Method and system for intelligently controlling temperature of concretes of dam under construction

A temperature control system and mass concrete technology, applied in construction, infrastructure engineering, etc., can solve problems such as slow information feedback, inability to accurately control the temperature of dam concrete, difficulty in refining concrete temperature control, and individualized temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] system structure

[0093] The intelligent temperature control system of the present invention comprises: a heat exchange device, a heat exchange auxiliary device, a control device and a dam data acquisition device.

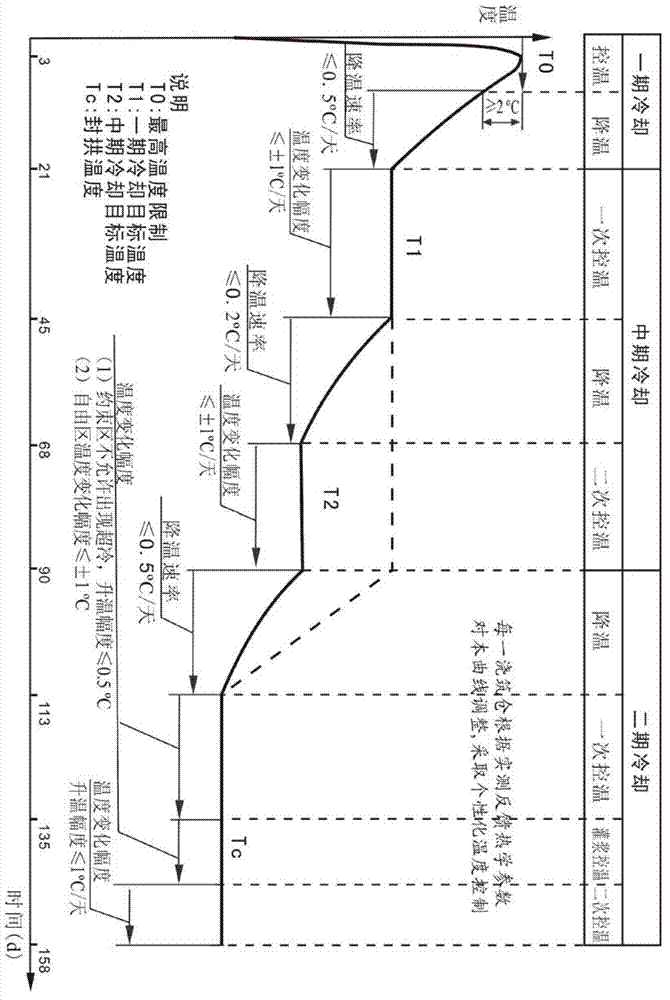

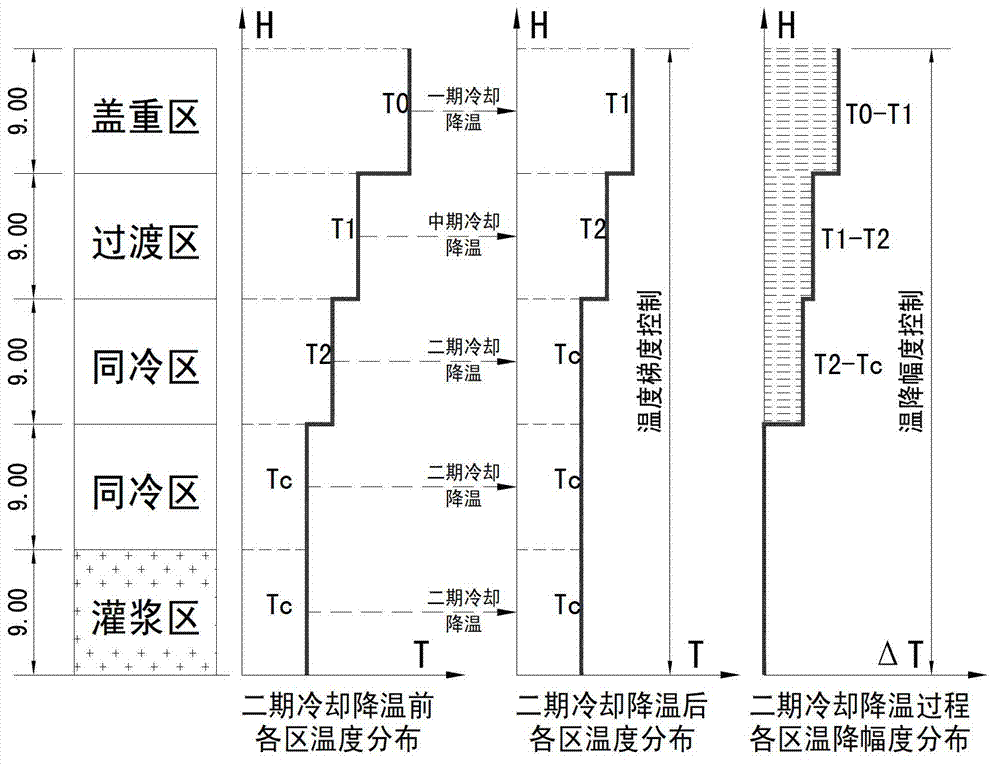

[0094] figure 1 , figure 2 They are the staged cooling strategy of the dam concrete, and the spatial gradient temperature control strategy of the dam concrete. image 3 It is a schematic diagram of the temperature distribution of the dam concrete from cooling to the final arch closure, image 3 It also indicates the dam sub-sections and the pouring characteristics of sub-bins.

[0095] For the convenience of explaining the dam area, an example is given here, see figure 2 , image 3 . The whole dam section is regarded as a grouting arch sealing area according to the height of 9m. Each pouring dam section is divided into five areas in the height direction to realize temperature gradient control. Transition zone, ⑤ heavy cover zone, such as figure...

Embodiment 2

[0136] On the basis of the first embodiment above, in order to fully illustrate the present invention, water is used as the heat exchange medium in the first embodiment. Embodiment 2 does not describe two solutions independent of Embodiment 1, but is obtained through adaptive modification on the basis of the solution in Embodiment 1. Concrete dam intelligent temperature control system using water as heat exchange medium, as attached Figure 5 shown.

[0137] The concrete dam temperature automatic control system at least includes a heat exchange auxiliary device, an on-site control device, and a remote end; the heat exchange auxiliary device is specifically a water end, and specifically includes: a cold water station 8, at least one water inlet pipe 9 and a water outlet pipe 10 Loop, according to the actual needs of water temperature, add multiple main water pipe loops. The on-site control device includes: temperature acquisition device (1, 2, 7, 14) 7;, wireless network brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com