Comprehensive wheel rolling former for asphalt mixture test specimen and test specimen manufacturing method

A kind of technology of asphalt mixture and forming machine, which is applied in the preparation of test samples, analysis materials, sampling, etc., which can solve the problems of asphalt mixture test piece surface turning back, road roller turning back is not allowed, etc., to achieve easy control of the preparation process, structure Simple, easy to install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

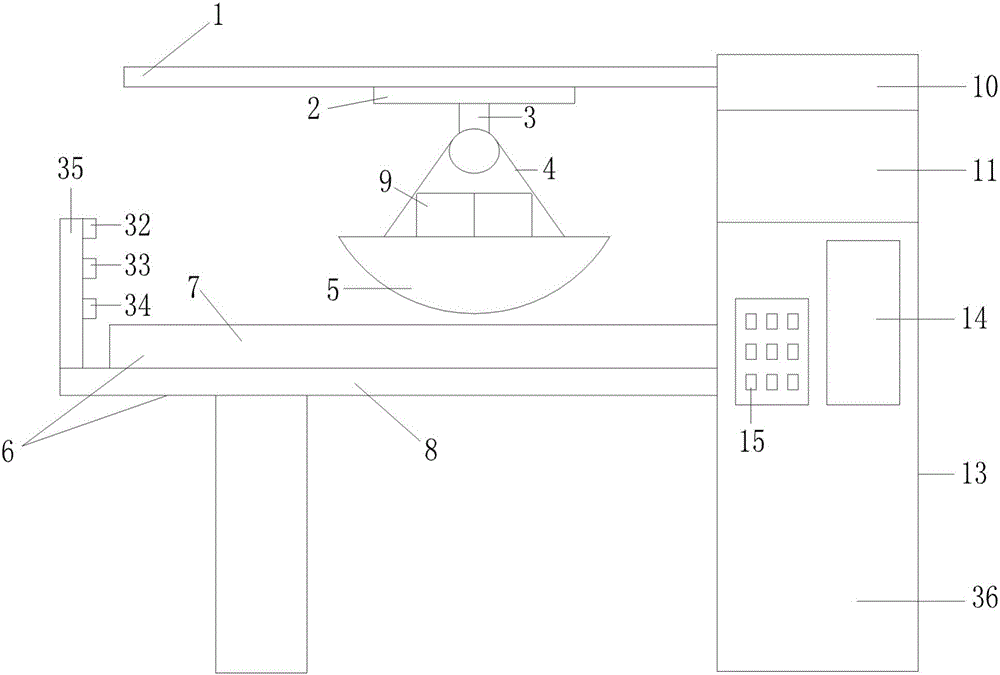

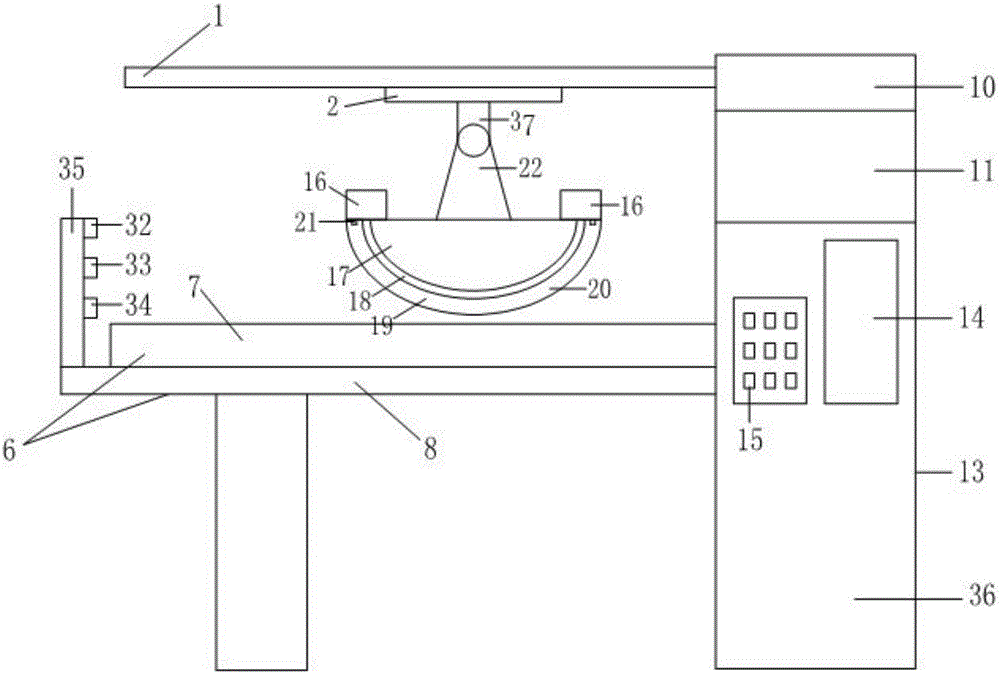

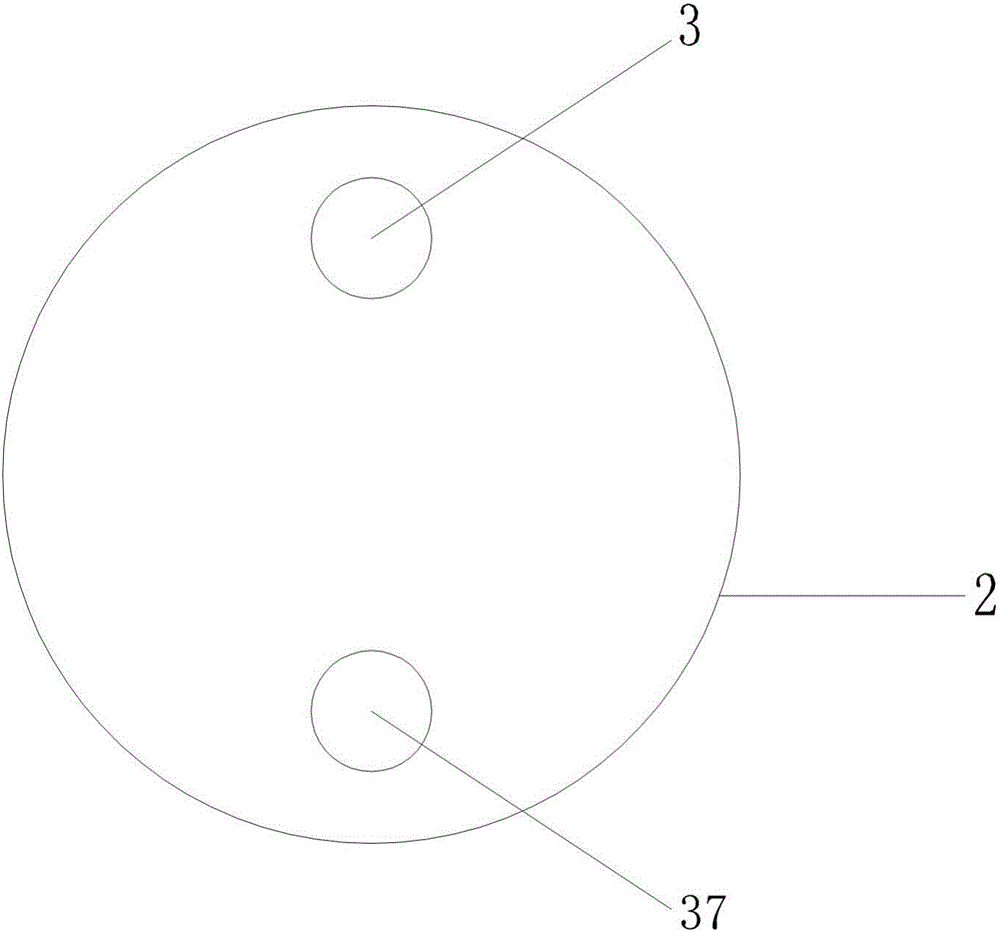

[0045] Such as Figure 1 to Figure 7 As shown, a comprehensive wheel-milling machine for asphalt mixture specimens includes a load frame 1, a roller converter 2, a sample support device 6, a roller driving device 11 and a control box 36, and the roller driving The device 11 is set on the control box 36, the load frame 1 is connected and fixed to the control box 36, the rolling wheel converter 2 is installed in the load frame 1, and the hydraulic dowel bar A3 and hydraulic The dowel bar B37, the rolling wheel driving device 11 is power connected with the rolling wheel converter 2, the rolling wheel driving device 11 drives the rolling wheel converter 2 to move back and forth along the load frame 1, and drives the rolling wheel 5 or the inflatable The rubber wheel 20 moves back and forth in the length direction of the test mold surface; the rolling wheel converter 2 is used to transmit the hydraulic power to the hydraulic dowel A3 or the hydraulic dowel B37 respectively, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com