Fast response linear motor, control method and integrated control chip

A linear motor, fast response technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of large size, small power, difficult to achieve fast response and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

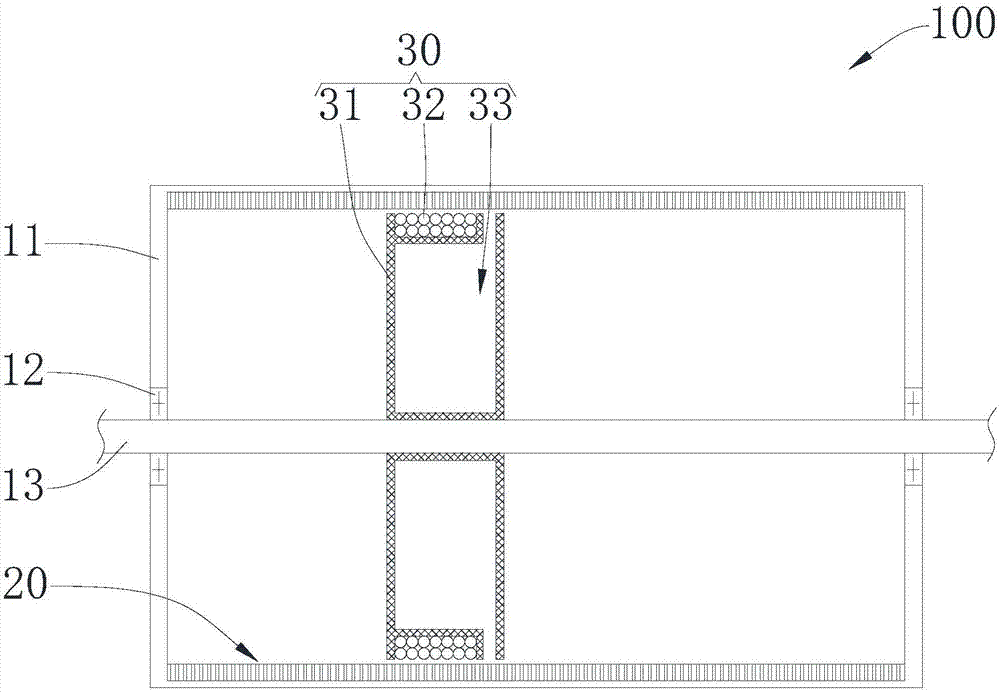

[0028] see Figure 1-Figure 3 , a fast-response linear motor 100 provided by an embodiment of the present invention includes a casing 11 , a stator 20 , a rotor 30 and a support shaft 13 ; the stator 20 is installed on the casing 11 , and the stator 20 is supported and protected by the casing 11 . The rotor 30 is slidably installed in the stator 20 so that the rotor 30 can move in the stator 20, and the rotor 30 is installed on the support shaft 13, the rotor 30 can be supported by the support shaft 13, and the rotor 30 can move along the support shaft 13. The support shaft 13 is installed in the casing 11 such that the casing 11 supports the support shaft 13 . The stator 20 includes a conductive sleeve made of conductive material. The rotor 30 includes a supporting frame 31 and a driving coil 32. The supporting frame 31 is installed on the supporting shaft 13, and the driving coil 32 is wound on the supporting frame 31. When the driving coil 32 is energized, the driving coil...

Embodiment 2

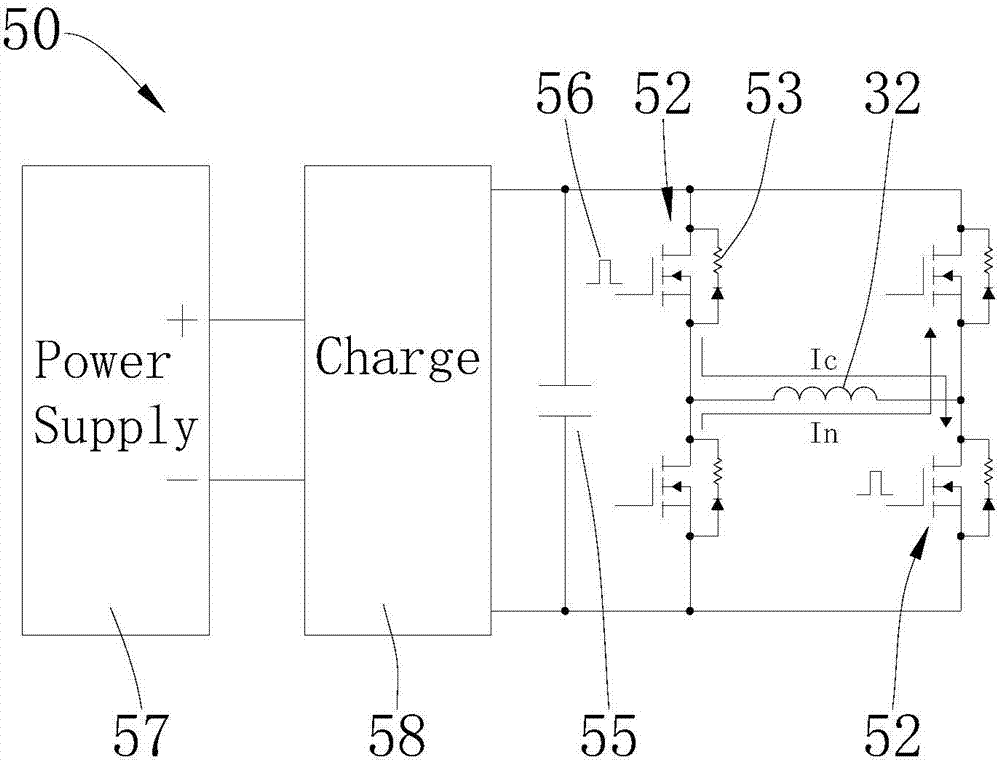

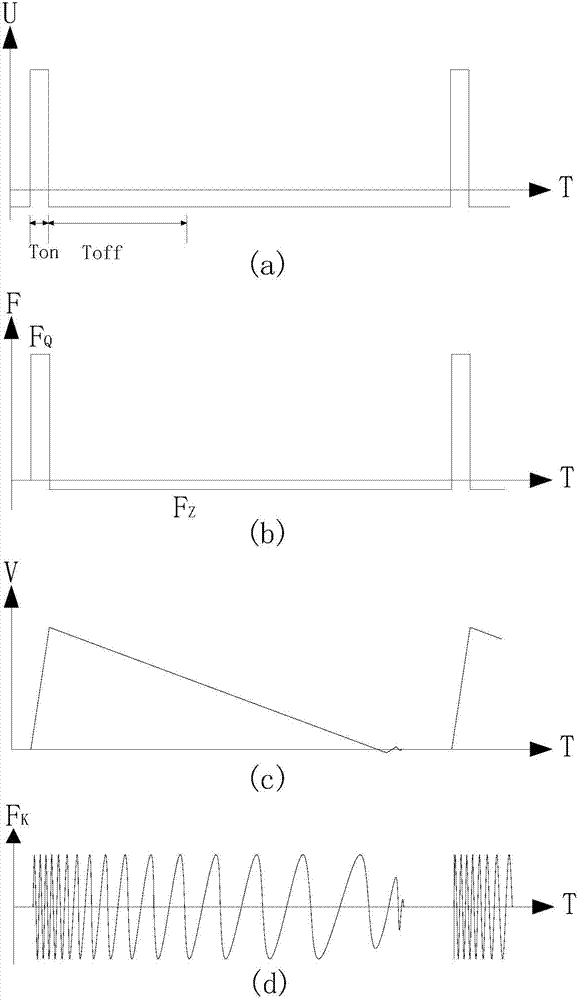

[0042] see Figure 4-Figure 10, the embodiment of the present invention provides a fast response linear motor 100a, including a casing 11, a stator 20, a rotor 30, a support shaft 13 and a control mechanism 40; the stator 20 is installed on the casing 11, and is supported and protected by the casing 11 Stator 20. The rotor 30 is slidably installed in the stator 20 so that the rotor 30 can move in the stator 20, and the rotor 30 is installed on the support shaft 13, the rotor 30 can be supported by the support shaft 13, and the rotor 30 can move along the support shaft 13. The support shaft 13 is installed in the casing 11 such that the casing 11 supports the support shaft 13 . The conductive sleeve of the stator 20 includes several magnetically conductive rings 21 and several spacer rings 22, and the magnetically conductive rings 21 and spacer rings 22 are alternately stacked. magnetism; then along the axial direction of the support shaft 13, one layer of magnetic conduction...

Embodiment 3

[0074] see Figure 11 and Figure 12 The difference between the fast-response linear motor 100b of this embodiment and the fast-response linear motor of Embodiment 1 is: each magnetic permeable ring 21 is provided with a number of first protruding teeth 23 protruding inward, and these first protruding teeth 23 are evenly distributed on the On each magnetic ring 21; the end 415 of the magnetic arm 41 away from the support shaft 13 is protrudingly provided with a number of second protruding teeth 416; along the radial direction of the stator 20: the distance between two adjacent first protruding teeth 23 is the same as the distance between two adjacent first protruding teeth 23 The distances between the two protruding teeth 416 are equal. First protruding teeth 23 are set on each magnetic conducting ring 21, and second protruding teeth 416 are provided on the magnetic permeating arm 41, which can form the function of a stepping motor, passing between the first protruding teeth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com