Germanium single crystal growth furnace and germanium single crystal growth temperature control method based on growth furnace

A growth furnace and germanium single crystal technology, which is applied in the field of germanium single crystal growth furnace and germanium single crystal growth temperature control, can solve the problems of low production efficiency and inaccurate temperature control in the furnace, and achieve the effect of breaking the technical blockade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

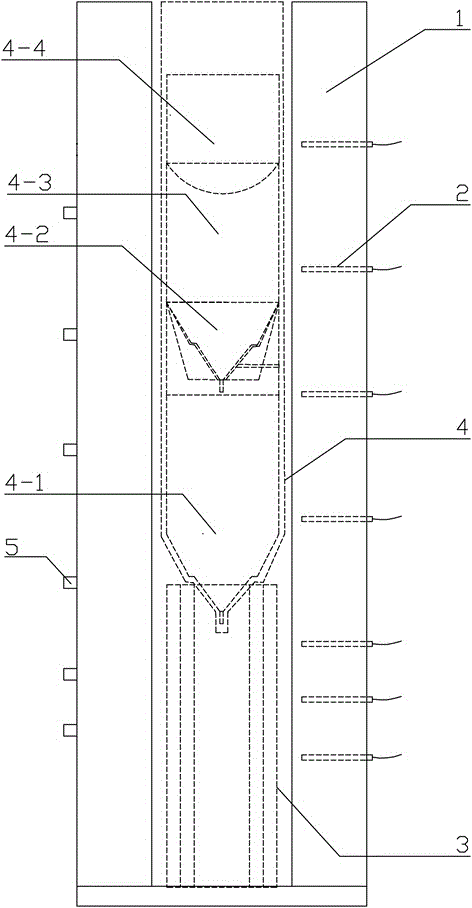

[0023] Embodiment 1: The germanium single crystal growth furnace of the present invention is vertically fixed on the base, and is characterized in that the growth furnace adopts a cylindrical stainless steel furnace body 1, and several heating electrodes 2 are arranged on the side wall of the furnace body 1 from bottom to top, along which The inner side of the furnace body 1 is provided with a ring-shaped insulating material; the support system 3 is provided along the bottom of the central axis of the furnace body 1, and the quartz special-shaped tube 4 is erected on the support system 3, and the lower layer crucible, the middle ring, and the upper layer crucible are arranged in the quartz special-shaped tube 4 from bottom to top in sequence As well as the sealing cap, the top of the quartz special-shaped tube 4 is covered with quartz wool.

[0024] The bottom of the quartz special-shaped tube 4 is closed, the lower part is funnel-shaped, the upper part is cylindrical, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com