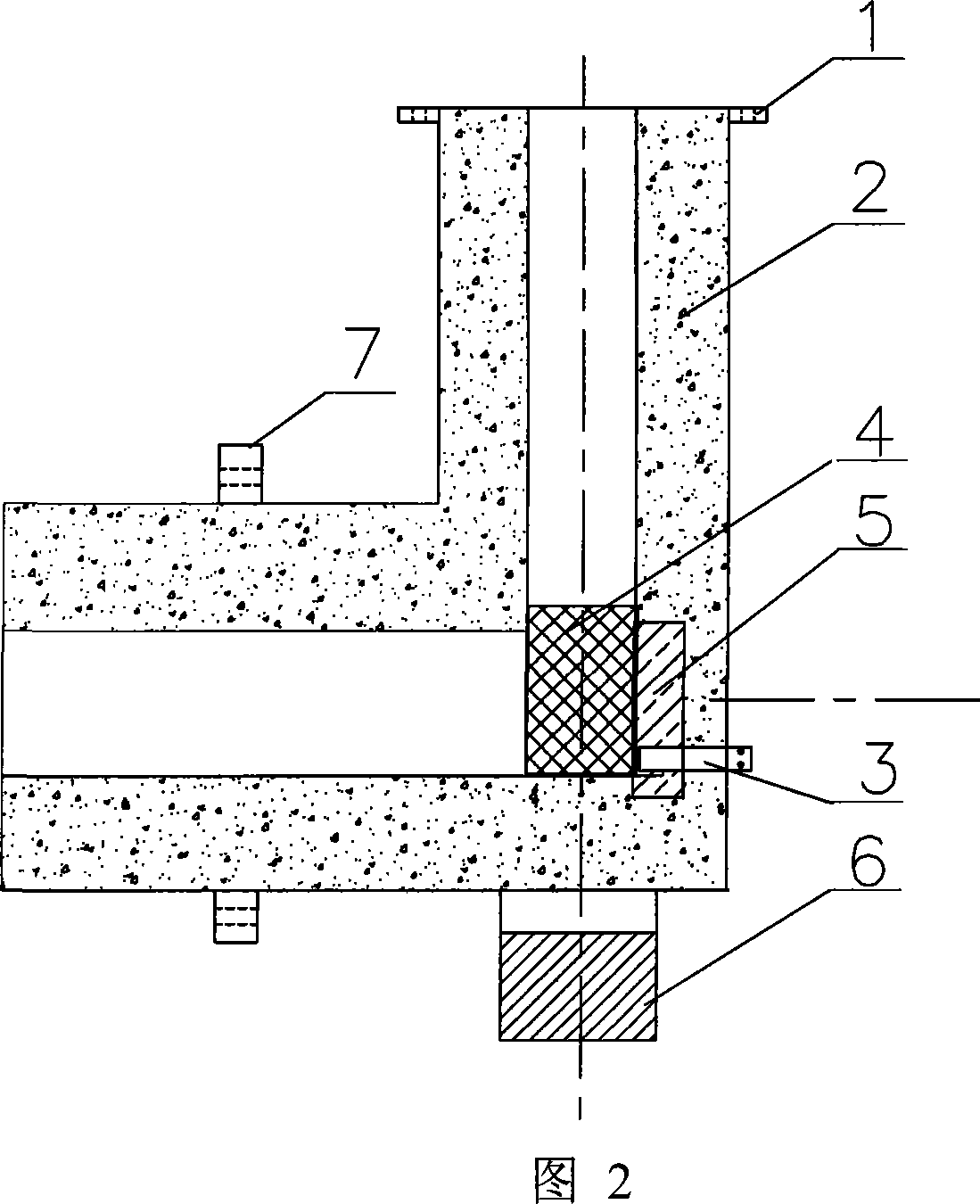

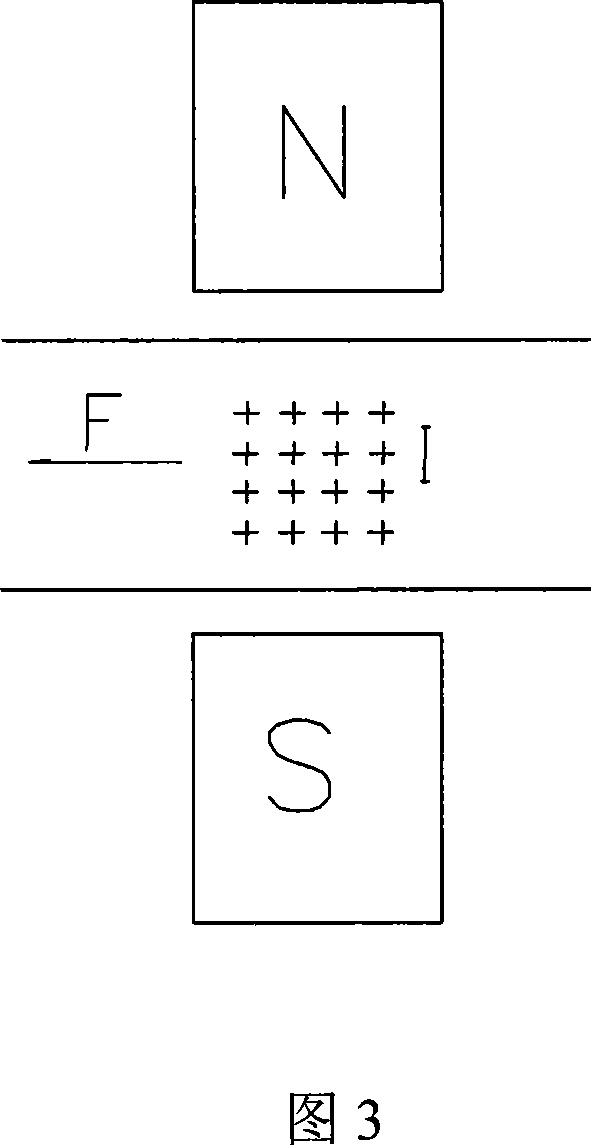

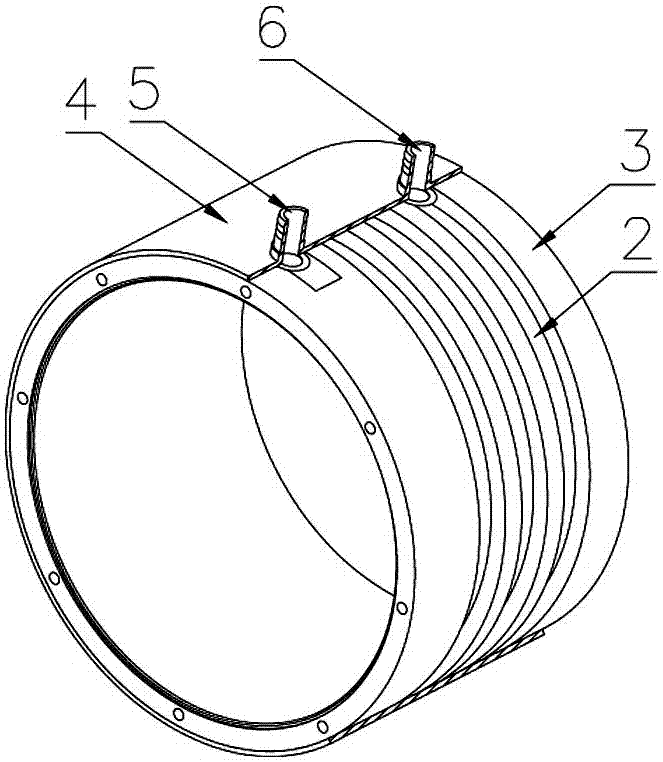

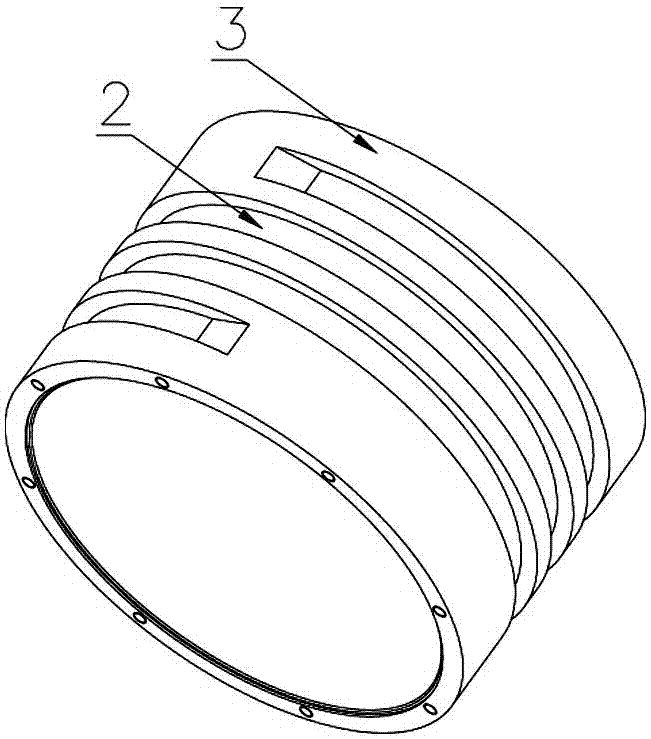

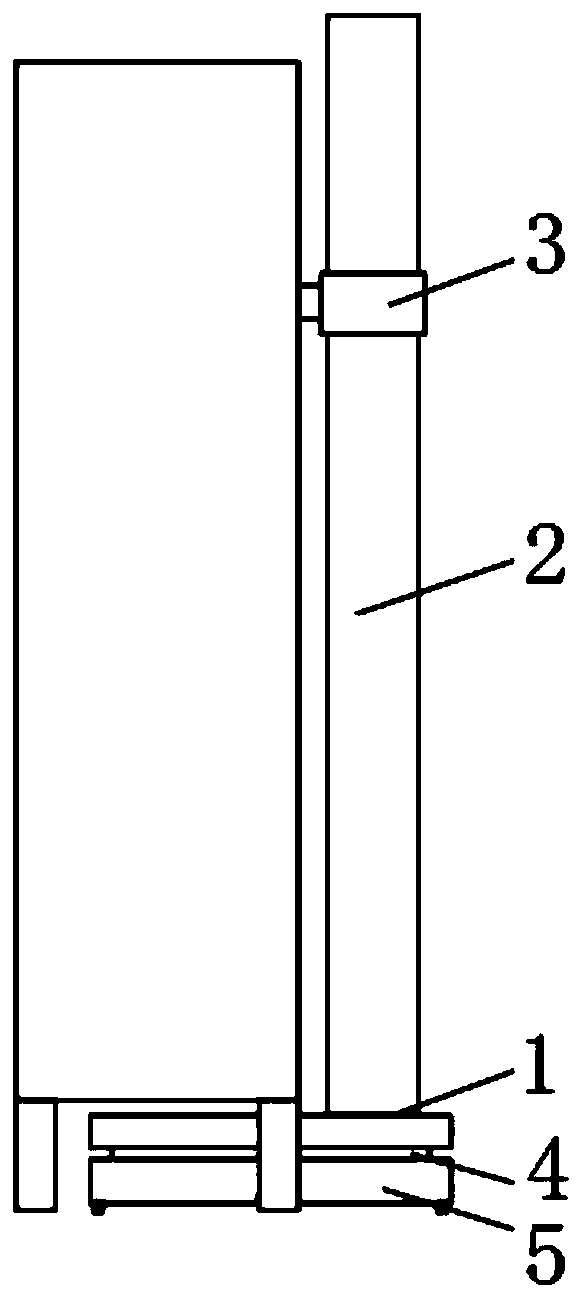

Direct-current electromagnetic pump for aluminum cell

ActiveCN101063211ASimple structureWork reliablyMolten metal supplying equipmentsPumpsEngineeringElectromagnetic pump

The invention discloses an electromagnetic pump especially a source-free direct current electromagnetic pump, which is characterized by the following: setting pump body (2) as L shape structure; arranging negative pole at L angle position of the pump body (2); arranging magnetic conduction plate (4) on the two laterals of the L angle in the pump body (2); connecting the two magnetic conduction plates to N pole and S pole of electromagnet (6) separately; constructing the negative pole 5 and the magnetic conduction plate (4) as component of pump groove; nesting energizing coil (8) on the electromagnet (6); connecting the negative (5) and the energizing coil (8) to site control pod. This invention possesses simple structure, liable work and small volume.

Owner:CHINA ALUMINUM INT ENG CORP

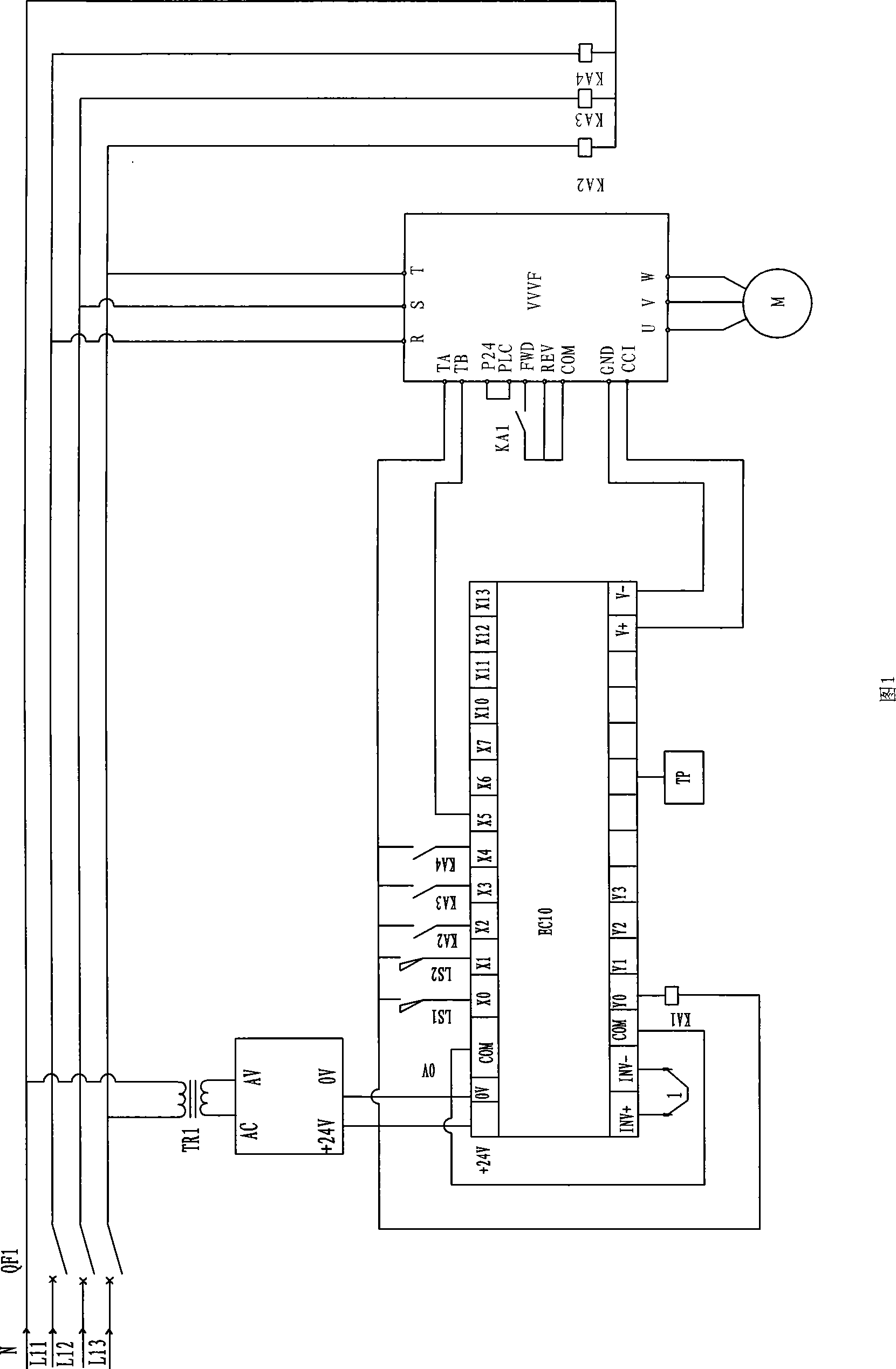

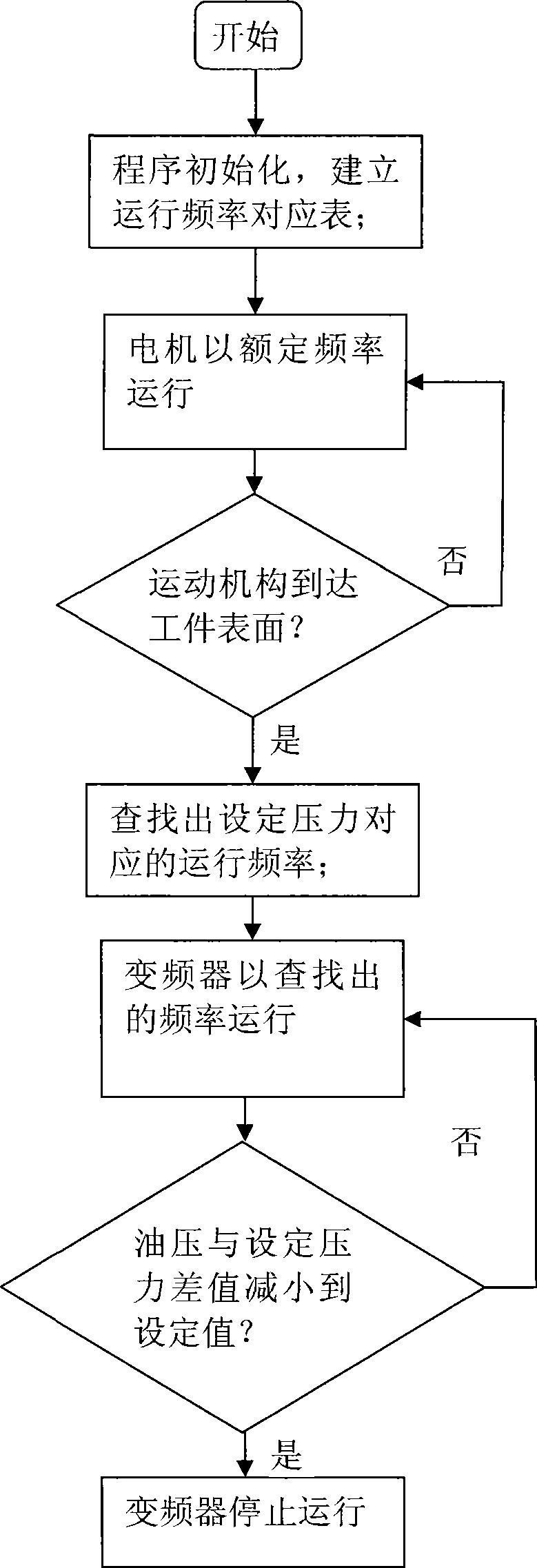

Automatic control system of hydraulic pump station

InactiveCN101436076AAutomatic and precise control of working pressurePrecise control of working pressureFluid pressure control using electric meansFrequency changerAutomatic control

The invention relates to an automatic control system for a hydraulic pumping station, which belongs to the technical field of an automatic control system for the hydraulic pumping station. The automatic control system for the hydraulic pumping station comprises a programmable controller PLC, a frequency converter which is connected to the front end of a hydraulic motor which drives a motion mechanism to move, and a pressure sensor which is arranged on an oil pipe, wherein the frequency converter and the pressure sensor are electrically connected with the programmable controller PLC respectively, and various controls are realized through programs of the programmable controller PLC. The automatic control system for the hydraulic pumping station has the advantages that a signal is transmitted to the PLC by the pressure sensor, and the working frequency of the frequency converter and the motor is controlled in real time by the PLC control program; the working pressure of dynamic oil of the hydraulic pumping station can be automatically and precisely controlled; a touch screen which is used as a man-computer interactive interface can be connected to the PLC, and the working pressure can be conveniently set on the touch screen; and the operation is simple and convenient, and the control precision is within 3 percent. The automatic control system for the hydraulic pumping station is not only suitable for various hydraulic machines of which main frames and hydraulic devices are detachable but also suitable for various hydraulic machines of which the main frames and the hydraulic devices are integrated into a whole.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

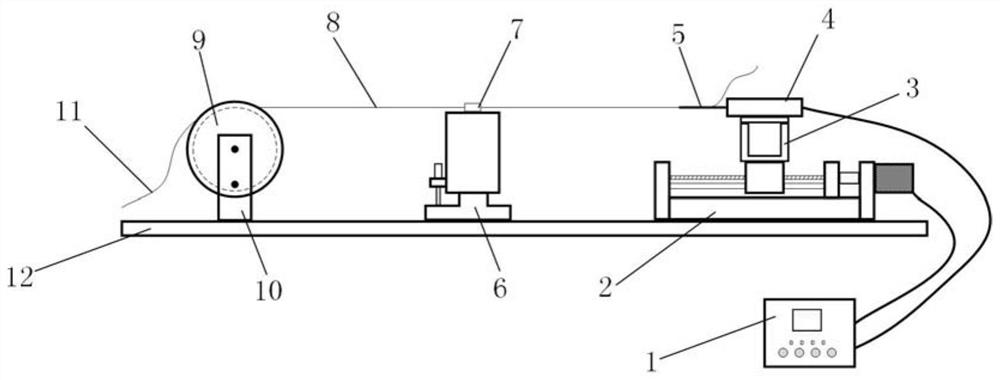

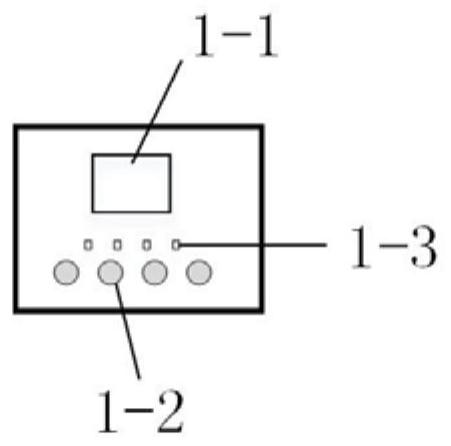

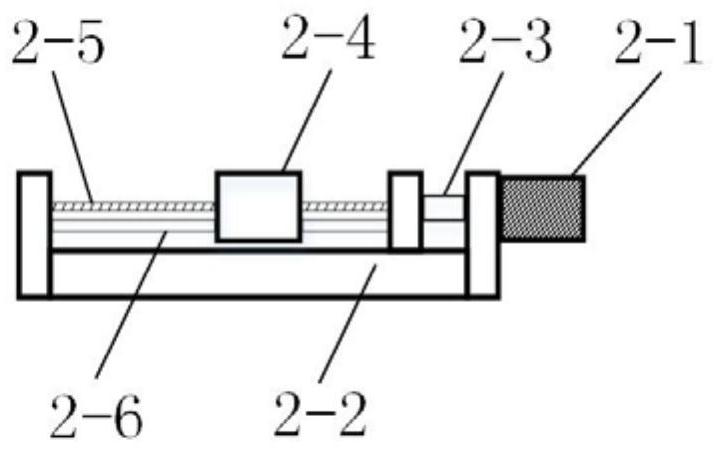

Optical fiber sensor packaging process prestress automatic control device and method

InactiveCN112710336AControl precise controlHigh control precisionProgramme controlComputer controlAutomatic controlEngineering

The invention discloses an optical fiber sensor packaging process prestress automatic control device and method. The device comprises a control module, a displacement module, a tension meter, a fine adjustment module, an optical fiber winding wheel and a base; the fine adjustment module is used for supporting an optical fiber sensor packaging structure, and the height of the fine adjustment module can be adjusted, so that an optical fiber is not subjected to external force in a vertical direction; one end of an optical fiber sensor tail fiber is wound and fixed on the optical fiber winding wheel, and the other end of the optical fiber sensor tail fiber is fixed on a tension meter connecting rod; the tension meter is installed on the displacement module through a supporting piece, moves in the direction of stretching or loosening the optical fiber along with the displacement module, sends a tension value to the control module in real time; and the control module compares the real-time tension value with a preset tension value to make a decision to control the displacement of the tension meter. According to the optical fiber sensor packaging process prestress automatic control device, closed-loop control can be performed on the prestress of an optical fiber sensor according to a preset value; the control device is simple in structure and high in control precision, can be copied, and can easily realize batch packaging of optical fiber sensors.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Asphalt pavement friction coefficient tester capable of simulating rainfall and testing method of asphalt pavement friction coefficient tester

ActiveCN106290145ASimple structureReasonable designUsing mechanical meansMaterial analysisWater storageSolenoid valve

The invention relates to an asphalt pavement friction coefficient tester capable of simulating rainfall and a testing method of the asphalt pavement friction coefficient tester. The asphalt pavement friction coefficient tester comprises a rain box which is divided into a main equipment region and an auxiliary equipment region; the main equipment region is separated into an upper part and a lower part through a rain collection bottom plate and the lower part is a water collection box; a water distribution pipe with a nozzle is arranged at the top of a right part of the upper part; two clamping strips are arranged at the bottom of the right part of the upper part; a test mold is arranged between the two clamping strips; a portable pendulum tester is arranged on an upper surface of the test mold; a water storage bucket is arranged at the bottom of the left part; the bottom of the water storage bucket is connected to a water pump in the water collection box through a water inlet pipe; a water pump is arranged at the top of the water storage bucket and the water pump is connected to the water distribution pipe through a water conveying pipeline; the water conveying pipeline is further upwards provided with a tee joint, a flow meter and a solenoid valve in sequence; the tee joint is connected with a water returning pipe which is provided with an adjusting valve and is connected to the water storage bucket; the auxiliary equipment region is provided with a control box. The asphalt pavement friction coefficient tester has the characteristics of simple structure and simplicity and convenience for operation.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Ink supply control system, printing machine and ink supply control method

The invention provides an ink supply control system, a printing machine and an ink supply control method; wherein the ink supply control system comprises at least one ink inlet electromagnetic valve which is arranged between an ink inlet cavity and a spray nozzel; at least one ink return electromagnetic valve which is arranged between an ink return cavity and the spray nozzle; a control device, which is electrically connected with the at least one ink inlet electromagnetic valve and the at least one ink return electromagnetic valve and is used for controlling the working states of the at leastone ink inlet electromagnetic valve and the at least one ink return electromagnetic valve according to different working instructions; the ink supply control system provided by the invention has a simple structure, saves the consumption of ink during ink drop maintenance of the printing machine of a spliced module sub-nozzle, increases the service life of the nozzle, accurately controls the actual ink drop time, and avoids the difficulty of frequently replacing the spliced module nozzle.

Owner:NEW FOUNDER HLDG DEV LLC +1

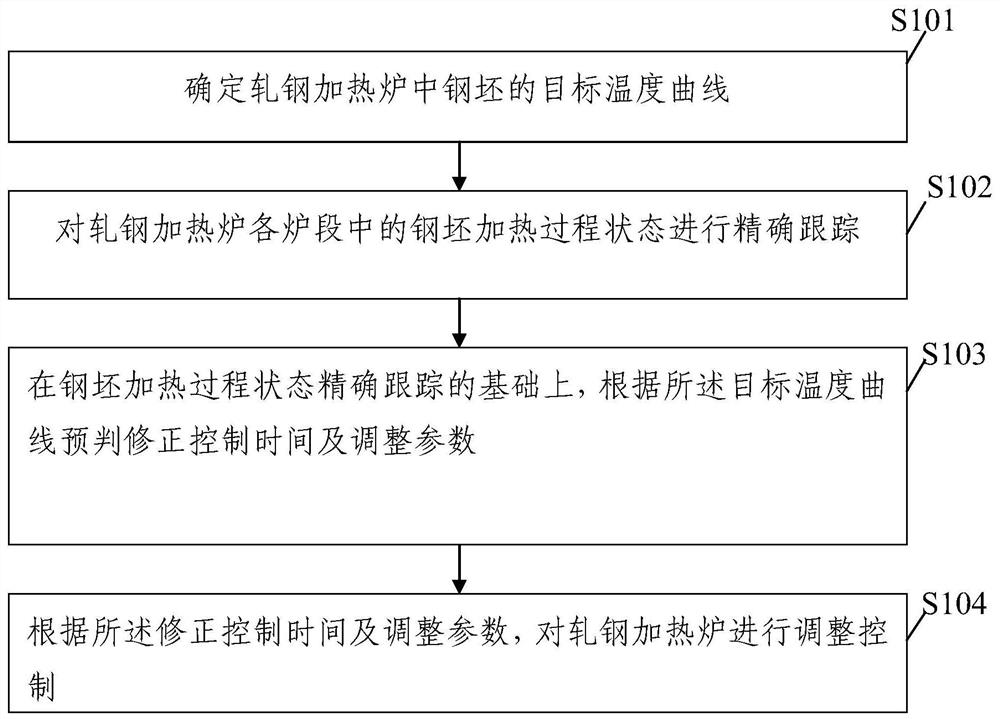

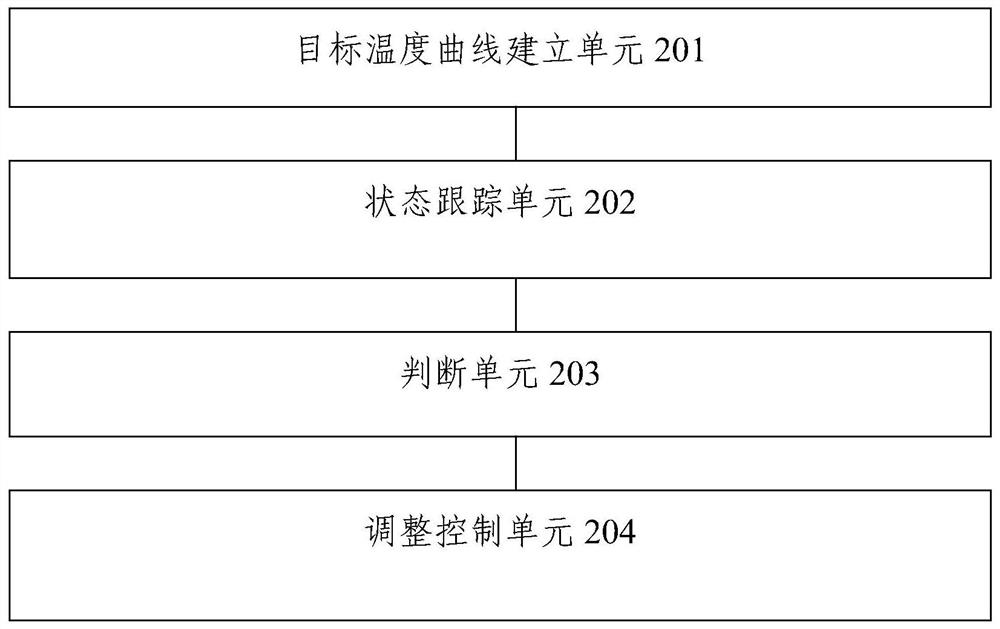

Control method and device for steel rolling heating furnace

PendingCN111809040AReduce shockRealize automatic judgmentFurnace typesHeat treatment process controlFurnace temperatureTemperature curve

The embodiment of the invention discloses a control method and device for a steel rolling heating furnace. The method comprises the steps of determining a target temperature curve of a steel billet inthe steel rolling heating furnace; accurately tracking the billet heating process state in each furnace section of the steel rolling heating furnace; on the basis of accurately tracking the state ofthe billet heating process, pre-judging and correcting control time and adjusting parameters according to the target temperature curve; and adjusting and controlling the steel rolling heating furnaceaccording to the correction control time and the adjustment parameters. By the adoption of the control method for the steel rolling heating furnace, automatic judgment and automatic adjustment of thefurnace temperature can be achieved in the mode that the steel billet heating process is controlled according to the target temperature curve, and therefore the purpose of accurately controlling the steel billet heating and cooling process is achieved.

Owner:深圳城市节能环保科技有限公司

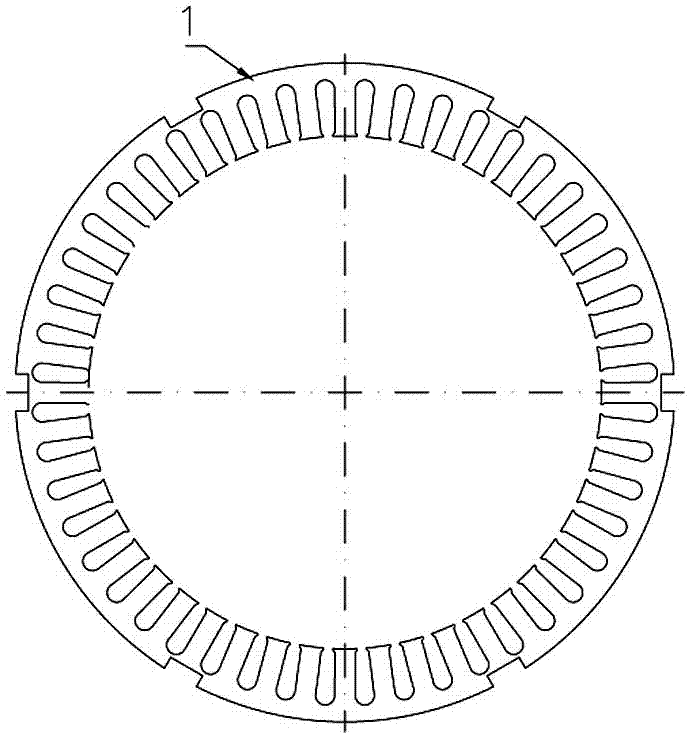

Permanent magnet synchronous motor for high power density electric automobile

InactiveCN106972721AImprove efficiencyImprove power densityMagnetic circuit rotating partsElectric machinesPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a permanent magnet synchronous motor for a high power density electric automobile. The motor comprises a motor body formed by a stator and a rotor. A stator iron core of the stator is of a deep-groove wide-teeth type structure. A stator winding is formed by multiple strands of parallelly wound fin wires. The rotor is of a surface-mounted magnetic steel structure. A stator housing is of an interlayer structure where a spiral water channel is arranged on the inner wall. A rotor iron core is of a hub-type structure. The magnetic steel are of tile-shaped structures with a set pole-arc coefficient which are embedded in the outer circumference of the rotor iron core, and solidified on the outer circumference of the rotor iron core through epoxy resin after being wound by glass fibers. The adjacent magnetic steel polarities are opposite to each other. A hub-type magnetic steel ring or a rotary transformer fixedly sleeves the back end part of a rotor shaft. The motor is advantaged by small size, light weight, big power intensity, strong overload capacity, capability of meeting actual operation working conditions of electric automobiles and increasing endurance journeys and remarkable energy saving effects.

Owner:ZHENGZHOU AIRCRAFT EQUIP +1

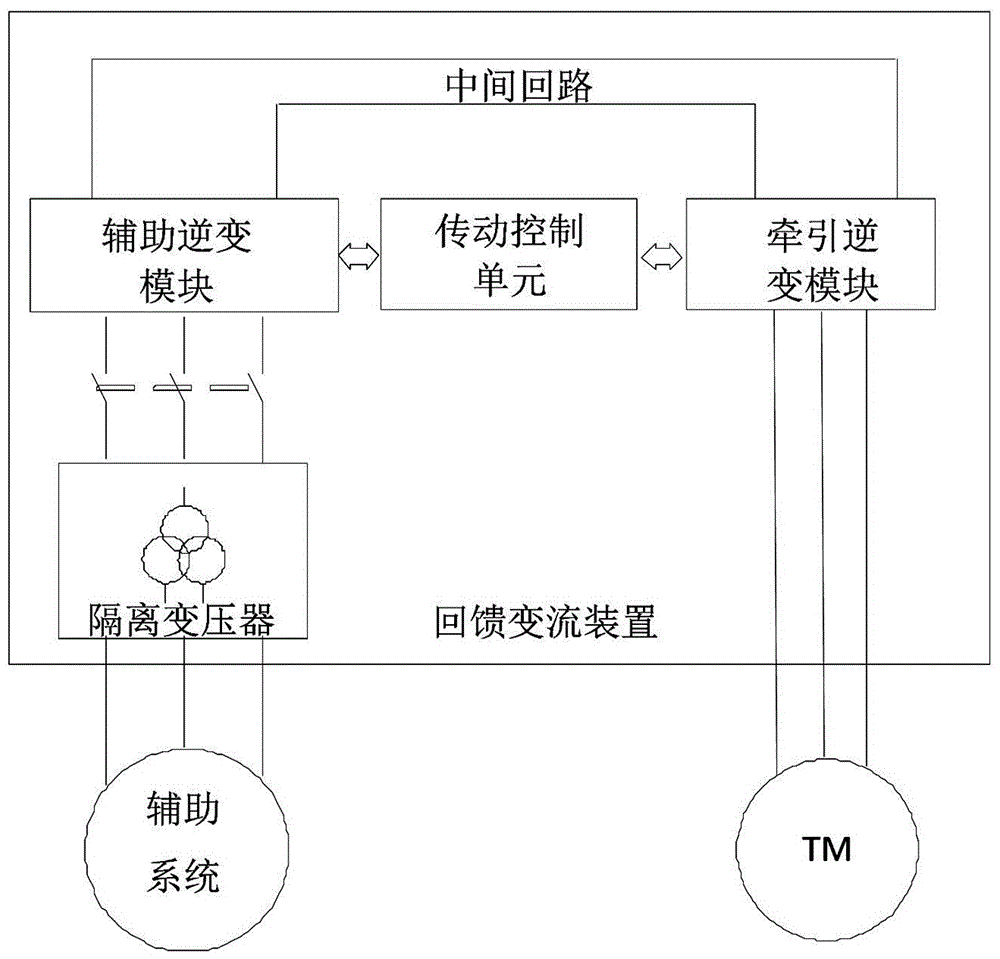

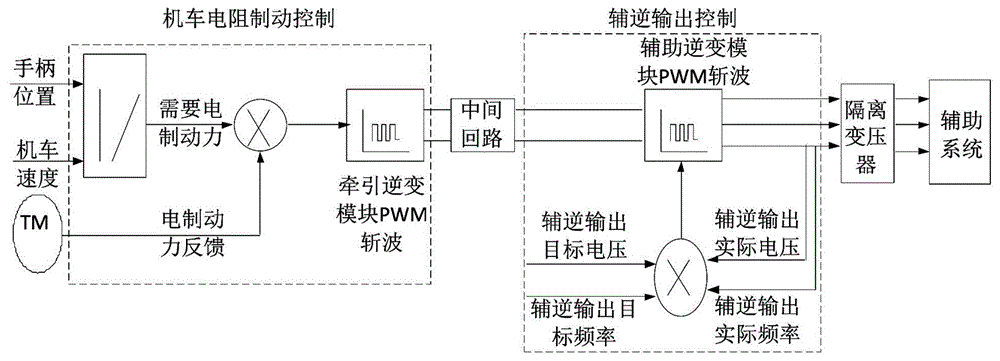

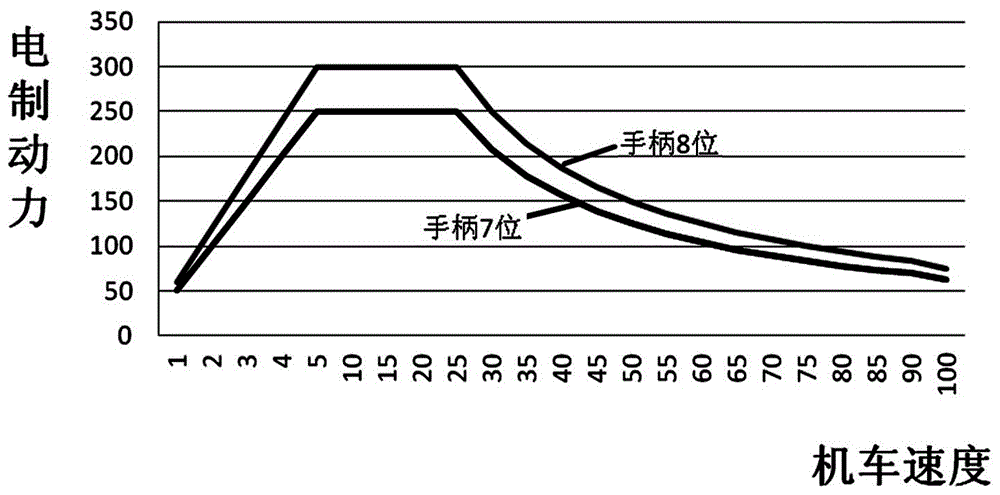

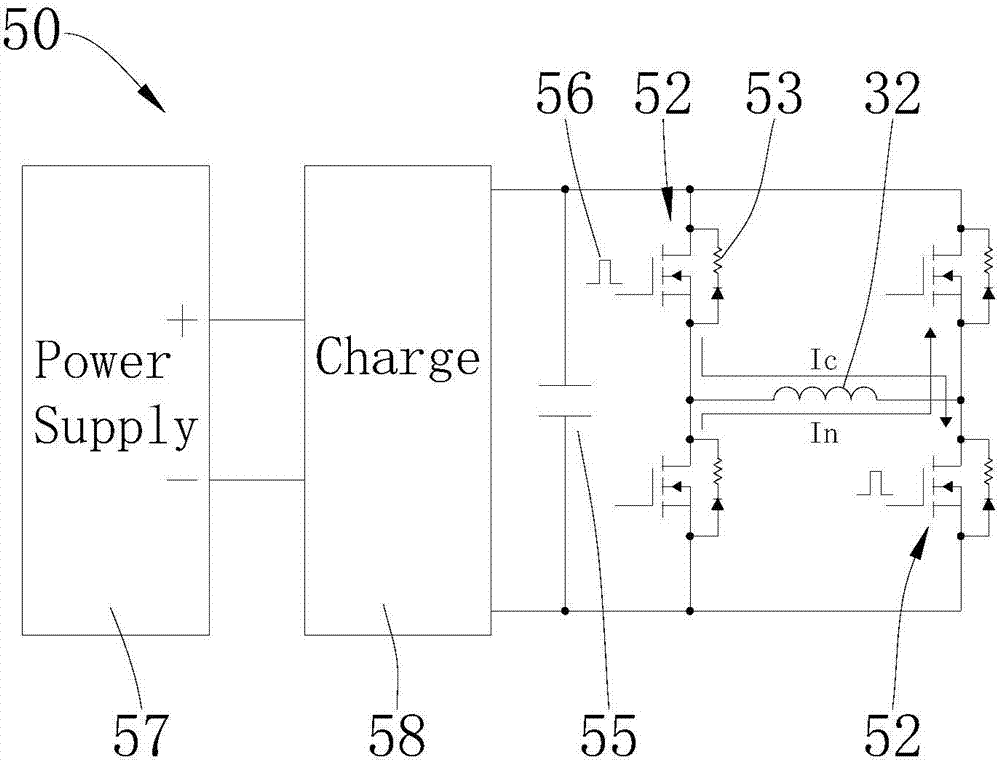

Internal combustion locomotive electric braking energy feedback converter and control method

ActiveCN106379177ASave installation spaceReduce weightElectrodynamic brake systemsElectric powerDC - Direct currentControl system

The invention discloses an internal combustion locomotive electric braking energy feedback converter which comprises a traction inversion module, an auxiliary inversion module, an isolation transformer and a transmission control unit, wherein the direct current end of the traction inversion module is connected with the direct current end of the auxiliary inversion module through an intermediate direct current circuit; the alternating current end of the auxiliary inversion module is connected with the input side of the isolation transformer; and the transmission control unit is respectively connected with the traction inversion module and the auxiliary inversion module. The internal combustion locomotive electric braking energy feedback converter does not need an auxiliary power generator or an auxiliary motor excitation control system, is used for supplying power to an auxiliary system by utilizing locomotive braking energy feedback, has the advantages of locomotive space saving, energy conservation, environmental friendliness and accurate control, and can be used for supplying high-quality electric energy to the auxiliary system.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

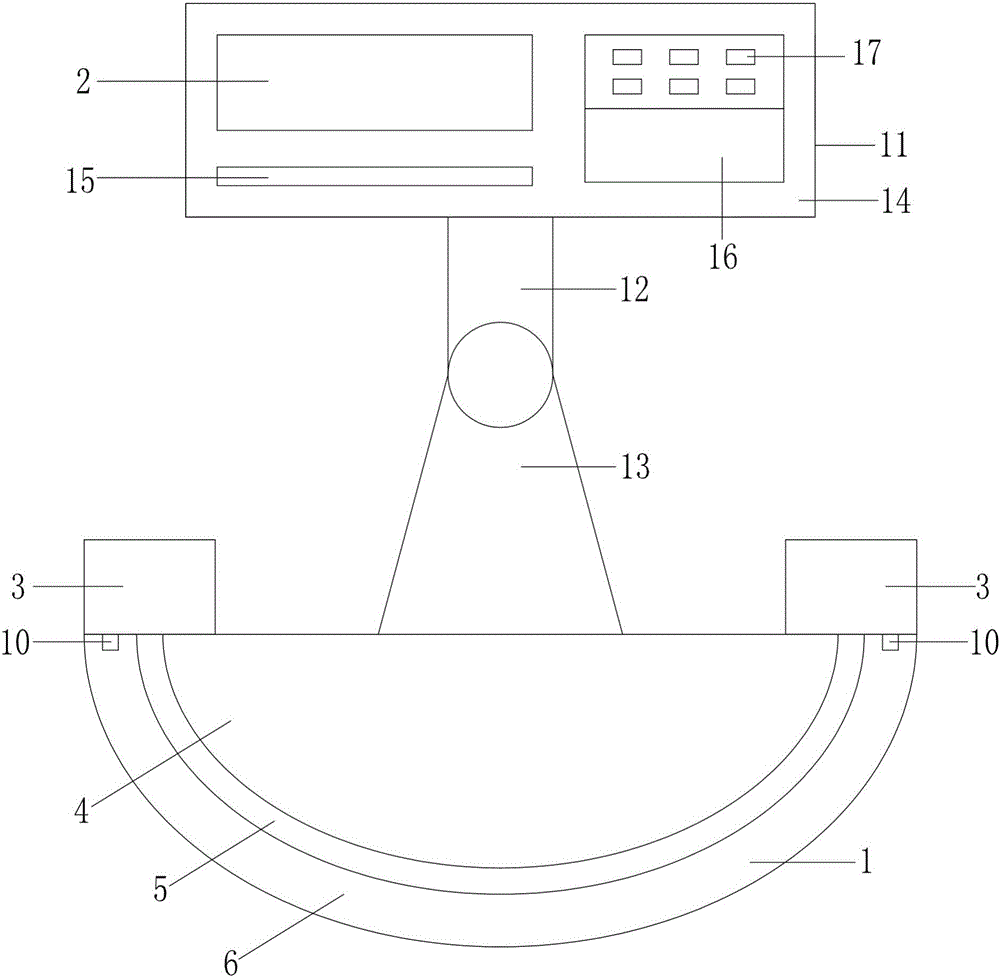

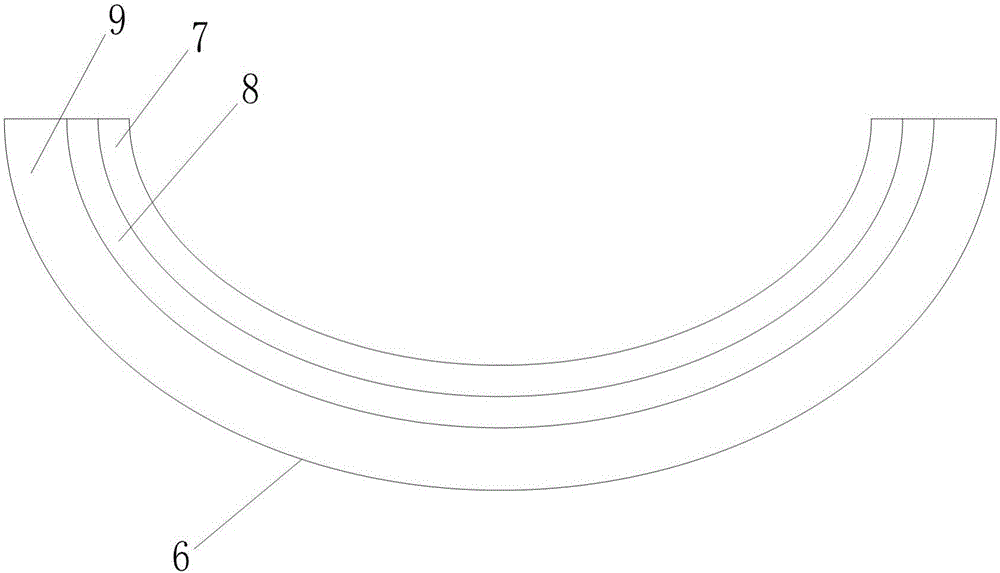

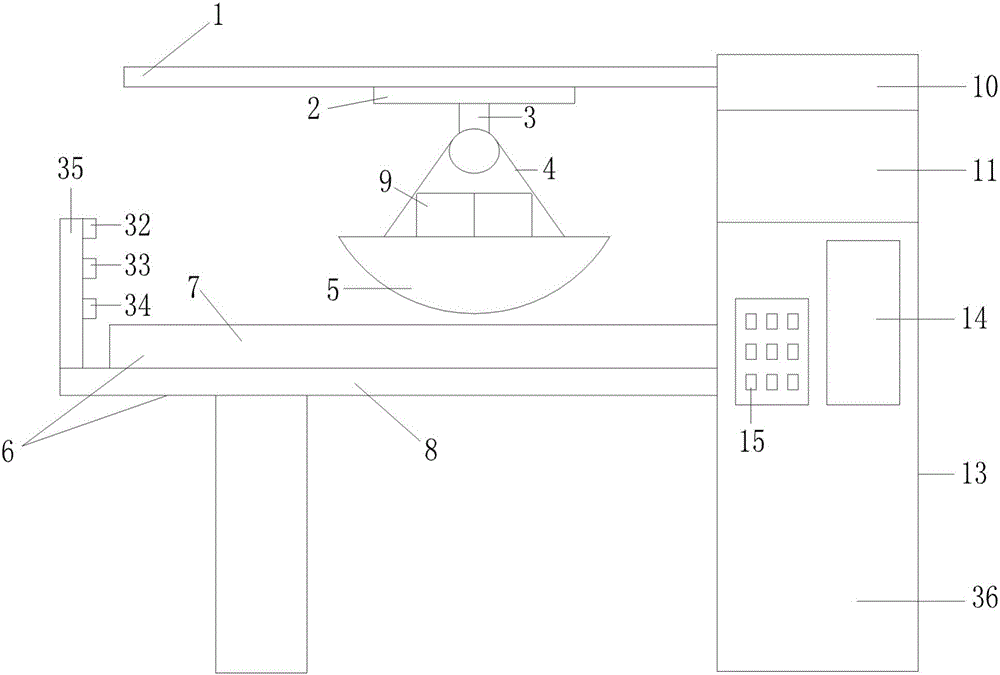

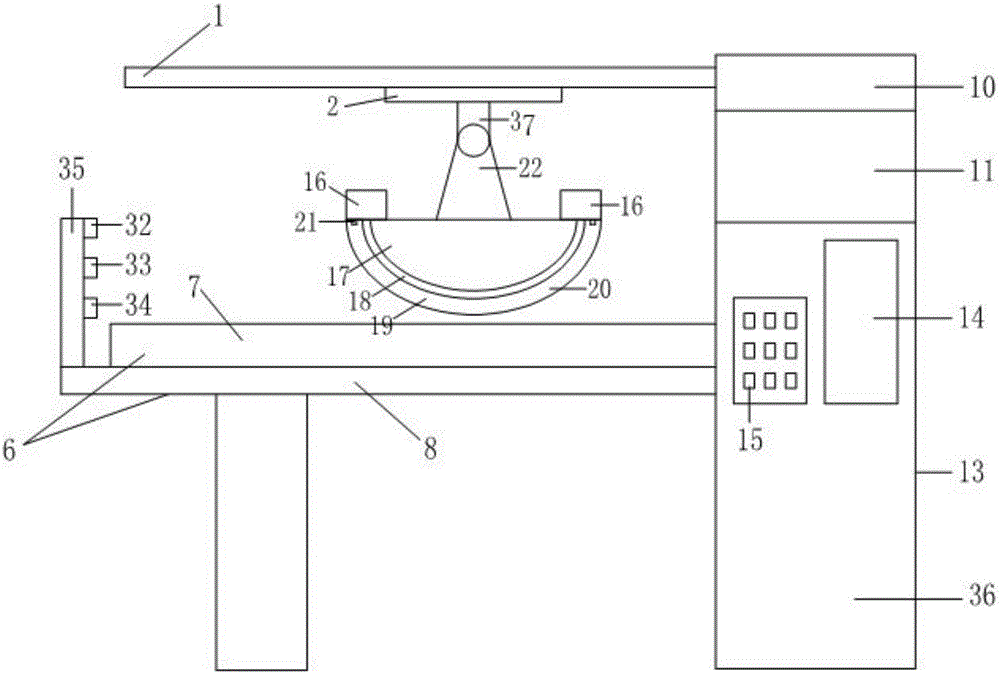

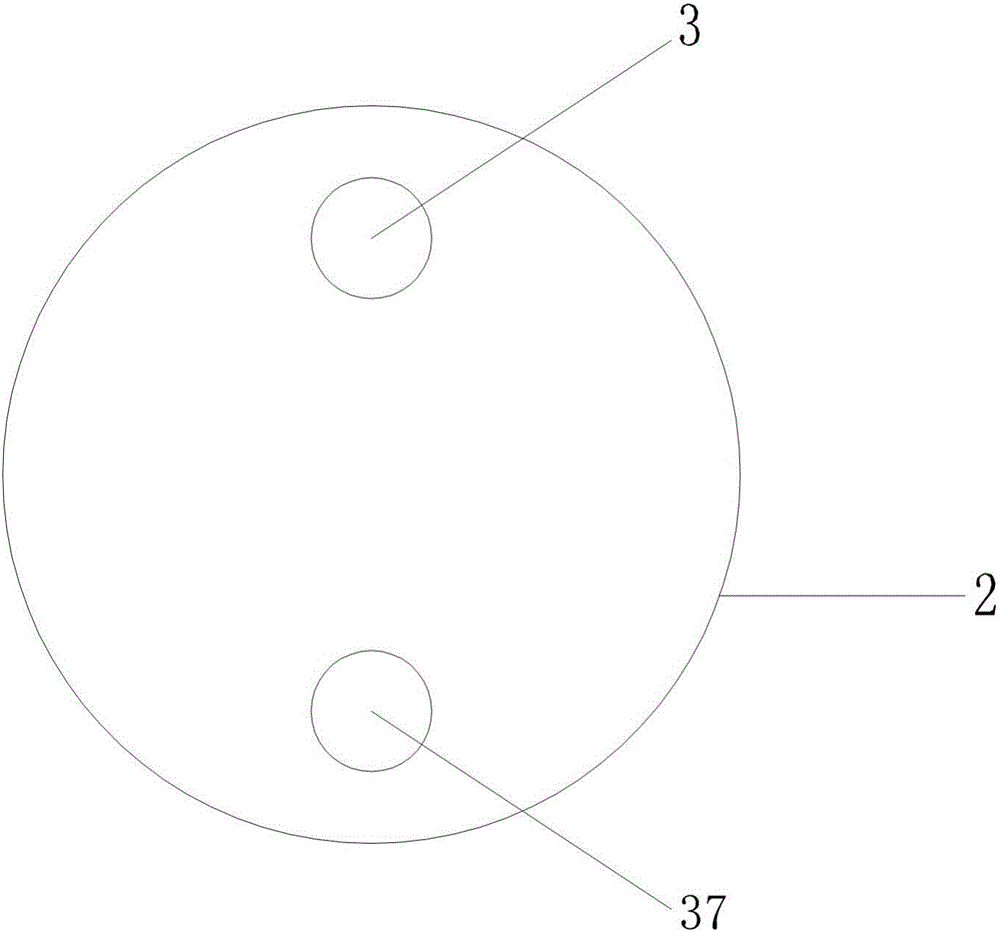

Simulation wheel-grind forming machine for bitumen mixture specimens and specimen manufacture method

ActiveCN106053179ASimple structureReasonable designPreparing sample for investigationHydraulic cylinderTweel

The invention discloses a simulation wheel-grind forming machine for bitumen mixture specimens and a specimen manufacture method. The simulation wheel-grind forming machine comprises a grind wheel, a grind wheel driving device, a grind inflating device and a control box. The grind wheel comprises a rim, a retainer ring and a tyre. The outer edge of the rim is provided with the retainer ring. The tyre encircles the outer edge of the rim through the retainer ring. The grind wheel driving device comprises a retarding mechanism, a rack, a hydraulic dowel bar, a hydraulic cylinder, a guide rail and a transmission chain. The retarding mechanism is in power connection with the transmission chain. The top of the hydraulic dowel bar is cooperatively and slidingly installed on a guide rail of the control box. The hydraulic dowel bar is cooperatively provided with the hydraulic cylinder. The hydraulic dowel bar has a telescopic motion bar. The bottom of the hydraulic dowel bar is hinged to the rack. The center of the top of the grind wheel's rim is fixedly connected to the bottom of the rack. The top of the rim is provided with the grind wheel inflating device for inflating the tyre. The simulation wheel-grind forming machine has a simple structure, is reasonably designed and is easy and simple to install, use and operate.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

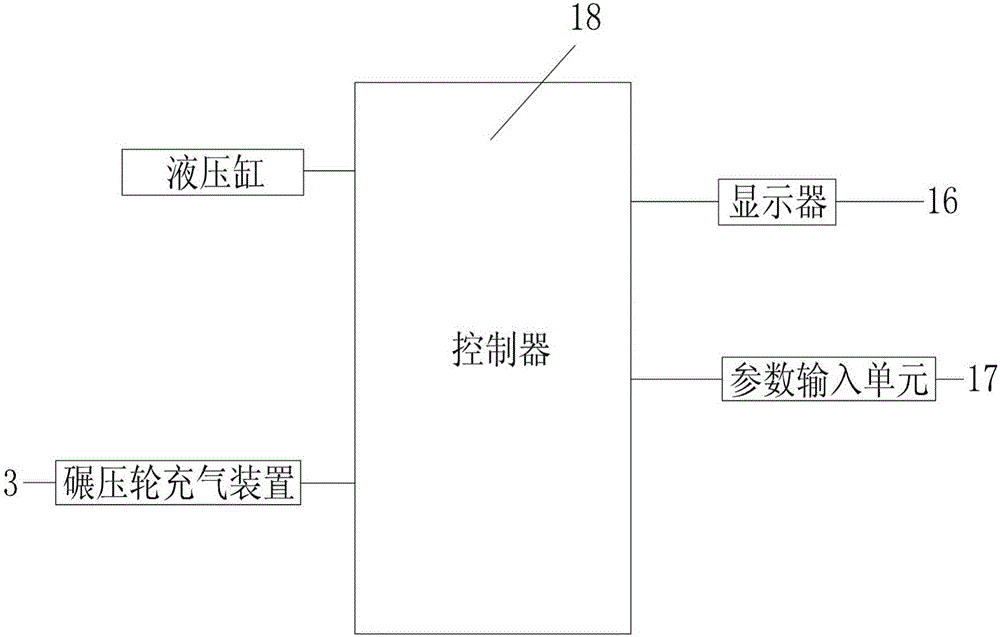

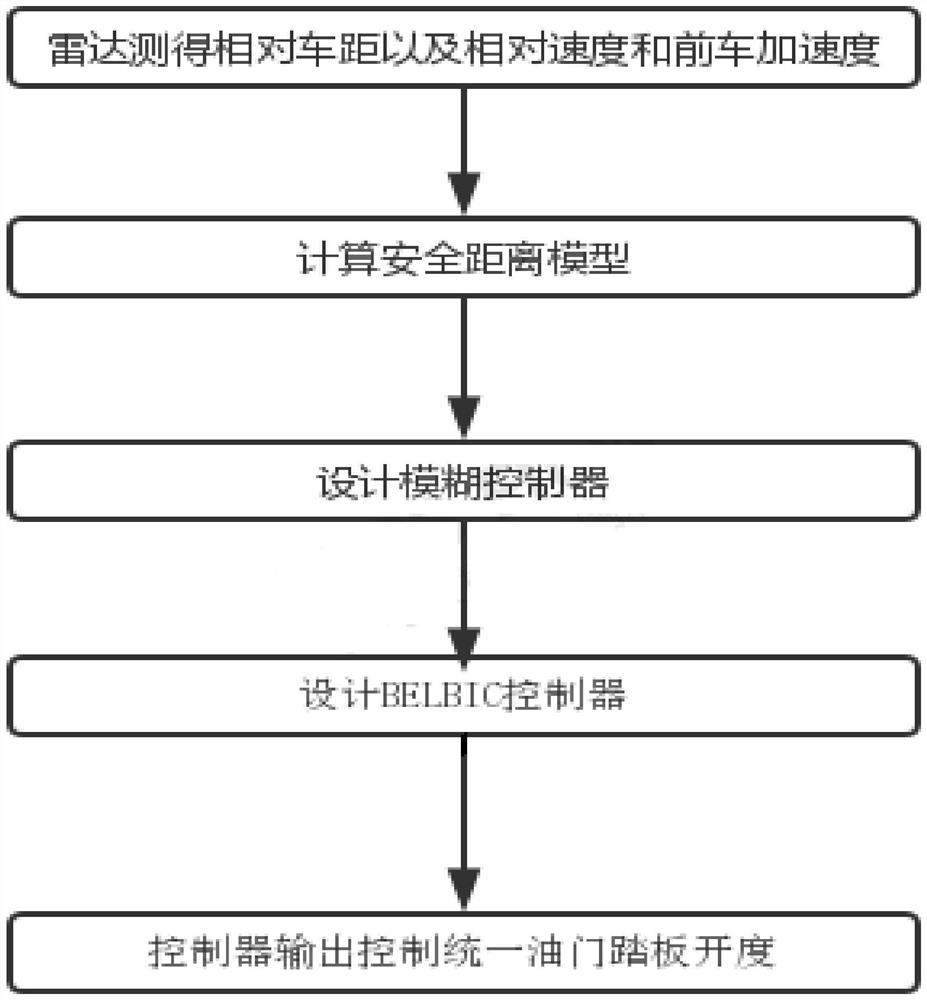

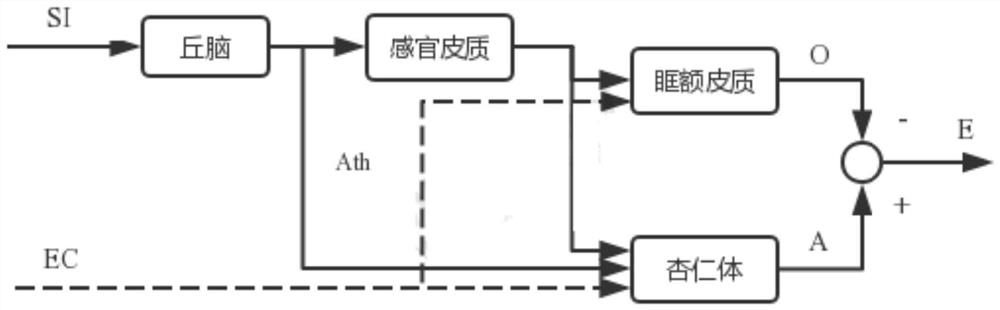

Car following control method based on brain emotion learning loop model and control system thereof

InactiveCN111845746AConsistent with decision-making behaviorImprove adaptabilityExternal condition input parametersAdaptive controlDriver/operatorControl system

The invention discloses a car following control method based on a brain emotion learning loop model and a control system thereof. The car following control method comprises the steps of designing a safety distance between a vehicle and a front vehicle; designing a distance error according to the safety distance; outputting an expected acceleration of the vehicle according to the distance error anda relative speed of the vehicle and the front vehicle; and designing an emotion controller based on the brain emotion learning loop model according to the expected acceleration of the vehicle, and finally taking the output of the emotion controller as an unified accelerator pedal opening degree of the vehicle to finally complete car following control. The method better conforms to a decision behavior of a driver, has advantages of a high adaptive capacity and a high response speed, and can realize accurate control of the speed.

Owner:HEFEI UNIV OF TECH

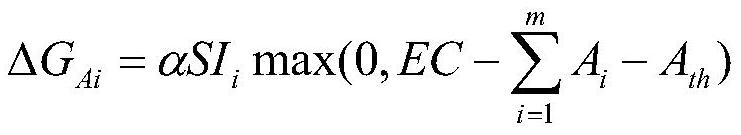

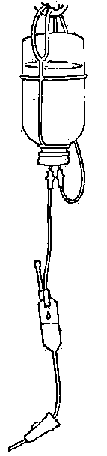

Vein infusion tube capable of automatically controlling dripping speed

InactiveCN104338197AControl precise controlPrecise control of dripping speedMedical devicesFlow monitorsAutomatic controlRemote control

The invention belongs to the technical field of medical instruments and particularly provides a vein infusion tube capable of automatically controlling the dripping speed. The vein infusion tube comprises an infusion tube body, an infusion tube conduit and a manual roller device, wherein the manual roller device sleeves the infusion tube conduit and comprises a roller bracket and a roller which is mounted between the left side wall and the right side wall inside the roller bracket; a micro remote control motor as well as a control processing module and a power supply for controlling the micro remote control motor to rotate forwardly and reversely are mounted on the right side wall of the roller bracket; the power supply is connected with each of the micro remote control motor and the control processing module; the rotating shaft of the micro remote control motor is connected with the shaft of the roller. Matched handheld equipment is adopted to emit an instruction to the control processing module, and through processing of the control processing module and the control on the motor, a transmission device is controlled, the moving amount of the manual roller is controlled, the infusion dripping speed is precisely controlled, and the problem in the prior art that the infusion dripping speed cannot be precisely controlled by operators is solved.

Owner:SHAANXI YIFU BEAUTY THERAPY TECH

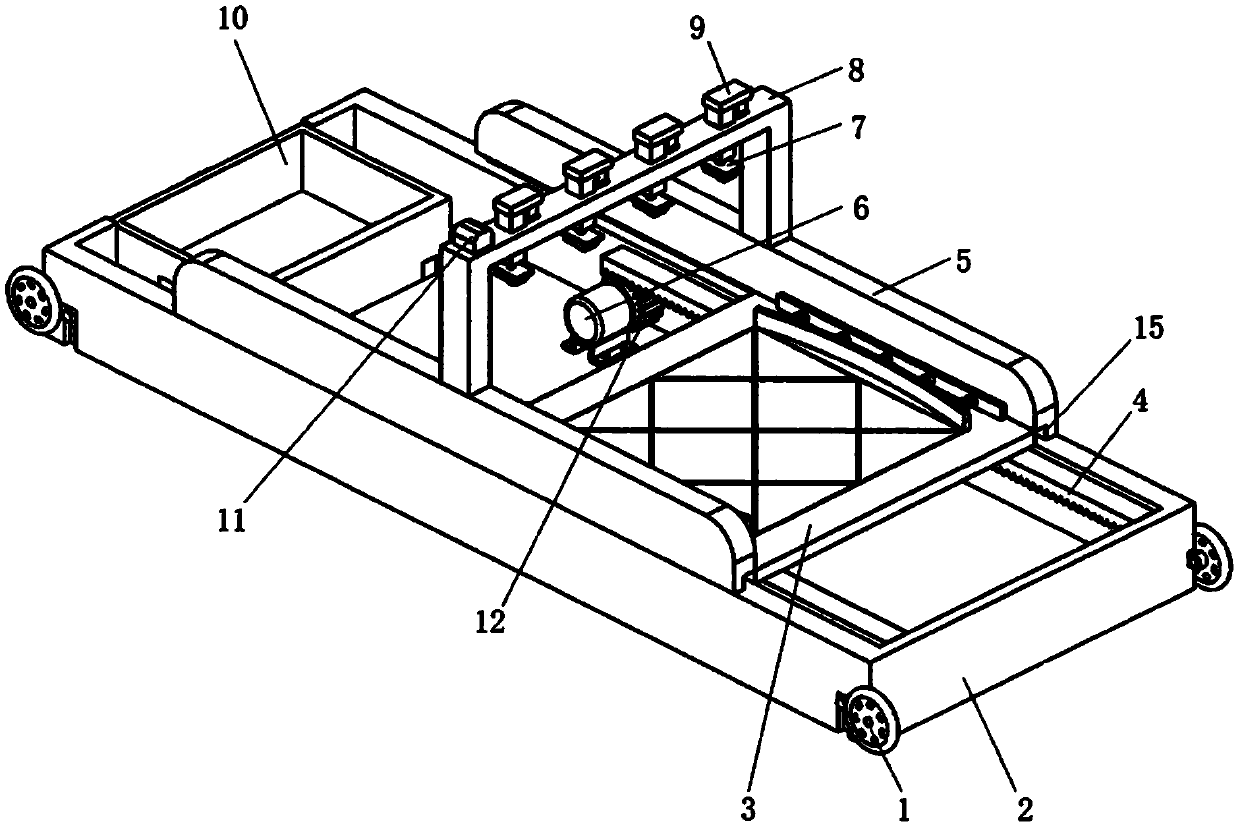

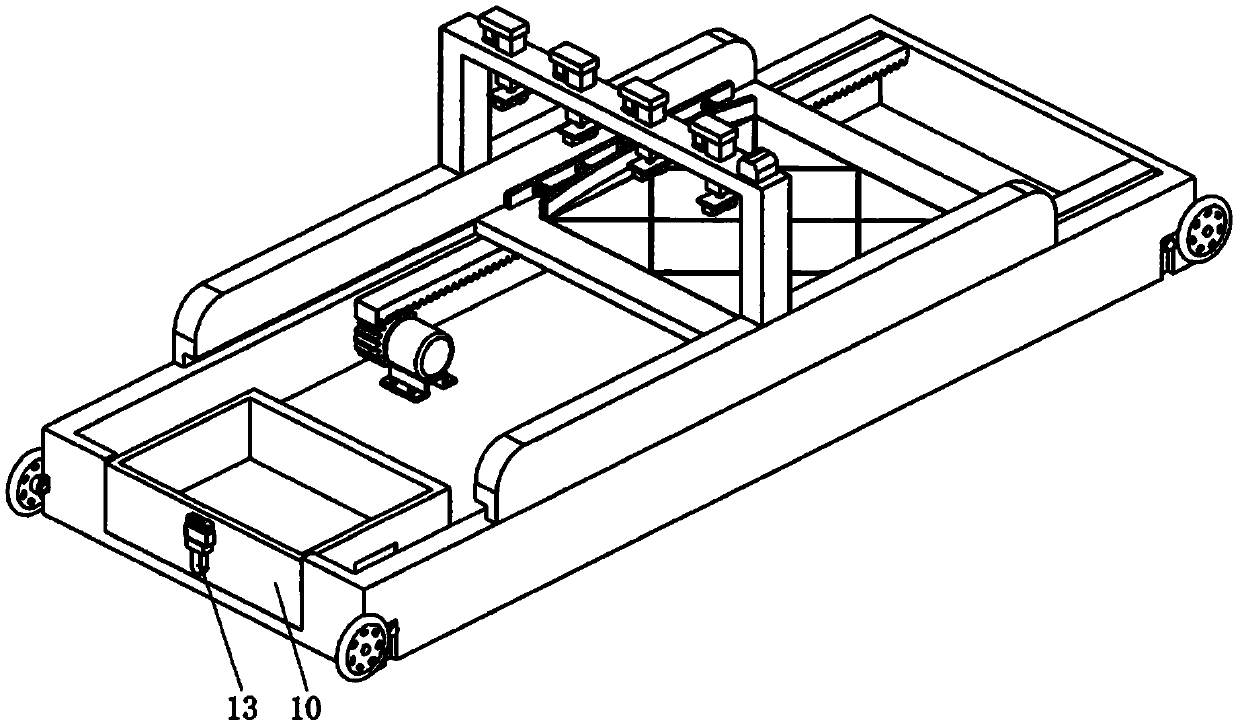

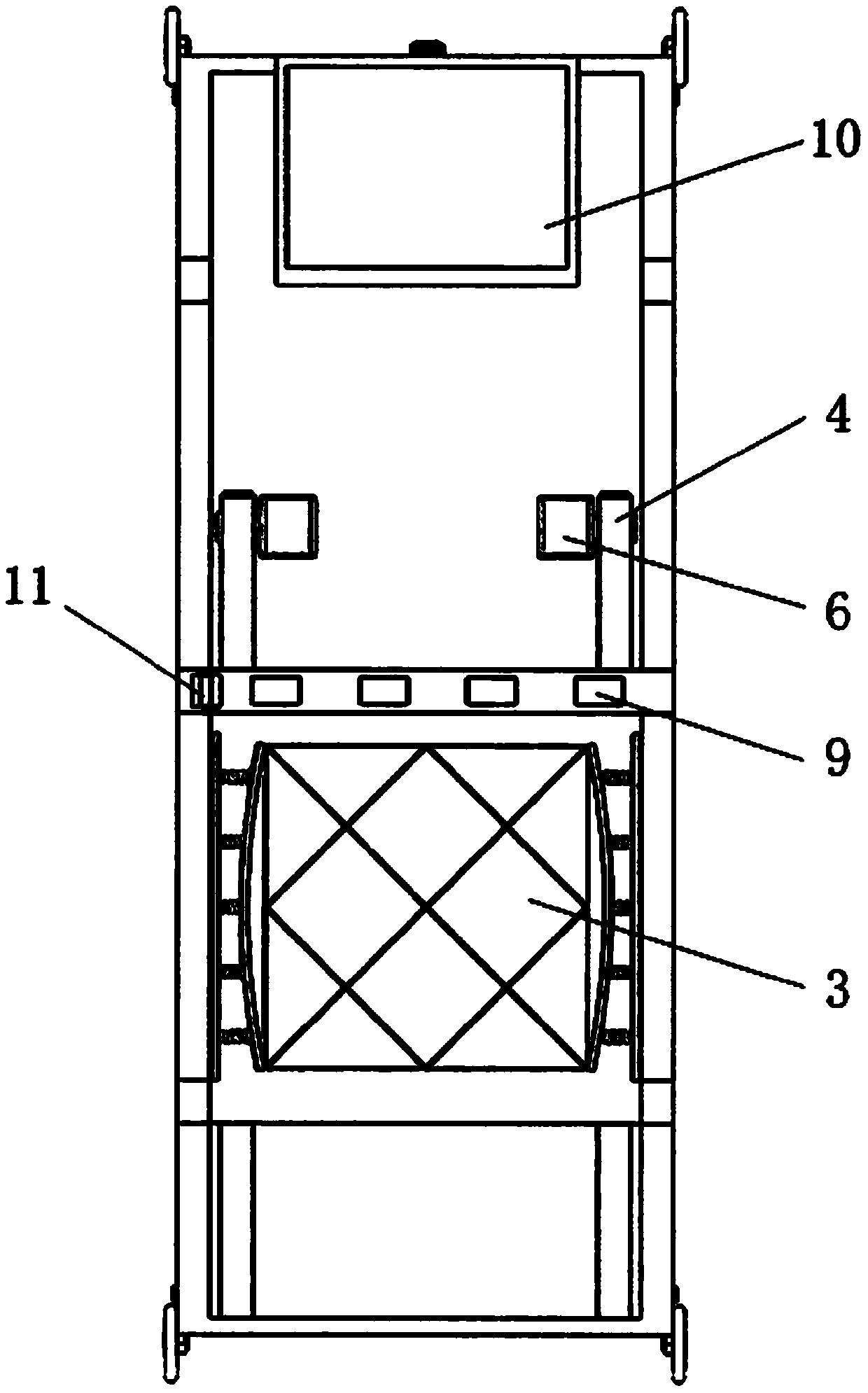

Unmanned carrying vehicle for high-density storage warehouse transportation

The invention relates to the technical field of storage equipment, and discloses an unmanned carrying vehicle for high-density storage warehouse transportation. The unmanned carrying vehicle comprisesa bearing base, bearing rods are fixedly connected to the upper end of the bearing base, lifting structures are movably connected to the bearing rods, and the lower end of the bearing base is movablyconnected with a mobile base through a rotating ring column. According to the unmanned carrying vehicle for high-density storage warehouse transportation, the projection of the lifting structures islocated inside the bearing base, so that regardless of the load, the projection of the gravity center is always located in the bearing base, the requirement of balance weight is small, the small and thin base can be stable, and the size of the carrying vehicle is reduced. Furthermore, the small vehicle can be driven into the bottom of a shelf. Meanwhile, the arrangement of a fork arm push-out structure is omitted, the position and posture of the carrying vehicle are judged and controlled by judging whether the electric potential of a vehicle body positioning device and a storage cell positioning device changes or not, and accurate control over operation of the carrying vehicle is completed at low equipment cost.

Owner:江苏勃曼工业控制技术有限公司

Method and system for intelligently controlling temperature of concretes of dam under construction

InactiveCN102852145BEasy to controlControl precise controlFoundation engineeringTemperature controlWater flow

The invention discloses a method and system for intelligently controlling temperature of concretes of a dam under construction. The system comprises a control device which communicates with a heat exchanging device and a heat exchanging auxiliary device, wherein the heat exchanging device is arranged at inner part or surface of the concrete dam, and is used for exchanging heat with the concrete dam and transmitting collected temperature information of the concrete dam to the control device; the heat exchanging auxiliary device inputs a heat exchanging medium to the heat exchanging device and outputs the medium from the heat exchanging device after the heat exchange; the control device is used for controlling the heat exchanging auxiliary device; and the control device can input a temperature control strategy of each casting bin. By the system and method disclosed by the invention, the temperature of the concrete dam can be detected in real time automatically, individualized temperature control strategies are provided to different casting bins, intelligent learning is performed according to actual conditions on site, and concrete thermal parameters which are the most accurate and realistic are selected for each casting bin, so that the precise control on water flow capacity and / or temperature can be realized, the precision for controlling the concrete dam temperature is high, the data is reliable, labour and water costs can be greatly reduced, and the anti-cracking effect of the dam is good.

Owner:上海高千软件科技有限公司 +2

Amphibious robot with wheel-paddle-leg composite configuration based on epicyclic gear train

The invention discloses an amphibious robot with wheel-paddle-leg compound configuration based on epicyclic gear trains, which includes a frame, a wheel-paddle leg device, a transmission system, a drive system and a control system, and two sides of the frame are symmetrically arranged with four independent The wheel paddle leg device, the drive system is connected with the wheel paddle leg device through the transmission system; the wheel paddle leg device includes epicyclic gear train, paddle leg device and outer wheel, the drive system includes three independent drive motors, and the drive motors are connected with the control system. The speed of the drive motor is controlled by the control system. The device adopts a synchronous belt transmission mode, has a variety of gait movement modes, and is suitable for a variety of complex road conditions.

Owner:青岛海艺自动化技术有限公司

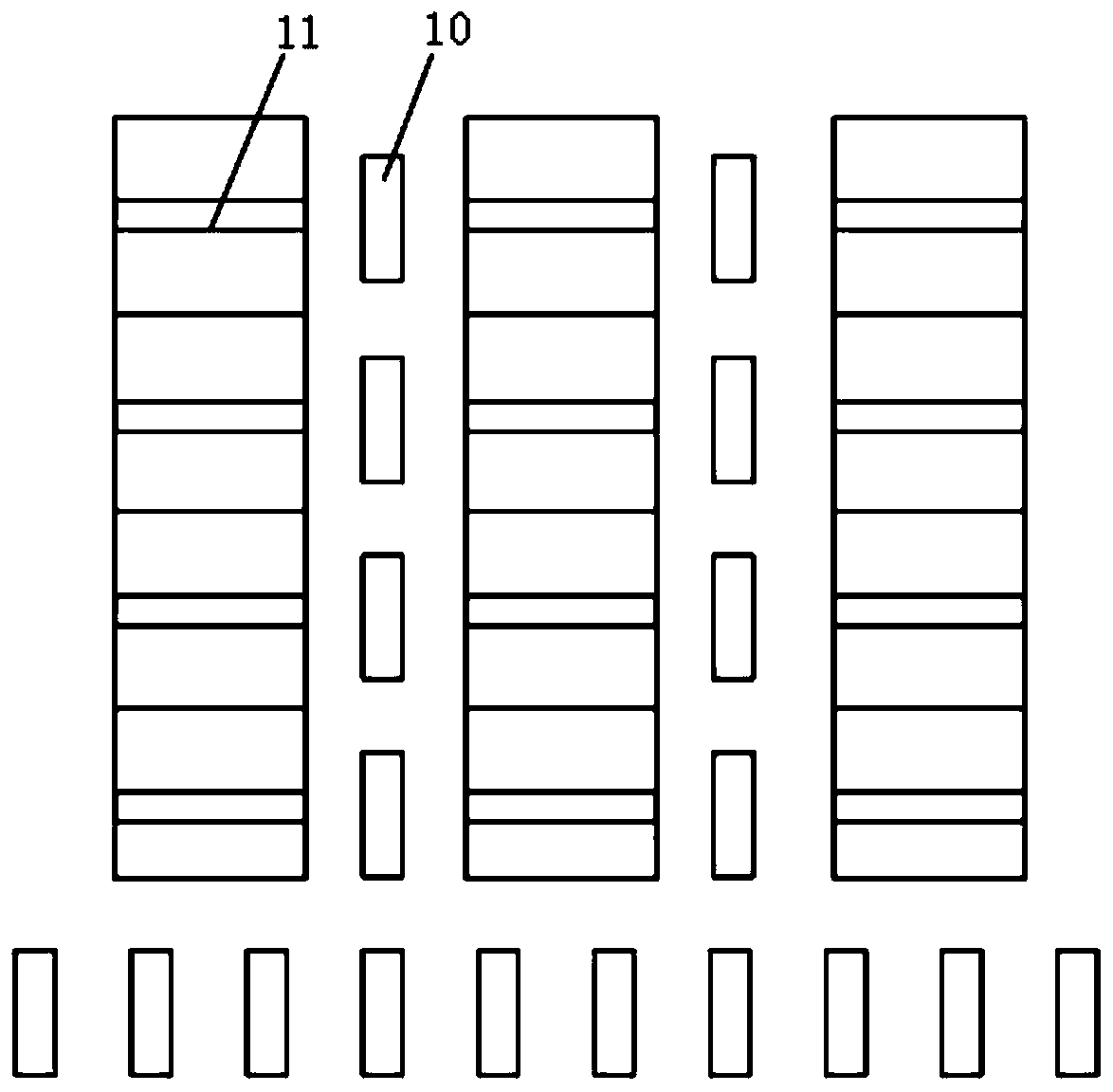

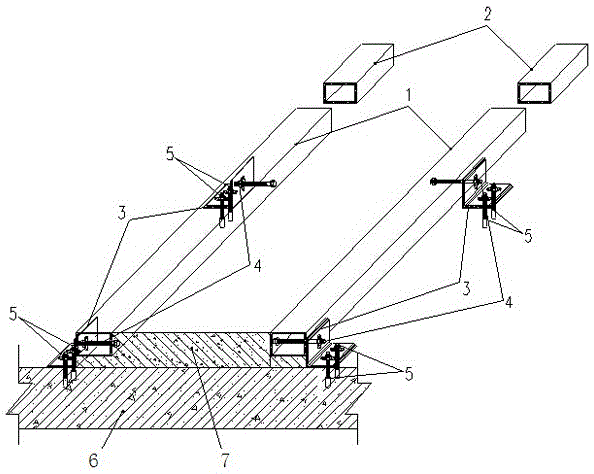

Elevation-adjustable superflat floor formwork

InactiveCN105155827AEasy to controlControl precise controlBuilding constructionsRoads maintainenceButt jointStructure based

The invention provides an elevation-adjustable superflat floor formwork, which comprises a square steel guide rail, square steel butt joint sleeves, a plurality of pieces of angle steel, a plurality of oppositely penetrating fastening screw bolts and a plurality of expansion screw bolts, wherein the square steel guide rail consists of two pieces of parallel square steel with the space being 2 to 3m; holes are drilled in the length direction at intervals being 1 to 2m and are used for fixing the oppositely penetrating fastening screw bolts; the square steel joint parts of the square steel butt joint sleeves are connected by internally connected sleeves; the length of the butt joint sleeves is 100 to 200mm; the two ends of the butt joint sleeves are embedded into the square steel guide rail for 50 to 100mm; a plurality of pieces of angle steel are used as connecting elements between the square steel guide rail and a structure base layer; the length of the angle steel is 80 to 100mm; a plurality of opposite passing fastening screw bolts are used as connecting fastening screw bolts between the square steel guide rail and the angle steel; the plurality of expansion screw bolts are in one-to-one correspondence to oval holes formed in the angle steel; and each piece of angle steel is anchored on a superflat floor structure base layer by two expansion screw bolts. The elevation-adjustable superflat floor formwork effectively solves the problem that the existing construction technology cannot meet the precision requirement of the superflat floor construction.

Owner:CHINA CEC ENG

Rainfall simulation rotary bituminous pavement friction coefficient tester and testing method thereof

ActiveCN106092875ASimple structureReasonable designUsing mechanical meansMaterial analysisSolenoid valveRoad surface

The invention relates to a rainfall simulation rotary bituminous pavement friction coefficient tester and a testing method thereof. The rainfall simulation rotary bituminous pavement friction coefficient tester comprises a rain box divided into a main equipment area and an auxiliary equipment area, wherein the main equipment area is divided into an upper part and a lower part by a rain collection baseplate, and a water collection box is arranged at the lower part; a water distributing pipe with nozzles is arranged at the top of the right part of the upper part; two clamp strips are arranged at the bottom of the right part of the upper part, and a test mold is placed between the two clamp strips; a dynamic rotary friction coefficient tester is arranged on the upper surface of the test mold; a water storage bucket is arranged at the bottom of the left part, and the bottom of the water storage bucket is connected to a water pump in the water collection box through a water inlet pipe; another water pump is arranged at the top of the water storage bucket and connected with the water distributing pipe through a water delivery pipeline; a tee joint, a flowmeter and a solenoid valve are sequentially arranged on the water delivery pipeline from bottom to top; the tee joint is connected with a water return pipe with an adjustment valve, and the water return pipe is connected to the water storage bucket; a control box is arranged in the auxiliary equipment area. The rainfall simulation rotary bituminous pavement friction coefficient tester is simple in structure, and simple and convenient to operate.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

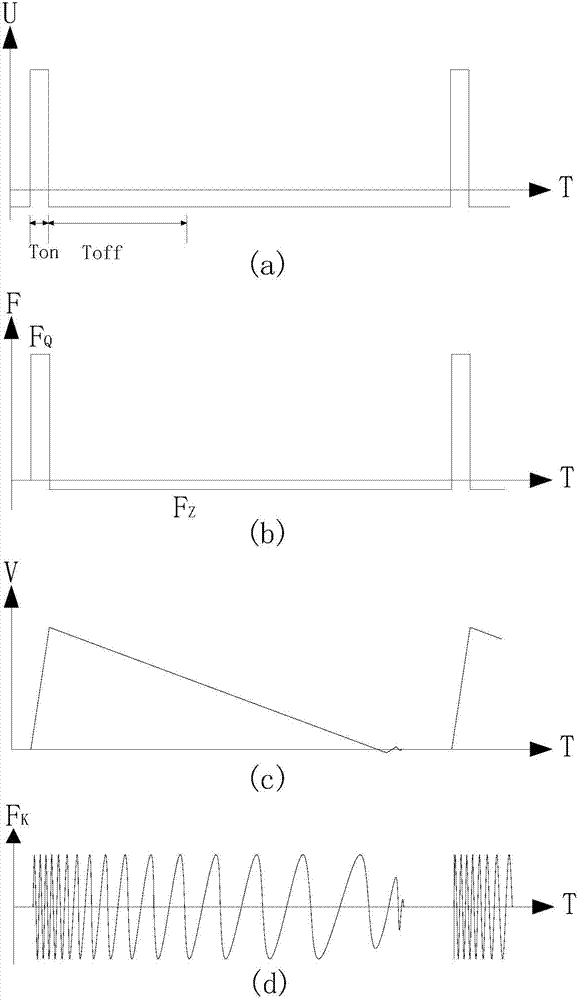

Fast response linear motor, control method and integrated control chip

InactiveCN105591519BControl precise controlResponse Precise ControlAC motor controlPropulsion systemsElectric machineConductive materials

The invention is suitable for the motor field, and provides a quick response linear motor, a control method of a quick response linear motor, and an integrated control chip. The quick response linear motor comprises a housing, a stator, a rotor, and a supporting shaft. The stator comprises a conductive sleeve, and the rotor comprises a supporting skeleton and a driving coil used for generating a driving magnetic field along the axial direction of the supporting shaft. The conductive sleeve of the stator of the quick response linear motor can be produced by adopting conductive materials, and the supporting skeleton of the rotor is provided with the driving coil in a coiled manner. When the current pulse passes through the driving coil, the induced current can be generated by the stator, and the magnetic field opposite to the above mentioned driving magnetic field can be generated, and then the rotor can be driven to move, and therefore the quick response can be realized. When the large instantaneous pulse current passes through the driving coil, the large power can be generated. The coiling direction of the driving coil is arranged around the axial direction of the supporting shaft, and the stator is in the shape of a sleeve, and therefore the size of the rotor can be small, and then the size of the linear motor is small.

Owner:刘华

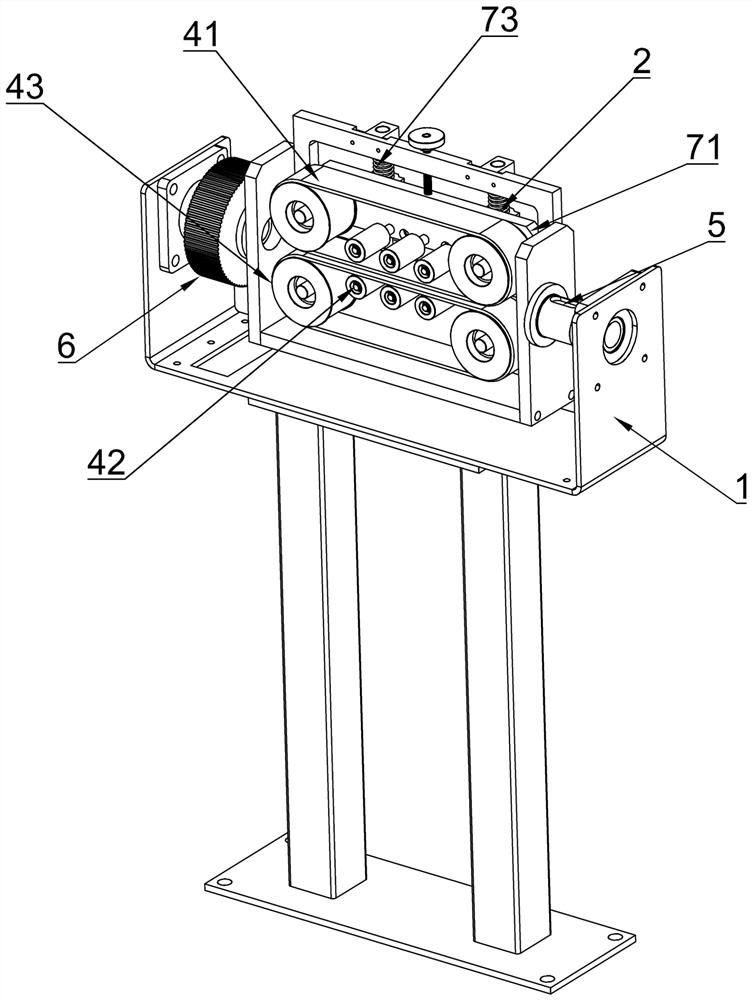

Comprehensive wheel rolling former for asphalt mixture test specimen and test specimen manufacturing method

ActiveCN106289904ASimple structureReasonable designPreparing sample for investigationAsphaltWheel drive

The invention discloses a comprehensive wheel rolling former for an asphalt mixture test specimen and a test specimen manufacturing method. The comprehensive wheel rolling former for the asphalt mixture test specimen comprises a load frame, a rolling wheel convertor, a specimen support device, a rolling wheel drive device and a control box. The rolling wheel drive device is arranged on the control box; the load frame and the control box are connected and fixed; the rolling wheel convertor is arranged in the load frame; a hydraulic dowel bar A and a hydraulic dowel bar B are arranged on the bottom part of the rolling wheel convertor; the rolling wheel drive device is in power connection with the rolling wheel convertor; the rolling wheel convertor is used for respectively transmitting hydraulic power to the hydraulic dowel bar A or the hydraulic dowel bar B; an outer wall of the hydraulic dowel bar A is in power connection with a rolling wheel through a rack I; an outer wall of the hydraulic dowel bar B is in power connection with an air-inflated rubber wheel through a rack II. The comprehensive wheel rolling former for the asphalt mixture test specimen provided by the invention has the advantages of simple structure, simplicity and convenience in operation, good using effect and the like.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

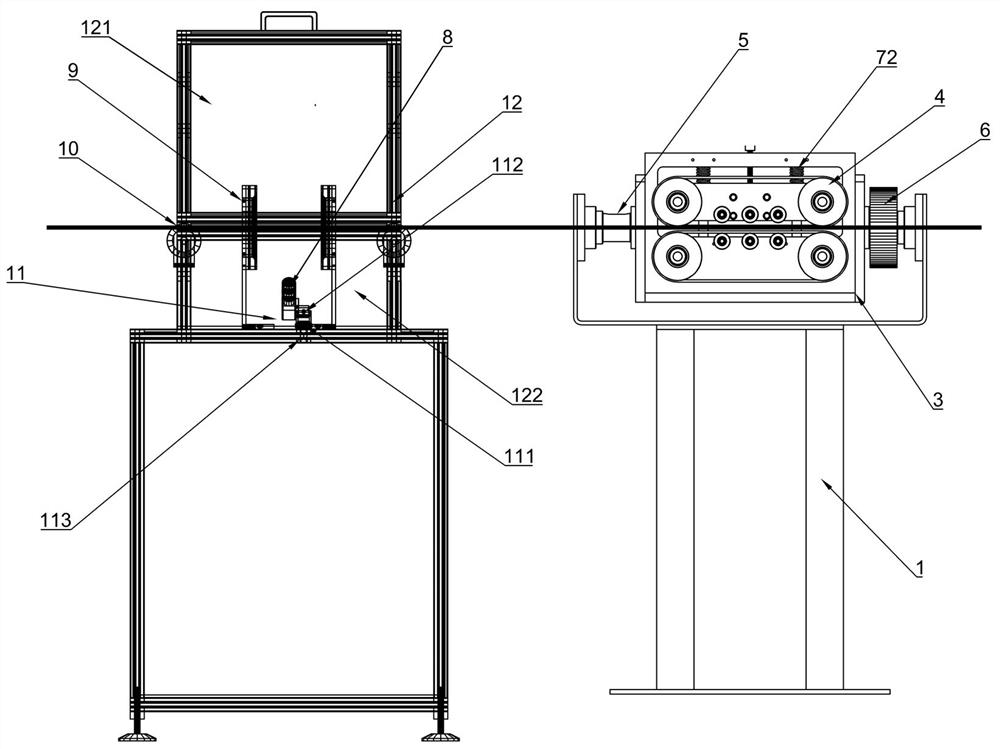

Visual automatic cable twisting equipment and system thereof

InactiveCN112895248AReduce workloadQuality assuranceFibre mechanical structuresCoatingsSynchronous motorMechanical engineering

The invention relates to the technical field of optical cable manufacturing equipment, in particular to visual automatic cable twisting equipment. A driving device is mounted on a support, two ends of a rotating base are mounted on the support through rotating shafts, the driving device drives the rotating base to rotate along the rotating shafts, a cable clamping assembly is mounted on the rotating base, a photographing box is arranged on the support, concave-surface rollers for supporting cables are arranged at square holes, a camera and an annular light source are arranged in the photographing box, the annular light source is located on the inner side of the square hole of the photographing box, the camera is electrically connected to an intelligent terminal, the intelligent terminal is electrically connected to a controller and the annular light source, and the intelligent terminal is electrically connected to the driving device through the controller. The equipment has the beneficial effects that the workload of operators is reduced, the quality of optical cables is ensured, the equipment judges the cross section directions of the optical cables (non-circular optical cables) of special structures or the positions of color bars of color-bar optical cables through the industrial camera and the visual system, the torsion angle pulse amount is calculated, and a synchronous motor is controlled to drive the cable twisting equipment, so that the torsion angles of the cross sections of the optical cables can be controlled according to the position of an ink-jet printer, and the positions of the marks on the optical cables are accurately controlled.

Owner:SHANTOU HIGH TECH ZONE AOXING OPTICAL COMM EQUIP

Special syrup for mooncakes and manufacturing process thereof

PendingCN109329887AHas a natural fragranceDelicate tasteSugar food ingredientsDough treatmentFood additiveBroken rice

The invention discloses special syrup for mooncakes. The special syrup for mooncakes comprises maltose, fructose, inverted sugar, white granulated sugar and a food additive. The special syrup for mooncakes prepared from refined rice or refined broken rice as a raw material enables the mooncakes to have natural delicate fragrance of rice. Meanwhile, the special syrup for mooncakes prepared from therice as a raw material has more delicate mouthfeel and better palatability, is closer to nutritional components required by human bodies, is convenient for metabolism of the human bodies, helps absorption of the human bodies, and has a wider range of applicable people. The special syrup for mooncakes disclosed by the invention has better palatability, can be better absorbed and metabolized in thehuman bodies, can rapidly supplement the blood-sugar content, and helps people to rapidly supplement energy. A preparation method provided by the invention has strict control, precise production process and accurate control of reactions, and is suitable for popularization and application in the production and processing industry of food.

Owner:江西金穗丰糖业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com