Servo motor direct-drive type servo valve

A servo motor and servo valve technology, applied in the field of servo valves, can solve problems such as easy drift of zero position, influence on reliability, and decrease in frequency response, and achieve the effects of improving oil pollution resistance, reducing processing difficulty, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

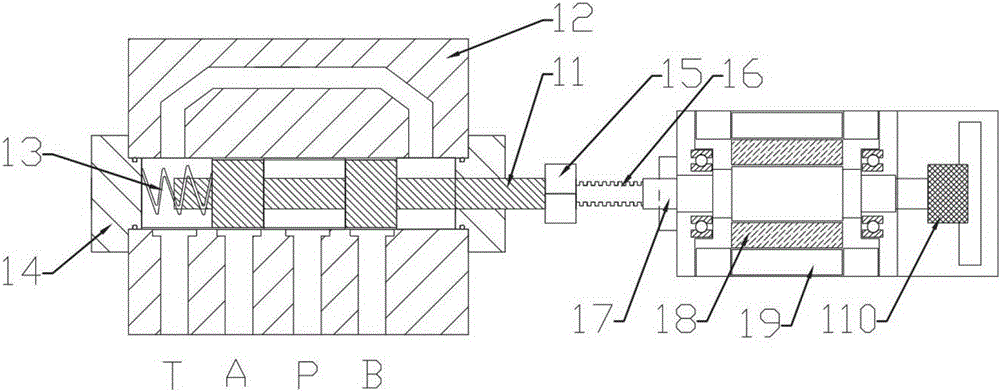

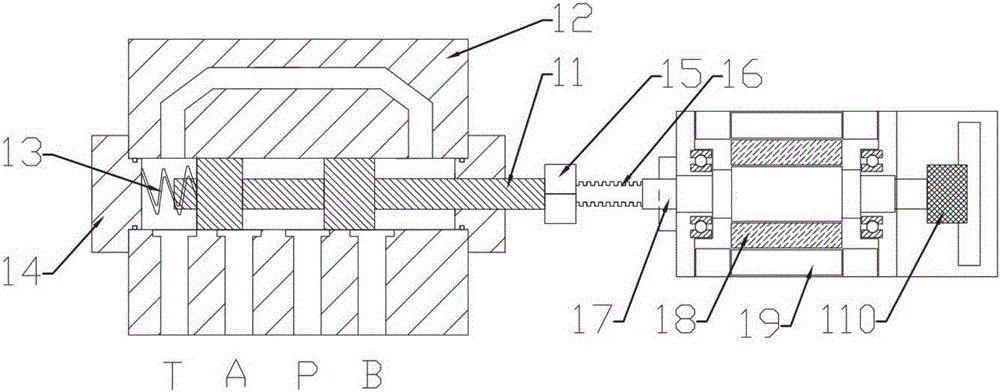

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] combined with figure 2 And attached image 3 , a servo motor direct drive type servo valve, which includes a main valve core 11, a valve body 12, a spring 13, a valve body end cover 14, a screw nut 15, a ball screw 16 and a servo motor; the main valve core 11 is slidingly installed in the valve body 12; the valve body 12 is provided with four oil ports; the main valve core 11 adjusts the connection between the four oil ports by changing the positions of the left, middle and right open state; the left end of the main valve core 11 is resisted by the spring 13 and the valve body cover 14; the right end of the main valve core 11 is connected with the screw nut 15, and the screw nut 15 is installed on the ball screw 16 , the servomotor includes a servomotor shaft 17, a servomotor rotor 18, a servomotor stator 19 and a rotary encoder 110; the left end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com