Rainfall simulation rotary bituminous pavement friction coefficient tester and testing method thereof

A technology of friction coefficient and asphalt pavement, which is applied in the direction of instruments, measuring devices, and mechanical devices, etc., can solve the problems that cannot reflect the friction coefficient of asphalt pavement, etc., and achieve the effect of high practical value, simple parameter adjustment, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

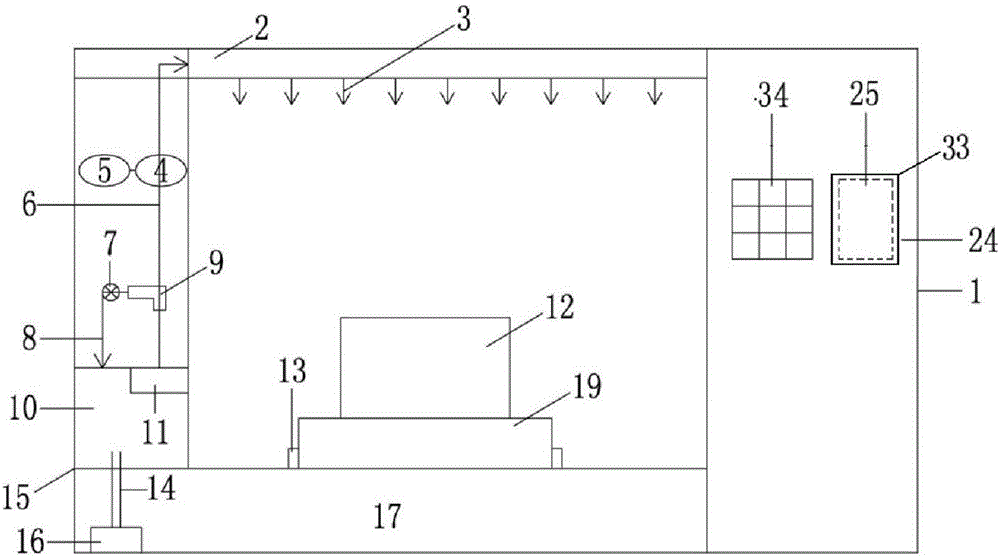

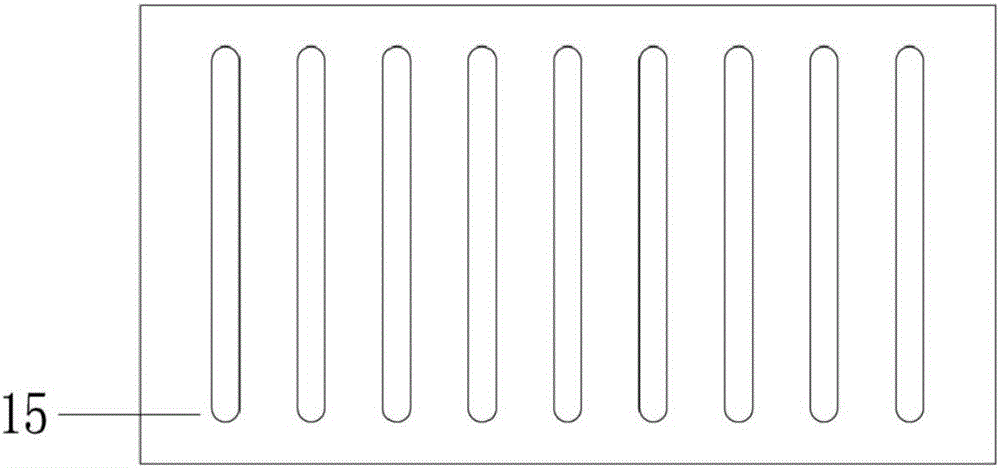

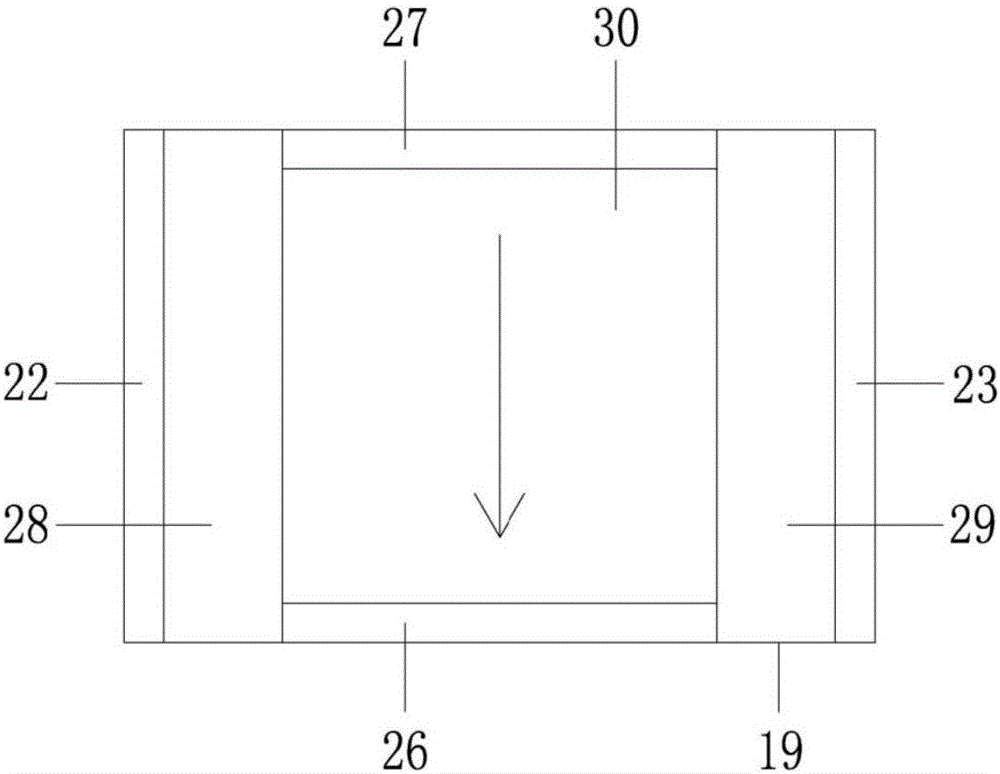

[0032]A rotary friction coefficient tester for asphalt pavement simulating rainfall, the tester includes a rain box 1 divided into a main equipment area and an auxiliary equipment area, the main equipment area is set on the left side of the rain box 1; The rain floor 15 is divided into an upper part and a lower part, the lower part is a water collection tank 17, and the upper part is divided into a left part and a right part; the right part is provided with a water distribution pipe 2 with a nozzle 3 at the top; the right part is provided with two A clip 13, a test mold 19 is placed in the middle of the two clips 13; the upper surface of the test mold 19 is provided with a dynamic rotary friction coefficient tester 12; the left part is provided with a water storage bucket 10 at the bottom, and the bottom of the water storage bucket 10 passes through The water inlet pipe 14 is connected to the water pump A16 in the water collection tank 17; the water storage tank 10 is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com