Elevation-adjustable superflat floor formwork

An adjustable, ultra-flat technology, applied in roads, road repairs, roads, etc., can solve problems such as the inability to meet the construction accuracy requirements of ultra-flat floors, achieve good promotion and application prospects, shorten the construction period, and avoid the effects of later repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

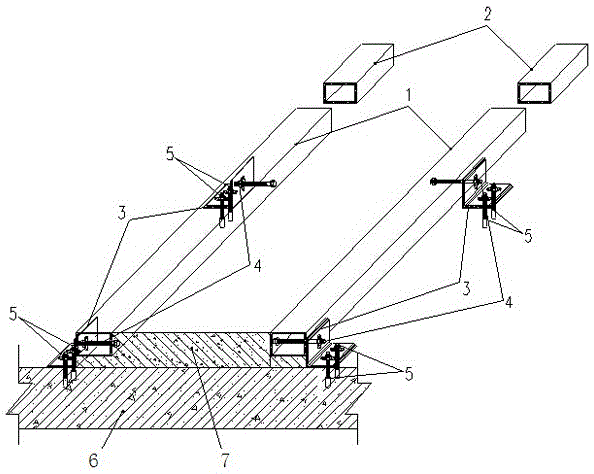

[0010] The content of the invention will be further described below in conjunction with the embodiments of the accompanying drawings.

[0011] Elevation-adjustable super-flat floor formwork, including full-length 1-square steel guide rail, 2-square steel butt joint sleeve, several 3-angle steels, several 4-cross-through fastening bolts, and several 5-expansion bolts.

[0012] The full-length 1-square steel guide rail is composed of two parallel 40×60 square steels with a distance of 2 to 3 meters, and φ10 holes are drilled at a distance of 1 to 2 meters along the length direction for fixing with 4-crossing fastening bolts. The square steel joint part of the 2-square steel butt sleeve is connected by an inner sleeve. The length of the 2-square steel butt sleeve is 100-200mm, and the two ends are embedded in the 1-square steel guide rail by 50-100mm to avoid the 1-square steel There is a misalignment of the connecting part of the guide rail, which causes the ground height differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com